EG&G ORTEC 458 Service manual

A

iNj

^.^EEs.G

cz:

a

r\/i

F='A

rxi

N'

Model

458

Pulse

Shape

Analyzer

.5^

ORTEC

458

PULSE

SHAPE

ANALYZER

Manual

Change

Sheet

March

8,1972

ECN3

In

Fig.

3.1

on

page

3,

negative-going

pulses

are

shown

for

each

of

the

four

indicated

pulses.

This

is

in

error;

all

four

should

be

positive-going

pulses

and

are

inverted

from

the

waveforms

that

will

be

seeen

on

an

oscil

loscope.

On

Schematic

458-0201-S1,

change

the

connection

from

the

collector

of

Q21

to

the

cathode

of

D24

to

show

that

it

is

actually

connected

from

the

col

lector

of

Q21

to

the

anode

of

D24.

On

Schematic

458-0301-SI,

change

the

value

of

R74

from

1.33K

to

1.47K;

change

the

value

of

C12

from

15

pF

to

10

pF;

add

RMS,

422

ohms

1%,

1/8

W,

MFTO

in

series

between

R31

and

the

junction

of

TP3,R78,

R79,

C11,

and

the

collector

of

Q14.

L

j

Model

458

Pulse

Shape

Analyzer

Operating

and

Service

Manual

Printed

in

U.S.A.

©

ORTEC

Incorporated

1971

993

03C

1171

02

STANDARD

WARRANTY

FOR

ORTEC

INSTRUMENTS

ORTEC

warrants

its

instruments

other

than

preampl

ifier

FET

input

transistors,

vacuum

tubes,

fuses,

and

batteries

to

be

free

from

defects

in

workmanship

and

materials

for

a

period

of

twelve

months

from

date

of

shipment

provided

that

the

equipment

has

been

used

in

a

proper

manner

and

not

subjected

to

abuse.

Repairs

or

replace

ment,

at

ORTEC

option,

wil

l

be

made

on

in-warranty

instruments,

without

charge,

at

the

ORTEC

factory.

Shipping

expense.wi

l

l

be

to

the

account

of

the

customer

except

in

cases

of

defects

discovered

upon

initial

operation.

Warranties

of

vacuum

tubes

and

semiconductors

made

by

their

manufacturers

wil

l

be

extended

to

our

customers

only

to

the

extent

of

the

manufacturers'

l

iabi

l

ity

to

ORTEC.

Special

ly

selected

vacuum

tubes

or

semiconductors

cannot

be

warranted.

ORTEC

reserves

the

right

to

modify

the

design

of

its

products

without

incurring

responsibil

ity

for

modification

of

previously

manufactured

units.

Since

in

stal

lation

conditions

are

beyond

our

control,

ORTEC

does

not

assume

any

risks

or

l

iabil

ities

associated

with

methods

of

instal

lation

or

with

instal

lation

results.

QUALITY

CONTROL

Before

being

approved

for

shipment,

each

ORTEC

in

strument

must

pass

a

stringent

set

of

qual

ity

control

tests

designed

to

expose

any

flaws

in

materials

or

workmanship.

Permanent

records

of

these

tests

are

maintained

for

use

in

warranty

repair

and

as

a

source

of

statistical

information

for

design

improvements.

ORTEC

must

be

informed

in

writing

of

the

nature

of

the

fault

of

the

instrument

being

returned

and

of

the

model

and

serial

numbers.

Fai

lure

to

do

so

may

cause

unnecessary

delays

in

getting

the

unit

repaired.

Our

standard

procedure

requires

that

instruments

returned

for

repair

pass

the

same

quality

control

tests

that

are

used

for

new-production

instruments.

Instruments

that

are

returned

should

be

packed

so

that

they

wil

l

withstand

normal

transit

handling

and

must

be

shipped

PREPAID

via

Air

Parcel

Post

or

United

Parcel

Service

to

the

nearest

ORTEC

repair

center.

Instru

ments

damaged

in

transit

due

to

inadequate

packing

wi

ll

be

repaired

at

the

sender's

expense,

and

it

wil

l

be

the

sender's

responsibi

lity

to

make

claim

with

the

shipper.

Instruments

not

in

warranty

will

be

repaired

at

the

standard

charge

unless

they

have

been

grossly

misused

or

mishandled,

in

which

case

the

user

wi

ll

be

notified

prior

to

the

repair

being

done.

A

quotation

wil

l

be

sent

with

the

notification.

DAMAGE

IN

TRANSIT

Shipments

should

be

examined

immediately

upon

receipt

for

evidence

of

external

or

concealed

damage.

The

carrier

making

del

ivery

should

be

notified

immediately

of

any

such

damage,

since

the

carrier

is

normal

ly

liable

for

damage

in

shipment.

Packing

materials,

waybi

l

ls,

and

other

such

documentation

should

be

preserved

in

order

to

establ

ish

claims.

After

such

notification

to

the

carrier,

please

notify

ORTEC

of

the

circumstances

so

that

we

may

assist

in

dam

age

claims

and

in

providing

replacement

equipment

if

necessary.

Ill

CONTENTS

Page

WARRANTY

ii

PHOTOGRAPHS

iv

1.

GENERAL

DESCRIPTION

1

2.

SPECIFICATIONS

2

3.

INSTALLATION

3

3.1

General

3.2

Connection

to

Power

3.3

Connection

to

Linear

Amplifier

Output

3

3

3

4.

OPERATION

4

4.1

General

4.2

Front

Panel

Controls

4

4

5.

CIRCUIT

DESCRIPTION

5

5.1

General

5.2

Detailed

Circuit

Description

5

5

6.

MAINTENANCE

9

6.1

Testing

Performance

6.2

Calibration

Adjustments

6.3

Walk

Adjustment

6.4

Troubleshooting

9

9

9

10

7.

