13.0Replacing/Setting

of

Disposable

Blades

Disconnectmachinefrompowerbefore

servicing!

Remove

fence.

Loosenhex.

bolts

of

lock

bar

with

toolset'sspanner

SW

10

mmby

turning

the

bolts

clockwise

(into

the

lockbar).Removelockbar

completewithbladefromcutterblock.Cleanlock

bar,lock

bar

seat

and

bladefromchips

and

dust

withoilyrag.Reverseblade

orfit

fresh

one

onto

lockbar.Placeassemblyintocutterblock

and

secure

in

place

by

turninghex.bolts-counter-

clockwise,

at

thisstageonlytightenboltslightly.

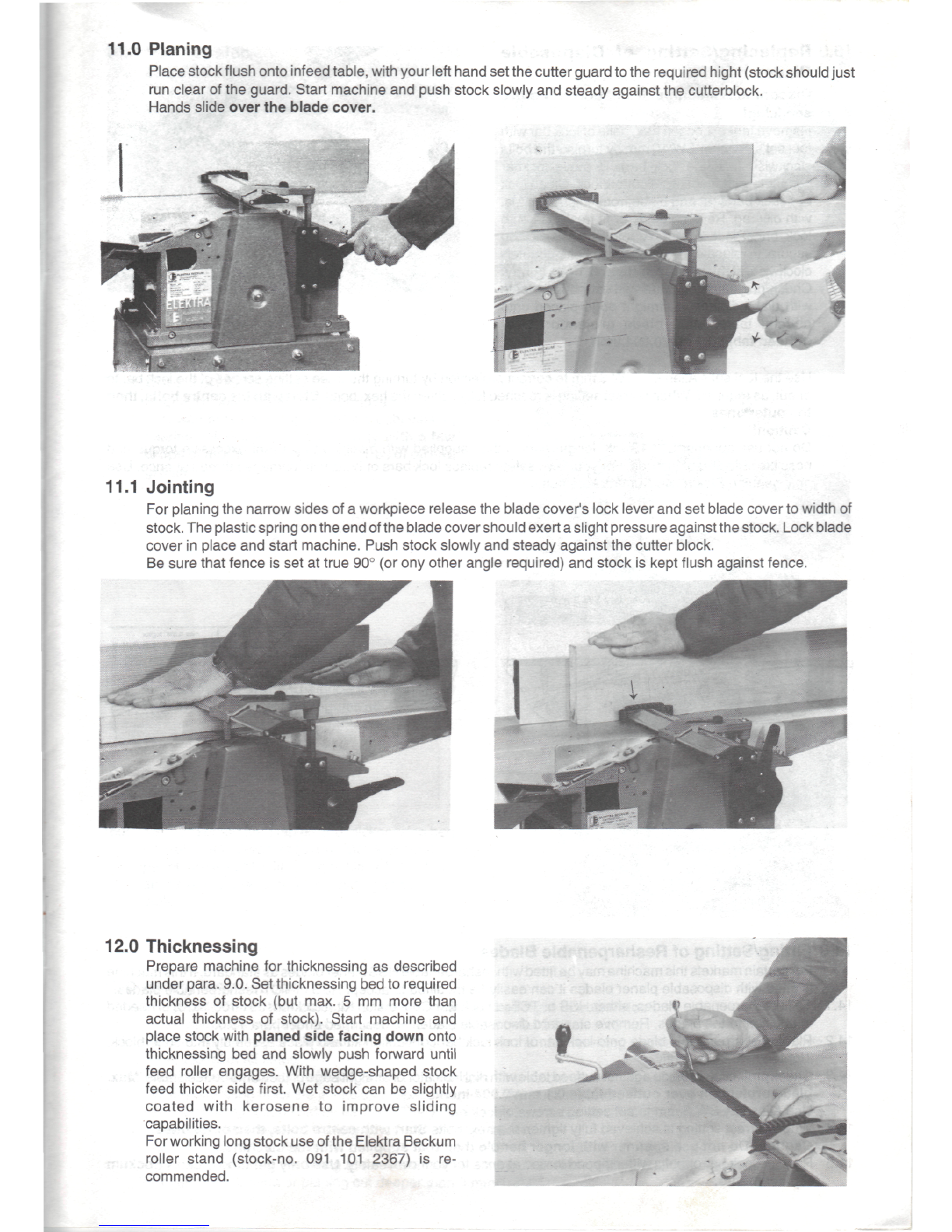

Checkprojection

of

bladeagainstoutfeedtable

withdialindicator

or

straightedgeplacedonto

outfeed

table.Max.bladeprojectionover

outfeedtable

0.1

mm/0.004inch.

Usethe

toolset'sAllen

keySW3 mmto

correctprojection

by

turning

the

threesettingscrews

ofthe

lock

barin

or

out,

as

required.Whencorrectsetting

is

reached

fully

tighten

the

hex.bolts.Startwith

the

centrebolts,then

the

outer

ones.

Caution!

Do

notuse

spanner

SW10

withlongerhandlethansuppliedwithmachine

to

preventexcessivetorque

and

possiblestripping

of

threads.

For

your

own

safetyreplacelockbars

or

boltswithdamagedthread

at

once.

Use

onlygenuineElektraBeckumreplacements.

i--~

Allen

keySW3 mm

Dialindicator

14.0

Fitting/Setting

of

ResharpenableBlades

For

certain

markets

thismachine

may

be

fittedwithresharpenable

HSS

planer

blades

as

standard.

If

thismachine

is

fittedwithdisposableplanerblades

itcan

easily

be

modified

to

accept

HSSorTCT

resharpenableblades.

14.1

To

fit

resharpenableblades,either

HSSor

TCT,

a

Lock

Bar

Conversion

Kit

(stock-no.

091

100

1020)

is

needed

in

addition

tothe

blades.Removestandarddisposableblades

as

descripedunderpara

13.0.

14.2

Placeresharpennablebladeontolock

barof

locklock

bar

conversion

kitand

placeassemblyintocutterblock.

Tighten

hex.

bolts

lightly.

14.3

Checkprojection

of

bladeagainstoutfeedtablewithdialindicator

or

straightedgeplacedontooutfeedtable.Max.

bladeprojectionoveroutfeedtable

0.1

mm/0.004inch.

Use

Allen

keySW3 mmtoset

settingscrews

of

lockbar.

14.4

Whencorrectsetting

is

achieved

fully

tighten

the

hex.boltsStartwithcentrebolts,thenouterones.

Caution!

Donotuse

spanner

with

longer

handle

than

that

supplied

with

the

machine.

14.5

Replacelock

baror

bolts

with

strippedthread

at

once

for

your

own

safety.

Use

onlygenuineElektraBeckum

replacements.