Elektral Tru-VEND Maxi-Kafe Specification sheet

1

“SHE SELLS, YOU EARN!... ®”

Maxi-Kafe®

INSTRUCTIONS FOR USE &

MAINTENANCE MANUAL

Version: 19.05

Headquarters & FACTORIES:

Elektral® Elektromekanik San. Ve Tic. A.S.

Izmir Ataturk Industrial Zone

M.K.Ataturk Blv.23 Cigli

35620 Izmir -TURKIYE

Phones : +90(0) 232-376 7300

Fax : +90(0) 232-376 7030

www.elektral.com.tr

2

CONTENTS PAGE

INTRODUCTION..................................................................................................................... 3

OPERATION AND SAFETY WARNINGS .............................................................................. 4

1 - GENERAL DESCRIPTION................................................................................................ 6

2 - MAIN UNITS ..................................................................................................................... 7

3 - TECHNICAL SPECIFICATIONS......................................................................................13

4 - INSTALLATION AND CLEANING ..................................................................................14

5 - PRODUCT LOADING AND INITIAL OPERATION.........................................................15

6 - PROGRAMMING............................................................................................................15

7 - MAINTENANCE AND CLEANING..................................................................................29

8 - USB MENU .....................................................................................................................29

9–MENU TREE ....................................................................................................................30

10 - SERVICE CENTRE AND CERTIFICATE OF WARRANTY...........................................32

3

INTRODUCTION

Dear User,

Thank you for purchasing the Maxi-Kafe® vending machine, a product manufactured by

ELEKTRAL. As a company developing integrated production, our quality certified production has

continued since 1978 based on high technology. This integration can be broadly described as

R&D, Electronics, Electromechanics, Production Lines, Mechanics Workshop, Moulding

Workshop, Plastic Injection and Vacuum Forming Group. With T.R. State Planning

Organization's various incentives, the factory has reached an approximately 20,000 m2

production area with the capability of making many electronic machines and components for

professional use. Most of our machines have been produced for the first time in our fatherland.

Starting with Germany, our company is technologically cooperating in terms of production,

representation and OEM production with the sector’s leading companies from UAE, Bulgaria,

India, Great Britain, Iran, Israel etc. We have direct or indirect exports to countries in Europe,

Asia, America, Africa. Furthermore, to expand our direct sale markets in foreign countries our

intensive works and exhibition activities continue uninterruptedly. As a result of our rapidly

growing export potential, our company has been awarded with a first place prize in 2004,

during "Rising stars of e-commerce in Turkey" competition. The same year we were awarded

with the “25’th Anniversary Award of EBSO (Aegean Area Chamber of Industry), “The Chamber

of Industry, Innovation, Employment” with continuous R&D projects being supported by

TUBITAK (Turkish Scientific Research Council). In 2011 Istanbul Chamber of Industry has

chosen our company as "INNOVATION FINALISTS". In the year 2012, with it’s innovative

Vending Machine project, Elektral has been awarded as an “TET (Turkish Electro Technology)

R&D Project Market Finalist” by the Ministry of Economy, Turkish Export Assembly and IMMIB

(Istanbul Mining and Metal Exporters Union). Another award won by Elektral is “The year 2013

First Rank in Innovation” organised by IAOSB (Izmir Ataturk Industrial Zone)-Ege University.

Believing that real growth target is to be achieved with a global industrial understanding and a

global move, Elektral is motivating all it’s employees with this understanding and continues

rapidly with an intensive R&D work to reach determined goals.

Tru-VEND® vending machines have been designed and produced to provide more spare time

to its owners. They ease your life in various situations with multipurpose and practical use. Our

products provide you profit and comfort for 24 hours continuously, loyal to the owner, with no

employee costs. Please note that as for all industrial machines, its necessary to periodically

check and maintain your machine. Please use the machine as recommended in this manual

ELEKTRAL PRODUCTS ARE PRODUCED IN ENVIRONMENTAL

FRIENDLY FACILITIES, CAUSING NO HARM TO THE NATURE

AND LIVING CREATURES.

Made in Turkey

Alteration rights reserved

No claims can be accepted by our firm regarding the

applications of this instrument from the second or third

parties.

