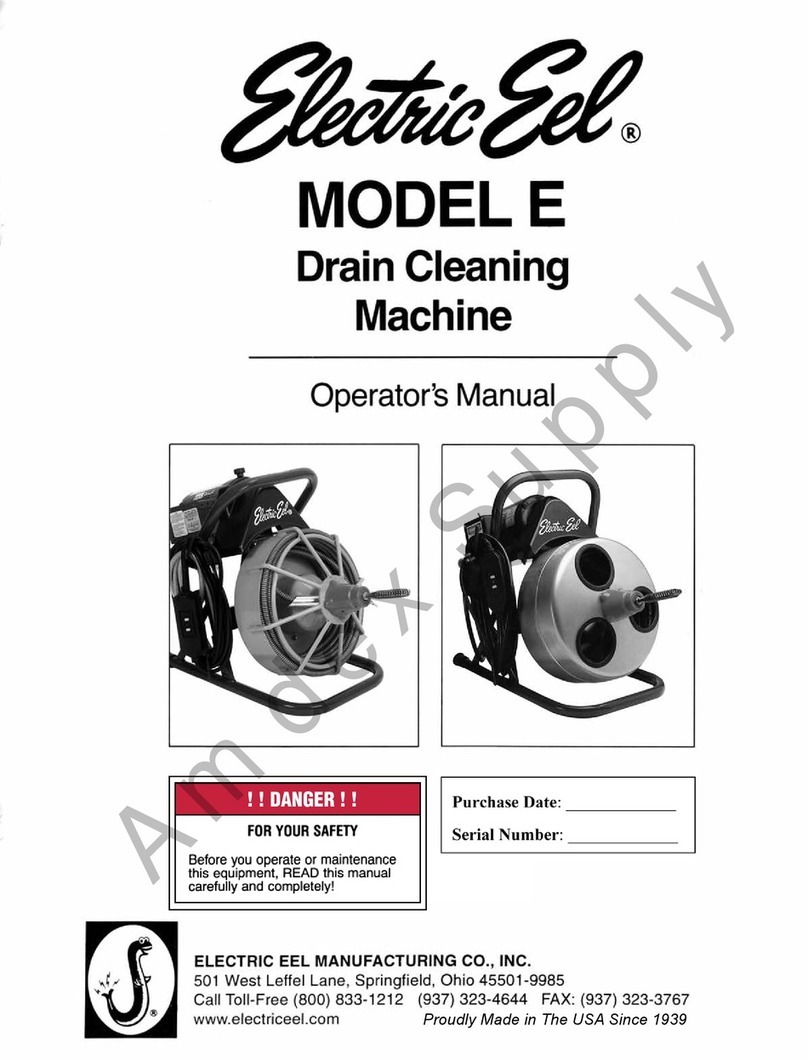

Electric Eel RF User manual

MODEL RF

Drain Cleaning Machine

Operator’s Manual

ELECTRIC EEL MANUFACTURING CO., INC.

501 West Leffel Lane, Springfield, Ohio 45501-9885

Call Toll Free (800) 833-1212 (937) 323-4644 FAX: (937) 323-3767

www.electriceel.com Proudly Made in The USA Since 1939

FOR YOUR SAFETY

Before you operate or

maintenance this equipment,

READthis manual carefully and

completely!

!! DANGER !!

The Electric Eel Model RF Drain

Cleaning machine is a professional

quality sewer and drain cleaning piece of

equipment. This machine is specifically

designed for cleaning 3” to 6” drain lines

up to 100 feet in length and features a

two-way auto cable feed for ease of

operation. A cable guide spring also

keeps hands off rotating cable near the

machine.

2

STANDARD EQUIPMENT

Electric Eel Model RF comes complete with:

•RF unit with auto cable feeder

•Cable guide spring

•100 ft. of 3/4” Tri-Max Cable

•Set of 3cleaning tools including:

!A-1DC starting drill

!U-3H grease tool(U-cutter)

!HDD-3S root saw

•1-FLSC1SC2 flexible leader

•SC-18 spanner wrench

•Tool bag to hold cleaning tools

SAFETY

INSTRUCTIONS

The following safety rules for operating

Electric Eel’s Sewer and Drain Cleaning

equipment MUST be read carefully

before operating this machine.

GENERAL SAFETY

DANGER

TO PREVENT SERIOUS BODILY

INJURY:

1. ALWAYS wear HEAVY leather

gloves and safety glasses when

operating equipment.

2. Place machine cable guide spring

at pipe opening. NEVER have

exposed cable.

3. DO NOT wear loose clothing or

jewelry while operating this

machine.

