Elcometer 270 User manual

User Guide

Elcometer 270

Pinhole Detector

www.elcometer.com

R

1

Gauge Overview

2

Box Contents

3

Getting Started

4

Using the Elcometer 270

5

Spares & Accessories

6

Warranty Statement

7

Technical Specification

8

Legal Notices & Regulatory Information

For the avoidance of doubt, please refer to the original English language version.

Dimensions: Detector (without Wand): 210 x 42 x 37mm (8.3 x 1.7 x 1.5”)

Weight: Detector, Wand Assembly, Batteries & Connecting Cable: 610g (21oz)

A Material Safety Data Sheet for the Wetting Agent (Kodak Photo-Flo™) supplied as an accessory for the

Elcometer 270 is available to download via our website:

http://www.elcometer.com/images/stories/MSDS/elcometer_270_wetting_agent.pdf

© Elcometer Limited 2009 - 2016. All rights reserved. No part of this document may be reproduced, transmitted,

transcribed, stored (in a retrieval system or otherwise) or translated into any language, in any form or by any

means (electronic, mechanical, magnetic, optical, manual or otherwise) without the prior written permission of

Elcometer Limited.

CONTENTS

www.elcometer.com

en-1

R

www.elcometer.com en-2

R

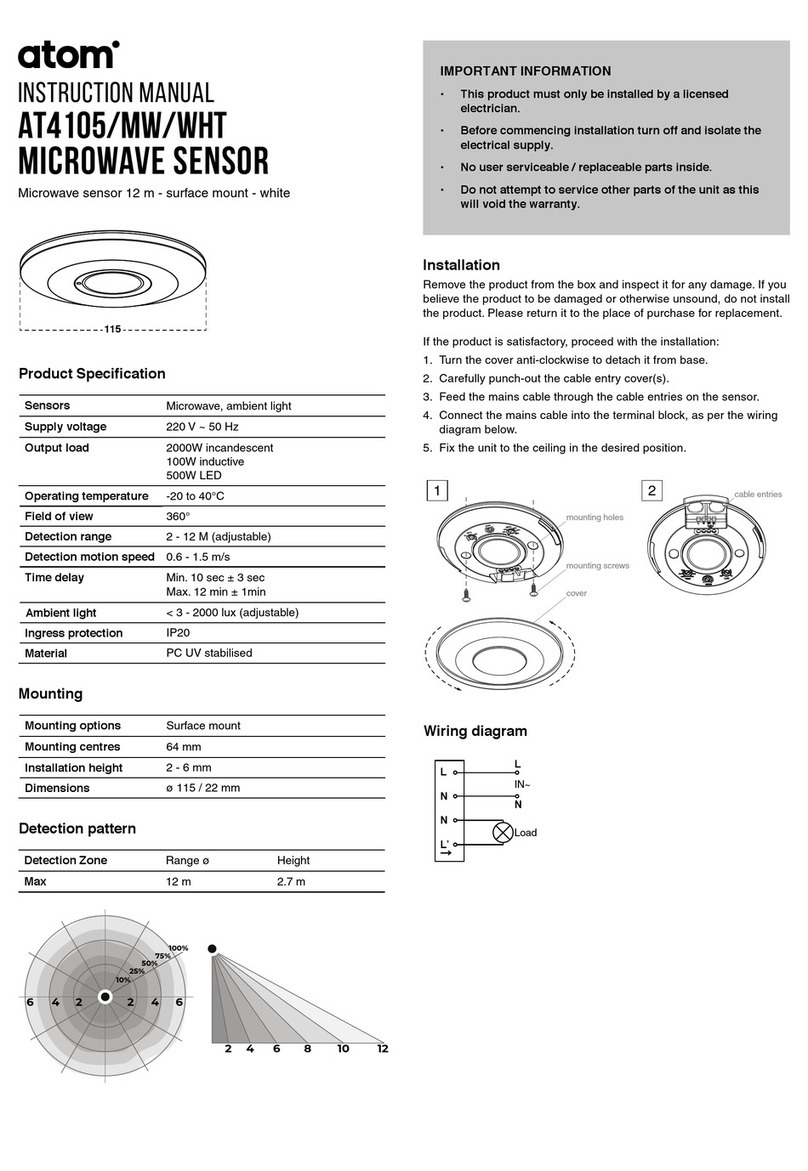

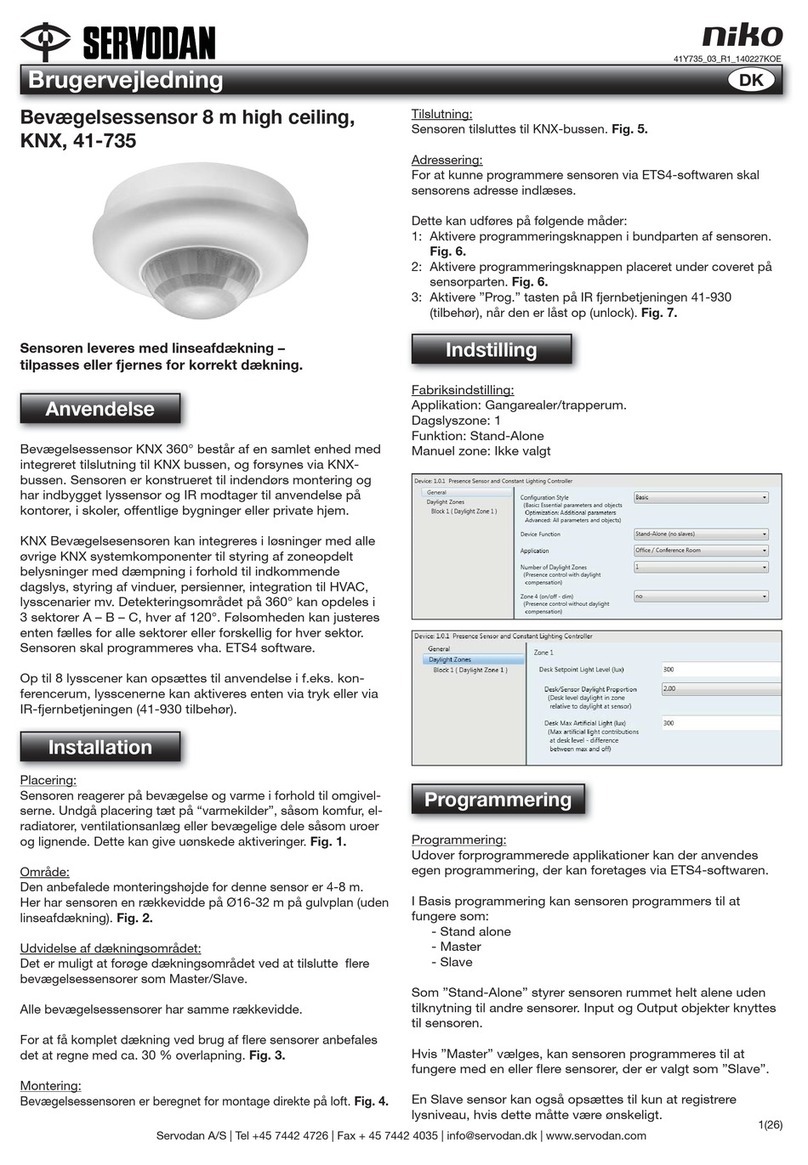

1 GAUGE OVERVIEW

The Elcometer 270 Pinhole Detector uses the ‘wet sponge’ method of

holiday detection.

When the wand sponge is passed over a pinhole, current flows from

the detector through the moisture in the hole to the substrate below

