Number: Sensing distance (unit: mm)

Number+M: Sensing distance (unit: m)

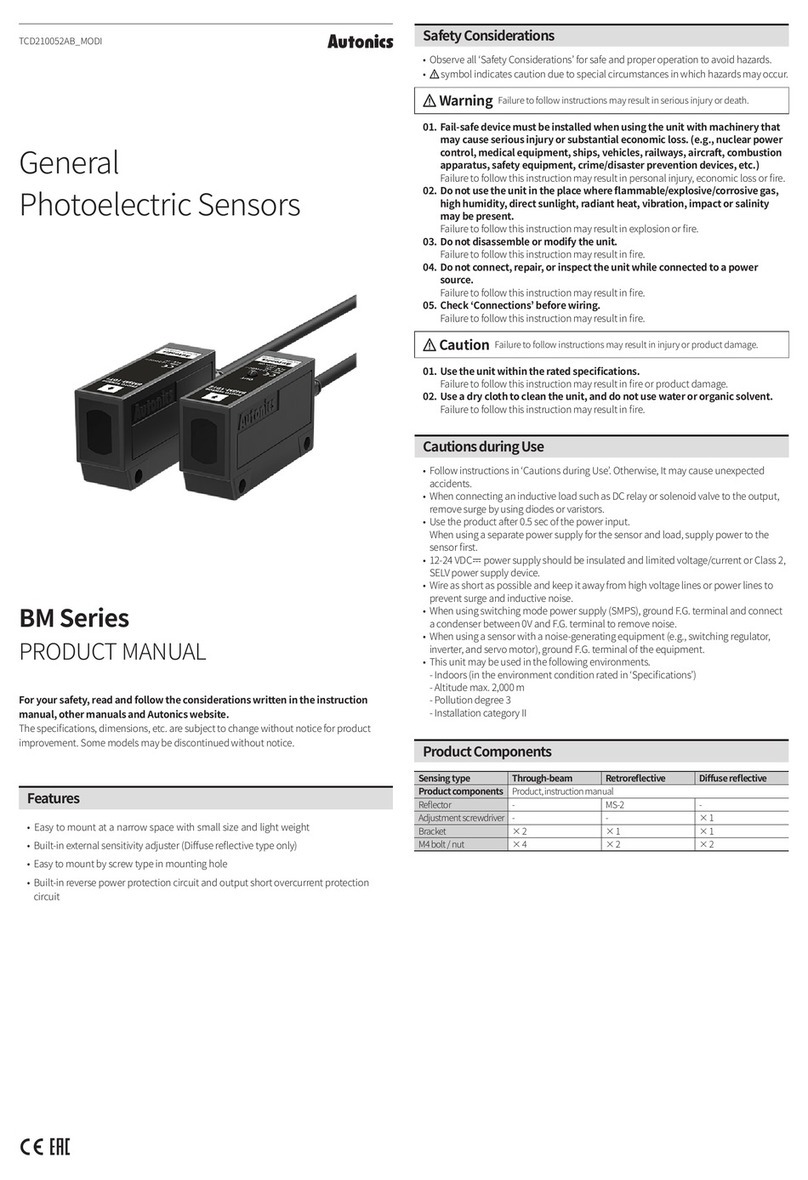

No mark: Cable type

W: Cable connector type

T: Through-beam

P: Polarized retroreective

D: Diuse reective

No mark: NPN open collector output

P: PNP open collector output

D: 10 - 30 VDCᜡ

No mark: Oil resistant type

T: Solid state (transistor)

• Be sure to install this product by following the usage environment, location, and specied

ratings. Consider the listed conditions below.

- Installation environment and background (reected light)

- Sensing distance and sensing target

- Direction of target’s movement

- Characteristic curves

• When installing multiple sensors closely, it may result in malfunction due to mutual

interference.

• For installation, tighten the screw with a torque of 0.5 N m. Mount the brackets correctly to

prevent the twisting of the sensor's optical axis.

• Do not impact with a hard object or bend the cable excessively. That could decrease the

product's water resistance.

• Although some of the cable connector types can have color dierences in the connector part

due to the coating, it does not aect operation and performance.

• Use this product after the test. Check whether the indicator works appropriately for the

positions of the detectable object.

