EGS Appleton WSRD Series Programming manual

EGS Electrical Group • 800-621-1506 • www.appletonelec.com Rev. B 08/12/08 Page 1

331114-1

INSTRUCTION SHEET

WSRD NEMA 4 Series:

Interlocked Appleton Powertite™ Compatible

Receptacle with heavy duty single throw dis-

connect switch.

ELECTRICAL RATINGS:

Maximum Voltage: 600VAC at 50-60 Hz*,

250 VDC 30, 60,100 Amperes — Continuous

Line Current not to exceed 80% of fuse rating

employed in other than motor circuits.

*For 400 Hz applications, consult factory.

Compliances:

• UL Listed

•UL50 for Enclosures

•UL1682 for Receptacles

•NEC wire bending space, Table 373-6(b)

•Federal Specification WS865C

•Major automotive specifications

STANDARD FEATURES:

• Epoxy coated finish on receptacle and switch

housing.

• Factory installed fuse pullers for fusible

disconnect switch.

OPTIONS:

• Electrical Interlocks : 1 N.O. or 1 N.C.

2 N.O. or 2 N.C.

Read instructions carefully and with full

understanding for safe installation and

operation.

Instructions for Installation, Operation and Maintenance of:

"WSRD" Interlocked Receptacles — 30, 60 & 100 Ampere

Except as expressly provided by Appleton

Electric LLC (Appleton) in writing, Appleton

products are intended for ultimate purchase

by industrial users and for operation by per-

sons trained and experienced in the use and

maintenance of this equipment and not for

consumers or consumer use. Appleton

warranties do not extend to, and no reseller

is authorized to extend Appleton's warranties

to, any consumer.

TABLE A

HORSEPOWER RATING:

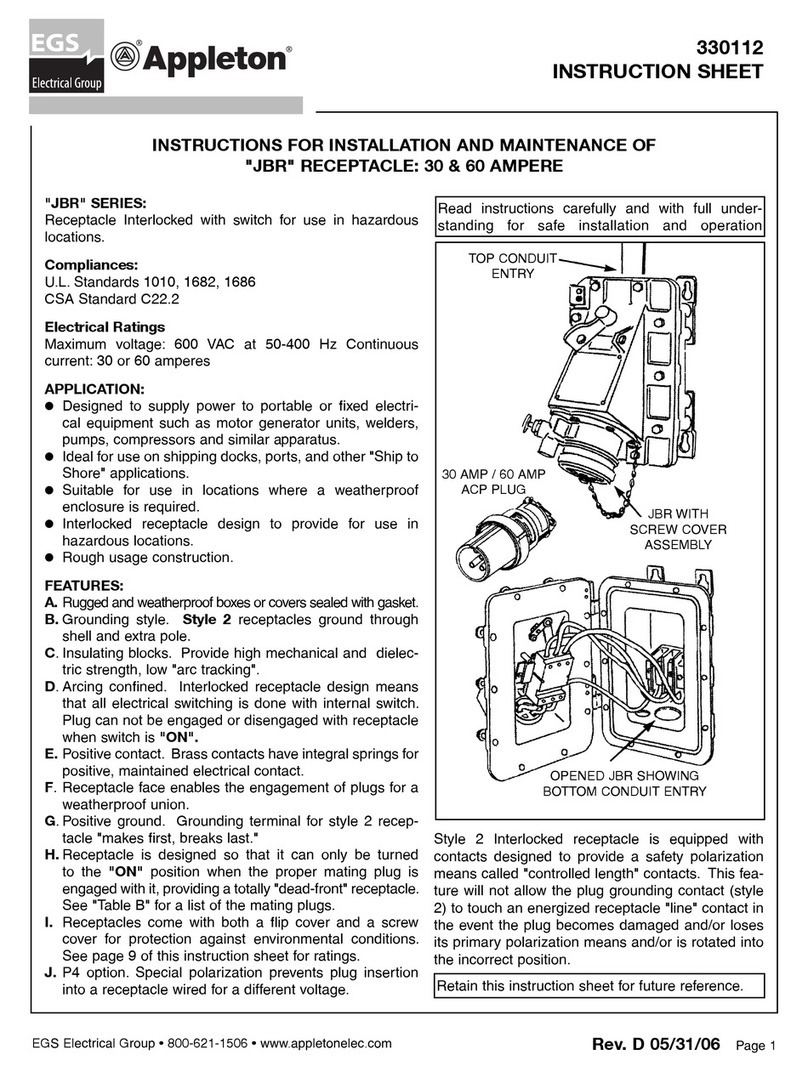

FIGURE A

Shown Above:

