INTRODUCTION AND WARNINGS

1

INTRODUCTION

This manual is a guide to the efficient use of the machine and also contains practical information concerning the

functioning, adjustments and user maintenance of your new scrubber/drier. Your machine has been designed and

constructed to ensure maximum performarnce and ease of operation in a wide variety of applications. Before delivery, the

machine has been tested in our factory and by our distributor to ensure that it is delivered to you in perfect condition. To

maintain the machine in this condition and guarantee functioning without problems, it is essential that the periodic

maintenance operations indicated in this manual are properly carried out. Before using the machine, carefully read this

manual and keep it within easy reach for your future reference. Indications of “LEFT” and “RIGHT” are as seen from the

operator position. If you should need any further information concerning the machine, please do not hesitate to contact

either Electrolux Euroclean or our local distributor.

MODIFICATIONS AND IMPROVEMENTS

Electrolux Euroclean aim toward continuous improvement of its machines and reserves the right to carry out modifications

and improvements whenever necessary without being obliged to update machines which have been sold previously.

SAFETY

You too can avoid accidents.

No accident prevention programme is effective without the total co-operation of the person directly responsible for the

functioning of the machine. The majority of accidents which may occur either during work or transferring the machine from

site to site are caused by the non-observance of the most elementary safety rules. An alert and cautious operator is the best

guarantee against accidents and is more effective than any other part of an accident prevention programme.

The machine must be switched off and disconnected from either its battery or mains supply before any servicing or

adjustment of operational parts be carried out. Ensure that any assistant is clear of the machine and that covers are closed

before switching on.

GENERAL SAFETY RULES

The rules below have to be followed carefully in order to

avoid damages to the operator and to the machine.

- Read the labels carefully on the machine; Do not cover

them for any reason and replace them immediately if

damaged.

- The socket for the power supply must be fitted with a

standard earthing (ground) system.

- With the brushes in working position, avoid touching or

passing over the mains cable. Avoid damaging by

squashing, bending or stressing.

- Where there is damage to the mains cable, stop the

machine, take off the plug from the mains system, and

replace the damaged cable immediately by calling the

Electrolux Service department.

- Do not mix different detergents, avoiding harmful odours.

- Do not place any liquid containers onto the machine.

- The storage temperature has to be between +15°C and +

55°C.

- The perfect operating temperature should be between 0°

C and 40° C.

- The humidity should be between 30 and 95%.

- Do not use the machine in explosive atmosphere.

- Do not use the machine as a means of transport.

- Do not use acid solutions which could damage the

machine.

- Avoid working with the brushes when the machine stands

still, in order to prevent floor damages.

- Do not vacuum iflammable liquids.

- In case of fire, use a powder extinguisher. Do not use

water.

- Do not strike shelvings or scaffoldings, where there is

danger of falling objects.

- Adapt the utilization speed to the adhesion conditions.

- Do not exceed over the limit gradient stated, to avoid

conditions of instability (2% max).

- The machine has to carry out simultaneously the

operations of washing and drying. Different operations

have to be carried out in areas which are not permitted

for the passage of non employed staff. Signal the areas

of moist floors with suitable signs.

- If the machine does not work properly, check by

conducting simple maintenance procedures. Otherwise,

it is better to ask for technical service.

-Where parts are required, ask for ORIGINAL spare parts

to an agent and/or to an authorized dealer.

- For any maintenance operation take off the power supply

from the machine.

- Do not take off the pieces which require the use of tools

to be removed.

- Do not wash the machine with direct water jets or with

high water pressure not with corrosive material.

- Every 200 working hours have a machine check through

a service department.

- The machine should not be abandoned, because of the

presence of toxic-harmful materials (batteries, oil etc.).

This disposal must be subject to the rules which provide

for its scrapping in appropiate centres.

- The machine does not cause any harmful vibrations.