APPLICATIONS

11

7.1

Neutron-Gamma

Discrimination

with

Stilbene

and

Liquid

Scintillators

7.2

Neutron—Gamma-Ray

Discrimination

in

Proportional

Counters

7.3

Rise-Time

Discrimination

in

X-Ray

Proportional

Counter

11

13

14

REFERENCES

15

BLOCK

DIAGRAM

and

SCHEMATICS

458-0101-B1

458-0201-SI

458-0301-SI

LIST

OF

FIGURES

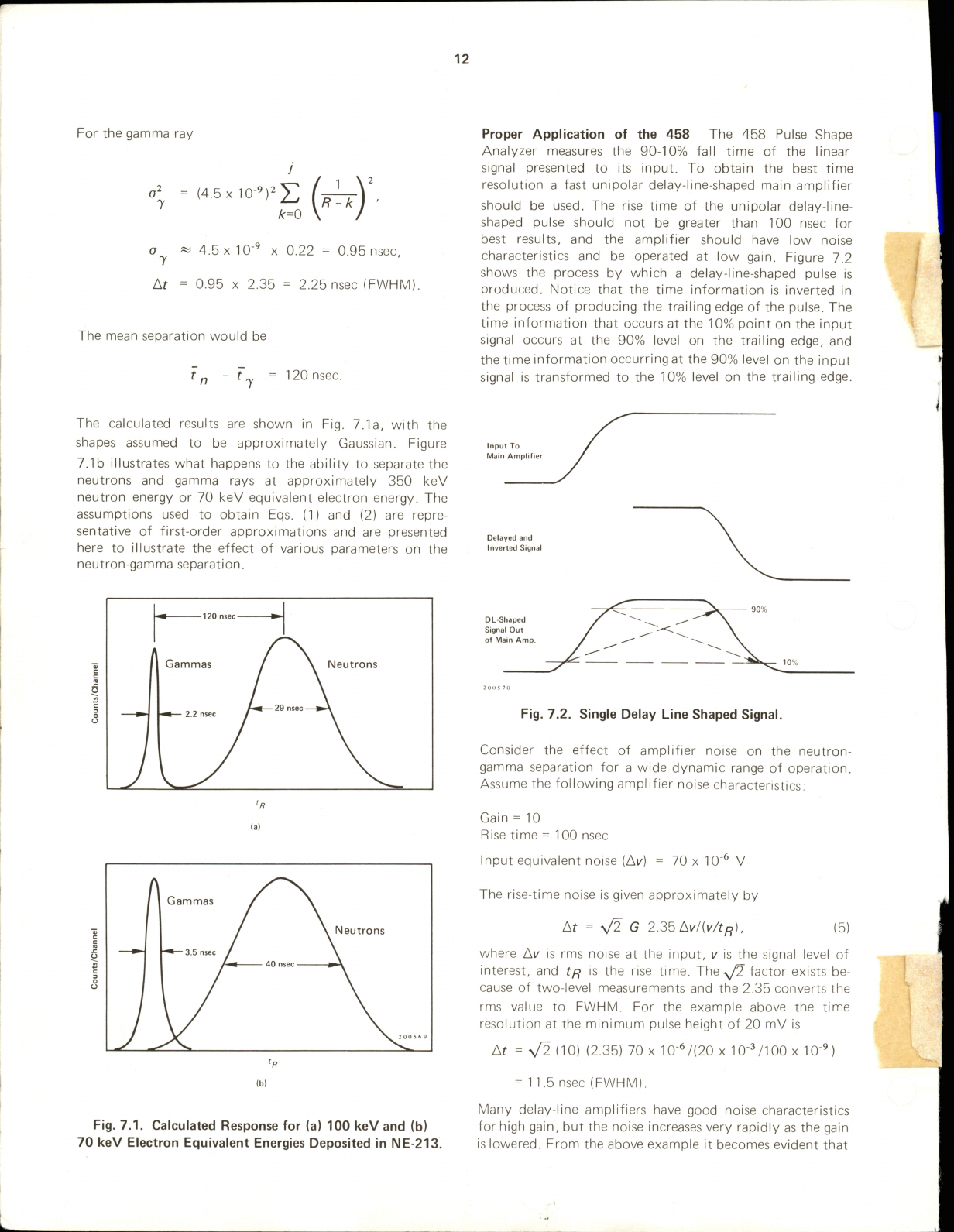

Fig.

3.1.

Waveforms

Observed

at

Test

Point

TP1

Fig.

5.1.

458

Timing

Diagram

Fig.

7.1.

Calculated

Response

for

(a)

100

keV

and

(b)

70

keV

Electron

Equivalent

3

6

Energies

Deposited

in

NE-213

12

Fig.

7.2.

Single

Delay

Line

Shaped

Signal

12

Fig.

7.3.

Block

Diagram

for

a

Typical

Neutron-Gamma

Separation

Experiment

13

Fig.

7.4.

Neutron-Gamma

Rise

Time

Spectrum

13

Fig.

7.5.

A

Typical

Neutron

and

Gamma

Rise

Time

Spectrum

from

a

Proton

Recoil

Proportional

Counter

13

Fig.

7.6.

Neutron-Gamma

Discrimination

System

with

Proportional

Counter

13

Fig.

7.7.

Background

Reduction

System

for

an

X-Ray

Proportional

Counter

14

Fig.

7.8.

Suggested

System

for

Setting

the

PSA

Window

of

the

458

14

Fig.

7.9.

Pulse

Shape

Spectrum

Taken

with

Proportional

Counter

System

Shown

in

Fig.

7.8

14

ORTEC^

^

MODEL

458

PULSE

SHAPE

ANALYZER

TIME

RANGE

0,6

0

4

,

0.8

INPUT

DISC.

»Sec

Volts

WALK

UPPER

LEVEL

LOWER

LEVEL

PSA

TIME

WINDOW

INPUT

WINDOW

'

L

Q

N

E

A

G

UL

c

OUTPUT

i

OUTPUT

1

SEIL

iriiniT

Dific.

e.

OliTiniT

y«€/

mZQ

'•fSf*

1

t

-.i-

■#

,L.-

ORTEC

458

PULSE

SHAPE

ANALYZER

1.

GENERAL

DESCRIPTION

The

ORTEC

458

Pulse

Shape

Analyzer

measures

the

fal

l

time

of

an

input

pulse

from

a

shaping

ampl

ifier

and

generates

a

l

inear

output

pulse

with

an

amplitude

that

is

proportional

to

the

fal

l

time.

It

also

includes

a

single

channel

analyzer

that

can

generate

either

of

two

logic

output

pulses,

based

on

the

measured

fal

l

time.

One

of

the

single

channel

logic

outputs

occurs

when

the

time

is

within

the

single-channel

window;

the

other

occurs

when

the

upper

level

setting

is

exceeded.

A

separate

logic

output

occurs

when

the

input

pulse

ampl

itude

exceeds

the

input

discriminator

threshold.

The

ORTEC

458

accepts

input

pulses

from

any

shaping

ampl

ifier,

RC,

active-filter,

or

delay-l

ine.

Its

l

inear

output

is

interpreted

as

a

measurement

of

the

pulse

shape

of

the

input

signal

.

The

output

is

independent

of

the

ampl

itude

of

the

input

and

depends

only

on

the

shape

(waveform)

of

the

input

signal

as

a

function

of

time.

The

shape

of

the

main

shaping

amplifier

output

varies,

depending

on

certain

experimental

conditions.

Although

there

are

several

examples

of

such

variations,

perhaps

the

best

known

is

the

neutron

and

gamma

response

in

certain

scinti

l

lators.

The

conditions

on

the

electronics

in

this

case

are

stringent

because

of

the

nonl

inear

response

of

the

scinti

l

lator

as

a

function

of

neutron

energy.

For

neutrons

with

energies

from

200

keV

to

10

MeV,

the

response

of

an

NE-213

scintil

lator

can

vary

over

a

500:1

range.

The

458

can

operate

satisfactorily

over

a

400:1

dynamic

range

in

these

neutron-gamma

appl

ications,

and

this

has

not

been

possible

heretofore.

This

unit

is

also

appl

icable

for

use

with

gaseous

detectors

for

particle

identification.

Gaseous

detectors

are

designed

so

that

the

charge

col

lection

time

(and

therefore

the

resulting

pulse

shape)

is

influenced

by

the

location

of

the

interaction

within

the

detector,

and

the

interaction

site

is

related

to

the

interacting

particle

type.

Another

appl

ication

of

pulse-shape

analysis

is

with

large

Ge(Li)

semiconductor

detectors.

With

the

458

events

that

interact

within

the

desired

portion

of

the

detector

can

be

selected,

and

those

that

occur

in

low

electric-field-strength

regions

can

be

rejected,

thereby

optimizing

the

energy

resolution

of

the

system.

Some

typical

appl

ications

of

the

458

for

timing

ex

periments

are

described

in

Section

7.

The

input

signal

from

the

main

amplifier

covers

the

0-

to

10-V

range.

The

input

discriminator

covers

the

complete,

range

from

20

mV

to

10

V.

The

input

wi

l

l

be

approxi

mately

symmetrical

for

delay-l

ine

and

active-fi

lter

amp

l

ifier

inputs.

For

classical

RC

fi

ltering

the

fal

l

time

wi

l

l

be

substantial

ly

longer

than

the

rise

time.

For

al

l

inputs

the

time

range

switch

should

be

set

to

be

equal

to

or

greater

than

the

fal

l

time

of

the

input.

Time

ranges

from

0.2

to

10

ftsec

are

selectable.

A

pulse-shape

analysis

"time

window"

is

provided

for

selection

of

a

time

region

within

the

time

range.

With

this

window

a

logic

gating

pulse

can

be

provided

for

al

l

input

pulses

that

have

a

preselected

shape

within

this

time

region.

