MEMBRANE DRYER

NP-MD-3_11-2015 - 2 - 11/2015

IMPORTANT INFORMATION

1. TECHNICAL DATA

Quantity of dry air

at 5 bar Up to 60 lit.min-1 Up to 120 lit.min-1 Up to 270 lit min

Nominal voltage 115V± 10%

230 V ± 10%

3x400 V ± 10%

frequency 50 - 60 Hz

Rated power 0,15A 0,15A

0,30 (for DK50 2x4VR/110)

Working pressure to 10bar

Drying performance atmosferický rosný bod -20°C

Use DK50-10 / DK50 PLUS DK50 2V / DK50 2V/50

/ DK50 2V/110

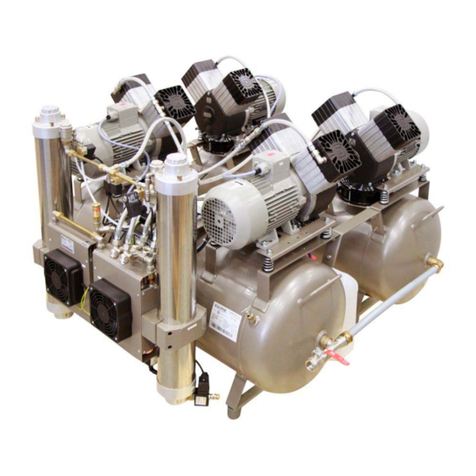

DK50 4VR/50 / DK50 2x2V/110

/ DK50 2x4VR/110

Weight

kg

6 6 / 6 / 8 11 / 8 / 16

Dimensions in mm

(w x d x h) 290x310x410 / 375x235x350 375x235x350 / 420x215x360 /

450x205x420

430x190x485 / 585x205x415

/ 560x190x400

Required drying performance can only be achieved when following the defined operating

conditions!

Drying performance will decline and the achieved dew point will drop if the dryer is operated

at any pressure below the minimum working pressure!

Dryer operation at a pressure of 0.5 Bar below the minimum working pressure can lower the

dew point at the outlet by more than 10°C!

Drying performance will decline and the achieved dew point will drop if the dryer is operated

at any temperature above the maximum working temperature!

2. PRODUCT DESCRIPTION

A pre-filter and micro-filter are installed in front of the membrane dryer in order to capture solids and condensate

and prevent the membranes from being contaminated and to deliver compressed air of the expected quality. The

clean compressed air enters the membrane dryer and the module comprised of the bundles of membrane fibres.

As the compressed air is circulated against the hollow fibres, the water molecules are compressed against the

walls of the membrane and the outlet air is dry. Water vapour molecules that form of the walls of the membranes

must be removed. This is performed using some of the dry air exiting the module. This regeneration air is then

expanded to atmospheric pressure, removing the water vapour away from the dryer.