24

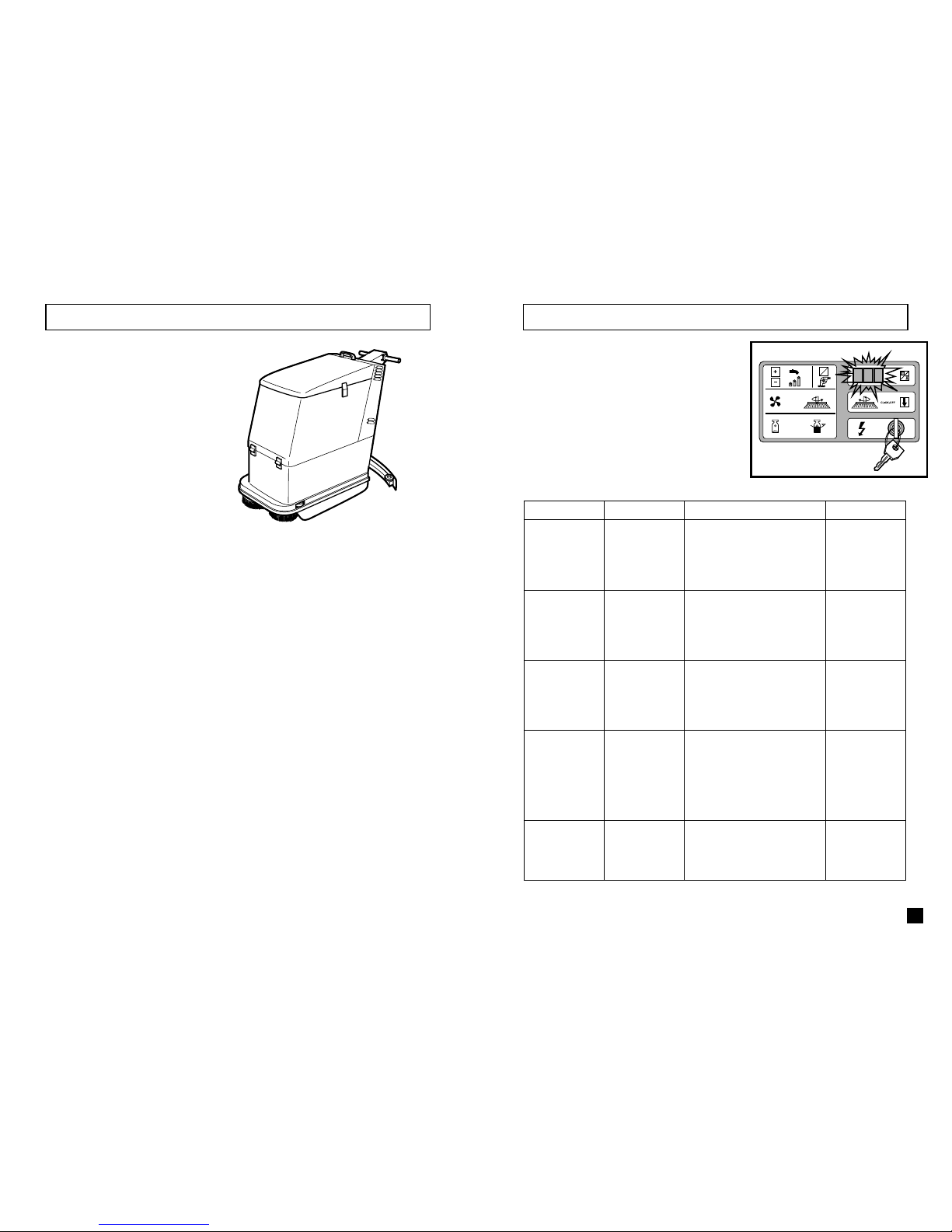

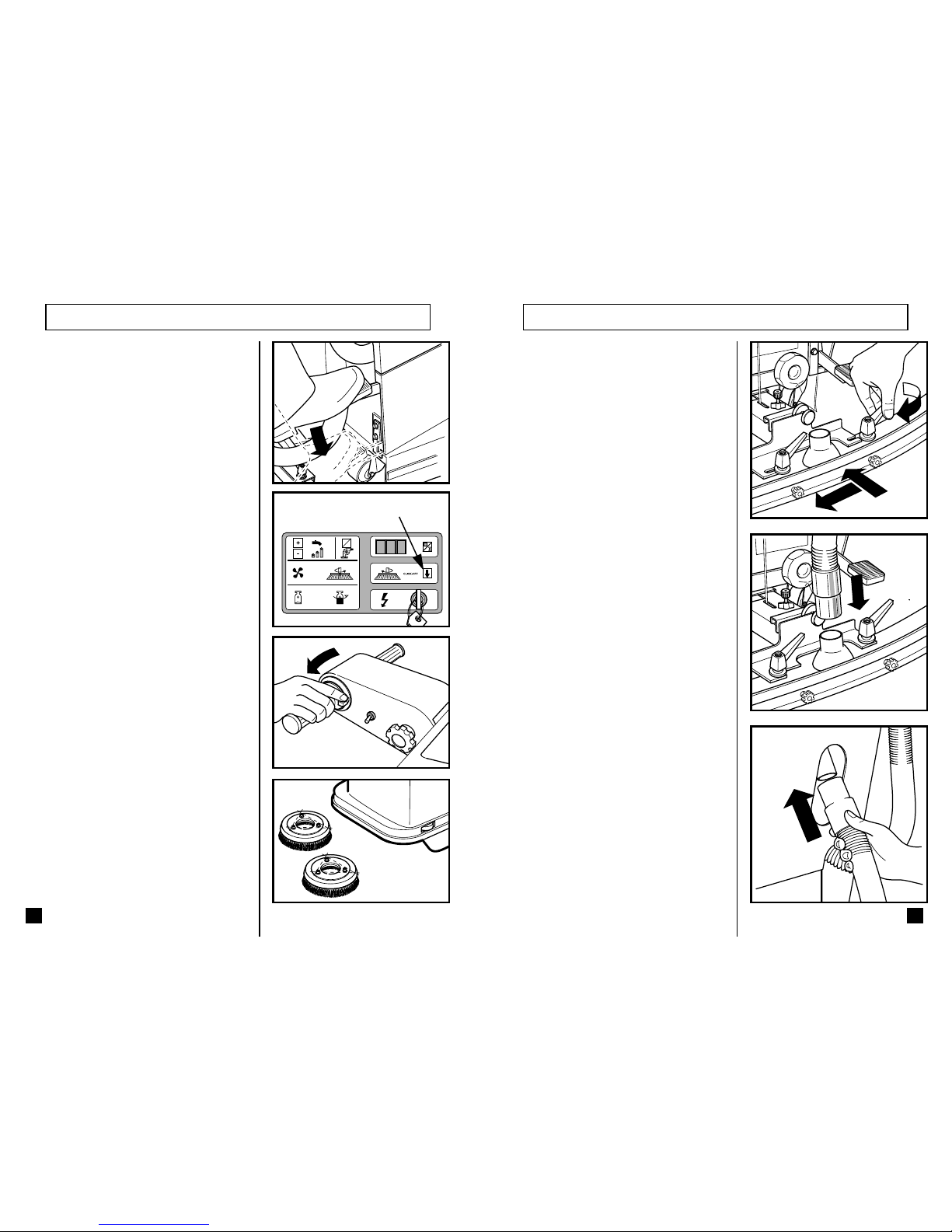

SAFETY FEATURES

For all models:

Safety micro switch:

Micro switch to shut off all the functions when the

tank unit is in the upright position. (SEMKO

APPROVAL).