In

this

way,

for

example,

al

l

neutron

events

can

generate

a

control

function

through

the

window

output,

whereas

the

gamma-ray

events

wi

l

l

produce

no

control

outputs.

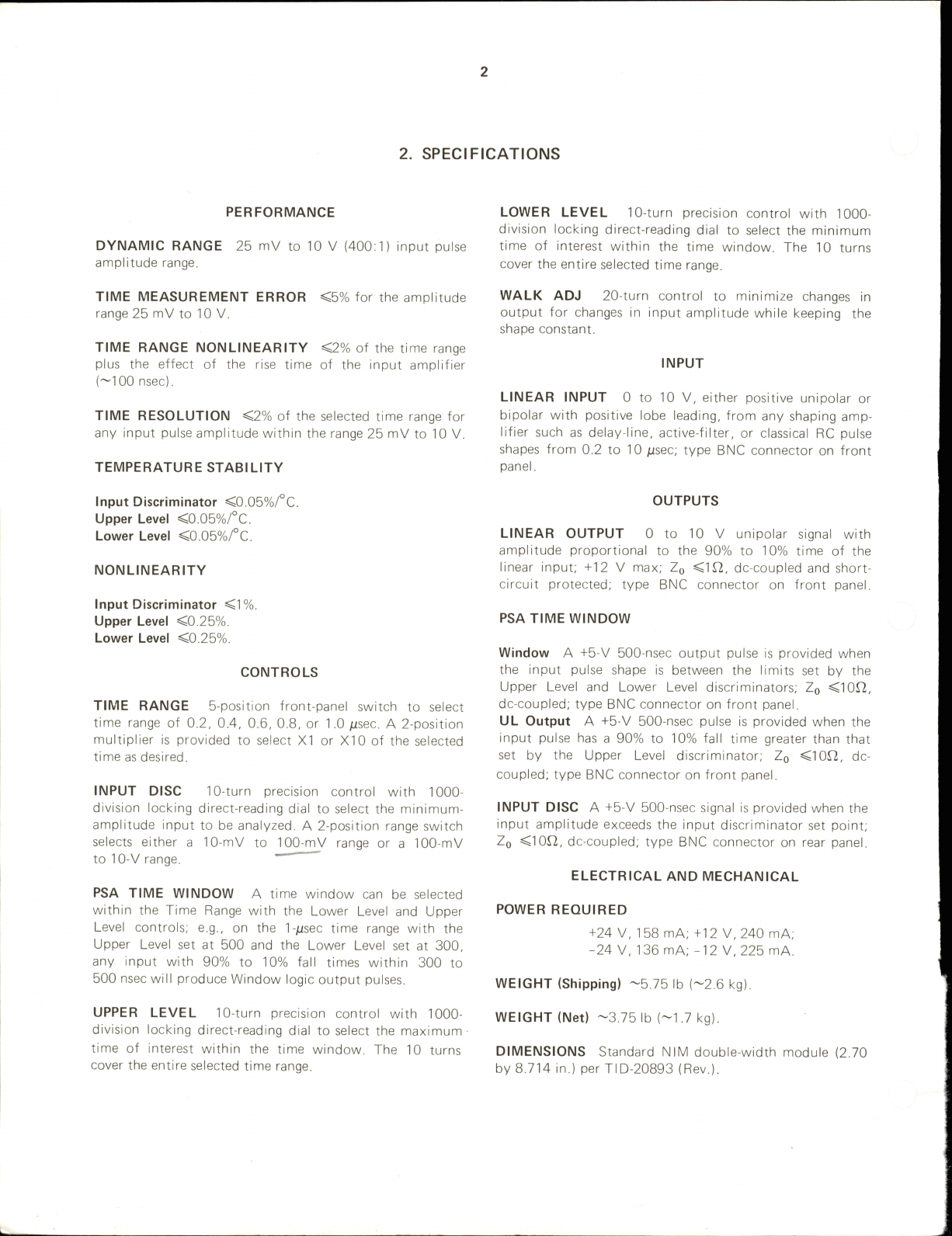

2.

SPECIFICATIONS

PERFORMANCE

DYNAMIC

RANGE

25

mV

to

10

V

(400:1)

input

pulse

ampl

itude

range.

TIME

MEASUREMENT

ERROR

<5%

for

the

ampl

itude

range

25

mV

to

10

V.

TIME

RANGE

NONLINEARITV

<2%

of

the

time

range

plus

the

effect

of

the

rise

time

of

the

input

amplifier

(~100

nsec).

TIME

RESOLUTION

<2%

of

the

selected

time

range

for

any

input

pulse

ampl

itude

within

the

range

25

mV

to

10

V.

TEMPERATURE

STABILITY

LOWER

LEVEL

10-turn

precision

control

with

1000-

division

locking

direct-reading

dial

to

select

the

minimum

time

of

interest

within

the

time

window.

The

10

turns

cover

the

entire

selected

time

range.

WALK

ADJ

20-turn

control

to

minimize

changes

in

output

for

changes

in

input

amplitude

while

keeping

the

shape

constant.

INPUT

LINEAR

INPUT

0

to

10

V,

either

positive

unipolar

or

bipolar

with

positive

lobe

leading,

from

any

shaping

amp

l

ifier

such

as

delay-l

ine,

active-fi

lter,

or

classical

RC

pulse

shapes

from

0.2

to

10

/tsec;

type

BNC

connector

on

front

panel

.

Input

Discriminator

<0.05%/°C.

Upper

Level

<0.05%/°C.

Lower

Level

<0.05%/°C.

NONLINEARITY

Input

Discriminator

<1%.

Upper

Level

<0.25%.

Lower

Level

<0.25%.

CONTROLS

TIME

RANGE

5-position

front-panel

switch

to

select

time

range

of

0.2,

0.4, 0.6, 0.8,

or

1.0

fisec.

A

2-position

multipl

ier

is

provided

to

select

XI

or

XI0

of

the

selected

time

as

desired.

INPUT

DISC

10-turn

precision

control

with

1000-

division

locking

direct-reading

dial

to

select

the

minimum-

ampl

itude

input

to

be

analyzed.

A

2-position

range

switch

selects

either

a

10-mV

to

100-mV

range

or

a

100-mV

to

10-V

range.

'

'

PSA

TIME

WINDOW

A

time

window

can

be

selected

within

the

Time

Range

with

the

Lower

Level

and

Upper

Level

controls:

e.g.

,

on

the

1-/tsec

time

range

with

the

Upper

Level

set

at

500

and

the

Lower

Level

set

at

300,

any

input

with

90%

to

10%

fal

l

times

within

300

to

500

nsec

wi

l l

produce

Window

logic

output

pulses.

UPPER

LEVEL

10-turn

precision

control

with

1000-

division

locking

direct-reading

dial

to

select

the

maximum-

time

of

interest

within

the

time

window.

The

10

turns

cover

the

entire

selected

time

range.

OUTPUTS

LINEAR

OUTPUT

0

to

10

V

unipolar

signal

with

ampl

itude

proportional

to

the

90%

to

10%

time

of

the

linear

input;

+12

V

max;

Zq

<1^2,

dc-coupled

and

short-

circuit

protected;

type

BNC

connector

on

front

panel

.

PSA

TIME

WINDOW

Window

A

+5-V

500-nsec

output

pulse

is

provided

when

the

input

pulse

shape

is

between

the

l

imits

set

by

the

Upper

Level

and

Lower

Level

discriminators;

Zq

<1012,

dc-coupled;

type

BNC

connector

on

front

panel

.

UL

Output

A

+5-V

500-nsec

pulse

is

provided

when

the

input

pulse

has

a

90%

to

10%

fal

l

time

greater

than

that

set

by

the

Upper

Level

discriminator;

Zq

<10^2,

dc-

coupled;

type

BNC

connector

on

front

panel

.

INPUT

DISC

A

+5-V

500-nsec

signal

is

provided

when

the

input

ampl

itude

exceeds

the

input

discriminator

set

point;

Zq

<10L2,

dc-coupled;

type

BNC

connector

on

rear

panel

.

