ektor EV-TWINSPOT-WP User manual

1. WELCOME

Installation Instructions

CONTENTS

CODE:1706, 1708, 1709

CODE:1707

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

11.

12.

13.

14.

15.

16.

17.

18.

19.

20.

21.

22.

23.

24.

25.

26.

27.

28.

Thank you for choosing this quality Ektor product.

This manual is intended to help you install this

product in a way that ensures the safety of yourself

and others. Whilst this Ektor product is designed

to be installed easily, we highly recommend you

take the time to read this manual thoroughly before

commencing installation. When installed correctly

and serviced regularly, this product will provide

hassle free operation for many years.

1706 EV-TWINSPOT-WP

1708 EV-TWINSPOT-WP-PRO

1707 EV-TWINSPOT-WP-PRO-B

1709 EV-TWINSPOT-WP-ULTP-B

1

Welcome

Overview

Safety warnings

Installation

Mounting

Range of movement

Terminal block wiring

Maintaining your Twinspot

Replacing the battery

Battery life

Power and battery charge

Wireless daughterboard

Self test / standard wiring / central battery system

DALI wiring / central battery system

Using the inverter with a switch

Using the inverter with a sensor

Accessories list

Non maintained / maintained jumper

Discharge rating selection

Self test indicator LEDs

Self test / commissioning interval programming

Product specifications

Construction sites

Testing precautions

Problem solving procedure

Warranty information

Compliance standards

Technical support and troubleshooting

MANUFACTURED

TO ISO9001

TWINSPOT IP65 EMERGENCY INSTALLATION INSTRUCTIONS

2. OVERVIEW

Ektor Generation III platform introduces you to a new era of emergency lighting control. With years in the

making, the third generation platform builds on the Ektor product ranges’ increasing quality, reliability and

performance. In choosing this Ektor product you can be comfortable that you have the best.

This product out of the box can be wired in any of these configurations:

• Self testing unit

• Standalone unit

• Standalone unit controlled with a switch or sensor

• DALI controlled remote testing unit

And can be used with a central battery system (monitored and non-monitored)

An optional wireless module can be added to allow you to connect to standard Wi-Fi networks for remote

testing and reporting.

Our Ektor Generation III platform also brings class leading technology which increases performance and

reliability including:

• Smart battery charging technology which reduces power consumption up to 90% while

increasing the service life of the battery

• Smart battery conditioning to ensure the best performance from the battery

• 450V Electrolytic capacitors which increase the products reliability

• Highly efficient design to reduce fatigue on the product

For buildings requiring longer durations such as 3, 4 and 8 hours the installer can change the jumpers found

on the unit for automatic scaling of the output. Moreover should you require non-maintained or maintained

output, the installer can select this on installation.

2

3. SAFETY WARNING

1. THIS PRODUCT MUST ONLY BE INSTALLED BY A LICENSED ELECTRICIAN.

2. BEFORE COMMENCING INSTALLATION TURN OFF AND ISOLATE THE ELECTRICAL SUPPLY.

3. DO NOT ENERGISE WITH PRODUCT OPEN OR DISASSEMBLED.

4. SUPPLY VOLTAGES WITHIN PRODUCT. ISOLATE SUPPLY VOLTAGES BEFORE OPENING OR SERVICING.

5. THE ONLY USER SERVICEABLE PART IS THE BATTERY PACK.

6. DO NOT ATTEMPT TO SERVICE OTHER PARTS OF THE FITTING AS THIS WILL VOID THE WARRANTY.

7. AS THE INSTALLER, IT IS YOUR RESPONSIBILITY TO ENSURE YOU COMPLY TO ALL RELEVANT BUILDING AND SAFETY

CODES FOR EXAMPLE THE BCA, AS3000. REFER TO APPLICATION STANDARDS FOR THE RELEVANT RULES.

