i

Contents

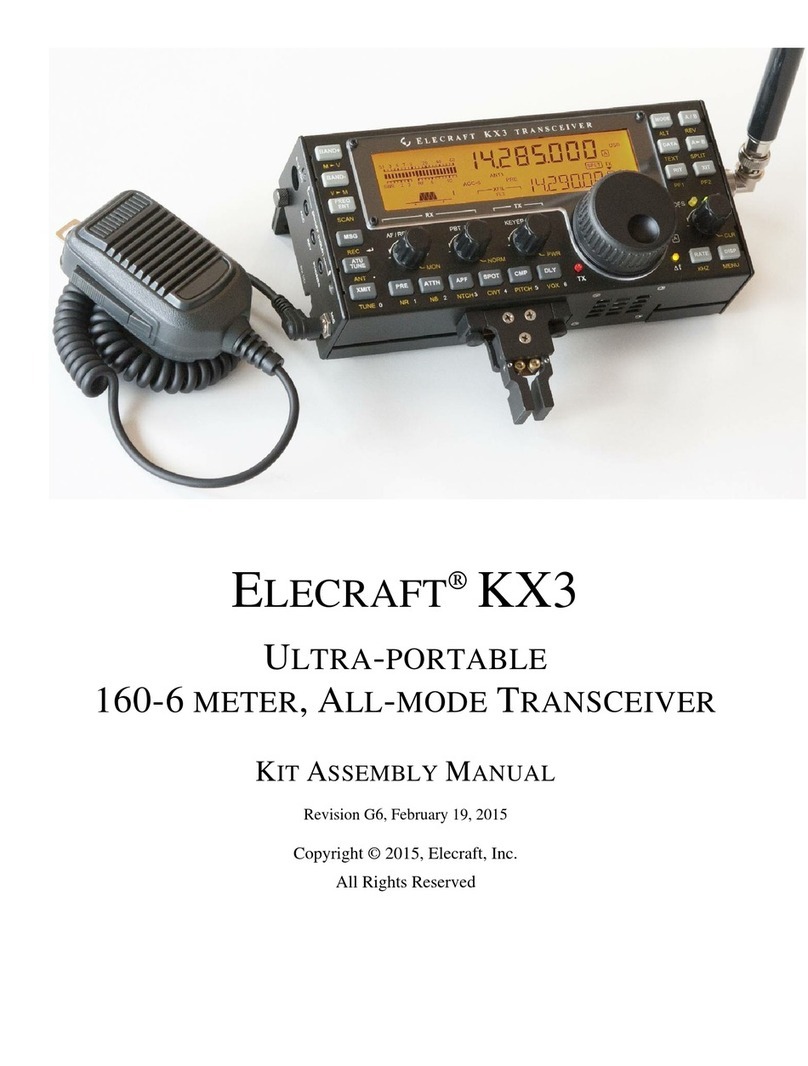

Introduction...................................................... 1

Customer Service and Support............................1

Technical Assistance.......................................1

Preventing Electrostatic Discharge Damage ... 3

How ESD Damage Occurs..................................3

Preventing ESD Damage.....................................3

Preparing for Assembly................................... 4

Overview of the Kit.............................................4

Tools and Test Equipment Required...................6

Unpacking and Inventory....................................7

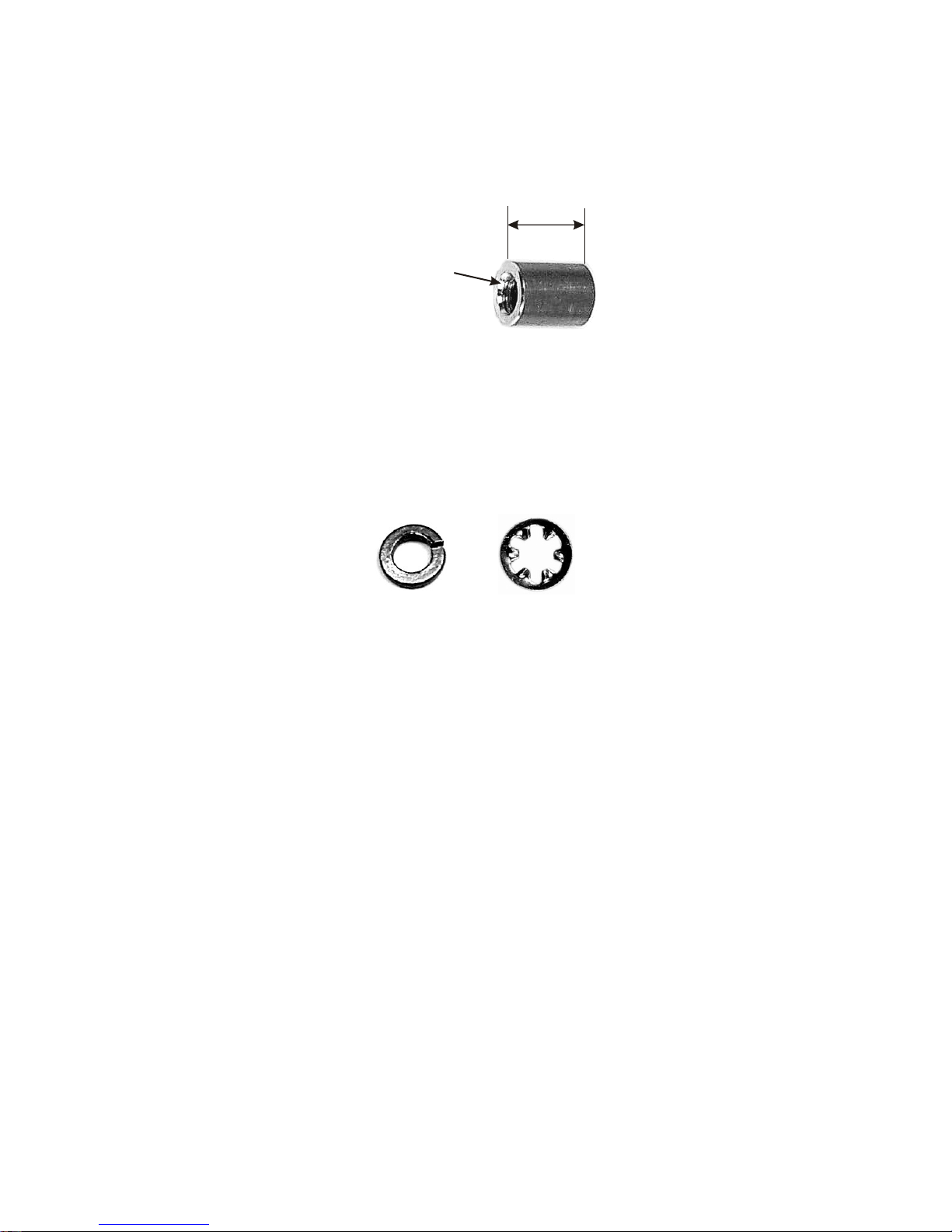

Screws.............................................................7

Standoffs .........................................................8

Lock Washers..................................................8

Assembly ......................................................... 9

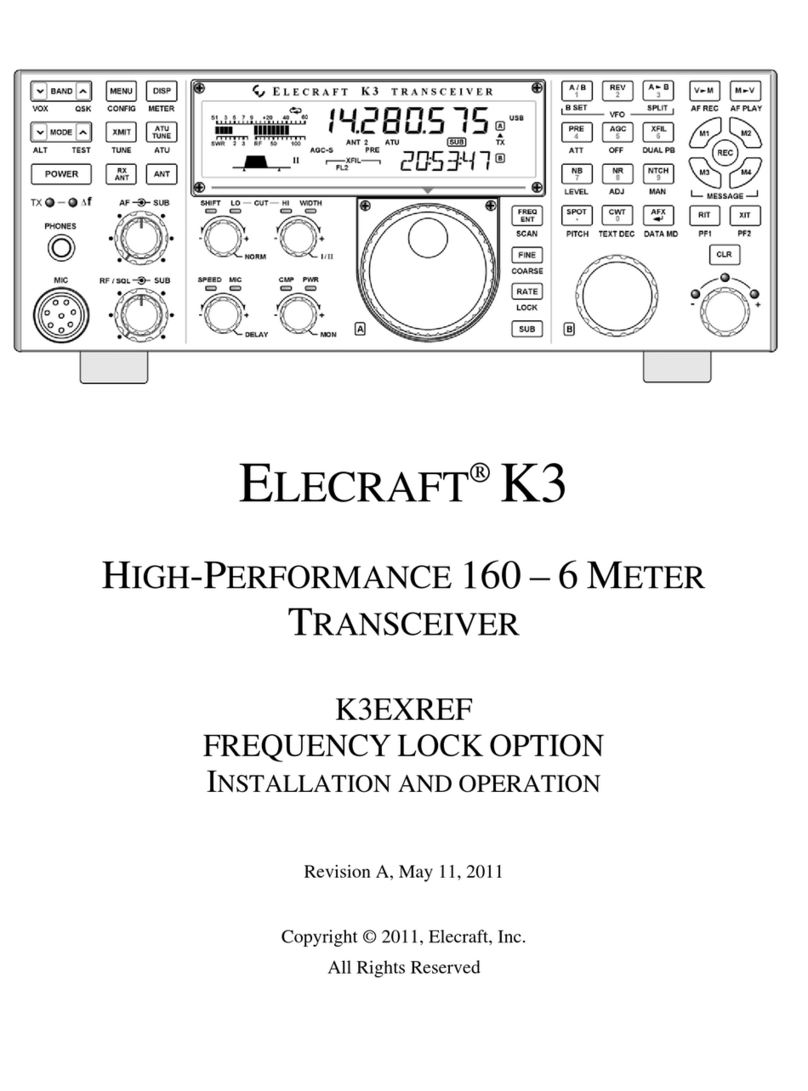

RF Board and Chassis.......................................10

RF Board Description ...................................10