ELECTRICAL

AND

MECHANICAL

POWER

REQUIRED

+24

V,

158

mA;

+12

V,

240

mA;

-24

V,

136

mA;

-12

V,

225

mA.

WEIGHT

(Shipping)

~5.75

lb

(~2.6

kg).

WEIGHT

(Net)

-3.75

lb

(-1.7

kg).

DIMENSIONS

Standard

NIM

double-width

module

(2.70

by

8.714

in.)

per

TID-20893

(Rev.).

3.

INSTALLATION

3.1.

GENERAL

The

ORTEC

458

contains

no

internal

power

but

must

be

used

in

conjunction

with

an

ORTEC

401/402

Series

Bin

and

Power

Supply,

which

is

intended

for

rack

mounting.

Therefore

if

other

equipment

is

operated

in

the

same

rack

(particularly

vacuum

tube

equipment)

there

must

be

sufficient

cool

ing

air

circulating

to

prevent

any

local

ized

heating

of

the

al

l-transistorized

circuitry

of

the

458.

The

temperature

of

equipment

mounted

in

racks

can

easi

ly

exceed

the

recommended

maximum

unless

these

pre

cautions

are

taken.

The

458

should

not

be

subjected

to

temperatures

in

excess

of

120°F

(50°C).

To

obtain

maximum

temperature

insensitivity,

the

458

should

not

be

exposed

to

high

velocity

drafts

of

cool

ing

air,

especial

ly

if

the

temperature

of

the

cool

ing

air

is

not

stable.

3.2.

CONNECTION

TO

POWER

The

Power

Supply

to

the

401

Bin

should

be

turned

off

when

modules

are

inserted

or

removed.

ORTEC

modular

instruments

are

designed

so

that

it

is

not

possible

to

overload

the

Power

Supply

with

a

ful

l

complement

of

modules

in

the

Bin.

Since,

however,

this

may

not

be

true

if

the

Bin

contains

modules

other

than

those

of

ORTEC

design,

the

Power

Supply

voltages

should

be

checked

after

the

modules

are

inserted.

The

ORTEC

401

Series

Bin

has

test

points

on

its

Power

Supply

control

panel

to

monitor

the

dc

voltages.

The

Power

Supply

voltages

should

read

within

±0.5%

of

the

nominal

values

for

proper

operation

of

NIM-standard

instruments.

3.3.

CONNECTION

TO

LINEAR

AMPLIFIER

OUTPUT

(a)

Pulse

Shape.

(b)

Baseline

Offset

with

R46

Adjusted

Too

Far

Clockwise.

/

u-y

The

input

to

the

458

is

furnished

through

a

front

panel

BNC

connector.

The

input

circuit

can

accept

0-

to

10-V

unipolar

signals

into

a

1000T2

load.

The

input

operating

range

is

from

100

mV

to

10

V

when

the

Input

Disc

range

switch

is

set

at

10

V.

When

the

switch

is

set

at

0.1.V,

the

input

operating

range

is

from

20

mV

to

10

V,

but

precautions

must

be

observed

to

obtain

this

wider

dynamic

range.

Use

the

fol

lowing

procedure

with

the

switch

set

at

0.1

V:

1.

If

the

l

inear

amplifier

has

a

dc

output

adjustment,

adjust

the

output

level

careful

ly

to

0

+

5

mV.

The

rise

time

of

the

output

pulse

should

be

less

than

1

/tsec.

2.

Use

a

pulse

generator

to

furnish

pulses

through

the

ampl

ifier.

Adjust

the

pulse

generator

ampl

itude

and

the

ampl

ifier

gain

for

an

amplifier

output

of

2

V.

Connect

this

to

the

458

Input.

3.

Connect

an

oscil

loscope

probe

to

test

point

TP1,

accessible

through

the

top

of

the

458.

Set

the

osci

l

loscope

for

0.5

V/division

and

1

^tsec/division.

The

osci

l

loscope

trace

should

be

similar

to

that

shown

in

Fig.

3.1a.

4.

Set

the

osci

lloscope

sensitivity

to

50

mV/division

and

adjust

R46,

located

between

the

test

point

and

the

front

(c)

Baseline

Offset

with

R46

Adjusted

Correctly.

(d)

Baseline

Offset

with

R46

Adjusted

Too

Far

Counterclockwise.

Fig.

3.1.

Waveforms

Observed

at

Test

Point

TP1.

panel,

for

a

zero

basel

ine

offset

simi

lar

to

that

in

Fig.

3.1c.

If

R46

does

not

have

sufficient

range

to

obtain

the

zero

basel

ine

offset,

use

R4

as

a

coarse

adjustment

and

then

complete

the

adjustment

of

R46.

5.

The

Input

Disc

dial

has

1000

divisions,

corresponding

to

its

range

of

100

mV.

Set

the

control

as

desired,

between

100

and

1000

dial

divisions,

to

determine

the

minimum

input

pulse

amplitude

that

wi

l

l

trigger

a

time

measurement.

4.

OPERATION

4.1.

GENERAL

The

ORTEC

458

Pulse

Shape

Analyzer

measures

the

time

during

which

the

input

waveform

falls

from

90%

of

its

peak

amplitude

to

10%

of

its

peak

amplitude,

pro

viding

the

peak

amplitude

is

sufficient

to

trigger

the

458

input

discriminator.

When

the

shape

of

the

input

pulse

varies,

due

to

the

nature

of

the

information

furnished

into

the

l

inear

ampl

ifier

preceding

the

458,

the

fal

l

time

of

the

pulse

wi

l l

vary

and

wi

l l

provide

a

variation

of

the

l

inear

output

ampl

itude

that

is

proportional

to

the

measured

time.

After

the

decay

time

has

been

converted

into

a

linear

output

pulse,

with

an

ampl

itude

range

of

0

to

10

V

corresponding

to

the

selected

time

range,

the

variety

of

pulse

ampl

itudes

that

are

avai

lable

through

the

l

inear

output

wil

l

reflect

the

nature

of

the

experiment.

For

example,

there

wi

l

l

be

two

principal

concentrations

of

pulse

heights

for

the

gamma-neutron

appl

ication,

whereas

an

experiment

that

identifies

the

location

of

interaction

in

a

detector

could

provide

a

fairly

equal

distribution

of

ampl

itudes

throughout

the

range,

iftus

the

adjustment

of

the

controls

for

the

single

channel

analyzer

and

the

uses

for

its

logical

outputs

wil

l

depend

upon

the

nature

of

the

experiment.

See

the

appl

ications

in

Section

7

for

further

suggestions.

4.2.

FRONT

PANEL

CONTROLS

TIME

RANGE

The

total

range

for

the

time

measurement

can

be

as

short

as

200

nsec

or

as

long

as

10

/jsec.

The

selected

range

wi

l l

be

converted

to

a

0-

to

10-V

range

of

l

inear

outputs.

The

appropriate

range

wi

ll

be

one

that

is

long

enough

to

accommodate

the

slowest

fal

l

time

but

is

as

short

as

possible

within

this

restriction.

INPUT

DISC

The

input

discriminator

must

be

triggered

by

an

input

pulse

in

order

for

its

fall

time

to

be

measured.

The

ampl

itude

of

the

input

pulse

from

the

l

inear

amplifier

is

the

parameter

that

is

measured

by

this

function.

When

the

sl

ide

switch

is

set

at

1

V,

the

10-turn

potentiometer

can

be

set

for

any

level

between

10

and

1000

dial

divisions,

corresponding

to

an

input

ampl

itude

range

of

100

mV

through

10

V.

For

a

more

precise

setting

at

lower

levels

the

sl

ide

switch

can

be

set

at

0.1

V,

and

the

usable

range

for

the

10-turn

potentiometer

is

then

about

100

dial

divisions

through

1000

divisions,

or

about

10

mV

through

100

mV.