Non-Fused Version Catalog Number

WSRD63542N4WSD

WSRD SERIES

Catalog Number DC

Volts

AC

Volts Amp Switch

Type

HP Rating AC

Stand. Max

Sheet Metal Enclosure NEMA 12

WSRD3352SQ 250 600 30 Fused 7.5 20

WSRD33542SQ 250 600 30 Non-Fused -- 30

WSRD3352WSQ 250 600 30 Fused 7.5 20

WSRD33542WSQ 250 600 30 Non-Fused -- 30

WSRD6352SQ 250 600 60 Fused 15 50

WSRD63542SQ 250 600 60 Non-Fused -- 60

WSRD6352WSQ 250 600 60 Fused 15 50

WSRD63542WSQ 250 600 60 Non-Fused -- 60

WSRD10352SQ 250 600 100 Fused 30 75

WSRD10342SQ 250 600 100 Non-Fused -- 75

WSRD10352WSQ 250 600 100 Fused 30 75

WSRD103542WSQ 250 600 100 Non-Fused -- 75

Stainless Steel Enclosure NEMA 3, 3R, 4, 4X, 12

WSRD3352N4SD 250 600 30 Fused 7.5 20

WSRD33542N4SD 250 600 30 Non-Fused -- 30

WSRD3352N4WSD 250 600 30 Fused 7.5 20

WSRD33542N4WSD 250 600 30 Non-Fused -- 30

WSRD6352N4SD 250 600 60 Fused 15 50

WSRD63542N4SD 250 600 60 Non-Fused -- 60

WSRD6352N4WSD 250 600 60 Fused 15 50

WSRD63542N4WSD 250 600 60 Non-Fused -- 60

WSRD10352N4SD 250 600 100 Fused 30 75

WSRD10342N4SD 250 600 100 Non-Fused -- 75

WSRD10352N4WSD 250 600 100 Fused 30 75

WSRD103542N4WSD 250 600 100 Non-Fused -- 75

EGS Electrical Group • 800-621-1506 • www.appletonelec.com 331114-1 Rev. B 08/12/08 Page 2

APPLICATION:

• Designed to supply power to portable or fixed

electrical equipment such as welders, infrared

ovens, batch feeders, conveyors and truck and

marine docks.

• Designed to supply three (3) phase, grounded

electrical power to the aforementioned electrical

equipment.

• Designed to provide an interlocked receptacle

for use in ordinary (non-hazardous) locations, as

defined by the National Electrical Code (NEC). In

addition, the receptacle is designed such that a

mating plug can only be engaged and disengaged

when the switch handle is in the "OFF" position.

• Ideal for use on shipping docks, ports, and

other "ship to shore" applications.

• Suitable for use in locations that require a degree

of protection from the elements (See TABLE

A). Enclosure cover and receptacle housing are

sealed with gaskets. The receptacle housing flip

cover is gasketed to seal against the housing.

In addition, mating plugs can be engaged to the

receptacle face to provide weatherproof union,

SHORT CIRCUIT RATING FUSED/

NONFUSED:

• Suitable for use on a circuit capable of delivering

not more than 10,000 RMS symmetrical Amperes,

600 VAC maximum .

WARNING

• Do not modify these devices in any way.

Replace missing or broken parts with the proper

replacement parts from Appleton Electric, LLC.

• Modification of these devices or substitution

of parts with non-standard parts may result in

serious or fatal personal injury from electrocution.

WARNING

• If any part(s) of "WSRD" unit or the mating plug appear

to be missing, broken or show signs of damage:

DISCONTINUE USE IMMEDIATELY!

This condition could cause serious or fatal personal injury

due to electrocution and/or equipment damage. Repair with

the proper replacement part(s) before continuing service.

WARNING

• Turn off power supplying WSRD interlocked receptacle

before and during installation and maintenance.

• Failure to do so may result in serious or fatal injury

from electrocution.