8. WHEN THE INSTALLATION IS COMPLETE, LEAVE THIS MANUAL WITH THE BUILDING’S OWNER/S FOR FUTURE REFERENCE.

TWINSPOT IP65 EMERGENCY INSTALLATION INSTRUCTIONS

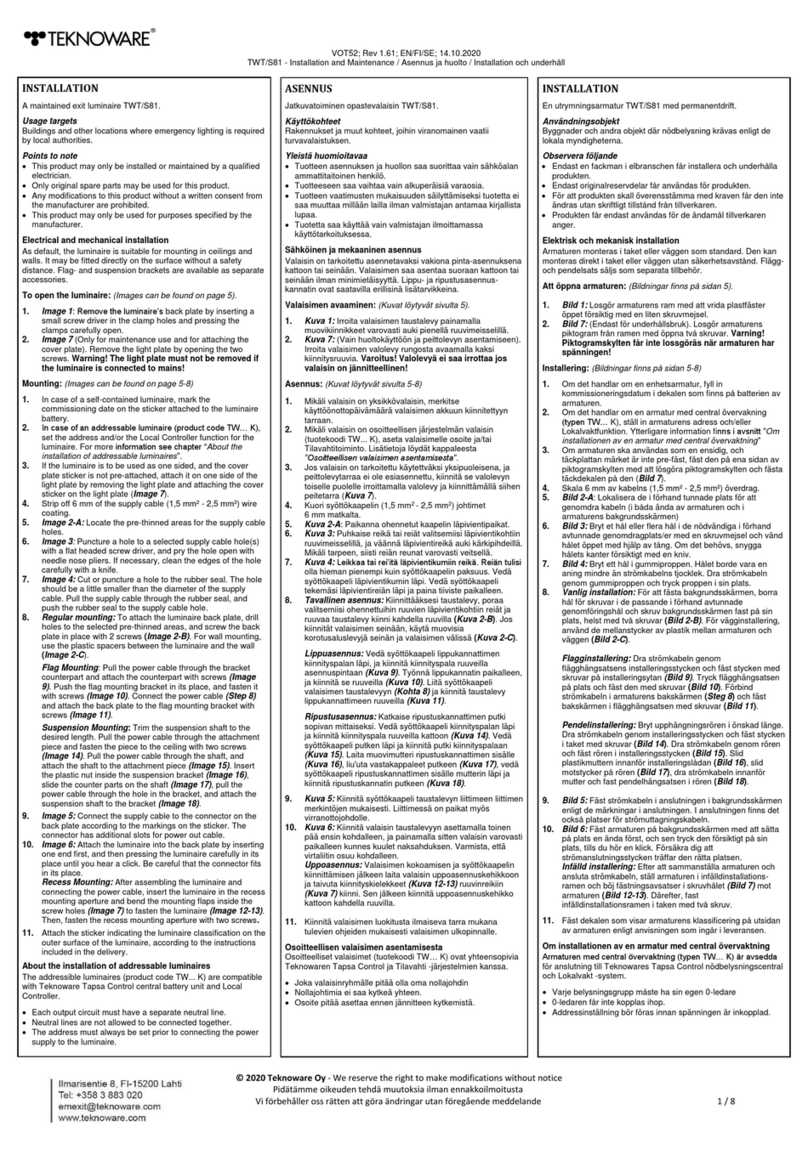

4. INSTALLATION

The Ektor Twinspot is designed to be wall mounted.

To install the Twinspot please follow the steps listed below:

1. Remove the product from the box and inspect it for any damage. If you believe the product to be

damaged or otherwise unsound, DO NOT install the product. Please pack it back into its box and return

it to the place of purchase for replacement. If the product is satisfactory, proceed with the installation.

2. To mount the Twinspot the cover MUST be removed. Remove the cover by unscrewing the cover

screws using a large flat blade screwdriver. Then pull the cover off as shown below.

3. The cover is to be removed for mounting the Twinspot, also battery replacement and servicing. All

installation options can be found in the following section of this manual.