All rights Reserved

4

Operation and Safety Warnings

Procedures & Safety Warnings before using the Maxi-Kafe®

Technical specifications of Maxi-Kafe®

Preparation for Maxi-Kafe®‘s installation

Programming, usage and related procedures of Maxi-Kafe®

The arrow-end lightning symbol inside the

equilateral triangle informs that there is high

amount of ‘un-insulated’ dangerous voltage to

cause an electric shock inside the product.

The exclamation mark inside the equilateral

triangle informs the user that there are important

instructions of usage and information inside the

booklets given with the equipment.

5

Maxi-Kafe ®Pre use, to do list and safety warnings

Do not wet the Maxi-Kafe®machine. Always unplug from the electricity

plug before proceeding and use only a damp cloth (not wet) to clean the

vending machine.

This is an electrical machine and there is a risk of electricity shock. Only

authorized, qualified and well informed personnel may operate and service

the machine.

Use the vending machine on Earthed Electrical Supply only.

Please carefully read the articles where you see this Warning Sign in the

User’s Manual.

Maxi-Kafe®is designed to operate between given electrical voltage

limitations only. 220 (±%10) VAC / 50 Hz

WARNING: Please follow the instructions given in the User’s Manual.

Incorrect usage can cause damage to the Vending Machine and/or

humans and the environment.

6

1- GENERAL DESCRIPTION

The Vending Machine that you have chosen has been produced by our factory using high

technology systems in parallel with other developing technologies and modern aesthetic design

providing versatile usage. Tru-VEND® Vending Machines can be used in all public areas such as

hotels, factories, hospitals, restaurants, clinics, cinemas, bus terminals, gas stations, doctor &

lawyer offices, malls, etc. Backwards traceability is also possible on the performed machine

modifications by the serial number on each machine.

International norms, in conformity with CE Norms and produced under ISO 9001: 2015 QMS.

All components are made of ROHS compliant Human Health Friendly production materials.

32-bit high performance ARM processor control with MDB/EXECUTIVE, EVA DTS protocol support

Distant connection and control via computer

Suitable for all monetary units

Easy user friendly interface and control menu

User friendly Graphic LCD display

20 buttons direct selection keypad

18 different direct selection instant hot drinks dispense

ability

6 levels sugar adjustment ability (No Sugar 0, Very Little 1,

Little 2, Medium 3, High 4, Plenty 5)

Automatic stirrer dispenser

8 ingredient canisters (Coffee, Sugar, Tea, Milk Powder,

Chocolate, Fruit Tea1, Fruit Tea2, Salep)

5 mixers with special insertion mixer motors

Easy product price programming feature

Date and time functions

OEM production facility for bulk orders

Practical design allowing easy maintenance

LED illuminated double layer polycarbonate sheet

advertisement space

Compatible with Coins Payment System, Change Giver, Bill

Validator, Cashless Payment Systems (Contactless

Cards/Tokens)

Protected with two fuses and door open switch off high

protection

Special design 5 arms cup mechanism, 360 carton cup

capacity automatic cup dispenser

Long-Lasting Components designed specifically against

calcification

4,5 L Boiler, thermostat protected 220V AC 1800W immersion heater

Dimensions: 660 (w) x 1800 (h) x 630 (d) mm Attractive Design Approx. Weight: 110 kg

1 Year Warranty, 10 years parts supply & After Sales Services Availability as per our ‘General

Conditions of Sales, Delivery & Warranty’

Note: ELEKTRAL reserves the right to make changes without notice to the features, optionals, prices and

“General Conditions of Sales, Delivery and Warranty”. Please confirm the specifications at the time of

your order!..