When

the

input

discriminator

is

trig

gered,

there

is

a

logic

output

pulse

through

the

rear

panel

BNC

designated

Input

Disc

Output.

WALK

ADJ

The

purpose

of

this

screwdriver

control

is

to

minimize

the

walk

when

measuring

decay

times

for

differing

input

pulse

ampl

itudes.

See

Section

6

for

cali

bration

information.

PSA

TIME

WINDOW

These

two

10-turn

potentiometers

are

the

controls

that

set

the

two

discriminator

levels

of

the

single

channel

analyzer

that

analyzes

the

l

inear

output

signal

of

the

458.

Since

any

selected

time

range

wil

l

be

converted

into

a

0-

to

10-V

linear

output

range,

the

1000

dial

divisions

on

each

potentiometer

are

directly

related

to

the

selected

time

range.

Whatever

their

settings

for

any

specific

appl

ication,

a

linear

output

amplitude

that

exceeds

the

Upper

Level

setting

wi

l

l

generate

a

logic

output

through

the

UL

connector

and

wil

l

inhibit

a

Window

output.

A

linear

output

ampl

itude

that

exceeds

the

Lower

Level

setting

but

does

not

also

exceed

the

Upper

Level

setting

wi

l l

generate

a

Window

output.

5.

CIRCUIT

DESCRIPTION

5.1.

GENERAL

A

block

diagram,458-0101-B1,

is

included

at

the

back

of

this

manual

.

There

are

also

three

schematics,

458-0201-SI

(Sheets

1

and

2)

and

458-0301-SI.

The

fol

lowing

circuit

description

refers

primarily

to

the

block

diagram.

The

ORTEC

458

Pulse

Shape

Analyzer

consists

of

three

basic

functions:

Input

and

Compression

Circuitry,

Dual

Constant-Fraction

Discriminator,

and

a

Time

to

Pulse

Height

Converter.

These

three

basic

functions

lead

to

the

generation

of

a

l

inear

output.

A

single

channel

analyzer

is

also

included

for

logical

analysis

of

the

l

inear

output

ampl

itudes.

The

input

and

compression

circuitry

provides

isolation

and

transforms

the

input

pulse

height

range

of

20

mV

to

10

V

into

a

range

of

100

mV

to

5

V.

The

effective

compression

is

from

500:1

down

to

only

50:1

in

pulse

height

variation.

The

Dual

Constant-Fraction

Discriminator

generates

two

time

markers.

The

first

time

marker

is

generated

at

a

point

on

the

trai

l

ing

edge

of

the

unipolar

input

pulse

when

the

pulse

has

decayed

to

approximately

90%

of

its

peak

ampl

itude.

The

second

marker

is

generated

when

the

input

pulse

has

decayed

to

approximately

10%

of

its

peak

ampl

itude.

The

Time

to

Pulse

Height

Converter

then

measures

the

time

between

the

90%

and

10%

markers

and

stores

the

time

information

on

a

capacitor.

The

voltage

on

the

capacitor

is

strobed,

shaped,

and

routed

to

the

l

inear

output.

This

voltage

is

in

the

range

of

0'to

10

V,

independent

of

the

input

ampl

itude

from

the

linear

amplifier.

The

Single

Channel

Analyzer

views

the

l

inear

output

signal

ampl

itude

and

generates

a

Window

output

at

strobe

time

if

the

output

amplitude

is

between

the

settings

of

the

Lower

Level

and

Upper

Level

controls

(UL

set

higher

than

LL).

If

the

ampl

itude

is

greater

than

the

setting

of

the

UL,

a

UL

logic

output

is

generated

at

strobe

time

and

a

Window

output

is

inhibited.

5.2.

DETAILED

CIRCUIT

DESCRIPTION

The

input

signal

is

attenuated

by

a

factor

of

2

by

R1

and

R2,

and

is

routed

to

the

input

unity-gain

ampl

ifier,

Q1

to

Q6

and

Q45.

Diodes

D1

and

D2

prevent

the

absolute

ampl

itude

of

the

signal

from

exceeding

10

V.

The

signal

at

the

emitter

of

Q45

is

routed

to

a

1-jusec

delay

l

ine

and

to

a

voltage

comparator,

IC1

.

The

purpose

of

the

com

parator

is

to

generate

a

logic

signal

when

the

input

signal

exceeds

+^

V.

When

the

Input

Disc

range

is

set

for

0.1

V,

the

logic

signal

starts

a

one-shot

multivibrator,

IC2A,

B,

and

C,

to

control

the

gain

in

the

compression

network.

For

this

condition

the

initial

gain

of

the

network

is

10

and

it

is

shifted

to

unity

when

the

input

logic

starts

the

one-shot.

The

signal

compressor

is

essentially

a

l

inear

gate

that

routes

the

signal

through

an

inverting

operational

amp

l

ifier

with

a

gain

of

10

if

the

input

signal

does

not

exceed

-1-1

V,

or

through

another

operational

amplifier

with

unity

gain

if

the

input

signal

does

exceed

-i-l

V.

The

decision

on

whether

or

not

the

input

signal

exceeds

the

-i-1-V

level

is

made

as

previously

described

by

IC1.

The

input

signal

is

delayed

1

fisec

by

DLi

and

inverted

by

operational

amp

l

ifier

0A1.

