All disclosures, notices and warranty conditions are being written on the back of the box. Released on 30th of March, 2011. Revision 1.0

Installation and mounting manual for EK-FC6990 water block

This product is intended for installation only by expert users. Please consult with a qualified technician for installation. Improper installation may result in damage to your equipment. EK Water Blocks assumes no liability

whatsoever, expressed or implied, for the use of these products, nor their installation. The following instructions are subject to change without notice. Please visit our web site at www.ekwaterblocks.com for updates.

Before installation of this product please read important notice, disclosure and warranty conditions printed on the back of the box or our home page.

The barb hose fittings require only a small amount of force to screw them in; otherwise the high flow fittings might break. These fittings do not need to be tightened with much force because the

liquid seal is made using o-rings. The use of an algaecide and corrosion inhibitors is always recommended for any liquid cooling system.

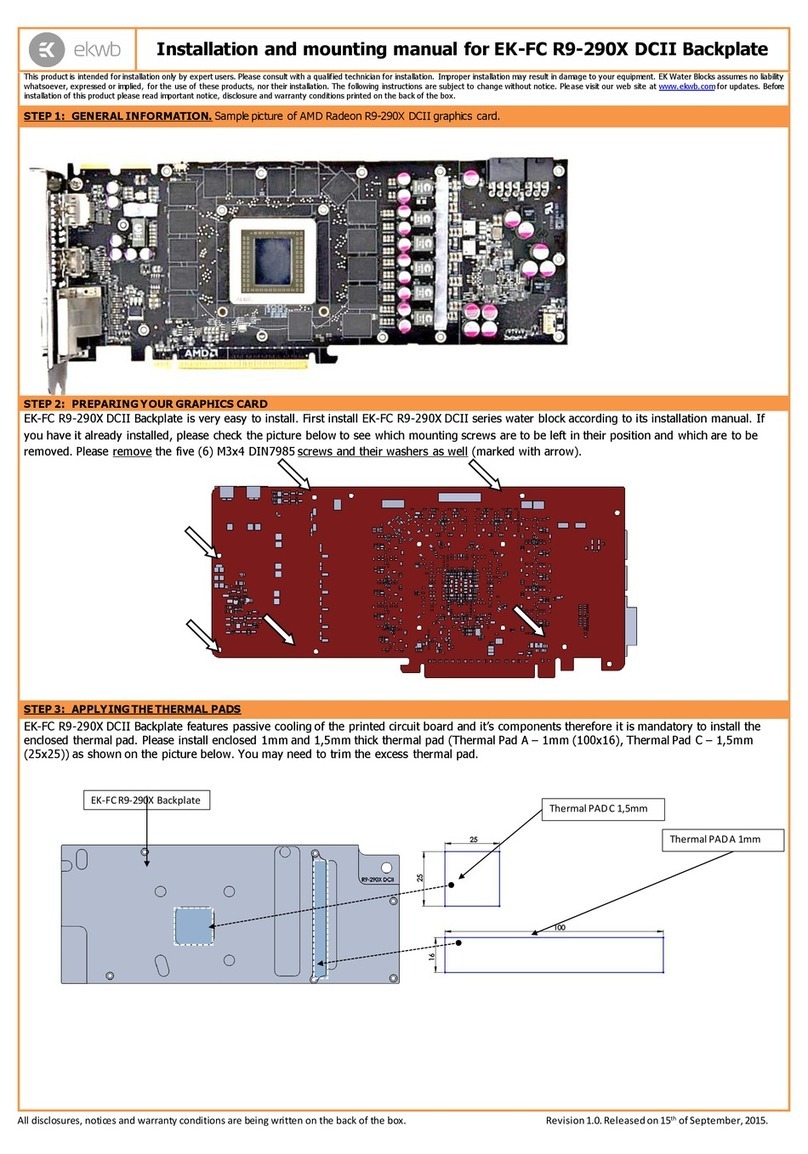

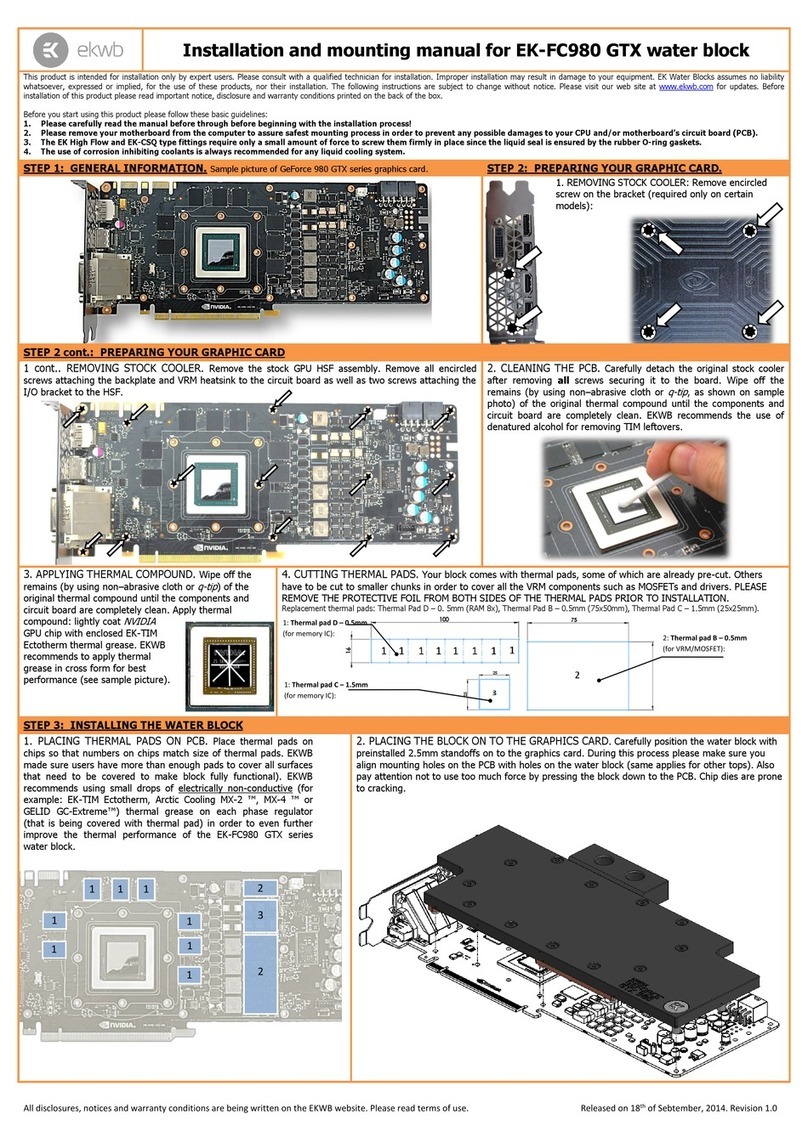

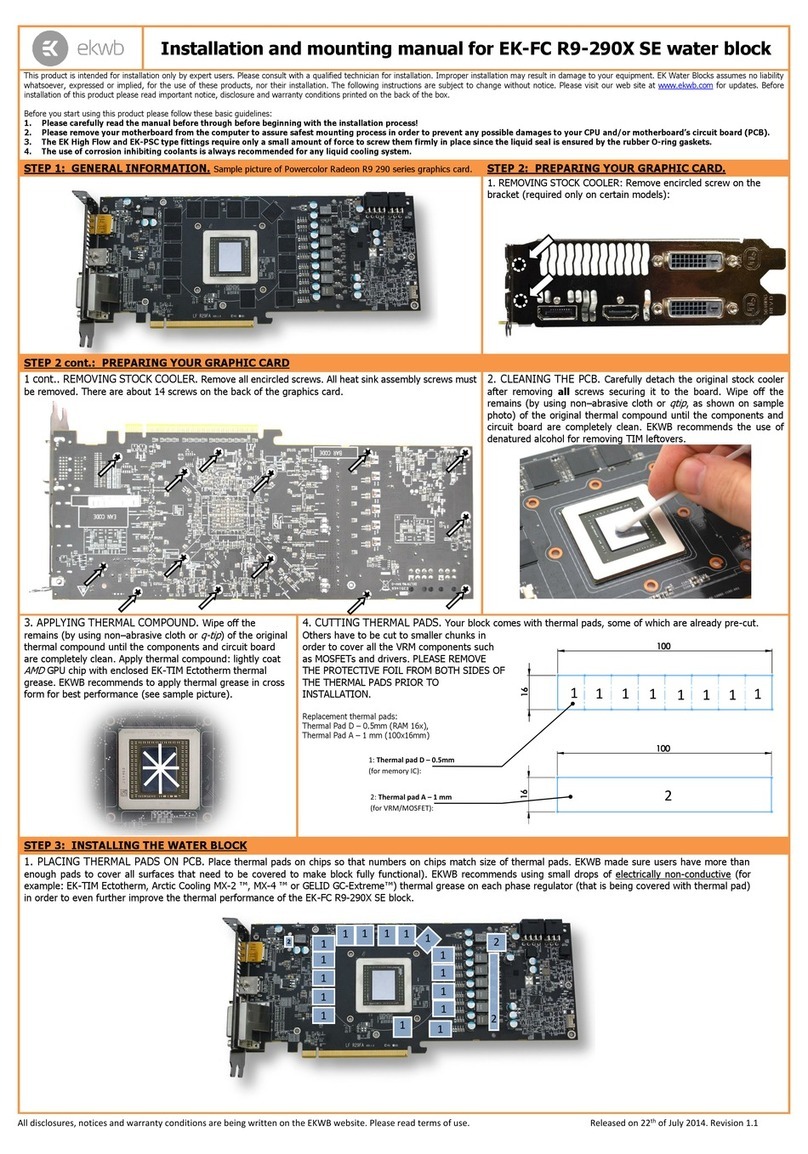

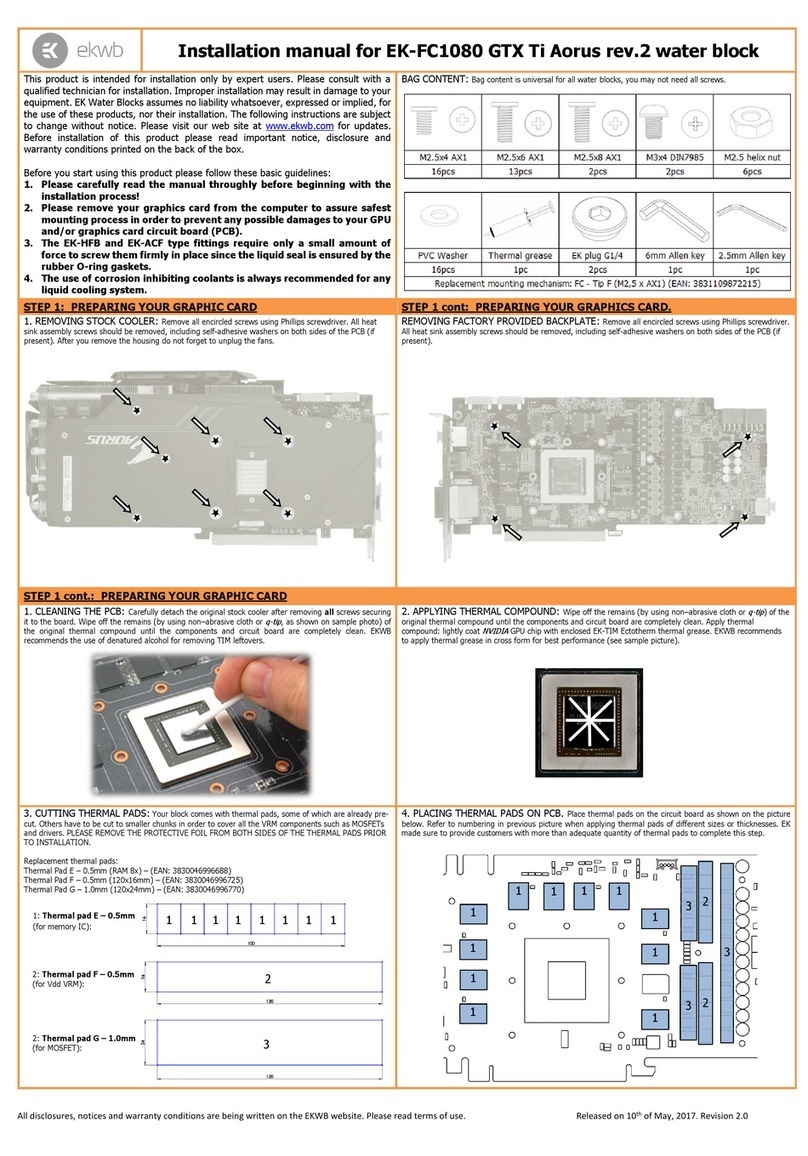

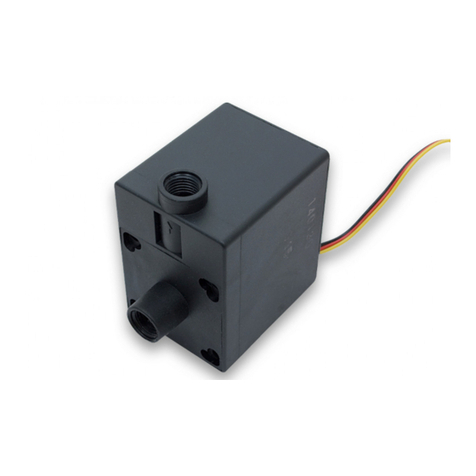

