Electrical Test Instruments MAC-20 User manual

MEMORY AMMETER CONTROLLER

MAC-20

INSTRUCTION MANUAL

Firmware Version 1.85 and above

Electrical Test Instruments, Inc.

1301 Avondale Road, Suite J

New Windsor, MD 21776

www.ETIPrecision.com

(410) 857-1880

Fax (410) 857-1387

Electrical Test Instruments MAC-20

Section III –MAC-20

==============================================================================

==============================================================================

Copyright(C) 1994-2004 Electrical Test Instruments, Inc. All Rights Reserved

Page III-1

MAC-20 Specifications

INPUT POWER:

120 VAC, SINGLE PHASE

50/60 HZ, 20 VA Max

CURRENT RANGES:

0-1,000 / 5,000 / 25,000 / 100,000 Amperes

CURRENT ACCURACY:

+/- 0.5% Reading + 0.5% Range + 1 Digit (Continuous)

+/- 1.0% Reading + 1.0% Range + 1 Digit (Pulse > 0.01 sec)

TIMER RANGES:

0-9.999 / 0-99.99 / 0-999.9 / 0-9999 Seconds

0-999.9 / 0-9999 Cycles

TIMER ACCURACY:

+/- 0.005 sec +/- 0.005% of reading +/- 1 count

DIMENSIONS AND NET WEIGHT

Height: 7.0 in. (178 mm)

Width: 19.0 in. (483 mm)

Depth: 6.0 in. (152 mm)

Weight: 10 lb. (4.55 kg)

STANDARD ACCESSORIES

Remote Initiate cable 1 S-B143

Contact Leads 1 pair S-A108

Electrical Test Instruments MAC-20

Section III –MAC-20

==============================================================================

==============================================================================

Copyright(C) 1994-2004 Electrical Test Instruments, Inc. All Rights Reserved

Page III-2

MAC-20 Unit Circuitry

The current measurement function of most breaker test sets is based on the

principle of an air core inductor, which may be used to sense a magnetic field,

which is proportional to the rate of change of current flowing in an adjacent

conductor. The output voltage of the inductor is therefore proportional to the

rate of change of current in the conductor. For practical purposes, the sensing

inductor is usually made in the form of a split core, or "fork", which fits closely

around the current-carrying buswork.

In the measurement system, in this case the MAC-20, the signal from the cur-

rent sensor (typically about 240 mV for 1000 Amperes), is connected to an inte-

grator, consisting of precision resistors and a capacitor. This signal is processed

by a variable-gain instrumentation amplifier, and a digitally programmable

gain circuit. An analog to digital converter (ADC), under microprocessor con-

trol, reads this signal to a precision of 12 bits (+/- 0.025%). This circuitry is con-

tained on a single PC board, originally developed for the Electrical Test Instru-

ments ORTMASTER system.

The heart of the MAC-20 consists of a microprocessor core unit, based on the

Zilog Z180, with associated ROM, RAM, and other circuitry, and manufactured

by ZWorld Engineering under the trade name SmartCore. It is connected to a

motherboard, which contains a regulated power supply, some support cir-

cuitry, and two programmable peripheral interface (PPI) IC's. One PPI is con-

figured as a Centronics parallel interface, and controls the A/D subsystem de-

scribed above. The other PPI interfaces to the keyboard / display PC board, de-

scribed below. Software contained in the ROM, (also known as "firmware"), per-

forms the required real-time data collection, measurement, user interface, and

output control functions.

The keyboard / display PC board contains virtually all of the hardware for the

user interface (LED displays and keyboard), as well as contact sensing and out-

put initiation circuitry. The eight LED digits are multiplexed, and have limited

alphanumeric capability for more flexible indication of such conditions as over-

range. The keys are scanned at roughly 30 times per second, and incorporate

LED's to indicate status. An audible indicator (beeper) sounds when a key is

pressed. The contact sensing circuit-

ry uses the key scanning system, with a transformer for isolation. The sensing

signal is a repetitive pulse of low voltage and low current, and contact sensing

leads may be handled without fear of shock. Two separate optically isolated

signals are provided for output initiation with an electromechanical contactor

or SCR. All functions of the keyboard / display PC board are handled by a single

PPI.

