Table of Contents

SECTION 5: ACCESSORIES ......................... 29

SECTION 6: MAINTENANCE ......................... 30

Schedule ...................................................... 30

Cleaning ....................................................... 30

Replace/Adjust ............................................. 30

V-Belts ......................................................... 30

Lubrication ................................................... 32

SECTION 7: SERVICE ................................... 33

Troubleshooting ........................................... 33

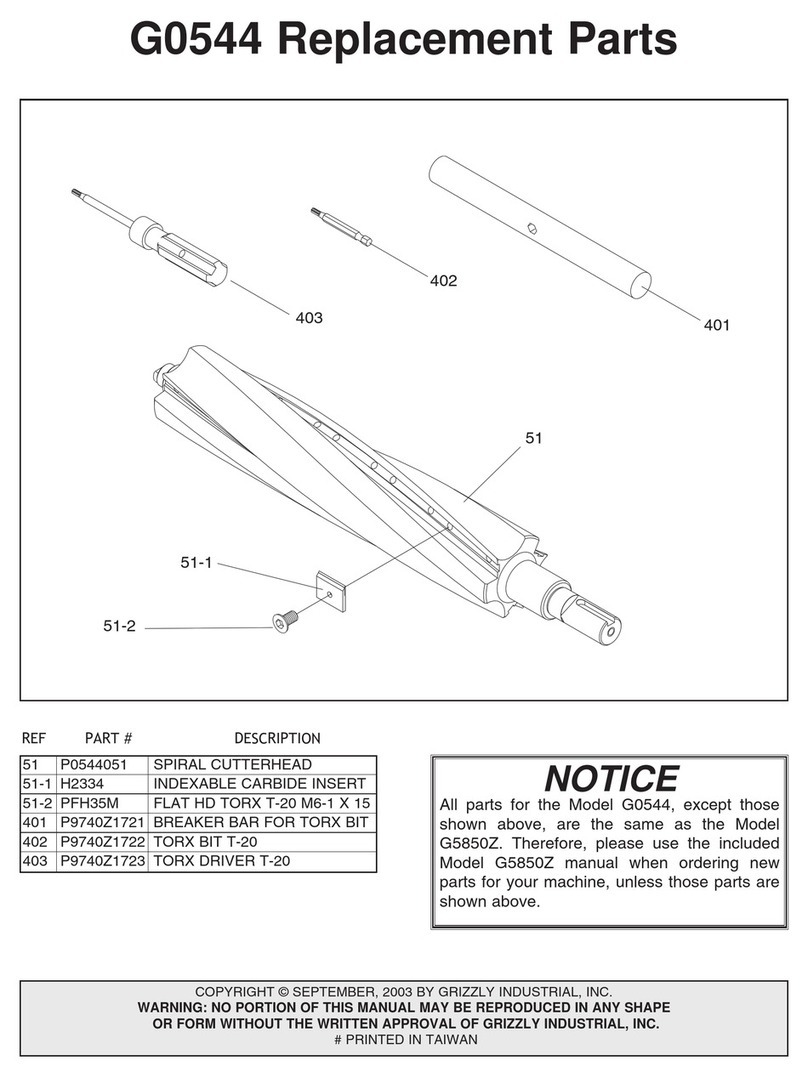

Rotating/Changing Carbide Cutters ............. 35

Table Chain Tension .................................... 36

Table Parallelism ......................................... 36

Adjust Infeed/Outfeed Rollers

& Pressure Bar ............................................ 38

Adjust Chipbreaker ...................................... 40

Adjust Depth Scale ...................................... 40

Adjust Table Gibs ........................................ 41

Calibrate Table Roller Scale ........................ 41

Anti-Kickback Fingers .................................. 42

V-Belt Pulley Alignment ............................... 42