NOTE: Remove the cover by

unscrewing the cover screws

using a flat blade screwdriver.

Twinspot cover

Twinspot cover screws

Battery

Inverter

Figure 1: Twinspot disassembly and installation

3

TWINSPOT IP65 EMERGENCY INSTALLATION INSTRUCTIONS

5. MOUNTING

1. Remove the Twinspot cover as shown in the installation instructions in section 4 (page 3) of this

instruction manual. This will allow for mounting holes to become visible.

2. Drill a hole in the Twinspot body in either of the recommended positions (A, B). Insert and tighten cable

gland to the Twinspot body, then wire as shown in section 7 (page 8).

3. Mount the Twinspot by fastening screws securely to a flat surface as shown below. Use supplied soft

washer to waterproof the Twinspot and then put the cover back in place to finish mounting.

SURFACE MOUNT

Figure 2: Surface mount installation

Figure 2: Twinspot headlight adjustment

4

M4 cap screw/

locknut detail

6. RANGE OF MOVEMENT

The Twinspots headlight range varies whether it is adjusted horizontally or vertically. To adjust the headlight

range the M8 bolts attaching them to the body must be slightly loosened.

Twinspot body

Headlights

M8 bolts

Screws not

supplied

Mounting holes Membrane switch

A

B

TWINSPOT IP65 EMERGENCY INSTALLATION INSTRUCTIONS

5

The figures below illustrate the headlights tilt movement and the coverage of the beam.

Figure 3: Twinspot headlight horizontal range of movement

Centre of rotation

Centre of rotation

45°

22.5°

22.5°

45°

Figure 4: Twinspot headlight upward range of movement

Centre of rotation

Headlight tilt max.

40°

Figure 5: Twinspot headlight downward range of movement

Centre of rotation

Headlight tilt max.

40°

TWINSPOT IP65 EMERGENCY INSTALLATION INSTRUCTIONS

6

7. TERMINAL BLOCK WIRING

9. REPLACING THE BATTERY

8. MAINTAINING YOUR TWINSPOT

Wiring schematic for the terminal block used with the Twinspot is illustrated below.

1. Use only the LiFePO4 battery recommended on the label found on the inverter/battery charger pack.

No other battery will work in this fitting, other than the type listed.

2. Access the battery by removing the product cover as shown in section 4 (page 3) of this manual.

3. Disconnect the battery from the product and if necessary, cut cable ties to release the battery from its

mounting position.

4. Replace the battery as was previously installed and then secure with cable ties.

5. Replace the Twinspot back into its previously mounted ceiling position and ensure the green charge light

is illuminated. Allow a few minutes for the battery to charge.

6. Allow a minimum 24 hours charging time before carrying out any discharge tests as per the requirements

in AS/NZS 2293, BCA or other relevant standards.

Figure 4: Wiring schematic

The Twinspot is connected to an unswitched active during normal operating conditions.

When disconnected from the mains supply, the Twinspot is powered by a LiFePO4 battery operated inverter.

Due to this, care should be taken when replacing the battery.

WARNING

L N L' DA2 DA1

TWINSPOT IP65 EMERGENCY INSTALLATION INSTRUCTIONS

Charge

current

Max charge current Max charge voltage Savings

Cell voltage

10. BATTERY LIFE

11. POWER AND BATTERY CHARGE

To maintain the economical life of this product it is required that the battery be discharged and recharged

at least once every 6 months. The battery life can be reduced if the battery is not discharged as per the

requirements of AS/NZS 2293 or an equivalent standard. Increasing the number of duration tests above that

as defined in AS/NZS 2293 or an equivalent standard can have a positive effect on the battery performance as

long as 12 discharge cycles per year is not exceeded.

The Ektor Generation III platform uses smart battery charging technology which reduces power consumption

and increases battery life.

During the first stage of operation the battery charger charges the battery until full. Afterwards, the unit goes

into a stage which charges the battery periodically. This reduces the battery temperature and reduces the

loss of electrolytes which ultimately increases the service life of the battery.