TABLE C

TABLE B

TIGHTENING TORQUE — LINE SIDE

DISCONNECT SWITCH LUG SCREWS

SLOTTED HEAD SCREWS

WIRE SIZE (AWG)

TORQUE (LB.-IN.)

#14 -#10 AWG

35

#8 AWG

40

#6 - #4 AWG

45

#3 - #2 AWG

70

ACP & CPH PLUGS FOR "WSR" RECEPTACLES

CABLE

DIAMETER (In.)

CURRENT

RATING

CATALOG

NUMBER

.390 - 1.375 30 ACP3034BC

.500 - .875 30 CPH3034B

.500 - 1.375 60 ACP6034BC

.500 - .750 60 CPH6034A

.750 - 1.00 60 CPH6034B

1.000 - 1.375 60 CPH6034C

.500 - 1.375 60 CPH6034BC

.875 - 1.906 100 ACP1034C

*CPH Plug is rated for NEMA 3R applications only.

EGS Electrical Group • 800-621-1506 • www.appletonelec.com 331114-1 Rev. B 08/12/08 Page 3

WARNING

•Use only cable or wire per the National Electrical Code

(NEC) for the given amp rating of the receptacle.

•Tighten the disconnect switch lug screws to the torques

given in TABLE C and TABLE E for the listed wire ranges.

•Failure to do so may result in over-stressed wire termina-

tions which could cause the conductors to pull out of the

disconnect switch lugs.

This could cause serious or

fatal injuries due to electrocution.

FIGURE B CONTACT PHASE

IDENTIFICATION MARKINGS

REAR VIEW OF RECEPTACLE

ASSEMBLY SHOWING CONTACT

IDENTIFICATION MARKINGS ON

RECEPTACLE INTERIOR.

DIMENSIONS: WSRD INTERLOCKED RECEPTACLE

(ASSEMBLY VIEW WITH COVER OPEN)

Unit shown is Catalog Number WSRD6352SQ (NEMA 12 Version)

FIGURE C

Device Rating Dimension in Inches

ABC

30 & 60 Amp 16.75 16.50 22.25

100 Amp 20.75 20.50 26.25

EGS Electrical Group • 800-621-1506 • www.appletonelec.com 331114-1 Rev. B 08/12/08 Page 4

EGS Electrical Group • 800-621-1506 • www.appletonelec.com 331114-1 Rev. B 08/12/08 Page 5

INSTALLATION INSTRUCTIONS FOR

“WSRD” INTERLOCKED RECEPTACLES

The WSRD receptacles are designed to accept clamp-

ing rings of the "ACP" plugs. Clamping rings fit onto the

receptacle to provide a degree of protection against the

elements and to prevent plug fallout when the receptacle

is in the "OFF" position. When the plug is withdrawn from

the receptacle, the gasketed flip cover closes tightly against

the receptacle housing to provide weather-proof conditions

(NEMA TYPE 12 ). Screw cap is required for NEMA TYPE

4 applications.

INSTALLATION

1. PREPARE MOUNTING POSITION:

Owners are responsible for damages or injuries if these

rules are not followed.

4. CONDUIT INSTALLATION:

A. Drill appropriate trade size hole in the top of the housing

according to the size of hub used. Drill this hole in the location

suggested in "FIGURE C".

B. Make sure hole is free of all burrs and sharp edges.

C. Install the corresponding hub in this hole according to the

instructions given with the hub kit.

D. At this point, ensure that all hubs are tightened appropriately.

WARNING

• Before starting with the installation, make sure the

WSRD interlocked receptacle is suitable for the intend-

ed location according to the National Electrical Code or

Canadian Electrical Code.

• If the interlocked receptacle is not suitable, serious

damage and injuries may result.

A. The WSRD interlocked receptacle must be mounted on

four (4) 1/4" maximum diameter steel bolts, securely fas-

tened to wall, column, strut or other vertical structure, in one

plane, and must be capable of supporting the unit, as well

as its associated conduit and wiring.

NOTE: These bolts are not provided with the WSRD inter-

locked receptacle.

B. Referring to "FIGURE C" for dimensions of the WSRD

interlocked receptacle, prepare the structure for the mount-

ing bolts by drilling, tapping, securing nuts or another meth-

od of providing threaded anchors for the bolts.