RF Board and Chassis Assembly Procedure.10

KANT3 or KAT3, Right Side and Rear Panels 18

KANT3 or KAT3 Description.......................18

KANT3 or KAT3, Right Side and Rear Panel

Installation Procedure....................................18

KIO3 Interface ..................................................23

KIO3 Description..........................................23

KIO3 Interface Installation Procedure ..........23

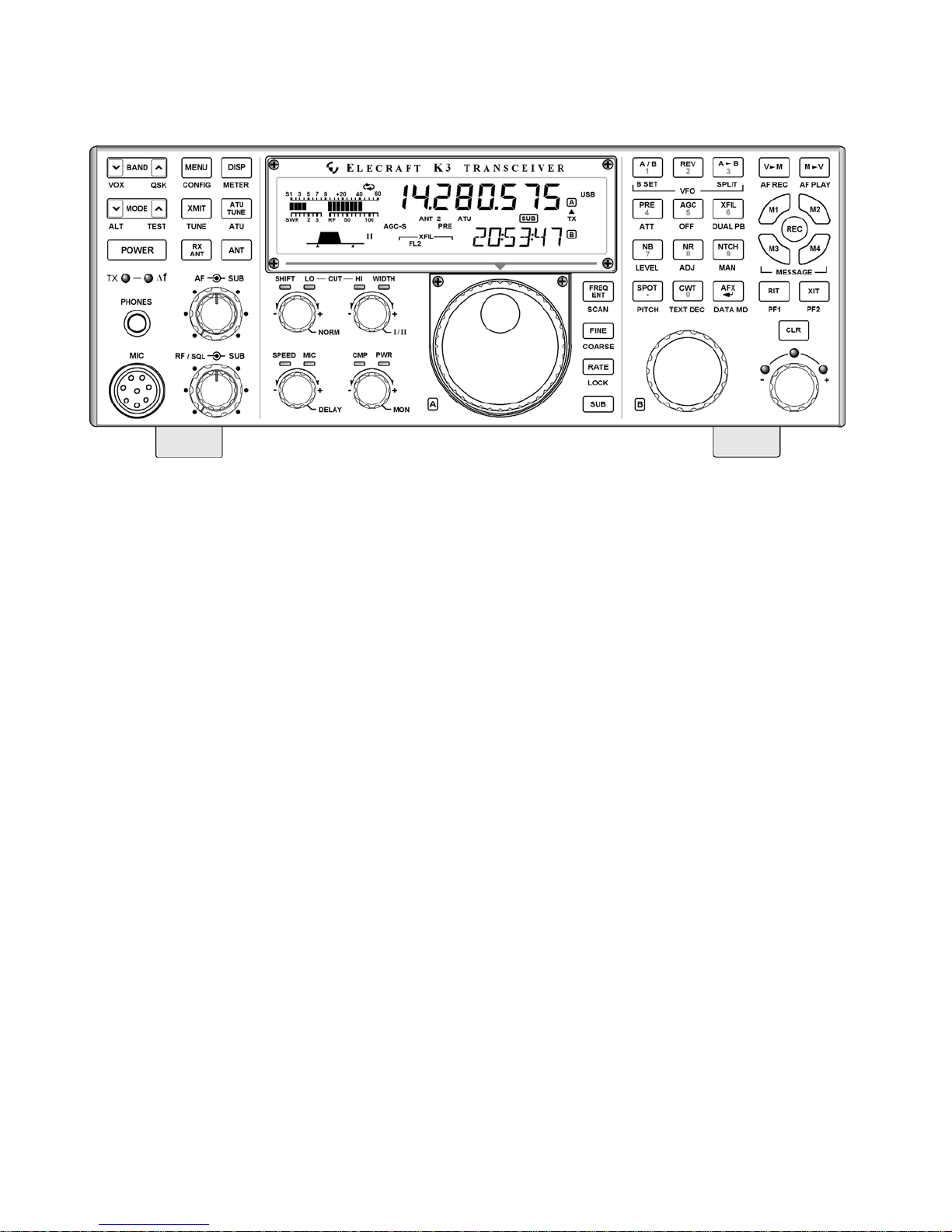

Front Panel and DSP.........................................26

Front Panel and DSP Description..................26

Front Panel Assembly Procedure..................26

Resistance Checks.........................................39

Initial Power On Check.................................40

KREF3 Reference Oscillator.............................40

KREF3 Description.......................................40

KREF3 Installation Procedure ......................40

KSYN3 Synthesizer ..........................................42

KSYN3 Description......................................42