Emitter - Receiver:

Install to face each other

Sensor - Reector:

At least 0.1 m apart,

install to face each other

(parallel with the sensing

side of the unit)

Sensor - Sensing target:

Install to face each other

(parallel with the sensing

side of the unit)

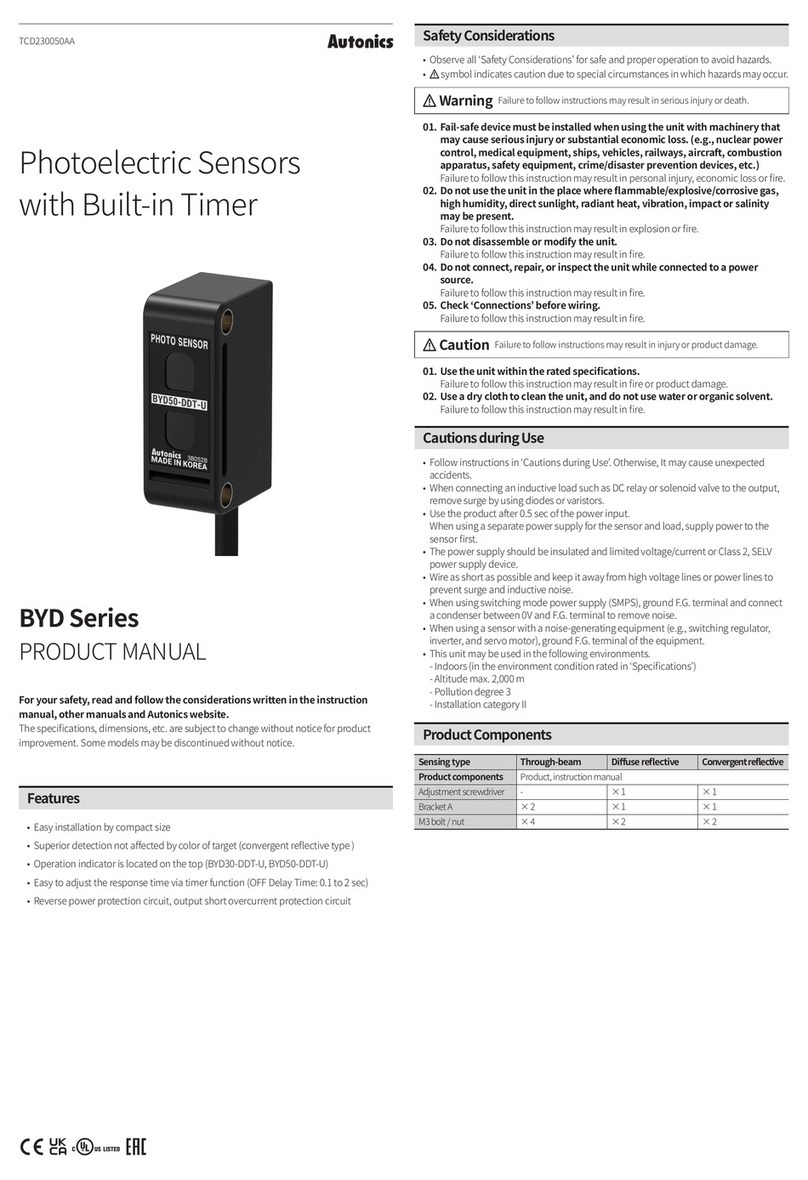

• Be sure to set the mode before power-on.

• Use the oered adjustment screwdriver. Do NOT turn with excessive force to prevent

product damage.

Received

Stable

Unstable

Unstable

level

Stability indicator

(green)

Operation indicator

(yellow)

Operation indicator

(yellow)

Transistor output

Transistor output

Stable

beam

• In Dark ON mode, the waveforms are reversed.

• Operation indicator and transistor output dier from the sensing method.

• Reector: MS Series

• Retroreective tape: MST Series

• Bracket B (BJP SERIES BRACKET B)

• M12 connector cable: CID(H)3-□, CLD(H)3-□

This is only for reference, the actual product does not support all combinations.

For selecting the specied model, follow the Autonics website.

BJR - ---

Sensitivity Adjustment

• Set the adjuster for stable Light ON area, minimizing the eect of the installation

environment.

• Use the oered adjustment screwdriver. Do NOT turn with excessive force to prevent

product damage.

• The steps below are based on Light ON mode.

STEP Status

01 Received

Turn the adjuster from MIN (━) to MAX (╋) sensitivity

and check the position (A) where the operation

indicator activates under the light ON area.

02 Interrupted

Turn the adjuster from (A) to MAX (╋) and check the

position (B) where the operation indicator activates

under the light OFF area.

If the operation indicator does NOT activate at the

MAX (╋, maximum sensitivity): MAX = (B).