DANGER

To prevent serious injuries including:

•Shock, electrocution or burns due

to improper grounding.

•Serious injuries to body, limbs or

hands and feet due to cables that

twist, kink and break.

•Eye injuries caused by loose cable,

thrown debris or splashed water.

READ SAFTEY INFORMATION

THOROUGHLY!

3

4. Use foot switch to operate machine

while keeping good footing and

balance at all times. DO NOT

OVERREACH.

5. Machine, foot actuator and cable

should be operated by one person

only. Additional personnel in the

working area should observe all

safety instructions.

6. ALWAYS keep all guards in place

during operation.

7. ALWAYS wear rubber-soled non-

slip shoes.

8. ALWAYS avoid direct contact of

skin, facial area and especially

eyes with drain water. Chemical

compounds used in drains can

result in serious burns and other

injuries.

9. Replace fittings, cables and any

rotating parts as soon as they

become visibly worn. Replace any

cables which become fractured,

bent, kinked, or any other damage

occurs.

10. NEVER attempt to service

equipment beyond the

recommendations of the operat-

ing instructions. All other

servicing should be referred to

qualified service personnel.

11. To maintain safe operation, use

only identical replacement parts

and cables from Electric Eel.

12. ALWAYS keep clear of rotating

cages/drums, shafts, pulleys,

belts, or other rotating parts.

GENERAL SAFETY -

ELECTRICAL

DANGER

TO PREVENT SERIOUS BODILY

INJURY AND TO AVOID DANGER

FROM ELECTRICAL SHOCK:

1. ALWAYS use a Ground Fault

Circuit Interrupter (GFCI) with a

properly grounded outlet for all

electrical cords, connections, and

parts as installed by factory and

DO NOT make any alterations.

2. NEVER use machine in damp or

wet conditions.

3. NEVER expose machine to rain.

4. THE USER SHOULD NEVER

ATTEMPT TO SERVICE THE

ELECTRICAL COMPONENTS.

For safety reasons, all electrical

replacement components should

be installed by a qualified

electrician.

5. ALWAYS disconnect the

power cord from the electrical

source before making any

adjustments or changes to

power units.

6. If an extension cord is used, the

power source MUST be equipped

with a Ground Fault Circuit

Interrupter (GFCI) and properly

grounded.

4

7. Only use 10/3 or larger three-wire

extension cords with three-prong

grounding plugs and three-pole

receptacles.

8. When using an extension cord

outdoors, only use those intended

for outdoor use. (Indicated on

cord by suffix “W-A” after cord

type.)

THE GROUND FAULT CIRCUIT

INTERRUPTER

(GFCI)

This machine is equipped with a Ground

Fault Circuit Interrupter (GFCI) which is

designed to prevent a serious electrical

shock. This device should be tested on

the jobsite before putting the machine

into operation as follows:

1. To ensure protection against

electric shock, test the device

before each use. When test button

is pushed in, the indicator light

should go off. Reactivate the

device by pushing the reset button

in. If the indicator light goes on,

the device is ready for use. DO

NOT use the device if the indicator

light does not go on when reset or

if the indicator light remains on,

when the test button is pushed in.

2. This device does not guard against

electric shock resulting from

defects or faults in any wiring

supplying power to this device, or

from contact with both circuit

conductors.

GENERAL SAFETY–

ROTATING CABLES

AND EQUIPMENT

DANGER

TO PREVENT SERIOUS BODILY

INJURY AND TO AVOID DANGER

FROM ROTATING CABLES AND

EQUIPMENT:

1. USE CAUTION AT ALL TIMES.

Cable can twist or kink and

cause serious injury. Fingers or

other body parts can be caught

in rotating parts.

2. NEVER handle the rotating

cable.

3. NEVER handle any cable

under tension. Relieve all

tension build up before

attempting to handle cable.

4. NEVER operate machine without

cable guide spring in place.

5. Use feeder to advance or retract

cable with motor switch in

FORWARD position for ALL

cleaning operations.

6. DO NOT continue to operate

machine when cleaning tool

becomes stuck in obstruction.

Excess torque on a cable

could cause it to fracture.

(Refer to operating instructions

to free cleaning tool.)

5

7. NEVER force a tool and cable into

a pipeline blockage. This may

overload the cable or tool and

cause it to fracture.

8. ALWAYS wear HEAVY leather

gloves and safety glasses when

operating machine.

9. Use correct tool for the job or

application. Check the tool

listing for the correct tool and

line size.

10. To maintain safe and efficient

operation, thoroughly clean all

cables with water after use.

Acids in the drain and sewer

lines attack and deteriorate the

metal of the cables and tools.