7

2- MAIN UNITS

Figure 1: Front View

1-LED ILLUMINATED

WINDOW

3- PRODUCT

DISPENSE HOLE

5-HINGE

6- GRAPHIC

LCD DISPLAY

2- TOUCH KEYPAD

7- BILL

VALIDATOR

ENTRY

9- COIN REFUND

BUTTON

10-COIN

REFUND

HOLE

4- CASHLESS

CARDS

8- COIN ENTRY

HOLE

8

Figure 2: Control cover rear view

11- CASHLESS

CARDS LOADER

15-COIN

TUBES

16-IR SENSOR

17-COINS BOX

20-CUP HOLDER

21-STIRRER

HOLDER

22-WASTEBOX

12-MAIN BOARD

13- BILL

VALIDATOR

14-COINS

LOADING HOLE

19-TOUCH

KEYPAD

MODULE

18-LED

LIGHTING

MODULE

9

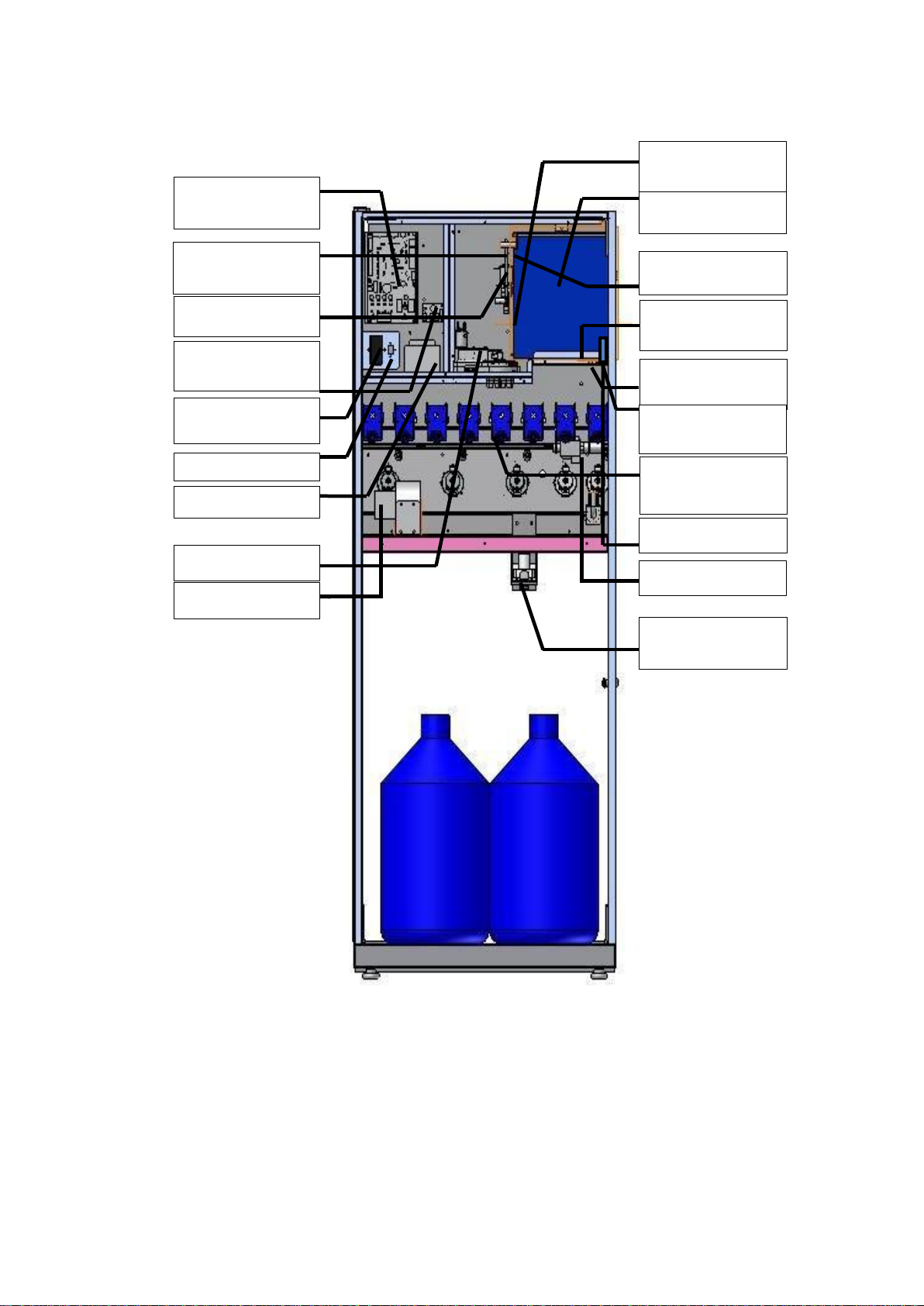

Figure 3: Product Containers

26-SUGAR

37-BOILER DRAINAGE

33- SECURITY

SWITCH

28-MILK POWDER

29-CHOCLATE

30- FRUIT TEA 1

31- FRUIT TEA 2

36 - MIXER

27-TEA

25-SALEP / TURKISH

COFFEE / 3 IN 1

24-COFFEE

32-PRODUCTS

FLOW HOPPER

23- UPPER LOCK

34-BOTTOM LOCK

38-PRODUCT FLOW

ROUTER

35-WASTE WATER

BUCKET

AND FLOAT BUOY

MECHANISM

10

49-BOILER

50- RESISTANCE

51-WATER FILLING

HOSE

52-WATER DRAIN

HOSE

54-PRODUCT

HOPPER MOTORS

39 -CONTROL

PCB

40-LEVEL

SENSOR

41-SOLENOID

VALVE

43-POWER

SOCKET

45-TRANSFORMER

47-STEAM FAN

56- WATER PUMP

42-SOLENOID

SLIDE CARD

44-USB SOCKET

55-THERMOSTAT

57- PRODUCT FLOW

ROUTER

46-DIVERTER

48-TEMPERATURE

SENSOR

Figure 4: Rear View

53-OVERFLOW

HOSE

11

2.1 Trunk

Main parts inside the trunk are explained hereunder

2.1.1 Boiler

The boiler tank capacity is 4,5 L and is equipped with a 1800 W Immersion Heater. The safety of

the Boiler Tank is controlled by a Temperature Sensor and Level Probe. The tank is well fitted to