and back to the detector via the signal return lead. This current flow

triggers an audible alarm and causes the alarm LED to flash.

a

1 Standard Wand Accessory (Flat Sponge)

2 Wand Accessory Connection Point

3 Signal Return Cable Connection Point

4 Battery Condition LED

5 On/Off Key and Voltage Selection Key

6 Pinhole Alarm LED

7 Selected Voltage (LED illuminates)

1

Elcometer

270

67.5

990

Volts

Elcometer

270

67.5

990

Volts

2

3

5

7

4

6

a Other accessories are available, see Section 5 ‘Spares & Accessories’ on page en-6.

www.elcometer.com

en-3

R

Elcometer 270 Pinhole Detector

Signal Return Cable, 4m (13')

Standard Wand Accessory (flat sponge)

AA Batteries, x3

Calibration Certificate (if ordered)

User Guide

2 BOX CONTENTS

3 GETTING STARTED

3.1 FITTING THE BATTERIES

Each gauge is supplied with 3 x AA alkaline batteries.

To insert or replace the batteries:

1 Unscrew the battery cap (turning

anti-clockwise).

2 Insert 3 batteries taking care to ensure

correct polarity.

3 Refit the battery cap.

3.2 BATTERY CONDITION

The battery condition is indicated by the LED on

the front keypad (a):

When the batteries contain adequate

charge, the battery condition LED is not

illuminated.

When the batteries reach the final 10% of

their capacity, the battery condition LED

illuminates continuously.

When the battery condition LED flashes,

the batteries are exhausted and new

batteries must be fitted.