03 -Set the adjuster at the mid position between (A) and

(B) for optimal sensitivity.

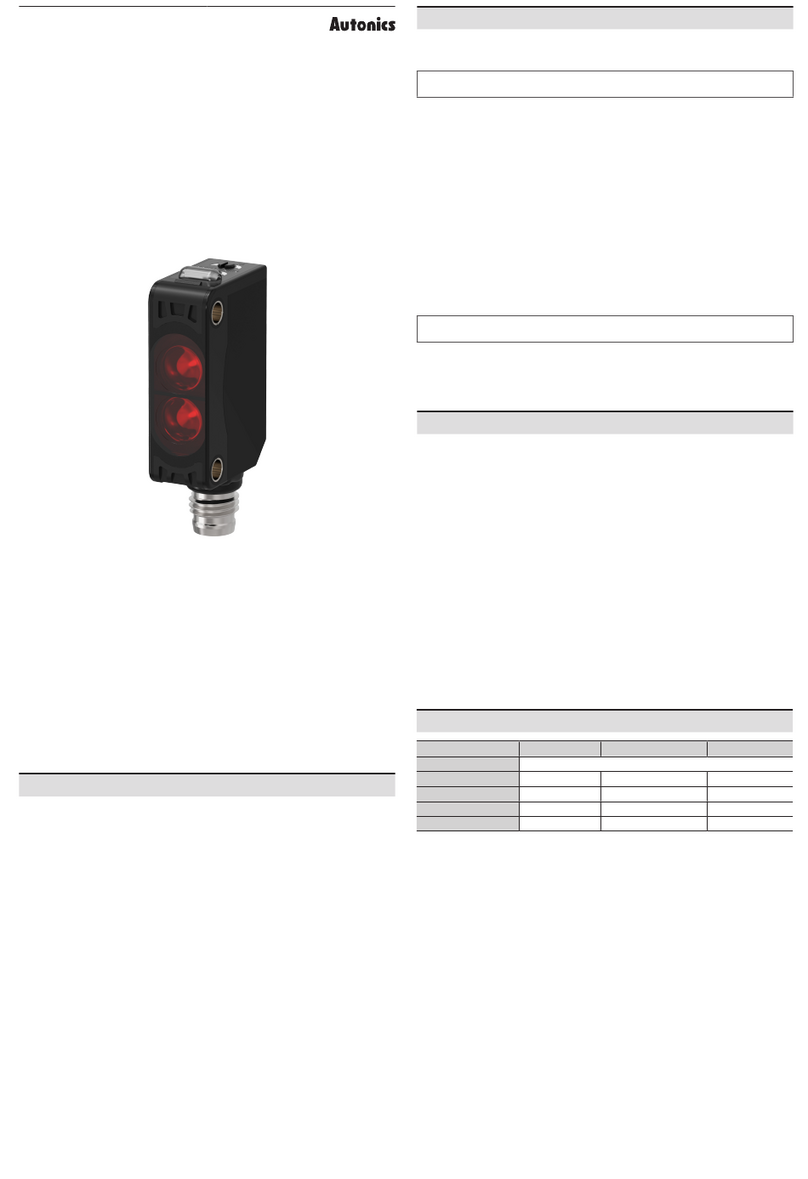

Dimensions

• Unit: mm, For the detailed drawings, follow the Autonics website.

• This dimensions shows the cable type.

Refer to the ‘Specications’ for the core, wiring, and connector spec.

3

Ø4, 2m

25.43.3

20

Receiver

CD

11

B

20

32

Emitter

11

E

A

20

32

Polarized retroreflective,

Diffuse reflective

Cable type

CD

11

A

B

8

12

32

AOptical axis of emitter DStability indicator (green)

BOptical axis of receiver EPower indicator (red)

COperation indicator (yellow)

Circuit

CIRCUIT

LOAD

OCP

SCP

Max. 100 mA

CIRCUIT

LOAD

OCP

SCP Max. 100 mA

• OCP (over current protection), SCP (short circuit protection)

• If short-circuit the control output terminal or supply current over the rated specication, normal control signal is

not output due to the protection circuit.

Connections

10-30 VDCᜡ

Brown

Blue

10-30 VDCᜡ

LOAD

Brown

Black

Blue

10-30 VDCᜡ

LOAD

Brown

Black

Blue

2

3

1

4

Pin Color Function

Brown +V

- -

Blue 0 V

Black OUT

• Connector pin ④ is N.C (not connected) terminal

for the emitter.

Max. 100 mA

Max. 100 mA