Electrical Test Instruments MAC-20

Section III –MAC-20

==============================================================================

==============================================================================

Copyright(C) 1994-2004 Electrical Test Instruments, Inc. All Rights Reserved

Page III-3

MAC-20 Software

A complete description of the software is beyond the scope of this manual;

however, the following brief overview may enhance your understanding of the

MAC-20. The SmartCore is based on a Zilog Z180 processor running at 9.216

MHz. Its instructions, written in C and assembly language, are contained in a

socketed EPROM, and data is stored in self-contained static RAM. The Z180

contains a programmable reload timer (PRT), which is set to provide an inter-

rupt at a rate of 1200 per second. A watchdog timer provides reset control and

protection from software hangup conditions.

Much of the processing takes place in the interrupt service routine (ISR), which

is executed 1200 times per second. This ISR reads the A/D converter, processes

the data, and determines the presence or absence of current. It also functions

as the main timer for pulse time measurement, and determines the repetition

rate of other processes. The multiplexing of the LED display, and the scanning

of the keyboard, are also handled by the ISR, but at slower rates of 300 times

per second or less.

While not servicing the ISR, the software executes an idle loop, which updates

information to the display, and performs functions requested by new key-

strokes.

Electrical Test Instruments MAC-20

Section III –MAC-20

==============================================================================

==============================================================================

Copyright(C) 1994-2004 Electrical Test Instruments, Inc. All Rights Reserved

Page III-4

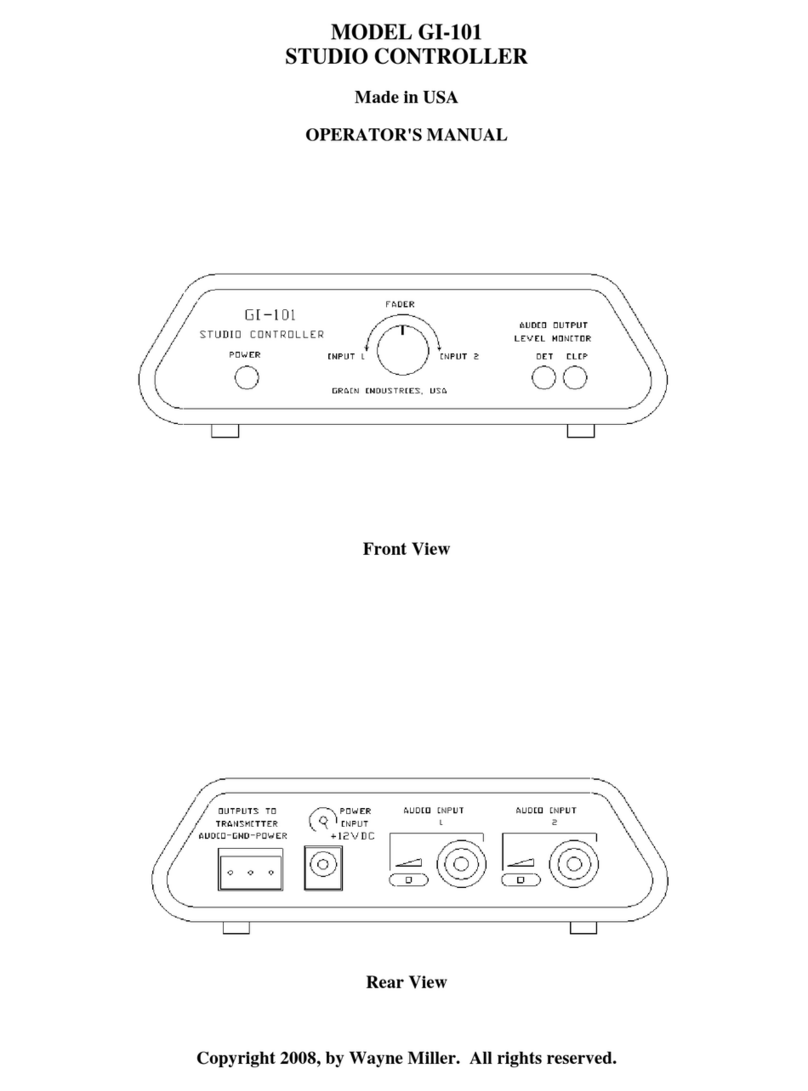

MAJOR PARTS IDENTIFICATION AND OPERATION

MAC-20 Control Panel

TIME DISPLAY: This 4 digit LED display normally indicates the elapsed time of

a current pulse. In SECONDS mode, it displays time up to 9.999 seconds, then

autoranges to 99.99 seconds, 999.9 seconds, and 9999 seconds. In CYCLES

mode, it reads time (based on 60 Hz), up to 999.9 cycles, then autoranges to

9999 cycles. If time exceeds maximum display capacity (10,000 seconds or

10,000 cycles), the display will read "OVER". In PRESET mode, the display indi-

cates the maximum time of initiation (ON time), in either cycles or seconds. A

reading of zero disables the PRESET function, and allows any time.

CURRENT DISPLAY: This 4 digit LED display indicates the output current. In

CONTINUOUS mode, as well as in MEMORY mode before and during a test,

the display indicates true-RMS output current in real time. After completion of

a test, in MEMORY mode, the display shows the true-RMS value as computed