Thus

the

signal

arrives

at

the

compressor

input

after

the

decision

has

been

made

on

what

the

gain

should

be

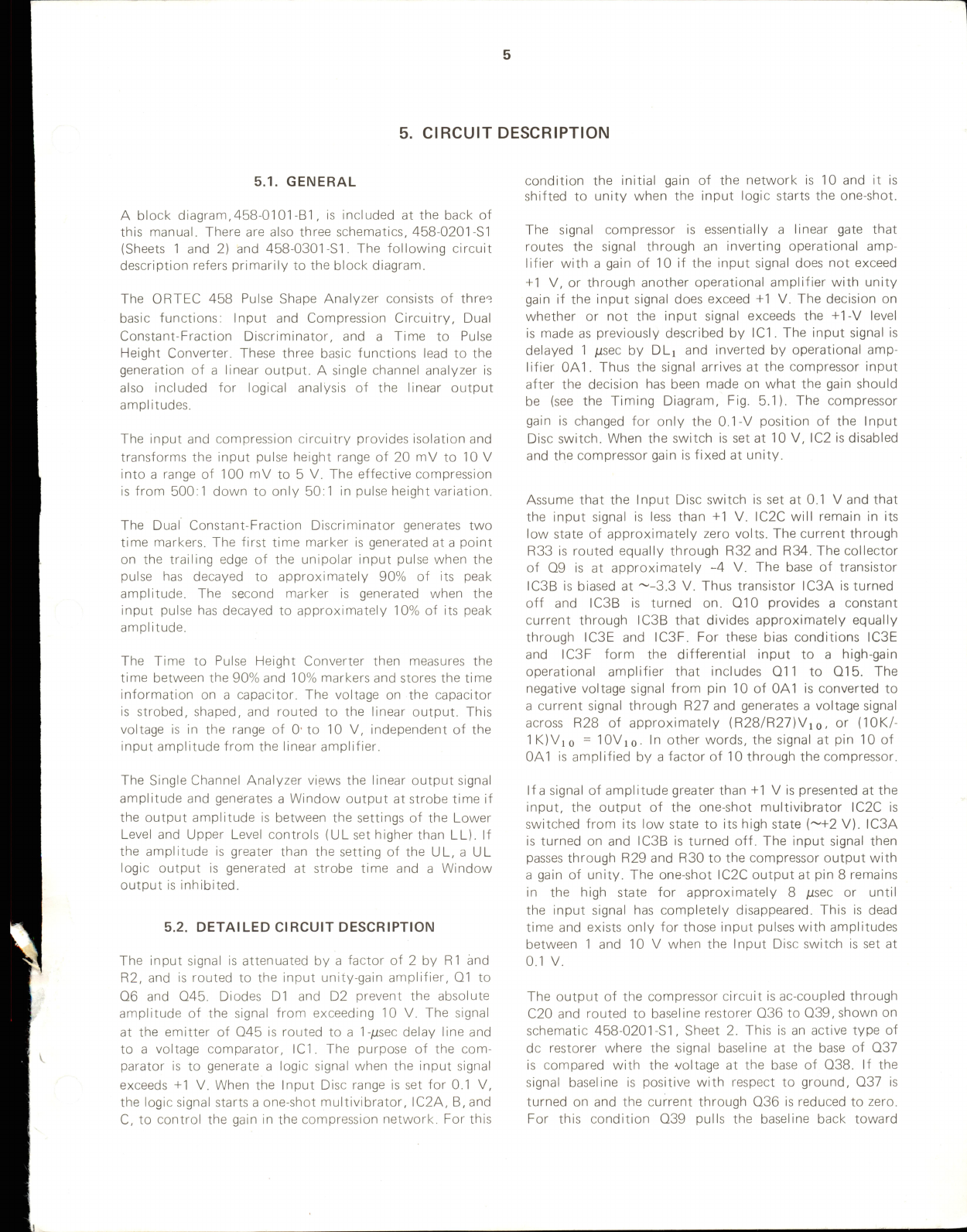

(see

the

Timing

Diagram,

Fig.

5.1).

The

compressor

gain

is

changed

for

only

the

0.1-V

position

of

the

Input

Disc

switch.

When

the

switch

is

set

at

10

V,

IC2

Is

disabled

and

the

compressor

gain

is

fixed

at

unity.

Assume

that

the

Input

Disc

switch

is

set

at

0.1

V

and

that

the

input

signal

is

less

than

-i-1

V.

IC2C

wil

l

remain

in

its

low

state

of

approximately

zero

volts.

The

current

through

R33

is

routed

equally

through

R32

and

R34.

The

collector

of

Q9

is

at

approximately

-4

V.

The

base

of

transistor

IC3B

is

biased

at

~-3.3

V.

Thus

transistor

IC3A

is

turned

off

and

IC3B

is

turned

on.

Q10

provides

a

constant

current

through

IC3B

that

divides

approximately

equally

through

IC3E

and

IC3F.

For

these

bias

conditions

IC3E

and

IC3F

form

the

differential

input

to

a

high-gain

operational

ampl

ifier

that

includes

Q11

to

Q15.

The

negative

voltage

signal

from

pin

10

of

0A1

is

converted

to

a

current

signal

through

R27

and

generates

a

voltage

signal

across

R28

of

approximately

(R28/R27)Vio,

or

(10K/-

1

KjVio

=

lOVio.

In

other

words,

the

signal

at

pin

10

of

0A1

is

ampl

ified

by

a

factor

of

10

through

the

compressor.

If

a

signal

of

ampl

itude

greater

than

-i-1

V

is

presented

at

the

input,

the

output

of

the

one-shot

multivibrator

IC2C

is

switched

from

its

low

state

to

its

high

state

{~+2

V).

IC3A

is

turned

on

and

IC3B

is

turned

off.

The

input

signal

then

passes

through

R29

and

R30

to

the

compressor

output

with

a

gain

of

unity.

The

one-shot

IC2C

output

at

pin

8

remains

in

the

high

state

for

approximately

8

/tsec

or

until

the

input

signal

has

completely

disappeared.

This

is

dead

time

and

exists

only

for

those

input

pulses

with

ampl

itudes

between

1

and

10

V

when

the

Input

Disc

switch

is

set

at

0.1

V.

The

output

of

the

compressor

circuit

is

ac-coupled

through

C20

and

routed

to

basel

ine

restorer

Q36

to

Q39,

shown

on

schematic

458-0201-SI,

Sheet

2.

This

is

an

active

type

of

dc

restorer

where

the

signal

basel

ine

at

the

base

of

Q37

is

compared

with

the

voltage

at

the

base

of

Q38.

If

the

signal

basel

ine

is

positive

with

respect

to

ground,

Q37

is

turned

on

and

the

current

through

Q36

is

reduced

to

zero.

For

this

condition

Q39

pul

ls

the

basel

ine

back

toward

7"

90%

7

10%

7

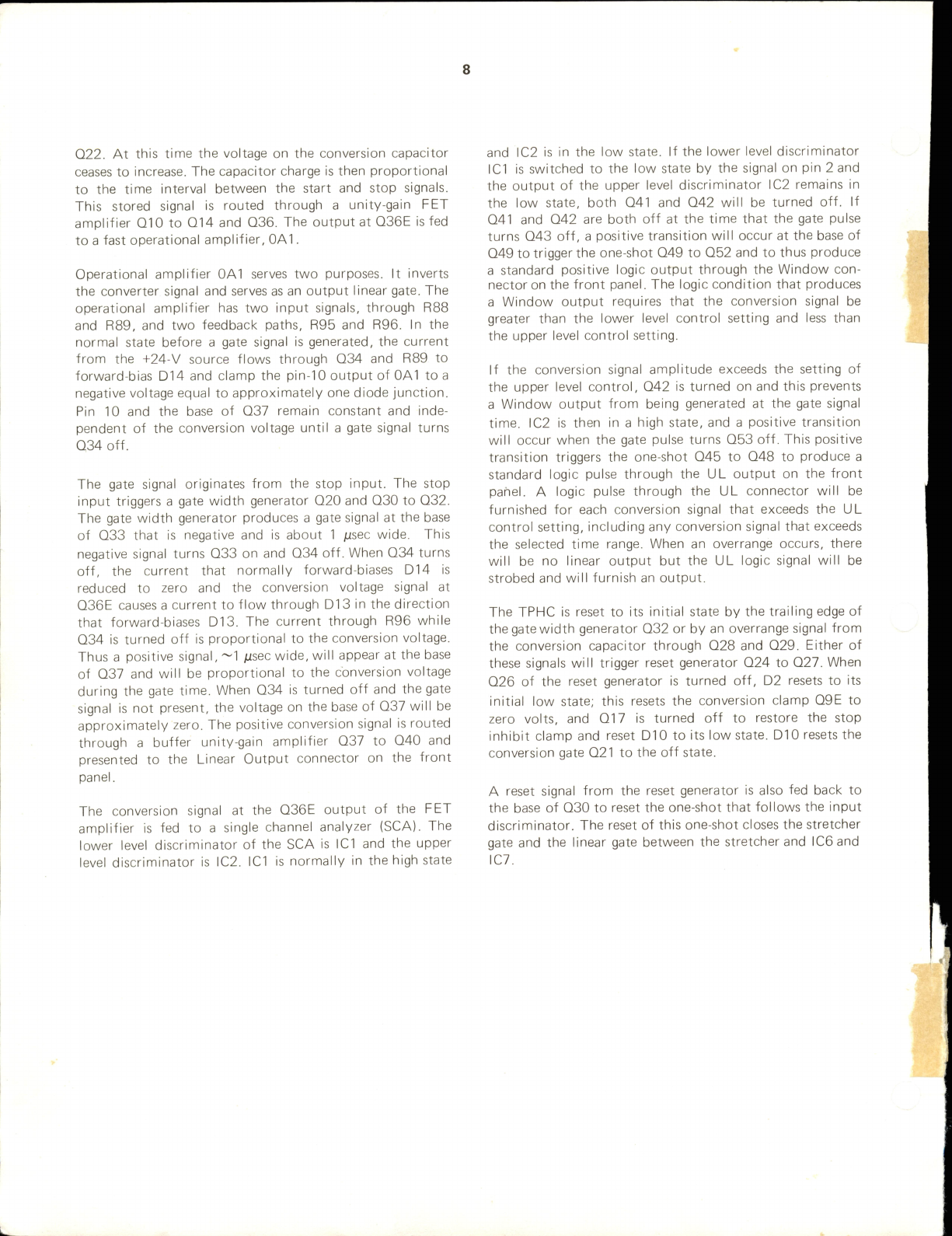

Reset

1

TiSec

Signal

Compressor

Input

Signal

Compressor

(X1

Pos

of

Input

Disc

Only)

Baseline

Restorer

Ouptut

Stretcher

Ouptut

Pulse

Stretcher

&

Linear

Gate

Input

ICG

Timing

Comp

IC7

Timing

Comp

Input

Disc.