STEP 1: GENERAL INFORMATION. Sample picture of AMD Radeon HD 6990 graphics card

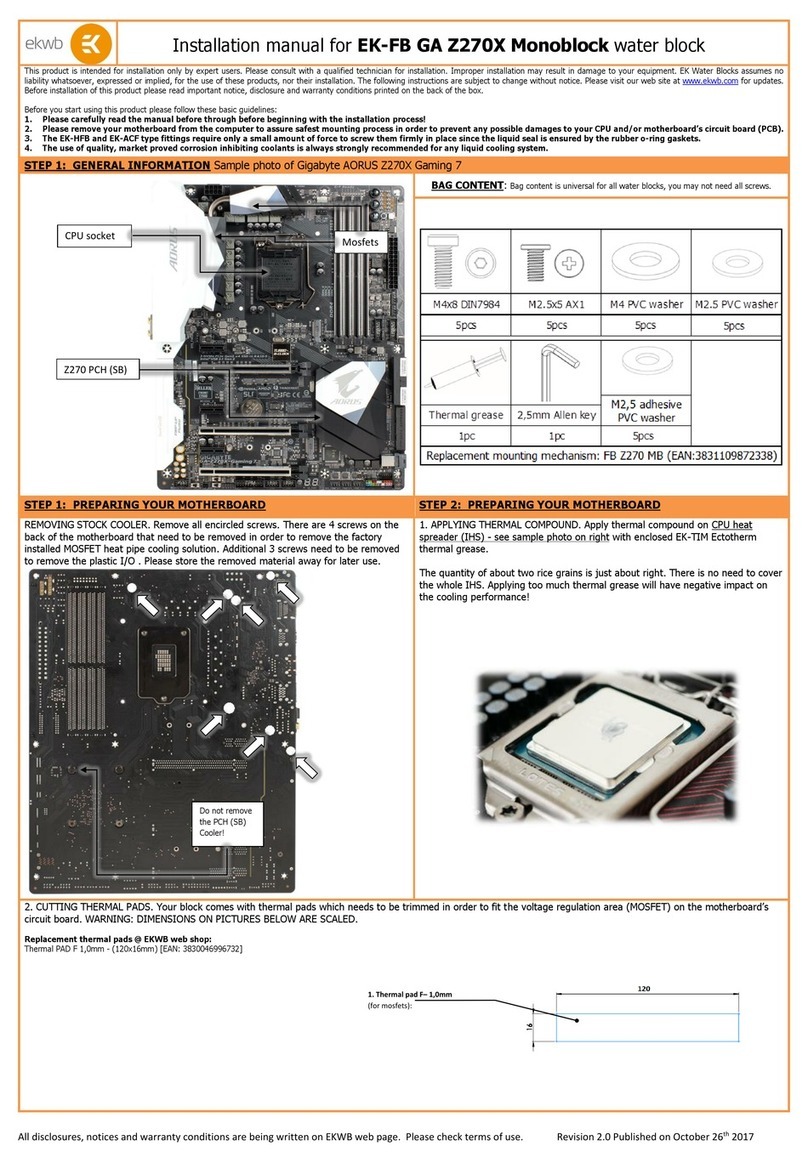

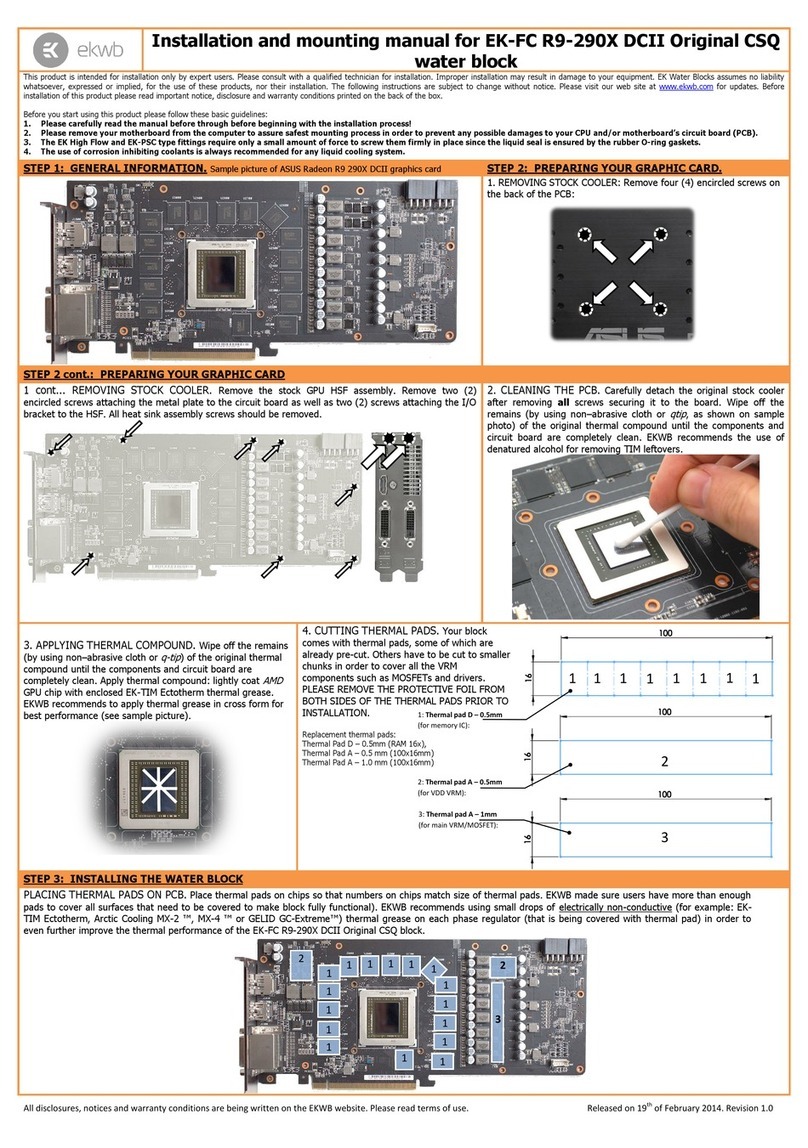

STEP 2: PREPARING YOUR GRAPHIC CARD.

1. REMOVING STOCK COOLER: Remove encircled screws

on the I/O bracket:

STEP 2 cont.: PREPARING YOUR GRAPHIC CARD

1 cont.. REMOVING STOCK COOLER. Remove all encircled screws. All heat sink assembly

screws and backplate should be removed. There are 19 screws on the back of the graphics

card.

2. CLEANING THE PCB. Carefully detach the original heat sink after removing all

fasteners securing it to the board and bracket. Wipe off the remains (by using

non–abrasive cloth or Q-tip, as shown on sample photo) of the original thermal

compound until the components and circuit board are completely clean. EKWB

does not recommend using any liquids for removing paste.