Infeed Roller Tension ................................... 43

Outfeed Roller Tension ................................ 44

Pressure Bar Tension .................................. 44

Digital Control Calibration ............................ 45

Electrical Components ................................. 46

Overview Wiring Diagram ............................ 48

Electrical Box 220V Wiring Diagram ............ 49

Controls Wiring Diagram .............................. 50

Motor Wiring Diagram .................................. 51

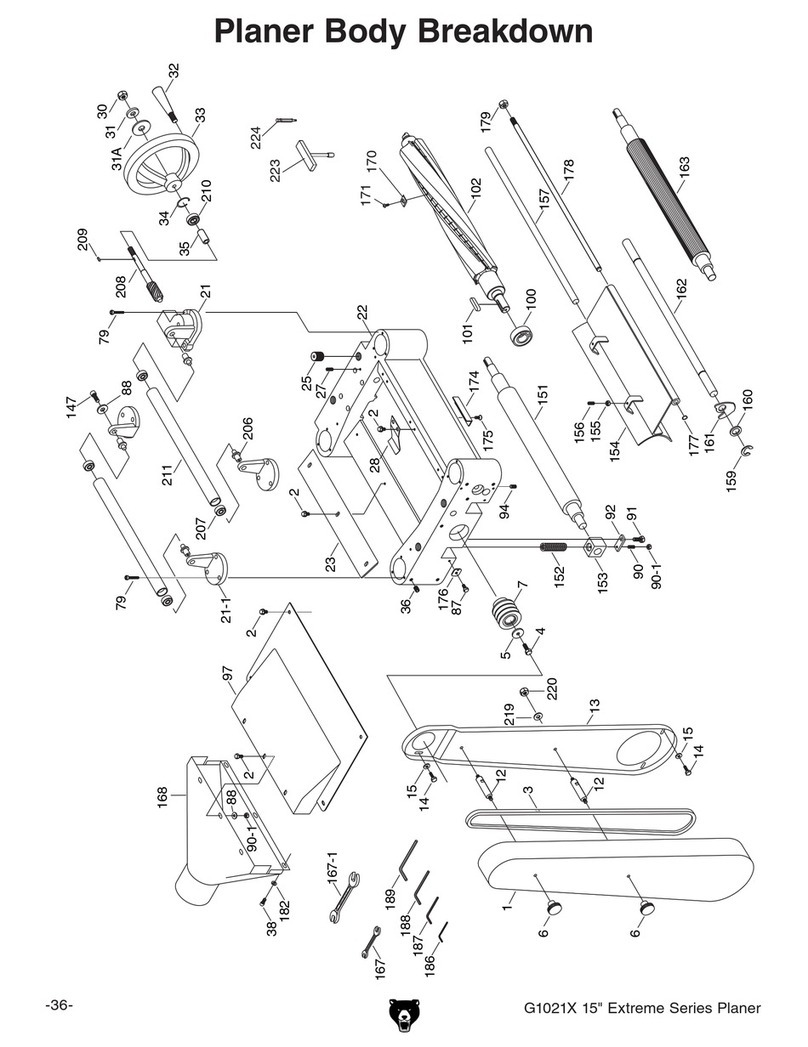

Base Parts Breakdown ................................ 52

Column Parts Breakdown ............................ 55

Electric Parts Breakdown ............................. 57

Gearbox Parts Breakdown ........................... 59

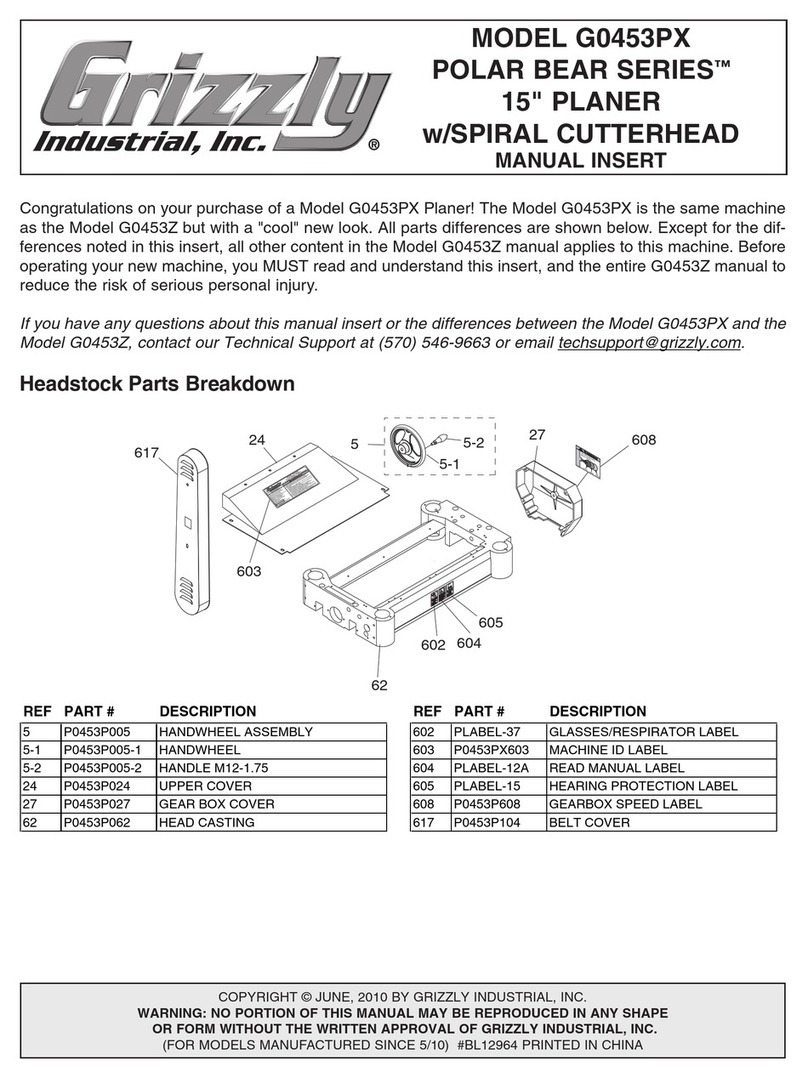

Headstock Parts Breakdown ....................... 61

Table Parts Breakdown ............................... 63

Label Placement .......................................... 65

WARRANTY AND RETURNS ........................ 69

INTRODUCTION ............................................... 2

Foreword ........................................................ 2