The smart battery charger also offsets the charging time by a random interval to un-synchronise all the

emergency lighting in the building. This reduces the average loading on a building’s infrastructure and reduces

any impacts of surges created by turning on large numbers of products simultaneously.

Figure 5: Example of included battery

Figure 6: Smart charge rate

1 x LiFePO4 battery (1302, 1303)

KIT INCLUDES:

1

7

TWINSPOT IP65 EMERGENCY INSTALLATION INSTRUCTIONS

8

12. WIRELESS DAUGHTERBOARD

13. SELF TEST/ STANDARD WIRING/ CENTRAL BATTERY SYSTEM

The Twinspot inverter also supports an optional wireless daughterboard. The driver must be disconnected

from mains and battery must be removed, before installing or changing any expansion module. More

information and a list of other accessories can be found in the Wireless design and installation guide. The

assembly for this part onto the inverter is shown below:

The inverter can be used in an automatic self-test mode which reduces the need for a test switch timer.

The self-test ability automatically disables if the unit is wired to DALI or the wireless daughterboard is attached.

Additionally the third generation platform can be wired to a central battery system. With this wiring the system

cannot report the light status (see Self test support document for more information).

Figure 7: Daughterboard assembly diagram

Figure 8: Inverter standard wiring diagram

2

1

Wireless daughterboard (6118)(optional)

Twinspot inverter (1231, 1248, 1249, 1250)

1

2

Installer wiredPrewired

TWINSPOT IP65 EMERGENCY INSTALLATION INSTRUCTIONS

14. DALI WIRING/ CENTRAL BATTERY SYSTEM

15. USING THE INVERTER WITH A SWITCH

16. USING THE INVERTER WITH A SENSOR

The Twinspot inverter supports DALI out of the box, illustrated in the hardwiring diagram

shown below. The inverter also supports central battery systems and can be monitored through DALI.

When used as a central battery system the devices can be tested with DALI.

A mains rated switch can be wired with this product to turn ON/OFF the non-emergency light in normal use.

This does not affect operation in emergency mode.

A mains rated sensor can be wired with this product to turn ON/OFF the light in normal use. This does not

affect operation in emergency mode.

Figure 9: Inverter DALI wiring diagram

Figure 10: Inverter switch wiring diagram

Figure 11: Inverter sensor wiring diagram

9

Mains rated switch

Mains rated sensor

TWINSPOT IP65 EMERGENCY INSTALLATION INSTRUCTIONS

10

17. ACCESSORIES LIST

18. NON MAINTAINED / MAINTAINED JUMPER

19. DISCHARGE RATING SELECTION

Below are the listings of the accessories and replacements compatible with the Twinspot.

A user can select the mode of operation for the Twinspot inverter. If the inverter is using a

switch input this is disregarded and not used.

The inverter supports a number of discharge ratings which can be selected by the user. The output from

the LED scale based on the discharge rating (see Twinspot Weatherproof Datasheet on ektor.com.au)

Figure 12: Maintained/non-maintained jumper

Jumper

Figure 13: Discharge rating selection

Remove expansion cover

C

B

A

PART

HOURS

INDICATOR

CODEEVOLT CODE

A

STATUS

B C

DESCRIPTION

COMPLETE UNITS

Twinspot Weatherproof

Twinspot Weatherproof Pro

Twinspot Weatherproof Pro Black

Twinspot Weatherproof Ultimate

1 hour

2 hours (default)