the VM Trunk and it is well insulated. Energy usage has been minimised therefore operating cost

has been reduced.

Do not touch the Maxi-Kafe®Boiler Tank when it is hot.

When draining out the water in the boiler tank, the red cork inside the end

of the water hose needs to be removed. Proceed with CAUTION as the

hose contains VERY HOT water. Make sure the vending machine is

unplugged from the mains and there is no electricity connection.

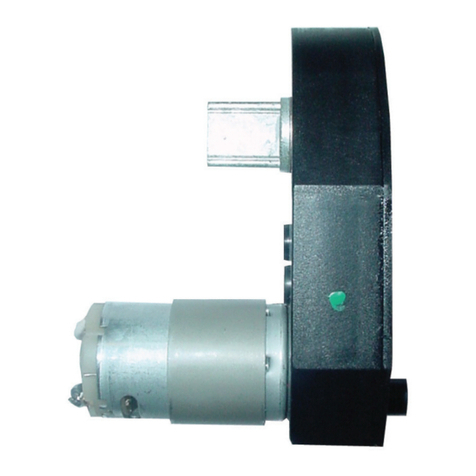

2.1.2 Ingredient Canisters and Motors

These storage containers are for powder form soluble drinks from where the soluble drinks are

being distributed into mixers via the canister motors. There are eight canisters in a standard

Maxi-Kafe coffee vending machine (See Figure 3 - 24, 25, 26, 27, 28, 29, 30, 31) and motors

(See Figure 2 - 16).

Product Placement into Canisters is as follows:

24 - Coffee 25 - Salep 26 - Sugar 27 - Tea

(or Turkish Coffee/3 in 1)

28 - Milk Powder 29 - Chocolate 30 - Fruit Tea 1 31 - Fruit Tea 2

The positions of Canisters and Canister Motors are not interchangeable.

Motors with various speeds are used depending on each ingredient

12

2.1.3 Mixers and Mixer Motors

Powder form soluble hot drinks are being prepared ready to be presented in mixer bowls with

hot water. There are 5 mixers and mixer motors in a standard Maxi-Kafe coffee vending

machine (See Figure 2 - 18).

The positions of Mixers and Mixer Motors are not interchangeable.

There is a steam lid on the top of the mixers. It takes away the vapour

forming on the mixer. This feature is important in terms of keeping the

ingredients safe and dry correctly for a long time.