3. APPLYING THERMAL COMPOUND. Apply thermal compound: lightly

coat both GPUs and bridge chip with for example Arctic Cooling MX-2 ™or

MX-4 ™ thermal grease. EKWB recommends to apply thermal grease in cross

form for best performance (see sample picture).

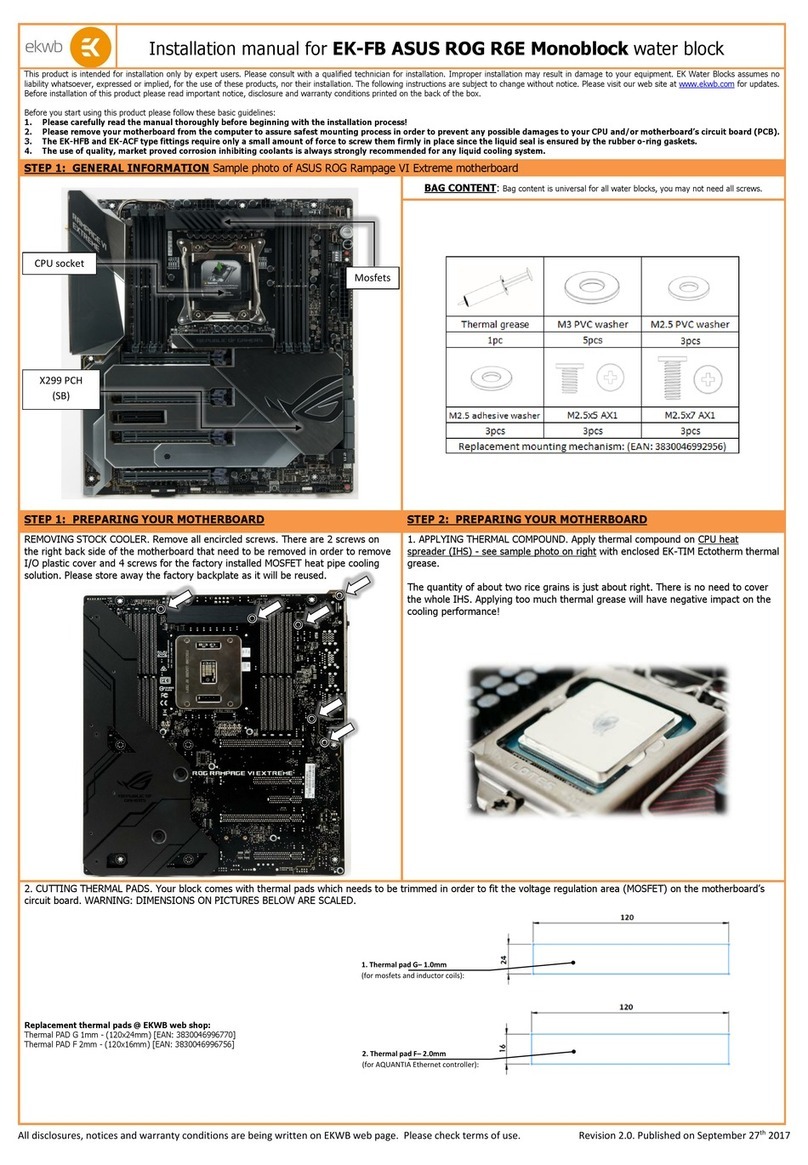

4. CUTTING THERMAL PADS. Your block comes with thermal pads, some of which are already

pre-cut. Others have to be cut to smaller chunks in order to cover all the VRM components and

PCIE lane splitter chip (PLEASE REMOVE FOIL ON BOTH SIDES OF THERMAL PADS PRIOR TO

INSTALLATION. WARNING: DIMENSION BELLOW ARE SCALED).

STEP 3: INSTALLING WATER BLOCK

1. PLACING THERMAL PADS ON PCB. Place thermal pads on chips so that numbers on chips match size of thermal pads. EKWB made sure users have more than enough pads

to cover all surfaces that need to be covered to make block fully functional). It is advised to use small drops of electrically non-conductive thermal grease on chips to make

thermal pads more adhesive and also to improve heat transfer.

Thickness 0.5mm (for memory ICs)

Thickness 0.5mm

(for VRM and PCIE lane splitter chip)