3 hours

4 hours

Central battery operation

N/A

N/A

NON MAINTAINED

MAINTAINED MODE

1706

1708

1707

1709

PARTS/REPLACEMENTS

Twinspot Weatherproof Inverter

Twinspot Weatherproof Pro Inverter

Twinspot Weatherproof Pro Black Inverter

Twinspot Weatherproof Pro Inverter

Battery 3000mAh 6.4V, 2 Cell LiFePO4

Battery 1500mAh 6.4V, 2 Cell LiFePO4

Wireless daughterboard

Easy commissioning module - DALI

Easy commissioning module - EKTOR

EV-TWINSPOT-WP

EV-TWINSPOT-WP-PRO

EV-TWINSPOT-WP-PRO-B

EV-TWINSPOT-WP-ULT

OFF

ON

ON

ON

OFF

OFF

OFF

OFF

ON

ON

OFF

ON

ON

OFF

OFF

ON

OFF

ON

OFF

ON

ON

LED is only ON in

emergency

LED is ON in normal and

emergency operation

EV-TWINSPOT-INV

EV-TWINSPOT-PRO-INV

EV-TWINSPOT-PRO-B-INV

EV-TWINSPOT-ULT-INV

EV-3000mAh-6.4V-LiFePO4

EV-1500mAh-6.4V-LiFePO4

EV-WIFI-DAUG

EV-ECM-DALI

EV-ECM-EKTOR

1231

1248

1249

1250

1303

1302

6118

5304

5305

TWINSPOT IP65 EMERGENCY INSTALLATION INSTRUCTIONS

11

20. SELF TEST INDICATOR LEDS

The table below shows the operation of the Twinspot status indicators:

INDICATOR DESCRIPTION

YELLOW

2sec ON / 2sec OFF

YELLOW

4sec ON / 1sec OFF

YELLOW

0.5sec ON / 0.5sec OFF

GREEN

1xFlash

Device is performing a duration test

Last duration test passed. The duration was met when last run.

Test ran less than five days ago

Last duration test failed. Failed to meet duration. The device is not

currently running a new test. Mains is on

A duration test is pending. The device is not in any self test and is

set to normal mode

21. SELF TEST/ COMMISSIONING INTERVAL PROGRAMMING

The self test mode must first be enabled to perform tests by switching the emergency power breaker, or

test button in the correct sequence. The test interval is fixed and set to 26 weeks / 182 days. The LEDs

indicate the status of the device and which functions are being performed. For more information refer to the

Configurations: Status LEDs and Device Modes document.

When self test mode is enabled the status LED will flash either 4x (switched active detected)

or 3x (switched active not detected) for 2 minutes.

The self test can also be enabled using the test button sequence below:

3X PRESS & RELEASE WAIT & REPEAT

WAIT 30 sec.

then repeat the

3X press & release

NOTE: If the wait in-between breaker or test button push sequences is longer than 50 seconds

then it will timeout and the procedure will need to begin again.

30 sec.

RELEASEPRESS RELEASEPRESS RELEASEPRESS

8 sec.

5X SWITCH CYCLES WAIT & REPEAT

WAIT 30 sec.

then repeat the

5X SWITCH CYCLE

OFF ON

OFF ON

OFF ON

OFF ON

OFF ON

30 sec.

8 sec.

TWINSPOT IP65 EMERGENCY INSTALLATION INSTRUCTIONS

12

Voltage (V)

Frequency (Hz)

Max. ambient temp.

Battery type

Class

Duration

IP rating

TWINSPOT

Max. power

TWINSPOT PRO

Max. power

TWINSPOT ULTIMATE

Max. power

Viewing distance

Mounting type

Wiring

Battery voltage

Charging time

Charger operation

Charger type

N/A

Surface mounted

Hard wired

6.4V

16 hours

Multi state

Smart charge

220~240V

50Hz

40°C

LiFePO4

2

Dependant on jumper

IP65

< 4.5W

< 7W

< 10W

22. PRODUCT SPECIFICATIONS

TWINSPOT

189mm

321mm

132mm

279mm 129mm

TWINSPOT IP65 EMERGENCY INSTALLATION INSTRUCTIONS

13

23. CONSTRUCTION SITES

IMPORTANT NOTE: Continuously switching the power supply to the fitting on and off during or after