Note: Batteries must be disposed of carefully to avoid environmental contamination.

Please consult your local Environmental Authority for information on disposal in

your region. Do not dispose of any batteries in fire.

3.3 SWITCHING ON / OFF

Press and hold the on/off key (b). The detector will emit an audible

signal and switch on or off.

x 3

Elcometer Limited

Edge Lane, Manchester M43 6BU

Tel: +44 (0)161 371 6000

Fax: +44 (0)161 371 6010

www.elcometer.com

Made in Great Britain

AAA/IEC LR6

x3

>2 Sec OK

<1 Sec Volts

10% 0%

a

b

www.elcometer.com en-4

R

3.4 SELECTING THE VOLTAGE

The Elcometer 270 is capable of testing at three voltages, depending

on model;

Part Number: D270----3; 9V and 90V

Part Number: D270----4; 9V, 67.5V and 90V

The LED for the voltage selected is illuminated (c). Press the on/off

key to change the voltage. The detector will emit an audible signal

and change to the next voltage.

9V: Suitable for coatings up to 300μm

(12mils) thick.

90V: Suitable for coatings up to 500μm

(20mils) thick.

67.5V: The US standard test requirement.

The voltage selected is retained when the

detector is switched off. When switched on

again, the voltage is set to the retained value.

3.5 CALIBRATION TEST

When the Elcometer 270 is switched on, or after changing voltage, the

unit will test the calibration of the internal voltage and sensitivity

setting. This test takes approximately four seconds.

During the test, the voltage indicator LED (c) flashes slowly and then

quickly. At the end of the test, the LED remains permanently

illuminated and the detector emits a loud double bleep to indicate a

successful test.

In the unlikely event that the detector does not achieve a successful

internal calibration test, replace the batteries - see Section 3.1 ‘Fitting

the Batteries’ on page en-3.

If fitting new batteries does not result in a successful calibration

test, contact Elcometer or your local supplier in order to restore the

correct calibration of the detector.