over the entire length of the pulse. This mode is indicated by a flashing LED on

the MEMORY key. If a reading exceeds the maximum value for the selected

range, the display will read "OVER".

This display is also used to indicate peak RMS and last average current.

After a test, when the timebase is in cycles mode, press the STOP key to dis-

play the value of the RMS current based on the highest peak reading. This

peak value is also used for the trip current reading if the breaker trips before

the preset time. This may be higher than the true RMS value of the entire

pulse, because of spikes and DC offset, or current dropoff as the breaker trips.

When the timebase is in SECONDS mode, press the STOP key to display the

last average RMS value displayed in CONTINUOUS mode. This is useful for

pickup tests. It may not be accurate for times less than 1 second.

INITIATE key: This key is used to turn ON the output of the test set. The LED in

the key indicates that the MAC-20 is attempting to turn the output ON, but

other conditions (such as interlocks) could keep the output from actually turn-

ing on. In MOMENTARY mode, the key must be held to keep output current

on. In MAINTAIN mode, once current is detected, the output will stay on until

the breaker trips, or the STOP or RESET button are pressed. The MAC-20 must

be RESET in order to initiate output, and in N.C. or N.O. contact modes, the

contact status (continuity) must indicate that the breaker is closed. If the out-

put on time exceeded the PRESET time, as indicated by flashing of the

PRESET key LED, the INITIATE key will automatically reset the MAC-20 and

turn the output on.

STOP key: This key is used to turn the output of the test set OFF. Its LED

Electrical Test Instruments MAC-20

Section III –MAC-20

==============================================================================

==============================================================================

Copyright(C) 1994-2004 Electrical Test Instruments, Inc. All Rights Reserved

Page III-5

indicates that output is not being turned on by the MAC-20, but other condi-

tions could cause output voltage to be ON. Use of this key is usually necessary

only when in MAINTAIN mode, and it is necessary to abort the test before the

breaker trips. NOTE: It is important to realize that the interlock system of the

circuit breaker test set may also turn the output off, but it will turn back ON

when the interlock condition is cleared (in N.O. and N.C. modes only).

The STOP key is also used to access peak RMS and last average RMS val-

ues. See description of CURRENT DISPLAY for details.

RESET key: This key resets the displays on the MAC-20, and arms the pulse

reading system. The LED on the key indicates that the system is reset and

armed. RESET also takes the unit out of PRESET ADJUST mode.