the installation process due to other processes being conducted on the building site could cause the fitting to

discharge and charge its battery many times during a short period which can impact negatively on the battery

life. It is not recommended that you connect the Ektor emergency products to the power supply if such

conditions are prevalent. If you choose to expose the Ektor emergency products to such harsh operating

conditions, Evolt may not honour any warranty on the life of the batteries or the dish. This Ektor emergency

product is designed to undergo regular discharge tests but it is recommended that the intervals between

consecutive tests are not less than two weeks. Frequent testing of the exit product will reduce the service life

of the battery. In order to prevent damage to the battery, leave the unswitched active circuit turned off at the

circuit breaker until such time as emergency lighting is required

24. TESTING PRECAUTIONS

When the Ektor emergency product is permanently connected to the mains supply you will need to allow 24

hours to charge its battery. Once the battery is fully charged you will need to conduct a manual discharge test

as per the requirements of AS/NZS 2293 or other relevant standards. At the time of printing, the Australian

standard requires that new fittings operate in emergency mode for at least 2 hours for their first discharge

test. Further tests are to be carried out at intervals of not more than six months. It is important that you keep

records of the initial test and ongoing tests in the building’s emergency service logbook. If the fitting is not to be

permanently connected to the mains supply at the time of installation, you must give it the mandatory 2 hour

test when you connect it permanently to the mains supply.

25. PROBLEM SOLVING PROCEDURE

If you have installed and connected the Ektor Twinspot as per the instructions contained within this manual

and the product fails to work properly, please use the following table as a guide to fixing the problem before

calling our office.

FAULT POSSIBLE CAUSES

Green LED is not lit

Green LED is lit but the lamp does not light when the test

switch is pressed

Lamp lights, but only temporarily, when test switch is

pressed or when the main power supply is turned off

• AC Supply is not connected

• AC Supply turned off

• Battery plug not connected to battery pack

• Lamp is damaged

• Lamp is not inserted properly

• Battery pack is damaged

• Battery pack not fully charged

• Battery pack is damaged

TWINSPOT IP65 EMERGENCY INSTALLATION INSTRUCTIONS

14

26. WARRANTY INFORMATION

Ektor products are distributed in Australia and New Zealand by Evolt Pty Ltd (Evolt).

The Australian Consumer Law as well as other Australian laws guarantee certain conditions, warranties and

undertakings, and give you other legal rights, in relation to the quality and fitness for purpose of Ektor products

sold in Australia.

In Australia, our goods come with guarantees that cannot be excluded under the Australian Consumer Law. You

are entitled to a replacement or refund for a major failure and compensation for any other reasonably foreseeable

loss or damage. You are also entitled to have the goods repaired or replaced if the goods fail to be of acceptable

quality and the failure does not amount to a major failure. What constitutes a major failure is set out in the

Australian Consumer Law.

Nothing in this Warranty purports to modify or exclude the conditions, warranties and undertakings, and other

legal rights, under the Australian Competition and Consumer Act and other Australian laws.

Ektor products are warranted in Australia for a period of 12 months from the date of delivery of the product,

provided that the products are properly stored, installed, used and maintained in accordance with the instructions

contained within their manual.

Products that have been altered in any way or used other than in accordance with their instructions are not

covered by this Warranty.

This Warranty is not transferable and is valid only in the hands of the purchaser of the product. The warranty

does not cover Ektor products other than those purchased from Evolt. Proof of purchase must be provided to

Evolt with any warranty claim. Evolt recommends that the purchaser attaches their proof of purchase to their

product manual.

If you wish to claim under this Warranty, you must, at your own expense, return the product or that part of

the product which you believe is defective, and proof of original purchase, your name, address and telephone

number and a certificate of installation or other document required by the law for the installation of electrical

products in the place in which the product was installed, to Evolt at the address above within 12 months from the

date of purchase. Please note that the Warranty does not cover removal or reinstallation of the product or that

part of the product which you believe is defective.