Replace mixer washers (O-ring) once a year.

2.1.4 Water Pump

It performs the task of pumping the water to the boiler. During inıtial operation it has to pump

4.5 L of water. Then it pumps a cup amount of water after each cup dispensed.

Operating the machine without water for a long time causes damage to

the pump and the pump needs to be replaced.

2.2 Front Door

The front door holds the electronic and electromechanic parts of the machine.

2.2.1 LCD Display

GLCD (Graphical Liquid Crystal Display - GLCD) is used for programming and throughout all

payment and product selection procedures (See Figure 1 - 6). Thereafter, will be referred as

“GLCD”.

13

2.2.2 Payment System (Optional)

The cost of the desired product is defined and paid through a payment system. These advanced

payment systems only accept pre-defined coins and bills and do not accept counterfeit coins

and bills.

When requested by the Customer, the Maxi-Kafe can be equipped with MDB Supporting Coin

Selector, Change Giver, Bill Validator and/or Cashless Payment System.

2.2.3 Capacitive Touch Keypad

Used for programming and selecting products. Use of the keypad is described in details under

the programming section.

2.2.4 Electronic Modules

The machine is fully micro-processor controlled; the electronic modules are listed below:

a) Main Board electronic module

b) Control PCB electronic module

c) Capacitive Touch Keypad

d) Solenoid slide card electronic module

e) Illumination electronic module

All models are being produced by Elektral. Spare parts and module

replacements have to be done by authorized personnel only, otherwise

irreversible damage can be caused to the machine and the guarantee becomes void

3. TECHNICAL SPECIFICATIONS

Operation: Electro-Mechanic Operating Principle

Power Supply: 220 VAC (± % 10) / 50 Hz.

Stand by Power: ~25W Resistance: ~ 1800W

Operating Temperature: 0° C +70° C

Humidity: % 95

Protection Class: IP20

Dimensions: 650 (W) x 1800 (H) x 570 (D) mm

Weight: ~ 110 kg

14

4. INSTALLATION AND CLEANING

The machine should be removed from its packaging in an upright position and has

to be placed on a stable flat surface. The machine should be brought to a balanced

position with the adjustable height bingo footers.

The equipment has a self-cleaning function (See chapter 6.2.6). It is necessary to clean the

Maxi-Kafe periodically with short intervals since it is serving drinks to people. During cleaning,

do not use any cleaning materials and/or chemicals which are not safe for human health.

Ensuring safe and healthy usage of the machine can be achieved by strictly following below

instructions. Apart from the periodic cleaning instructions below, visible marks on the machine

must be wiped using a soft, hygienic and slightly damp cloth. Especially during frequent usage

of the machine, the cleaning has to be done more often as described in below periodic cleaning

instructions.

The water temperature during self-cleaning process has to be as same as

when the machine is in operation.

Chemical solutions must not be used during cleaning the machine by hand.

Only warm water should be used.

Disconnect the machine from the electricity supply before commencing the

cleaning process.

Do not connect and operate the machine if the power supply is not an

earthed electricity supply.

4.1. Daily Cleaning

Choose "AUTO CLEANING" from the menu to clean the mixers. Check if the product canisters

are full. Take away the water from the excess water tray.

4.2. Weekly Cleaning

Take the mixers off and wash with hot water. Wash the product flow routers. Clean the excess

water tray with hot water. Clean the product powder fallen inside the machine.

4.3. Monthly Cleaning

Take off the product canisters and do functioning test. Wash and dry the canisters. Test and

check if the extractor fans are functioning. Open the back cover and clean around the electronic

board with the help of a small vacuum cleaner. Do not neglect monthly graph checks.

15

WELCOME

INSERT COIN

13.01.ŞİFRE DE

4.4. Annual Cleaning

Check the boiler, the solenoid, the water distributers etc… in the machine for lime scale. Clean

if needed. Change the parts listed for periodic replacement in the user manual. Check the usage

labels and the physical state of the machine.