3 GETTING STARTED (continued)

c

www.elcometer.com

en-5

R

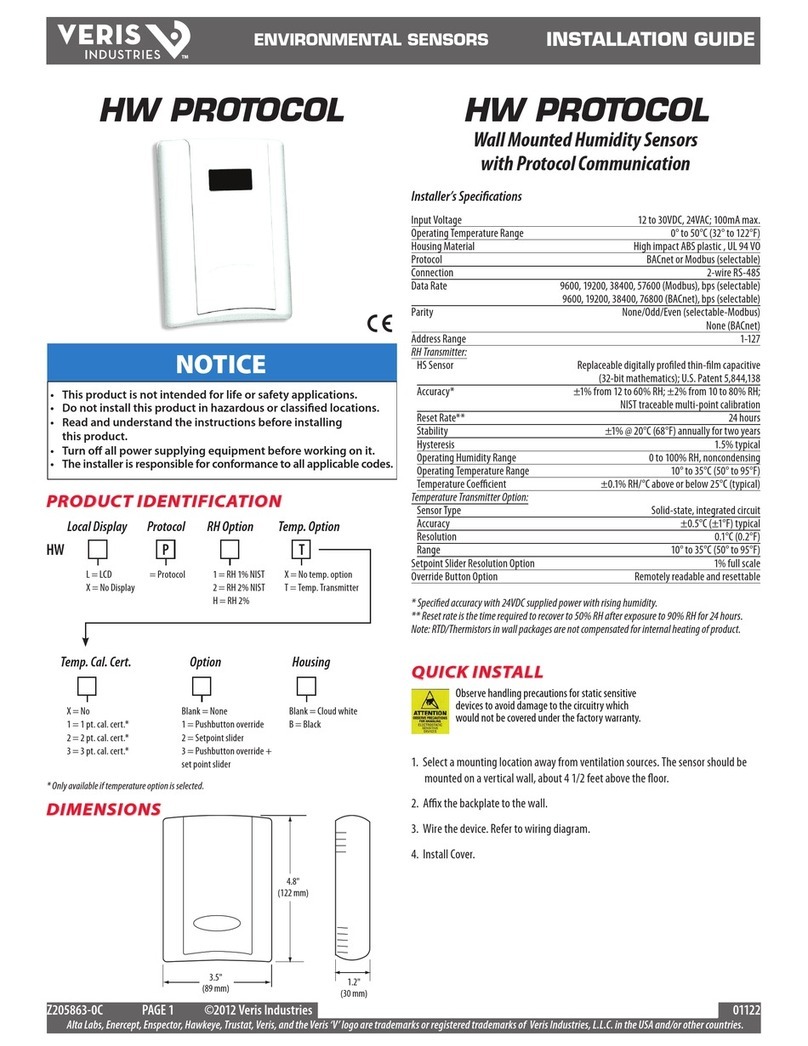

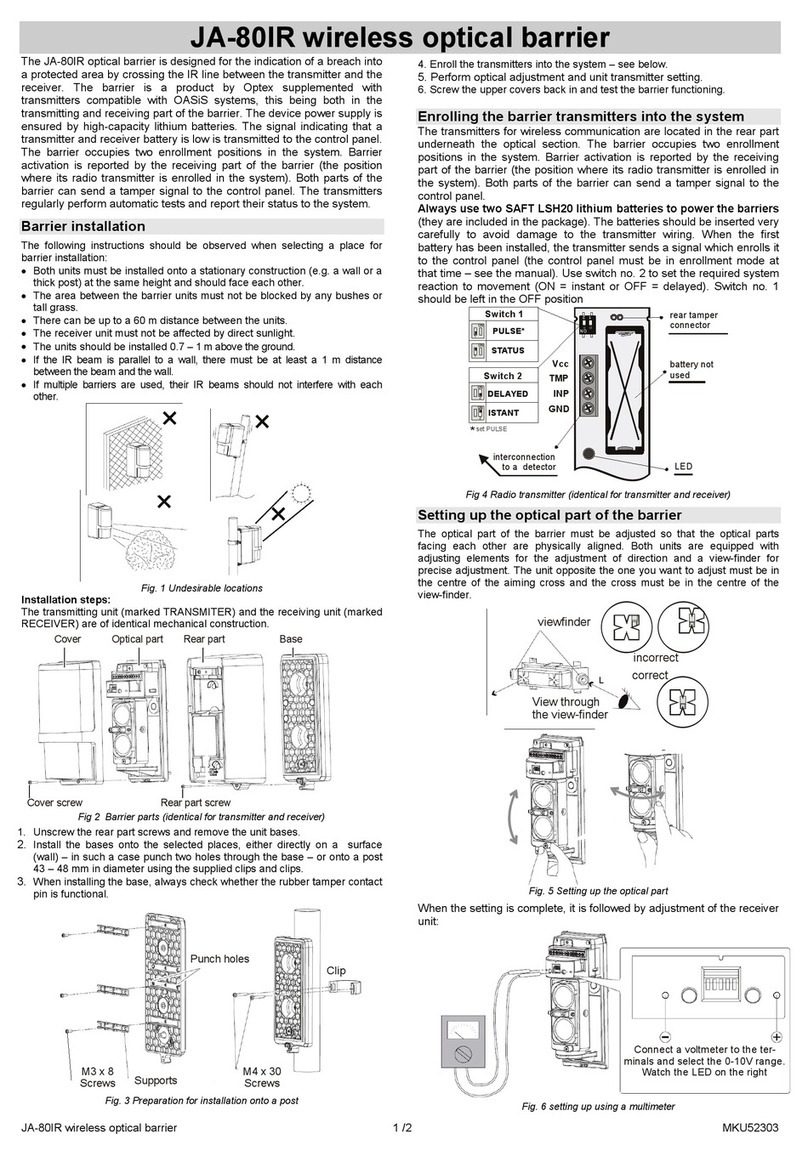

4 USING THE ELCOMETER 270

The Elcometer 270 generates a voltage which is used to test

for holes in a coating applied to a metal surface. Should a user

make contact with the wand while holding the earth signal

return lead, a very mild shock may be experienced with the

higher voltage settings. The current capability of the detector is

low and the health risk directly from the voltage is negligible.

1 Connect the signal return cable to an uncoated part of the metal

substrate using the crocodile clip.

2 Moisten the sponge with clean tap water.

Tap water contains salts which allow it to conduct electricity. To maximise the

efficiency of the Elcometer 270, add a surfactant such as Kodak Photo-flo™ to the

water. Kodak Photo-flo™ can significantly reduce the surface tension of the water,

therefore allowing the moisture to penetrate the smallest of pinholes - see Section 5

‘Spares & Accessories’ on page en-6. Follow the dilution instructions supplied with

the surfactant.

3 Keeping the sponge clear of the test surface, switch on the

detector.

Wait approximately four seconds for a loud double beep indicating that the internal

calibration test routine is complete - see Section 3.5 ‘Calibration Test’ on page en-4.