KSYN3 Installation Procedure......................42

Loudspeaker......................................................44

Loudspeaker Description ..............................44

Loudspeaker Installation Procedure..............44

KPA3 Shield......................................................47

KPA3 Shield Description..............................47

KPA3 Shield Installation Procedure .............47

Bottom Cover....................................................49

Bottom Cover Description ............................49

Bottom Cover Hardware Installation ............49

KNB3 Noise Blanker ........................................51

KNB3 Noise Blanker Description.................51

KNB3 Installation .........................................51

Battery BT1.......................................................52

Battery BT1 Description ...............................52

Battery BT1 Installation Procedure ..............52

KBPF3 General Coverage Receive Option ......53

KBPF3 Description....................................... 53

KBPF3 Installation .......................................53

Power Amplifier Jumper Block........................54

Finishing the Enclosure .................................... 54

Fan Opening Cover....................................... 54

Bottom Covers.............................................. 55

Top Cover.....................................................56

Test and Calibration.......................................57

Initial Power Checks......................................... 57

Synthesizer Calibration.....................................58

Filter Setup ....................................................... 58

Reference Oscillator Calibration ......................58

TX Gain Calibration.........................................58

Option Modules................................................58

Enable Modules................................................58

KPA3 100-Watt Amplifier Installation ............58

Other Calibration Procedures ...........................59

Wattmeter Calibration (Optional)..................... 59

S-Meter Calibration (Optional).........................59

Appendix A, Illustrated Parts List................................ A1