C. Install the two top bolts leaving 3/16" to 5/16" under the

heads.

• The bolts must be engaged at least five (5) full threads.

2. MOUNTING THE WSRD INTERLOCKED

RECEPTACLE:

Place the interlocked receptacle on the previously prepared

mounting bolts, with the receptacle face ①at the lower-most

position ( See FIGURE C ). Make sure that the shanks of the

bolts are in the small part of the key-hole slot in the mounting

bracket. Install the two lower bolts. Tighten mounting bolts to

18-20 lb.-ft. torque to secure assembly in place.

3. OPENING ENCLOSURE COVER:

A. Referring to "FIGURE C", loosen the two (2) door

latches.

B. The cover ➂is now free to swing open on its hinges.

C. Note that the cover ➂is not intended to be removed from

the housing ➃, since the range of travel (swing) of the cover

is adequate to service the inside of the unit.

TABLE D

TERMINAL WIRE RANGE AND STRIPPING GUIDE

A

GROUNDING CONDUCTOR

LINE CONDUCTORS

5. WIRING:

A. Referring to "FIGURE C", feed line side wiring into housing

➃through hub opening. Note - wiring must be rated 60

deg. C. or 75 deg. C. copper.

B. Strip the individual conductors per "TABLE D".

C. Connect wires to the proper disconnect switch lugs ➄by

loosening, but not removing, lug screws ➅. Insert conductors

including all strands into lugs according to your established

wiring scheme. Tighten lug screws ➅ to the appropriate value

shown in "TABLE C". Please note the wire markers on the

wires ➆ connected between the receptacle ➇ and disconnect

switch lugs ➄. These wire markers correspond to the contact

identification markings found on the back of the receptacle

contact block. Refer to "FIGURE B".

6. ELECTRICAL TESTING:

All wiring must be checked and tested to ensure that all circuits

are according to plan and that there are no unwanted opens,

shorts or grounds. Do not apply power until the following

steps are completed:

A. Test to verify correct phasing and ground connections.

B. Test insulation resistance by meggering, high voltage or hi-

pot test, to be sure the system does not have any short circuits

or unwanted grounds.

AMPERE

RATING

STRIP LENGTH (In.) TERMINAL WIRE RANGE (AWG)

CONDUCTOR

A

BUILDING WIRE

30 .63

#14 - #2 (Cu)

60 .63

#6 - #2 (Cu)

100 .63

#4 - #1/0 (Cu)

7. CLEAN COVER AND HOUSING:

Before closing the cover ➂, it is strongly recommended that

all dirt, debris and other foreign materials be removed from

the interior.

•This action should be taken to help eliminate the possibility

of unwanted shorts or grounds.

•Make sure the cover gasket surface is clean and free of any

tears or damage.

•Clean the mating surface of the housing ➃in the same

manner as the enclosure cover ➂.

8. CLOSE ENCLOSURE COVER:

A. Close the cover ➂.

B. Engage latches ➁.

9. POWER:

With all electrical tests successfully completed, the door

latched closed and the receptacle turned "OFF", power may

be applied to the WSRD unit.

10. OPERATION:

A. The WSRD interlocked receptacle can now be turned to

the "ON" position by lifting the operating handle ➉to the

upper-most position.

•SAFETY FEATURE - The receptacle is interlocked to the

operating handle mechanism so that a mating plug cannot be

removed when the switch is in the "ON" position.

B. A hole is provided in the housing lock-out ➈and operat-

ing handle ➉for the use of a padlock ( See "FIGURE C" ) to

prevent unauthorized movement of the operating handle ➉

from the "OFF" position.

11. MAINTENANCE:

A. INSPECTION: Complete unit must be inspected regularly.

Schedule of inspections is determined by frequency of use

and environmental conditions.

• It is recommended that inspections be carried out at

least once a year.

DURING THE INSPECTIONS, PERFORM AT LEAST

THE FOLLOWING:

1. Electrical power supplying the WSRD interlocked receptacle

must be turned "OFF" before performing maintenance.

2. Inspect all conductor terminations for secureness.

• Confirm torque values given in "TABLE C" and "TABLE E".

• Discoloration due to excessive heat is an indication of

possible problems and should be thoroughly

investigated and repaired as necessary.