4 Select the test voltage required - see Section 3.4 on page en-4.

5 Pass the sponge over the coated surface.

d

Elcometer

270

67.5

990

Volts

If the sponge passes across a pinhole in the

coating, the alarm LED will flash (d) and an

audible alarm will sound. The alarm will stop

when the sponge moves away from the

pinhole.

6 If required, locate the pinhole more precisely

by retesting the area using a corner of the

sponge only.

Note: Sponge wands will eventually wear; the life of the sponge will depend on use

and the abrasive nature of the coatings. Replacement sponges are available

along with a comprehensive selection of wand accessories - see Section 5

‘Spares & Accessories’ on page en-6).

www.elcometer.com en-6

R

5 SPARES & ACCESSORIES

Description

Part Number

Standard Wand with Flat Sponge

A universal at sponge to suit almost all applications.

T27016867

Flat Sponge Set, Pack of 3

150 x 60 x 25mm (6 x 2.3 x 1")

T27018050

Roller Wand with Roller Sponge

Ideal for large at surface inspection.

T27016960

Spare Roller Sponge

T27018051

Telescopic Wand Adaptor

Extends to 1m (39"), ideal for oors or high areas.

Supplied with lead and belt clip. Sponge not supplied.

T27016998

Separate Wand Adaptor

For use with extension pieces. Supplied with lead

and belt clip.

T27016999

Extension Piece

Extends to 0.4m (16.5"). Extension pieces can be

connected together to make longer wands.

T27016965

Wetting Agent, 50ml (1.7oz) Bottle

Kodak Photo-Flo™ supplied. Can significantly

reduce the surface tension of the water, therefore

allowing the moisture to penetrate the smallest of

pinholes.

T27018024

Signal Return Cable, 4m (13')

Complete with crocodile clip and connection plug.

T99916954

Signal Return Cable, 10m (32')

Supplied on a drum complete with crocodile clip and

connection plug.

T99916996

Pinhole Inspector’s Kit

Supplied with standard wand with at sponge, roller

wand with roller sponge, telescopic wand adaptor,

extension piece (x2), 10m (32') signal return cable,

wetting agent, spare at sponge, spare roller sponge

and AA batteries (x3). The kit does not include the

Elcometer 270 instrument - to be ordered separately.

T27018191

Pinhole Inspector’s Kit Carry Case

Empty case with foam cut-outs only

T27018025

Note: A Material Safety Data Sheet for the Wetting Agent (Kodak Photo-Flo™)

supplied as an accessory for the Elcometer 270 is available to download via our

website:

http://www.elcometer.com/images/stories/MSDS/elcometer_270_wetting_agent.pdf

7 TECHNICAL SPECIFICATION

R

Coating Thickness

Range

9V:

up to 300µm (12mils)

67.5V:

up to 500µm (20mils)

90V:

up to 500µm (20mils)

Sensitivity

9V:

90kΩ ±5%

67.5V:

125kΩ ±5%

90V:

400kΩ ±5%

Accuracy of Setting

±5%

Operating Temperature

10 to 50°C (32 to 122°F)

Power Supply

3 x AA Batteries

(rechargeable batteries can be used)

Battery Lifeb

9V:

up to 200 hours

67.5V:

up to 100 hours

90V:

up to 80 hours

Dimensions

Detector only: 210 x 42 x 37mm

(8.3 x 1.7 x 1.5”)

Standard Wand: 175mm (6.9") long

(including sponge)

Weight

610g (21oz)

(Detector, Wand Assembly, Batteries & Connecting Cable)

6 WARRANTY STATEMENT

The Elcometer 270 is supplied with a 12 month warranty against

manufacturing defects, excluding contamination and wear.

b If using rechargeable batteries, battery life will be reduced by up to 75% .

This product meets the Electromagnetic Compatibility Directive and the Low Voltage Directive.

This product is Class B, Group 1 ISM equipment according to CISPR 11.

Group 1 ISM product: A product in which there is intentionally generated and/or used conductively coupled

radiofrequency energy which is necessary for the internal functioning of the equipment itself.

Class B product: Suitable for use in domestic establishments and in establishments directly connected to a

low voltage power supply network which supplies buildings used for domestic purposes.

is a registered trademark of Elcometer Limited, Edge Lane, Manchester, M43 6BU.

United Kingdom

All other trademarks acknowledged.

The Elcometer 270 Pinhole Detector is packed in cardboard packaging. Please ensure that this packaging is

disposed of in an environmentally sensitive manner. Consult your local Environmental Authority for further

guidance.

8 LEGAL NOTICES & REGULATORY INFORMATION

R

TMA-0265 Issue 08 - Text with cover 18064

Other manuals for 270

1

Table of contents

Other Elcometer Security Sensor manuals