Output

I

7

90%

7

10%

7

Reset

TPHC

Start

TPHC

Stop

Start

Tunnel

Diode

Memory

Stop

Inhibit

Gate

Stop

Tunnel

Diode

Memory

Conversion

Cap

Voltage

Gate

Width

Generator

Linear

Output

TPHC

Reset

Window

Output

-

0.5

iusec

'1

Msec

1

Msec

b

I

1

UL

Output

(only

if

UL

Disc,

exceeded)

J

L

Fig.

5.1.

458

Timing

Diagram.

zero

volts.

If

the

basel

ine

goes

negative,

Q37

turns

off

and

approximately

3

mA

of

current

flows

through

Q36

to

bring

the

basel

ine

back

toward

zero

very

rapidly.

After

the

baseline

is

restored,

the

signal

is

routed

into

three

level

discriminators,

IC5, IC6,

and

IC7,

and

to

a

pulse

stretcher,

Q16

through

Q29.

When

the

signal

goes

positive,

stretcher

capacitor

C28

is

charged

by

the

current

through

Q25.

The

voltage

on

C28

is

control

led

by

the

closed-loop

unity-gain

amplifier,

Q23

to

Q28,

which

feeds

the

C28

voltage

back

to

the

gate

of

the

input

differential

pair.

If

the

voltage

on

C28

tries

to

exceed

that

of

the

input

signal,

Q17

turns

on

and

Q16

turns

off

to

reverse-bias

Q19

and

Q20.

With

Q19

and

Q20

turned

off,

the

voltage

on

C28

ceases

to

increase.

All

this

is

the

action

of

the

stretcher

before

the

input

reaches

its

peak.

When

the

input

signal

reaches

its

peak

and

starts

to

decrease,

diode

D24

reverse-

biases.

The

charge

on

C28,

which

is

equal

to

the

peak

amplitude

of

the

input

pulse,

wil

l

remain,

providing

that

the

gate

transistor,

Q22,

is

turned

off

before

the

peak

has

been

reached.

The

voltage

on

C28

is

routed

to

the

output

of

the

stretcher

and

to

the

base

of

Q32

through

the

unity-gain

ampl

ifier,

Q23

to

Q28.

The

gate

signal

for

the

stretcher

is

derived

from

the

level

discriminator,

IC5.

The

positive

signal

comes

from

the

baseline

restorer,

Q36

to

Q39,

to

the

IC5

discriminator.

The

ampl

itude

of

the

signal

that

is

required

to

change

the

IC5

discriminator

state

from

low

to

high

is

determined

by

the

Input

Disc

10-turn

front

panel

control

and

by

the

range

that

is

set

by

its

slide

switch

(a

function

not

shown

on

the

block

diagram).

The

Input

Disc

control

sets

a

positive

voltage

on

pin

2

of

IC5.

When

the

signal

exceeds

the

pin-2

voltage,

IC5

changes

states

from

high

to

low

and

generates

a

negative

output

pulse.

This

negative

pulse

is

inverted

through

IC4A

to

trigger

a

one-shot

multivibrator,

IC4B

and

IC4C.

The

multivibrator

output

is

routed

through

IC4D

and

transistor

Q29

to

the

base

of

Q22,

the

stretcher

gate

transistor.

The

gate

signal

reaching

the

base

of

Q22

is

negative

enough

to

turn

Q22

off.

The

output

of

IC4C

remains

in

the

positive

state

until

the

system

reset

is

generated

(see

Fig.

5.1).

The

one-shot

multivibrator,

IC4B

and

IC4C,

also

triggers

a

second

0.5-/tsec

one-shot

multivibrator,

IC2D,

Q7,

and

Q8.

The

output

at

QBE-

is

routed

to

the

rear

panel

BNC

connector.

Input

Disc

output.

The

stretcher

output

is

routed

to

a

l

inear

gate,

Q32

to

Q35,

which

is

normally

closed.

The

same

signal

that

opened

the

stretcher

is

routed

to

the

base

of

Q34,

which

is

normal

ly

on.

When

Q34

is

turned

on,

its

current

holds

the

base-emitter

junction

of

Q32

reverse-biased,

and

this

prevents

the

stretcher

signal

from

reaching

pin

2

of

IC6

and

IC7.

Before

Q34

is

turned

off

by

the

gate

signal,

a

negative

voltage

is

forced

on

the

base,

of

Q33

which

is

transferred

to

pin

2

of

IC6

and

IC7.

This

causes

discriminators

ICG

and

IC7

toassumea

low

voltage

state

before

gate

Q34

is

opened.

When

the

gate

signal

turns

Q34

off,

the

stretcher

signal

is

routed

through

Q32

and

Q34

to

pin

2

of

ICG

and

IC7.

The

stretcher

signal

at

the

emitter

of

Q33

has

an

ampl

itude

with

reference

to

ground

that

is

approximately

90%

of

the

peak

ampl

itude

of

the

signal

presented

at

pin

3

of

ICG

and

IC7.

The

stretcher

signal

is

presented

to

ICG

without

attenuation,

but

this

signal

is

attenuated

further

so

that

the

stretched

signal

at

pin

2

of

IC7

is

approximately

10%

of

the

peak

ampl

itude

of

the

signal

present

at

pin

3.

The

outputs

of

both

discriminators

remain

in

the

low

state

until

a

time

after

the

peak

of

the

input

signal

.

As

the

input

goes

beyond

the

peak

and

decays

toward

zero,

there

is

a

time

when

the

voltage

on

pin

3

of

ICG

is

equal

to

the

90%

stretched

signal

on

pin

2

of

ICG,

and

ICG

changes

from

its

low

state

to

its

high

state

as

the

pin-3

signal

goes

further

negative.

This

generates

the

first

timing

signal

to

start

the

time

measurement

of

the

input

signal

.

The

second

time

marker

is

generated

by

IC7

as

the

signal

voltage

on

pin

3

goes

more

negative

than

the

10%

stretched

signal

on

its

pin

2.

The

output

transition

of

IC7

is

then

from

its

low

state

to

its

high

state,

the

same

as

previously

described

for

ICG.

This

signal

wil

l

stop

the

time

measure

ment

of

the

input

signal

.

The

output

signals

from

both

ICG

and

IC7

are

differ

entiated,

and

the

positive

transitions

are

fed

through

separate

fast

ampl

ifiers

to

the

start

and

stop

inputs

of

the

Time

to

Pulse

Height

Converter.

The

start

time

marker

that

originated

at

ICG

is

routed

through

fast

ampl

ifier

Q1

and

Q2

(see

schematic

458-0301-S1)

to

the

start

input

tunnel

diode

D2

of

the

TPHC.

The

start

signal

triggers

D2

to

its

high

state,

where

it

remains

until

a

system

reset

is

gen

erated.

The

high

state

of

D2

is

routed

through

the

amp

l

ifier

Q3

to

Q6

to

the

conversion

clamp

Q7

to

Q9

and

to

the

stop

inhibit

clamp

Q17.

When

Q17

turns

on,

current

through

R42

is

rerouted

from

tunnel

diode

D10

through

Q17

and

this

sets

the

proper

bias

current

so

that

the

stop

signal

wil

l

be

able

to

change

the

state

of

D10.

The

start

signal

from

D2

turns

Q5

on.