3. Check grounding and bonding effectiveness/continuity.

• Retorque connections to original values.

04. Check gaskets for damage. Replace as necessary.

05. Check all hubs for tightness and retorque as neces-

sary.

06. Clean interior of all foreign materials.

07. Make sure all openings are closed.

08. Make sure that receptacle assembly flip-cover 11 seals

againts the receptacle housing.

09. Make sure the receptacle assembly nameplate located

on the outside of the cover remains clean and legible.

• Do not paint nameplate

.

10. Make sure the assembly labels located on the inside of

the cover remain clean and legible.

B. DISCONNECT SWITCH:

Disconnect switches occasionallt fail with use and need to

be replaced.

The disconnect switch used in this receptacle must only be

replaced with the same type and brand as factory installed.

Doing so will not affect the UL Listing.

To replace disconnect switch -

• Referring to "FIGURE C", loosen the line and load side lug

screws hof the disconnect switch and remove wires from

the switch. Take note of the orination of these wires for proper

reassembly. Also note that the wires ithat connect the

recptacle to either the disconnect switcch directly (non-fused

version), or connect the receptacle to the fuse base (fused

version) are numbered according to the phase location (See

"FIGURE B").

• Remove disconnect switch and fuse base (if applicable)

mounting screws mountin screws 14. Remove disconnect

switch 12 and fuse base 13 (if applicable).

• Replace disconnect switch and fuse base, if applicable, with

the appropriate switch kit as shown in "TABLE E", reversing

the steps taken to remove them. Make sure to reconnect the

wires to the same locations as before disassembly. Replace

fuses, if necessary, for fused receptacle.

used in this interlocked receptacle is not replaceable. In case

of disconnect switch failure, entire unit must be replaced.

WARNING

• If any part(s) of the "WSRD" unit or the mating plug

appear to be missing, broken or show signs of damage:

DISCONTINUE USE IMMEDIATELY!

This condition could cause serious or fatal personal injury

due to electrocution and/or equipment damage. Repair with

the proper replacement part(s) before continuing service.

•It is recommended that an electrical preventive main-

tenance program, such as found in the National Fire

Protection Bulletin NFPA 70B, be followed in addition to

the above.

Note that the WSRD interlocked receptacle cannot be

turned "ON" without a mating plug engaged.

Appleton

Disconnect Switch

Cat. No.

Switch Type Assembly Used In

WSRNT30F Fused WSRD3352SQ

WSRNT30U Non-Fused WSRD33542SQ

WSRNT60F Fused WSRD6352SQ

WSRNT60U Non-Fused WSRD63542SQ

WSRNT100F Fused WSRD10352SQ

WSRNT100U Non-Fused WSRD103542SQ

TABLE F SWITCHING KITS

• Torque the mounting screw lto 15-20 lb. -in. to secure dis-

connect switch and fuse base, if applicable, in place.

• Torque the lug screw hto the appropriate value shown in

"TABLE C" and "TABLE F".

EGS Electrical Group • 800-621-1506 • www.appletonelec.com 331114-1 Rev. B 08/12/08 Page 6

EGS Electrical Group • 800-621-1506 • www.appletonelec.com 331114-1 Rev. B 08/12/08 Page 7

C. RECEPTACLE ASSEMBLY:

The receptacle assemblies shown in "Table F" can be

replaced without affecting the U.L. Listing.

To replace the receptacle assembly -

•Referring to "FIGURE C", loosen the load side lug screws

➅ of the disconnect switch 12 or fuse base 13, (if applicable),

and remove wires.

•Remove the four (4) receptacle assembly mounting screws

16 that fasten the assembly to the housing ➃. Support the

assembly so that it does not fall from unit.

•Do not allow unit to be used until problem is

corrected.

•Remove the old receptacle assembly and replace it with the

new unit. Replacing the unit can be accomplished by revers-

ing the steps needed to remove it. Tighten the four (4) recep-

tacle assembly mounting screws 16 to 19-25 Ib.-in. to secure

unit to housing.

•Place the appropriate wires into the correct lug locations

and tighten lug screws to the appropriate value shown in

"TABLE E".

