CONTENTS

10/2022 5 NP-DK50 2V-3_10-2022-AD

CONTENTS

IMPORTANT INFORMATION........................................................................................................6

1. CONFORMITY WITH THE REQUIREMENTS OF EUROPEAN UNION DIRECTIVES ....6

2. INTENDED USE ..............................................................................................................6

3. CONTRAINDICATIONS AND SIDE-EFFECTS................................................................6

4. SYMBOLS........................................................................................................................6

5. WARNINGS.....................................................................................................................7

6. STORAGE AND TRANSPORT ........................................................................................9

PRODUCT DESCRIPTION ..........................................................................................................10

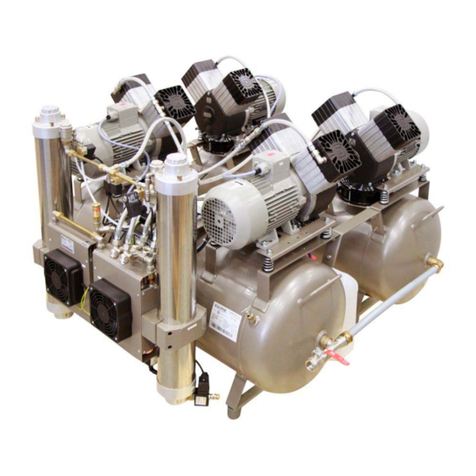

7. VARIANTS.....................................................................................................................10

8. ACCESSORIES.............................................................................................................10

9. PRODUCT FUNCTION..................................................................................................11

TECHNICAL DATA......................................................................................................................16

INSTALLATION...........................................................................................................................25

10. INSTALLATION CONDITIONS ......................................................................................25

11. COMPRESSOR ASSEMBLY.........................................................................................25

12. PNEUMATIC CONNECTION.........................................................................................28

13. ELECTRICAL CONNECTION........................................................................................32

14. COMPRESSOR PLACEMENT IN THE CABINET..........................................................33

15. COMMISSIONING .........................................................................................................35

16. PNEUMATIC AND ELECTRICAL DIAGRAMS...............................................................36

OPERATION................................................................................................................................42

17. SWITCHING ON THE COMPRESSOR..........................................................................43

18. SWITCHING OFF THE COPRESSOR...........................................................................43

AD DRYER ..................................................................................................................................44

19. PRINCIPLE OF OPERATION ........................................................................................44

20. USER INTERFACE/SETTINGS .....................................................................................45

21. MAIN SCREENS............................................................................................................47

22. INDICATION OF MAINTENANCE AND ALARM STATES..............................................49

PRODUCT MAINTENANCE ........................................................................................................52

23. PRODUCT MAINTENANCE...........................................................................................52

24. LONG-TERM SHUTDOWN............................................................................................60

25. DISPOSAL OF DEVICE.................................................................................................60

TROUBLESHOOTING.................................................................................................................61

26. REPAIR SERVICE.........................................................................................................63

ANNEX ......................................................................................................................................420

27. INSTALLATION RECORD ...........................................................................................420