PRINT key combination: On models equipped with a printer option, the STOP

and RESET keys may be pressed simultaneously to send the time and current

readings in ASCII format to a printer or other device, via the serial port.

MAINTAIN key: This key toggles the MAINTAIN mode for initiation; its LED indi-

cates that this mode is enabled. When in MAINTAIN mode, the INITIATE key

need only be pressed briefly to turn output on. MAINTAIN must be set in order

to read pulse current when output is initiated by means other than the MAC-

20.

For test sets with motorized vernier, the MAINTAIN key may be pressed

while output is ON to provide automatic current hold. The LED in the

MAINTAIN key will blink while this mode is set, and the vernier motor will be

activated whenever the current varies more than 5 amperes from the value

displayed when the key was pressed. The key may be pressed again to return

to normal mode. STOP or RESET will also discontinue current hold.

SIMULATOR key combination: Pressing the LATCH and RESET keys simultane-

ously toggles the SIMULATOR mode. In this mode, the INITIATE key produces

a simulated current pulse of 2.4 cycles, or 0.040 seconds, with an amplitude

about ½ full scale. When in SIMULATOR mode, the unit will beep once every

three seconds.

N.O. key: This key is used to set the Normally Open contacts mode. In this

mode, lack of continuity on the CONTACTS binding posts indicates that the

protective device under test is in its normal (non-tripped) mode, and ready to

accept current. In N.O. mode, after the INITIATE key is pressed, the timer starts

when current (about 3% of range) is detected. The timer stops when the STOP

key is pressed or continuity is sensed at the CONTACTS binding posts. Timing

accuracy in this mode is typically +/- 0.01 seconds.

N.C. key: This key is used to set the Normally Closed contacts mode. In this

Electrical Test Instruments MAC-20

Section III –MAC-20

==============================================================================

==============================================================================

Copyright(C) 1994-2004 Electrical Test Instruments, Inc. All Rights Reserved

Page III-6

mode, continuity on the CONTACTS binding posts indicates that the protec-

tive device under test is in its normal (non-tripped) mode, and ready to accept

current. This mode may be used for testing multi-pole breakers by connecting

the CONTACTS binding posts to an unused pole. In N.C. mode, the timer starts

as soon as current (about 3% of range) is detected after the INITIATE key is

pressed, and stops when the STOP key is pressed or a break in continuity is

sensed at the CONTACTS binding posts. Timing accuracy in this mode is typi-

cally +/- 0.01 seconds.

C.L. key combination: When the N.O. and N.C. keys are pressed simultaneously,

both LEDs light, indicating C.L. mode (Current Latch). This is the normal

power-up default mode for the test set, and is recommended for all tests, un-

less there is a good reason for using contacts to sense trip. In this mode, cur-

rent is continuously sampled, and when it exceeds approximately 10% of the

current range value, the timer starts, and calculation of pulse current begins.

When current stops (or drops below a dynamically determined threshold

value), the timer stops running, and the final value for pulse current is calcu-

lated and displayed. If the output was initiated by the MAC-20, it is turned OFF.

NOTE: in C.L. mode only, the contacts jacks may be used for remote initiation

(see below).

PRESET key: This key toggles the PRESET ADJUST mode, indicated by illumi-

nation of its LED. When PRESET ADJUST is active, the adjacent SECONDS and

CYCLES keys respectively lower and raise the preset time in seconds or cycles,

depending on the timebase that was selected. Both keys may be pressed sim-

ultaneously to reset the time limit to zero, which disables the time limit func-

tion. When not in PRESET mode, the LED will flash if the displayed time ex-

ceeds the preset limit.

SECONDS key: This key normally selects the SECONDS timebase. If the

PRESET mode is selected, this key is used to LOWER the preset time limit by

decrements of 1.000 second (5.000 seconds above 10.00) with the SECONDS

timebase, or 1.0 cycles with the CYCLES timebase. If it is held, the reading will

decrease at a rate of about 5 intervals per second. If a preset time limit was set

in SECONDS mode, the output will be turned off within 200 milliseconds of

the limit. SECONDS or CYCLES timebase may be selected at any time before,

during, or after a test.