Evolt’s total liability under this Warranty is limited to the cost of repair or replacement of the faulty product. Evolt

may satisfy its obligations under this Warranty in full by repair or replacement of a faulty product.

This Warranty does not apply to consumable items such as lamps or batteries or other items that can be classified

as consumable.

For the avoidance of any doubt, any and all warranties or conditions which are not guaranteed under the

Australian Competition and Consumer Act or the Australian Competition and Consumer Regulations 2010 and

which are not expressly included in this Warranty as additional warranties or conditions are excluded.

This Warranty does not cover loss or damage caused by wear and tear, misuse, incorrect installation or

operation, failure to clean and maintain, incorrect voltage or non-authorised electrical connections, adverse

external conditions (such as power surges and dips, acts of God, exposure to heat, corrosion, insect or vermin

infestation), use of non-authorised or defective parts or globes, or to items that have been repaired other than by

Evolt or a repairer approved by Evolt.

TWINSPOT IP65 EMERGENCY INSTALLATION INSTRUCTIONS

15

27. COMPLIANCE STANDARDS

STANDARD TITLE

Australian/ New Zealand

Standards

AS/NZS 2293-3:2005+A1:2010

AS/NZS 60598-2-22:2005

AS 61000.3.2:2007 + A1:2009

AS/NZS CISPR 15:2011

Emergency escape lighting and exit signs for buildings.

Part 3: Emergency escape luminaires and exit signs.

Luminaires Part 2.22: Particular requirements - Luminaires for

emergency lighting (IEC 60598-2-22, Ed. 3.1(2002) MOD).

Electromagnetic compatibility (EMC) - Limits - Limits for

harmonic current emissions (equipment input current

(16 A per phase) (IEC 61000-3-2, Ed.3.0 (2005) MOD).

Limits and methods of measurement of radio disturbance

characteristics of electrical lighting and similar equipment.

European Committee

for Standardisation

EN 60598-1:2008+A11:2009

EN 60598-2-22:1998+A1:2003+A2:2008

EN 55015:2006+A1:2007+A2:2009

EN 61547:2009

EN 61000-3-2:2006+A1:2009+A2:2009

EN 61000-3-3: 2008

Luminaires - Part 1: General requirements and tests.

Luminaires - Part 2-22: Particular requirements -

Luminaires for emergency lighting.

Limits and methods of measurement of radio disturbance

characteristics of electrical lighting and similar equipment.

Equipment for general lighting purposes - Electromagnetic

compatibility (EMC) immunity requirements.

Electromagnetic compatibility (EMC) Limits. Limits for

harmonic current emissions (equipment input current ≤

16 A per phase).

Electromagnetic compatibility (EMC) - Part 3-3: Limits -

Limitation of voltage changes, voltage fluctuations

and flicker in public low-voltage supply systems, for

equipment with rated current <= 16 A per phase and

not subject to conditional connection.

28. TECHNICAL SUPPORT AND TROUBLESHOOTING

For further assistance in using this product, consult your nearest wholesaler or Evolt Pty Ltd.

This manual suits for next models

7

Table of contents

Popular Lantern manuals by other brands

Sealite

Sealite SL-C510-AIS Installation & service manual

BEGA

BEGA 84 387 Instructions for use

Claessens' Kids

Claessens' Kids KID'SLEEP MY LANTERN quick start guide

Dorcy

Dorcy LT-033 Operation & instruction manual

Teknoware

Teknoware TWT81 Series Installation and Maintenance

EG-Solar

EG-Solar MALI - Light operating instructions

Sunna Design

Sunna Design iSSL Maxi user manual

Daintree

Daintree GE current Lumination LIB installation guide

Cooper

Cooper AtLite ATLEM1002HR16SD installation instructions

Raytec

Raytec XR8 Mounting & installation

NAMENE

NAMENE WATU Assembly instructions

Home Decorators Collection

Home Decorators Collection HB7056A-163 E instruction manual