•Test the unit for proper function by performing the following

tasks: ELECTRICAL POWER MUST BE TURNED "OFF"

BEFORE PERFORMING TESTS. Close the cover ➂and

throw the switch to the "ON" position to make sure that no

interference between new receptacle assembly and switch

exists. Also verify that a mating plug can not be removed

from the receptacle when the switch is in the "ON" position.

If unit functions properly, it can be returned to service. If unit

does not function properly, check the mounting of the recep-

tacle assembly to the housing.

When finished with installation, file and retain

these instructions for future reference during

inspection and maintenance.

TABLE E

TABLE F "WSRD" INTERLOCKED RECEPTACLE REPLACEMENT PARTS

All statements, technical information and recommendations contained herein are based on information and tests we

believe to be reliable. The accuracy or completeness thereof are not guaranteed. In accordance with Appleton Electric, LLC

"Terms and Conditions of Sale", and since conditions of use are outside our control, the purchaser should determine the suit-

ability of the product for his intended use and assume all risk and liability whatsoever in connection herewith.

REFERENCE

NUMBER AMPACITY DESCRIPTION PART NUMBER QUANTITY PER

ASSEMBLY ASSEMBLY USED IN

1

30

ELECTRICAL INTERLOCK, 1 N.O., 1 N.C. WSAUX1 1 WSRD3352SQ &

ELECTRICAL INTERLOCK, 2 N.O., 2 N.C. WSAUX2 1 WSRD33542SQ

ELECTRICAL INTERLOCK, 1 N.O., 1 N.C. WS30AUX1 1 WSRD3352N4SD &

ELECTRICAL INTERLOCK, 2 N.O., 2 N.C. WS30AUX2 1 WSRD33542N4SD

60

ELECTRICAL INTERLOCK, 1 N.O., 1 N.C. WSAUX1 1 WSRD6352SQ &

ELECTRICAL INTERLOCK, 2 N.O., 2 N.C. WSAUX2 1 WSRD63542SQ

ELECTRICAL INTERLOCK, 1 N.O., 1 N.C. WS60AUX1 1 WSRD6352N4SD &

ELECTRICAL INTERLOCK, 2 N.O., 2 N.C. WS60AUX2 1 WSRD63542N4SD

100

ELECTRICAL INTERLOCK, 1 N.O., 1 N.C. WSAUX1 1 WSRD10352SQ &

ELECTRICAL INTERLOCK, 2 N.O., 2 N.C. WSAUX2 1 WSRD103542SQ

ELECTRICAL INTERLOCK, 1 N.O.,1 N.C. WS100AUX1 1 WSRD10352N4SD &

ELECTRICAL INTERLOCK, 2 N.O., 2 N.C. WS100AUX2 1 WSRD103542N4SD

2

30 Switching Kit - Fused WSRNT30F 1 WSRD3352SQ

Switching Kit - Non-Fused WSRNT30U 1 WSRD33542SQ

60 Switching Kit - Fused WSRNT60F 1 WSRD6352SQ

Switching Kit - Non-Fused WSRNT60U 1 WSRD63542SQ

100 Switching Kit - Fused WSRNT100F 1 WSRD10352SQ

Switching Kit - Non-Fused WSRNT100U 1 WSRD103542SQ

30 RECEPTACLE ASSEMBLY - 3W - 4P WRDK3034 1

WSRD3352SQ&

WSDR33542SQ

WSRD3352N4SD

WSDR33542N4SD

60 RECEPTACLE ASSEMBLY - 3W - 4P WRDK6034 1

WSRD6352SQ

WSRD63542SQ

WSRD6352N4SD

WSRD63542N4SD

100 RECEPTACLE ASSEMBLY - 3W - 4P WRDK1034 1

WSRD10352SQ

WSRD103542SQ

WSRD10352N4SD

WSRD103542N4SD

TIGHTENING TORQUE — LINE SIDE

DISCONNECT SWITCH LUG SCREWS

SLOTTED HEAD SCREWS

WIRE SIZE (AWG)

TORQUE (LB.-IN.)

#14 -#10 AWG

35

#8 AWG

40

#6 - #4 AWG

45

#3 - #2 AWG

70

EGS Electrical Group • 800-621-1506 • www.appletonelec.com 331114-1 Rev. B 08/12/08 Page 8

This manual suits for next models

24

Table of contents

Other EGS Power Supply manuals