5. PRODUCT LOADING AND INITIAL OPERATION

Before connecting your Maxi-Kafe coffee vending machine to the electricity power supply,

proceed with the following;

Open the front door of the machine. There is a water intake hose at the lower section of

the Maxi-Kafe. Insert the water intake hose into a carboy full of water.

Load powder form soluble ingredients into canisters. The ingredients have to be suitable

for vending machines. (See chapter 2.1.2 Product Placement into Canisters)

Load suitable size carton or plastic cups one within another, into the five columns on the

top of the Cup Dispenser Mechanism

The cups have to be slick, not wet and not crushed. Do not mix plastic and

carton cups. To prerevent mechanism breakages, do not force or interfere

with the part where the cup dispencer tines are located.

Plug the machine to an earthed electricity power supply.

When the front door is closed the machine automatically starts working.

Note: If you need the machine to operate while the front door is open, the safety key lid

has to be placed on the key.

The boiler operates only when the water inside is above a certain level. The status is

displayed on the GLCD once operation starts. If there is not enough water in the boiler,

the pump starts pumping in water. If the Boiler Tank does not fill up within 6 Minutes

then “No Water” message will appear on GLCD. To fill up the boiler tank, switch off the

machine from the mains and switch it on again. Initial heating may take some time.

Once completed ready to operate Message appears on GLCD.

Select the sugar level of your choice and enter the product code to take a product. With

the Payment System equipped Maxi-Kafe, money has to be inserted first.

6- PROGRAMMING

All Programming and Operation controls of Maxi-Kafe®can be done using the

GLCD and the Capacitive Touch Keypad.

SUGAR(+) button EXIT/NO,

SUGAR(-) button SELECT/SAVE/YES,

CUP ONLY button is used to scroll UP in the menu,

HOT WATER button is used to scroll DOWN in the menu

16

MAIN MENU

STATISTICS

PRICES

PAYMENT SYSTEM

SETTINGS

DOSES

… …

MAIN MENU

STATISTICS

PRICES

PAYMENT SYSTEM

SETTINGS

DOSES

… …

STATISTICS

PRODUCT COUNTERS

AUDIT DATA

FAILURES

MAIN MENU

STATISTICS

PRICES

PAYMENT SYSTEM

SETTINGS

DOSES

… …

PASSWORD

[0***]

Open the machine door and the protection door. Press the

red button (MENU BUTTON) on the electronic module.

Enter your password by using (HOT WATER) button to scroll down and (CUP ONLY) button to

scroll down in the menu. Factory default password is 4 “zeros”. It is sufficient to press button

SUGAR(-), meaning SELECT four times.

6.1 Main Menu

Use buttons UP (CUP ONLY) and DOWN (HOT WATER) to

scroll to the menu required. Then press SUGAR(-)(SELECT)

to enter the menu

6.1.1 Statistics: All statistical information available can be

seen inside this menu

17

PRICES

PRICE SETTINIGS

PAYMENT SYSTEM

PROTOCOL

MDB SETTINGS

EXEC. SETTINGS

PARA. SETTINGS

SETTINGS

TEMPERATURE SET 80° C

CUP SENSOR

FIRST LANGUAGE

SECOND LANGUAGE

… …

DOSES

COFFEE LONG

CAPPUCCINO

COFFEE MILK

MOCHACCINO

TEA

… …

TEST AND CLEANING

DISPENSE CUP

DISPENSE STIRRER

FUNCTION TEST

CLEAN MIXERS

INSTANT TEMPERATURE

MACHINE INFO

SOFTWARE VERSION

HARDWARE VERSION

TRACE NUMBER

SOFTWARE VERSION 2

… …

6.1.2 Price Settings: This menu is for price settings

6.1.3 Payment System: This menu is for the payment

system settings.

6.1.4 Settings: This menu is for the settings of the

machine. By using SUGAR(-) (SELECT) choose the settings

required and amend or go to the sub settings. The

amendments can be confirmed by pressing SUGAR(-)

(SELECT) button. Use SUGAR(+) (EXIT) to exit the menu.

6.1.5 Doses: Product dosages adjustment is done in this

menu. Use SUGAR(-)(SELECT) button to enter the required

menu to make changes. When entered product settings,

the GLCD displays the water and powder required in

seconds. The setting requiring amendment can be selected

with SUGAR(-)(SELECT) and by using UP(CUP ONLY) and

DOWN(HOT WATER) the value can be amended and new

value entered.