CYCLES key: This key normally selects the CYCLES timebase. If the PRESET

mode is selected, this key is used to RAISE the preset time limit by increments

of 1.000 seconds (5.000 seconds above 10.00) with the SECONDS timebase, or

1.0 cycles with the CYCLES timebase. If it is held, the reading will increase at a

rate of about 5 intervals per second. If a preset time limit was set in CYCLES

mode, the output will be turned off within several milliseconds after the limit

Electrical Test Instruments MAC-20

Section III –MAC-20

==============================================================================

==============================================================================

Copyright(C) 1994-2004 Electrical Test Instruments, Inc. All Rights Reserved

Page III-7

has been reached. SECONDS or CYCLES timebase may be selected at any time

before, during, or after a test.

MEMORY key: This key toggles the MEMORY mode, indicated by illumination

of its LED. When in CONTINUOUS mode (LED off), the current display always

reads the real-time continuous output current of the test set. In MEMORY

mode (LED on), the current display will read the continuous output current

until the test is complete. At this time, the LED will flash, and the display will

read the computed true-RMS value of the entire current pulse for the duration

indicated on the TIME display. This key may be pressed at any time before,

during, or after the test, to toggle between the two modes.

As described above, pressing the STOP key provides access to display of

peak RMS and last average RMS current.

1000 A range key: This key selects the 1000 ampere range, which provides best

accuracy of readings up to about 1000 amperes. Nominal currents close to this

limit, when applied to the device under test, will sometimes cause higher peak

currents, causing the display to read "OVER", indicating an overrange condi-

tion. If this happens, select the next higher range. Pressing any range switch

will also RESET the MAC-20.

5 KA range key: This key selects the 5.000 KA range, for output currents up to

about 5,000 amperes. See above for information common to all ranges.

25 KA range key: This key selects the 25.00 KA range, for output currents up to

about 25,000 amperes. See above for information common to all ranges.

100 KA range key: This key selects the 100.0 KA range, for output currents up to

about 100,000 amperes. See above for information common to all ranges.

CONTINUITY lamp: This LED lights when continuity is detected at the

CONTACTS binding posts in N.O. and N.C. modes. The beeper will also sound

whenever contacts change state.

CONTACTS/REMOTE jacks: These jacks provide a low-power AC signal which

detects continuity in N.O. and N.C. modes, or is used with a pushbutton cord

switch for remote initiate function (see below). A resistance of about 100 ohms

or less will be interpreted as continuity. Although the signal is low power and

transformer isolated, it is good practice to avoid touching any conductive sur-

face connected to these terminals. CAUTION: NEVER CONNECT THESE

TERMINALS TO ANY LIVE CIRCUIT!

REMOTE INITIATE: In C.L. mode only, the CONTACTS jacks provide a remote in-

itiate function. For safety reasons, this function is disabled in MAINTAIN mode,

Electrical Test Instruments MAC-20

Section III –MAC-20

==============================================================================

==============================================================================

Copyright(C) 1994-2004 Electrical Test Instruments, Inc. All Rights Reserved

Page III-8

unless a preset value is set in CYCLES timebase.

SERIAL port: This standard serial port may be connected to a printer, com-

puter, or other device to print or store time and current values of test results in

ASCII format. It is set for 9600 baud, 8 bits, 1 stop bit, no parity. This information

is sent at the end of each test, or by pressing the Stop and Reset keys.

REMOTE TERMINAL JACK: This RJ-12 modular jack provides a six wire connec-

tion to a remote serial terminal, which provides complete monitor and control

functions as well as advanced features such as serial number entry and

date/time functions. Complete details will be provided with special firmware

for this option.