Deterioration will cause

weakness in cable and tools and

result in fracture or breakage. A

light coating of oil applied to the

cable before storing will help

prevent rusting and premature

failure.

11. Replace all cables and tools that

become deteriorated, worn,

kinked, bent, or any other

damage that occurs.

MACHINE SET-UP

DANGER

TO PREVENT SERIOUS BODILY

INJURY:

NEVER USE ANY CABLE IN THIS

MACHINE OTHER THAN ELECTRIC

EEL 3/4” DIAMETER CABLE.

DISCONNECT POWER CORD

BEFORE ANY SET UP OR

MAINTENANCE IS ATTEMPTED.

This machine comes completely

assembled except for the cable guide

spring. Simply connect cable guide

spring to feeder with snap pin. (See

Figure #1)

Figure 1

6

TOOL SELECTION

It is important to choose the proper

cleaning tool for each cleaning

application. See the tools outlined

below.

Standard Tools Included with the

Model RF Kit:

1. SC-18 Spanner Wrench

2. U3H Grease Tool (U-Cutter)

3. HDD-3S Root Saw

4. A-1DC Starting Drill Tool

5. 1-FLSC1SC2 Flexible Leader for

Negotiating P-Traps

OPERATING

INSTRUCTIONS

DANGER

OPERATOR MUST BE

THOROUGHLY FAMILIAR WITH

ALL SAFETY INSTRUCTIONS

BEFORE OPERATING

EQUIPMENT.

FOR AUTOMATIC CABLE

FEEDER

1. WITH POWER OFF, attach a

small spear-type cleaning tool to

the end of the cable. This tool

will enable you to bore a starter

hole in the obstruction, allowing

backed-up water to drain.

NOTE: The flexible leader should

be used with the A-1DC Starting

Tool when negotiating P-Traps or

severe bends in the line.

2. Place machine cable guide spring

at pipe opening. NEVER have

exposed cable.

3. Position foot actuator for easy

operator accessibility.

4. Make sure switch is in

FORWARD position. Run

machine in FORWARD at all

times during cleaning operation.

5. Place one HEAVY leather gloved

hand on the cable guide spring

to control cable as it rotates

inside; and use other hand to

work the feeder control lever.

DANGER: Operator must keep one

HEAVY leather gloved hand on

cable guide spring at all times

during operation.

1

234

5

7

6. WITH POWER ON, in order to

feed cable, the operator must

move the feeder control lever from

NEUTRAL (the position midway

between FORWARD and REVERSE)

to the FORWARD position, while

depressing the foot actuator. (See

Figure #2 for FORWARD feeder

position)

Figure 2

NOTE: The speed at which the cable

is fed initially can be controlled by

moving the control lever toward

FORWARD to increase speed and

moving back toward NEUTRAL to

slow speed.

NOTE: If the feeder control lever is

initially put in FORWARD but the

cable is not advancing, then turn the

cable tension knob in a clockwise

direction until the cable begins to

advance. (See Figure #3)

DO NOT over-tighten cable tension

knob as it may damage feeder

bearings.

Figure 3

7. Continue to automatically feed

cable until obstruction is met.

When cable begins to drag or

rotation becomes difficult, move

the lever to the NEUTRAL

position and allow tool to cut

away at the obstruction. (See

Figure #4 for NEUTRAL feeder

position)

Figure 4

DANGER: NEVER force the cable

or tool into the obstruction. Choose

the proper feeding speed in order to

give a smooth cutting action.

8

8. If tool becomes hung up in the

obstruction, move control lever to

the REVERSE position to back

out tool. (See Figure #5)

Figure 5

9. After tool has been removed

from obstruction, move control

lever back to the FORWARD

position and continue to work

through obstruction.

10. To retrieve cable from line,

move control lever to the

REVERSE position (while

continuing to operate cage in

forward rotation) and cable will

back out of line and feed into

cage.

NOTE: It is recommended to use a

continuous flush of water to clean

tool, cable and sewer line as cable is

retrieved.

11. When tool is close to cleanout

opening, return Control Lever to

NEUTRAL position, place switch

in OFF position, release foot

actuator and allow machine to

come to a complete stop.

DISCONNECT POWER CORD.

12. Pull remaining cable and tool

from drain line and hand-feed

cable back into machine.

MAIN SEWER OR SEPTIC

TANK OVERUN

Operator should determine the

approximate distance from cleanout

opening to the main sewer or septic

tank. Overrunning cable into these

areas can cause cables to twist or

knot-up preventing their retrieval.

Table of contents

Other Electric Eel Ultrasonic Jewelry Cleaner manuals