6.1.6 Machine Test and Cleaning: This menu is for

testing the hardware equipped on the Vending Machine

(motors, IR Product Sensor etc.

6.1.7 Machine Information: This menu shows the

software and hardware information on the machine as well as the tracking numbers.

18

AUDIT DATA

VENDS TOTAL

VENDS PARTIAL

DISCOUNTS PARTIAL

COIN BOX PARTIAL

… …

PRODUCT COUNTERS

GLOBAL COUNTER 60 NOS

COFFEE LONG

CAPPUCCINO

COFFEE MILK

… …

6.1.8 Factory Settings: The machine can be returned to

default factory settings using this menu. When selected a

message informing of the reset is shown on the GLCD. If

“NO” is selected it returns to the main menu. If “YES” is

selected default factory settings are loaded to the machine.

Make your selection by using UP(CUP ONLY) and

DOWN(HOT WATER) scroll buttons.

6.2 Menus

To enter the sub menus, you need to enter the Main Menu and scroll. Choose the required

menu using the scroll buttons, use the SUGAR(-)(SELECT) button to enter the menu. Do the

required amendments/settings by using UP (CUP ONLY) and DOWN(HOT WATER) scroll

buttons. Use the SUGAR(-)(SELECT) to save the changes made, use the SUGAR(+) (EXIT)

button to exit without saving.

6.2.1 Statistics Main Menu

6.2.1.1 Product Counters

This menu shows the number products sold after the last

reset. The number value of sold products for each product

can be reset by selecting that number. This menu also allows

adjusting the payment system settings. All counters can be

reset by selecting to reset counters.

6.2.1.2 Account Information

This menu shows the monetary value of the products sold

after the last reset.

Total Sales: The net revenue amount collected from the

time the machine had started operating. This value cannot be

reset.

Vends Partial: The revenue amount collected after the last

reset.

Discounts Partial: The total discount amount after the last reset.

Coin Box Partial: This value is the total amount of money collected in the cash box. The VM

equipped with Change Giver first collects the coins into its tubes then fills up the Cash Box. This

value can be reset.

Partial Stacker: This value is the amount of banknotes collected in the Bill Validator Stacker.

This value can be reset.

Partial Tubes: This value is the total sales amount with coins. This value can be reset.

MAIN MENU

SETTINGS

DOSAGES

TEST VE TEMIZLEME

DEVICE

FACTORYRI

Load Defaults?

YES NO

19

FAILURES

01: 015(1) - 0 24/02/2016 14:05

02: 004(1) - 0

03: 003(1) - 0

04: 004(1) - 0

... …

Cashless Sale: Cashless card sales total

Cashless Loading: Cashless card loadings total done in the machine

Partial Coin Change: The total amount of coins change given by the machine

Partial Banknote Change: The total amount of banknotes change given by the machine

Partial Recycler: The total amount of banknotes held in the machine’s recycler part. This

value can be reset.

Partial Residuary: The total value of money inserted into the machine without any sales. This

value can be reset.

Current Recycler: The total amount of banknotes currently held in the machine’s recycler part

Current Tubes: The total amount of coins currently held in the machine’s tubes

Reset Counters: This menu is used for reseting all audit data

6.2.1.3 Failures (Errors)

These are codes for the errors occurring during the

machine operation. Pre-defined Error Codes are as listed

below:

ERROR

CODE

ERRORS

1

L_HEATERTIMEOUTERROR,

HEATER TIMEOUT ERROR

2

L_HEATINGCHECKERROR,

HEATING CHECK EROOR

3

L_HEATERSAFETYERROR,

HEATER SAFETY ERROR

4

L_NTCUNPLUGGEDERROR,

NTC UNPLUGGED ERROR

5

L_DIVERTERTIMEOUTERROR,

DIVERTER TIMEOUT ERROR

6

L_CUPDISPENSERTIMEOUTERROR,

CUPDISPENSER TIMEOUT ERROR

7

L_EEPROMTIMEOUTERROR,

EEPROM TIMEOUT ERROR

8

L_EEPROMCHECKSUMERROR,

EEPROM CHECKSUM ERROR

9

L_FALTYTEMPERATURESENSORERROR,

FALTY TEMPERATURE SENSOR ERROR

10

L_NPOSITIONERTIMEOUTERROR,

NPOSITIONER TIMEOUT ERROR

11

L_SPECIFICSLAVEERROR,

SPECIFICSLAVE ERROR

12

L_MEMORYFAULTERROR,

MEMORY FAULT ERROR

13

L_CUPDISPENSERTURRETTIMEOUTERROR,

CUP DISPENSER TURRET TIMEOUT ERROR

20

14

L_TPADCONNECTIONFAILUREERROR,

TPAD CONNECTION FAILURE

15

L_WASTEBOXFULLERROR,

WASTE BOX FULL

16

L_OVERCURRENTERROR,

OVER CURRENT ERROR

17

L_OVERCURRENTMIXERERROR,

OVER CURRENT MIXER ERROR

18

L_EEPROMMEMORYFAULTERROR,

EEPROM MEMORY FAULT ERROR

19

L_ESPRESSOBREWERTIMEOUT,

ESPRESSO BREWER TIMEOUT

20

L_ESPRESSOGRINDERTIMEOUT,

ESPRESSO GRINDER TIMEOUT

21

L_ESPRESSODOSERSOLENOIDTIMEOUT,

ESPRESSO DOSER SOLENOID TIMEOUT

22

L_ESPRESSOBOILERPUMPTIMEOUT,

ESPRESSO BOILER PUMP TIMEOUT

23

L_ESPRESSODOSERSWITCHERERROR,

ESPRESSO DOSER SWITCHER ERROR

24

L_ESPRESSOWATERFLOWERROR,

ESPRESSO WATER FLOW ERROR

25

L_NMECHANICALERROR,

N MECHANICAL ERROR

51

L_PUMPTIMEOUT,

PUMP TIMEOUT ERROR

52

L_CUPDISPENERNOCUP,

CUP DISPENSER ERROR NOCUP

101

L_MDBCOINBASIC

MDB COIN BASIC

102

L_MDBBILLBASIC,

MDB BILL BASIC

103

L_MDBCOINADVANCED,

MDB COIN ADVANCED

104

L_MOTOROVERCURRENTEROR,

MOTOR OVER CURRENT ERROR

105

L_FLASHERROR,

FLASH ERROR

106

L_TOUCHBOARDERROR,

TOUCH BOARD ERROR

107

L_RTCERROR,

RTC ERROR

108

L_IRSENSORERROR,

IR SENSOR ERROR

109

L_MDBCOMMUNICATIONERROR,

MDB COMMUNICATION ERROR

110

L_COINDISPENSEERROR,

COIN DISPENSE ERROR

151

L_BROWNOUTRESETERROR

BROWN OUT RESET ERROR

152

ERR_TPAD_Timeout,

TPAD TIMEOUT ERROR

153

L_TPADGENERALERROR

TPAD General ERROR

401

L_NONSPECIFICERROR

NON SPECIFIC ERROR

402

L_CHECKSUMERROR1,

CHECKSUM ERROR1

403

L_CHECKSUMERROR2,

CHECKSUM ERROR2

404

L_LOWLINEVOLTAGEDETECTED,

LOWLINE VOLTAGE DETECTED

405

L_NONSPECIFICDISCRIMINATORERROR,

NON SPECIFIC DISCRIMINATOR ERROR

406

L_FLIGHTDECKOPEN,

FLIGHT DECK OPEN

407

L_ESCROWRETURNSTUCKOPEN,

ESCROW RETURN STUCK OPEN

408

L_COINJAMINSENSOR,

COIN JAM INSENSOR

409

L_DISCRIMINATIONBELOWSPECIFIEDSTANDARD,

DISCRIMINATION BELOW SPECIFIED STANDARD

410

L_VALIDATIONSENSOR_A_OUTOFRANGE,

VALIDATION SENSOR A OUT OF RANGE

Table of contents

Other Elektral Vending Machine manuals