Electrical Test Instruments MAC-20

Section III –MAC-20

==============================================================================

==============================================================================

Copyright(C) 1994-2004 Electrical Test Instruments, Inc. All Rights Reserved

Page III-9

MAC-20 Internal Parts

INPUT CONNECTOR: This connector, located on the upper rear corner of the

MAC-20, provides 120 VAC control power, and connects to the air core CT (cur-

rent sensor), and initiate circuitry of the test set. The wiring of this connector is

essentially compatible with that of the EIL Accu-Amp, and is designed to facili-

tate removal of the MAC-20 for service or shipment. Additional pins are used to

provide isolated logic level control for motorized vernier raise and lower for the

current hold feature.

ANALOG INTERFACE PC BOARD: This PC board, located near the input con-

nector, contains all of the MAC-20 analog circuitry. It has two potentiometers

for zero offset, and one potentiometer for gain. On older versions, it also pro-

vides unregulated 10 VDC for the I/O board

MICROPROCESSOR I/O BOARD: This PC board, located adjacent to the analog

interface, contains a regulated power supply and support circuitry for the mi-

croprocessor core module, and programmable peripheral interfaces for the

analog board and keyboard / display board. It also supplies regulated 5 VDC for

the keyboard / display board. Its power supply is derived from a 16 VCT AC

source, which is also used for zero crossing detection required for programma-

ble initial phase angle. There are also two serial ports, one of which is used for

the remote serial terminal, and the other used for interface to a computer or

serial printer.

MICROPROCESSOR CORE MODULE: This small PC board, manufactured by

ZWorld Engineering and called the SmartCore, contains a Zilog Z-180 micro-

processor, crystal controlled clock, support circuitry, static RAM, and socketed

program EPROM. If changes to firmware are required, the EPROM must be re-

placed. THIS SHOULD BE DONE ONLY BY PERSONNEL EXPERIENCED IN

HANDLING STATIC SENSITIVE ELECTRONIC COMPONENTS.

KEYBOARD / DISPLAY BOARD: This large PC board, located on the front panel,

contains both LED displays and all keys used in the MAC-20. It also contains an

audible beeper, and circuitry for the continuity light, contacts sensing, and

output initiation. It connects to the motherboard with a 26 pin ribbon cable

and a two conductor power cable.

Electrical Test Instruments MAC-20

Section III –MAC-20

==============================================================================

==============================================================================

Copyright(C) 1994-2004 Electrical Test Instruments, Inc. All Rights Reserved

Page III-10

Figure II-2: MAC-20 Front Panel

TIME CURRENT

Electrical Test Instruments, Inc.

Model MAC-20

Monitor Ammeter Controller

SERIAL PORT

TERMINAL

Electrical Test Instruments MAC-20

Section III –MAC-20

==============================================================================

==============================================================================

Copyright(C) 1994-2004 Electrical Test Instruments, Inc. All Rights Reserved

Page III-11

SERVICE INFORMATION AND DOCUMENTATION

MAINTENANCE AND CALIBRATION OF THE MAC-20

The MAC-20 is manufactured using solid state components that should not re-

quire extensive maintenance. However, the accuracy of the MAC-20 is critical

to the testing of circuit breakers, and is dependent upon the output of an air-

core current sensing coil, which could change due to movement caused by

shock or vibration encountered in transporting the test set. Other factors

which may affect calibration are contact resistance in the control cable, unu-

sual magnetic fields, insulation leakage, and aging of electronic components

in the MAC-20. Therefore, proper operation and calibration should be checked

at regular intervals, and adjusted if proper equipment is available.

The inherently delicate nature of electronic circuitry and metering make it

generally inadvisable to leave the MAC-20 fastened into the breaker test set

while it is being transported, and subject to shock and vibration. The standard

rack-mount hardware and twist-lock connector make it simple to remove the

MAC-20 and carry it separately. Suggested periodic maintenance consists of

the following:

1. Clean the lenses of the LED displays with a plastic cleaner.

2. Clean the front panel with a soft brush and cloth.

3. Perform basic field operational check as described below.

Field calibration of the MAC-20 may be performed as follows:

1. Obtain a current measuring calibration standard capable of reading TRUE-

RMS current up to at least 1000 Amperes to an accuracy of at least 0.25%.