Contact Info ................................................... 2

Machine Data Sheet ...................................... 3

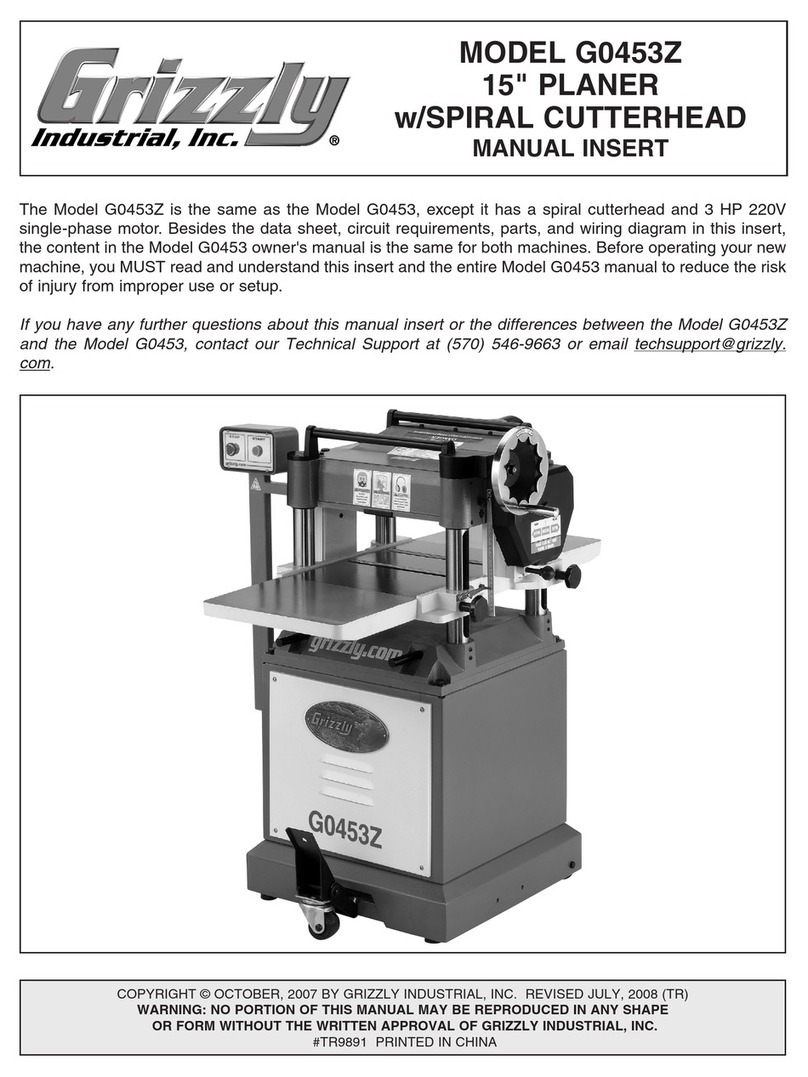

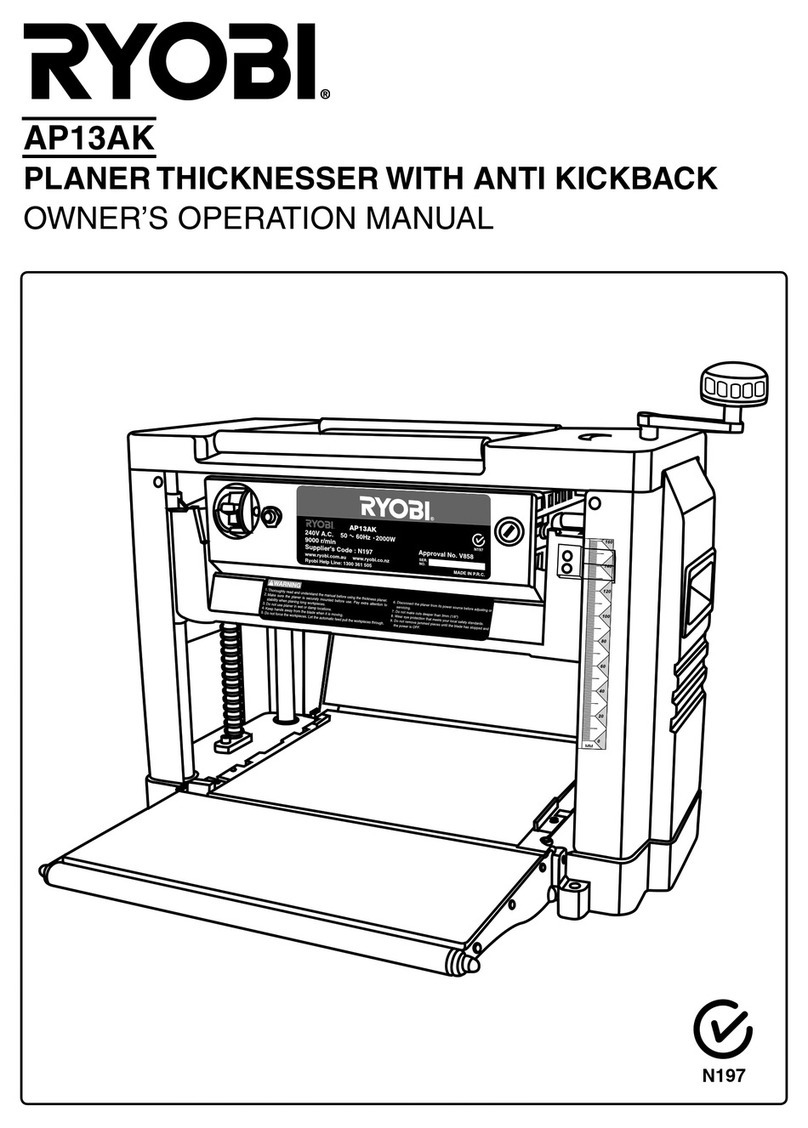

Identification of Planer Features .................... 5

Identification of Controls ................................ 6

Identification of Planing Components ............ 7

SECTION 1: SAFETY ....................................... 8

Safety Instructions for Machinery .................. 9

Additional Safety Instructions for Planers .... 10

SECTION 2: CIRCUIT REQUIREMENTS ...... 11

220/440V 3-Phase ....................................... 11

Grounding .................................................... 11

Phase Converter .......................................... 11

Rewiring to 440V ......................................... 12

SECTION 3: SETUP ....................................... 13

Setup Safety ................................................ 13

Items Needed for Setup ............................... 13

General Inspection ....................................... 13

Inventory ...................................................... 14

Clean Up ...................................................... 15

Site Considerations ...................................... 15

Lifting and Moving ........................................ 16

Mounting to Shop Floor ............................... 17

Table Extension Wings ................................ 18

Dust Hood .................................................... 19

Dust Collection ............................................. 19

Cutterhead/Feed and Table

Gearbox Oil Levels ...................................... 20

Connecting to Power ................................... 20

Test Run ...................................................... 21

Safety Feature Tests ................................... 21

Tighten V-Belts ............................................ 23

Recommended Adjustments ........................ 23

SECTION 4: OPERATIONS ........................... 24

Operation Safety .......................................... 24

Table Handwheel ......................................... 24

Power Controls ............................................ 25

Basic Operation ........................................... 27

Operation Tips ............................................. 27

Power Feed Rate ......................................... 28

Table Rollers ................................................ 28