This

forward-biases

Q7

to

turn

off

Q8

and

conversion

clamp

Q9.

The

conversion

current

source

is

normally

on,

providing

current

to

the

clamp

transistor

Q9E.

Before

the

clamp

Q9

is

turned

off,

the

conversion

capacitor

is

clamped

to

near

zero

volts.

When

the

clamp

is

removed,

the

conversion

current

is

rerouted

from

Q9E

to

the

conversion

capacitors

C7

to

C9.

The

voltage

on

the

conversion

capacitor

is

a

ramp

that

increases

in

a

negative

direction.

As

the

conversion

capacitor

is

being

charged,

the

stop

signal

comes

through

the

fast

ampl

ifier

Q15,

Q16

to

cause

D10

to

change

from

a

low

state

to

a

high

negative

state.

This

transition

is

routed

through

ampl

ifier

Q18

and

Q19

to

a

gate-width

generator

and

to

the

conversion

gate

transistor

Q21

.

The

D10

transition

causes

Q21

to

saturate

and

to

take

all

of

the

conversion

current

that

normal

ly

flows

through

Q22.

At

this

time

the

voltage

on

the

conversion

capacitor

ceases

to

increase.

The

capacitor

charge

is

then

proportional

to

the

time

interval

between

the

start

and

stop

signals.

This

stored

signal

is

routed

through

a

unity-gain

FET

amplifier

Q10

to

Q14

and

Q36.

The

output

at

Q36E

is

fed

to

a

fast

operational

amplifier,

OAl.

Operational

ampl

ifier

OAl

serves

two

purposes.

It

inverts

the

converter

signal

and

serves

as

an

output

l

inear

gate.

The

operational

amplifier

has

two

input

signals,

through

R88

and

R89,

and

two

feedback

paths,

R95

and

R96.

In

the

normal

state

before

a

gate

signal

is

generated,

the

current

from

the

-I-24-V

source

flows

through

034

and

R89

to

forward-bias

D14

and

clamp

the

pin-10

output

of

OAl

to

a

negative

voltage

equal

to

approximately

one

diode

junction.

Pin

10

and

the

base

of

Q37

remain

constant

and

inde

pendent

of

the

conversion

voltage

unti

l

a

gate

signal

turns

034

off.

The

gate

signal

originates

from

the

stop

input.

The

stop

input

triggers

a

gate

width

generator

O20

and

Q30

to

032.

The

gate

width

generator

produces

a

gate

signal

at

the

base

of

033

that

is

negative

and

is

about

1

/tsec

wide.

This

negative

signal

turns

033

on

and

034

off.

When

034

turns

off,

the

current

that

normally

forward-biases

D14

is

reduced

to

zero

and

the

conversion

voltage

signal

at

Q36E

causes

a

current

to

flow

through

013

in

the

direction

that

forward-biases

013.

The

current

through

R96

while

034

is

turned

off

is

proportional

to

the

conversion

voltage.

Thus

a

positive

signal,

~1

jjisec

wide,

wi

ll

appear

at

the

base

of

037

and

wi

l

l

be

proportional

to

the

conversion

voltage

during

the

gate

time.

When

034

is

turned

off

and

the

gate

signal

is

not

present,

the

voltage

on

the

base

of

037

wil

l

be

approximately

zero.

The

positive

conversion

signal

is

routed

through

a

buffer

unity-gain

amplifier

037

to

O40

and

presented

to

the

Linear

Output

connector

on

the

front

panel

.

The

conversion

signal

at

the

036E

output

of

the

FET

ampl

ifier

is

fed

to

a

single

channel

analyzer

(SCA).

The

lower

level

discriminator

of

the

SCA

is

IC1

and

the

upper

level

discriminator

is

IC2.

IC1

is

normally

in

the

high

state

and

IC2

is

in

the

low

state.

If

the

lower

level

discriminator

101

is

switched

to

the

low

state

by

the

signal

on

pin

2

and

the

output

of

the

upper

level

discriminator

102

remains

in

the

low

state,

both

Q41

and

Q42

wi

l l

be

turned

off.

If

Q41

and

Q42

are

both

off

at

the

time

that

the

gate

pulse

turns

Q43

off,

a

positive

transition

wil

l

occur

at

the

base

of

Q49

to

trigger

the

one-shot

Q49

to

Q52

and

to

thus

produce

a

standard

positive

logic

output

through

the

Window

con

nector

on

the

front

panel

.

The

logic

condition

that

produces

a

Window

output

requires

that

the

conversion

signal

be

greater

than

the

lower

level

control

setting

and

less

than

the

upper

level

control

setting.

If

the

conversion

signal

ampl

itude

exceeds

the

setting

of

the

upper

level

control,

Q42

is

turned

on

and

this

prevents

a

Window

output

from

being

generated

at

the

gate

signal

time.

102

is

then

in

a

high

state,

and

a

positive

transition

wil

l

occur

when

the

gate

pulse

turns

Q53

off.

This

positive

transition

triggers

the

one-shot

Q45

to

Q48

to

produce

a

standard

logic

pulse

through

the

UL

output

on

the

front

panel

.

A

logic

pulse

through

the

UL

connector

wil

l

be

furnished

for

each

conversion

signal

that

exceeds

the

UL

control

setting,

including

any

conversion

signal

that

exceeds

the

selected

time

range.

When

an

overrange

occurs,

there

wi

l l

be

no

l

inear

output

but

the

UL

logic

signal

wi

ll

be

strobed

and

wi

l l

furnish

an

output.

The

TPHC

is

reset

to

its

initial

state

by

the

trai

ling

edge

of

the

gate

width

generator

Q32

or

by

an

overrange

signal

from

the

conversion

capacitor

through

Q28

and

Q29.

Either

of

these

signals

wi

l

l

trigger

reset

generator

Q24

to

Q27.

When

Q26

of

the

reset

generator

is

turned

off,

D2

resets

to

its

initial

low

state;

this

resets

the

conversion

clamp

Q9E

to

zero

volts,

and

Q17

is

turned

off

to

restore

the

stop

inhibit

clamp

and

reset

D10

to

its

low

state.

D10

resets

the

conversion

gate

Q21

to

the

off

state.

A

reset

signal

from

the

reset

generator

is

also

fed

back

to

the

base

of

Q30

to

reset

the

one-shot

that

follows

the

input

discriminator.

The

reset

of

this

one-shot

closes

the

stretcher

gate

and

the

linear

gate

between

the

stretcher

and

IC6and

IC7.

%

6.

MAINTENANCE

6.1.

TESTING

PERFORMANCE

The

fol

lowing

material

wi

l l

aid

in

instal

l

ing

and

checking

out

the

458.

It

consists

of

information

on

front

panel

controls,

waveforms,

test

points,

and

output

connectors.

Test

Equipment

The

following,

or

equivalent,

test

equip

ment

is

needed:

1.

ORTEC

419

Pulse

Generator

2.

ORTEC

410

Ampl

ifier

3.

Tektronix

547

Oscilloscope

4.

100f2

attenuator

box

Preliminary

Procedures

Before

making

the

functional

checks,

take

the

following

preliminary

steps:

1.

Visually

check

module

for

possible

damage

due

to

shipment.

2.

With

power

off,

plug

module

into

an

ORTEC

401/402

Series

Nuclear-standard

Bin

and

Power

Supply,

and

check

for

proper

mechanical

al

ignment.

3.

Switch

ac

power

on,

and

check

the

dc

power

voltage

at

the

test

points

on

the

402

Power

Supply

control

panel

.

Functional

Checks

The

following

checks

should

be

made

to

assure

the

correct

function

of

the

458:

1.

Connect

the

direct

output

of

the

pulse

generator

to

the

osci

lloscope

trigger.

Connect

the

attenuated

output

of

the

pulse

generator

to

the

input

of

the

ampl

ifier.

Place

all

attenuator

switches