This may consist of a shunt or current transformer, in conjunction with a

digital multimeter or laboratory grade AC ammeter.

2. Set up the breaker test set for normal breaker testing. If adjustments are

anticipated, remove the MAC-20 from the test set and remove the top

cover.

3. Connect the calibration standard to the desired output tap. If cables are

used, it is recommended that they be twisted so as to minimize radiation

and pickup of stray magnetic fields.

4. Apply power to test set, and allow at least one minute for circuits to stabi-

lize.

Electrical Test Instruments MAC-20

Section III –MAC-20

==============================================================================

==============================================================================

Copyright(C) 1994-2004 Electrical Test Instruments, Inc. All Rights Reserved

Page III-12

5. Check ammeter zero in all ranges. If reading on current meter is greater

than 1% of range, internal zero adjustment may be required.

6. Set MAC-20 Range to 1000 A, and adjust output of breaker test set to ex-

actly 800 Amperes. If Coarse Tap is 1, and Output Control Vernier is less

than 50%, additional resistance must be added to output circuit. This is im-

portant, because waveform distortion is more prevalent at lower levels.

7. If the MAC-20 reading differs from the standard by more than rated accu-

racy, adjust the gain potentiometer on the analog board for proper read-

ing. If an error of more than 5% is noted, and unit has been in service, the

accuracy and validity of previous tests may be questionable; otherwise,

there may be a problem in the test setup.

8. Check calibration at 200, 400, 600, and 1000 Amperes.

9. Adjust the current to zero, and press RESET key.

10. Raise the current slowly, until the timer begins to run. This is the Current

Latch Threshold, which should be about 10% of range.

11. Set the current at 50% of full scale (500 A), and stop the current.

12. Set the MAC-20 to MEMORY mode, and press the RESET Switch.

13. Initiate a fast momentary pulse of no more than 6 cycles (0.1 Sec) duration.

The meter should read the same value, within 1% of reading + 1% of range,

that was set in step 11 above.

14. Check pulse reading operation in this manner for currents of 200, 400, 600,

and 1000 Amperes, and varying duration.

15. Set Timer Timebase to SECONDS. Press Master Reset Switch. Set N.O.

mode. Using a stopwatch, initiate for exactly ninety (90) seconds. Timer

should read 90.00 Seconds, +/- 0.01 Seconds. (Note: actual reading may

vary because of inability to control and measure pulse length.)

16. If everything checks out, the MAC-20 can be assumed to be in calibration,

and no other adjustments are required.

Electrical Test Instruments MAC-20

Section III –MAC-20

==============================================================================

==============================================================================

Copyright(C) 1994-2004 Electrical Test Instruments, Inc. All Rights Reserved

Page III-13

PARTS LIST (MAC-20):

The overall schematic is on the following pages. The parts list is provided

below. Please refer to both when ordering replacement parts.

ITEM

QTY

DESCRIPTION

REF DES

Part Number

1

1

Connector, Male, 16 pin

J1

M-C134

2

11

Connector Pin, Male

J1

M-A127

3

1

Fuse Holder, Chassis

XF1

M-B177

4

1

Fuse, 2A, 250 V, SloBlo

F1

M-B178

5

1

Transformer, 120 VAC/16VCT

T1

M-C145

6

1

LED lens, Green

XDS1

M-B133

7

2

Banana Jack, Yellow

BP1,2

M-B175

8

1

PC Board, Display/Keypad

PCB1

S-B101

9

1

PC Board, MAC20 I/O

PCB2

S-B102

10

1

PC Board, Analog signal

processing

PCB3

S-B103

11

1

Ribbon Cable Ass’y, DB25

S-A102

12

1

Ribbon Cable Ass’y, 26 pin

S-A103

13

1

Serial Interface cable ass’y

S-A106

14

1

RJ12 jack ass’y

S-B116

15

2

Handle, brass, nickel plated, 4”

M-C103

16

2

Display frame, red lens

M-B136

17

14

Push Button LED Indicator Switch

M-B137

18

1

Line Filter

M-C177

19

4

Spacer, 4-40X3/4

M-A122

20

1

MAC-20 Front Panel

M-D105

21

1

MAC-20 Chassis Enclosure

M-D107

22

1

MAC-20 Top Cover

M-D108

Electrical Test Instruments MAC-20 Retrofit Package

Section III –MAC-20

===============================================================================================================

=============================================================================================================

Copyright(C) 1994-2003 Electrical Test Instruments, Inc. All Rights Reserved

OVERALL SCHEMATIC (MAC-20):

Electrical Test Instruments MAC-20 Retrofit Package

Section III –MAC-20

==============================================================================

==============================================================================

Copyright(C) 1994-2003 Electrical Test Instruments, Inc. All Rights Reserved

Electrical Test Instruments Retrofit Package

Section V - Service Information and Documentation

==============================================================================

WARRANTY

Electrical Test Instruments, LLC, will correct any defect

in workmanship or material for two years after date of

purchase of any Electrical Test Instruments product.

Such corrective measures will be limited to repairing or

replacing the unit, at Electrical Test Instruments' option.

This limited warranty shall not apply to equipment

which has been subjected to negligence, accident or

damage by operation, maintenance or storage, or to

non-normal use or service. This limited warranty does

not cover reimbursements for transportation, removal,

installation, repair or replacement, except as may

otherwise be specifically agreed to in writing by

Electrical Test Instruments. The foregoing is in lieu of all

other warranties expressed or implied, and all other

obligations or liabilities whether arising under contract,

negligence or otherwise, on the part of Electrical Test

Instruments. In no event shall Electrical Test

Instruments be liable for consequential or special

damages, including but not limited to loss of use, loss of

income, loss of profit or cost of replacement.

Other manuals for MAC-20

1

Table of contents

Other Electrical Test Instruments Controllers manuals

Popular Controllers manuals by other brands

AP

AP CGM user manual

Tekmar

Tekmar House Control 401 Quick setup guide

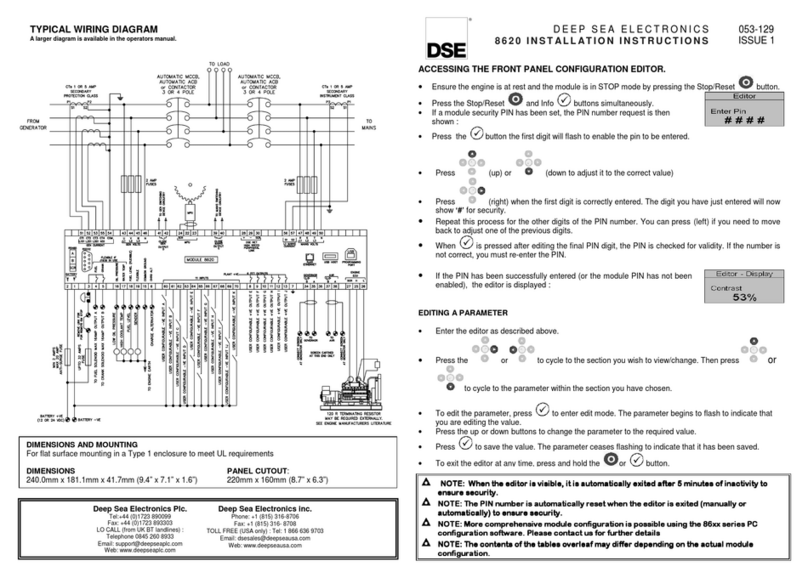

Deep Sea Electronics Plc

Deep Sea Electronics Plc 8620 Installation instructions and instructions for use

Pixlip

Pixlip 410164 user manual

White Rodgers

White Rodgers 50X57-843 installation instructions

Long range

Long range MT4300 quick start guide