Table of Contents

1. Introduction...............................................................................................................................5

1.1 Important Notes on Wall Thickness Measurement ................................................................5

Prerequisites for the use of ultrasonic wall thickness gauges.................................................5

1.1.1 Training of the Person in Charge of Testing..................................................................6

1.1.2 Limitations to Ultrasonic Testing....................................................................................6

1.1.2.1 Ultrasonic Wall Thickness Testing...........................................................................6

1.1.2.2 Influence of the Material to be tested.......................................................................7

1.1.2.3 Influence of Changes in Temperature......................................................................7

1.1.2.4 Measurement of the Residual Wall Thickness .........................................................7

1.1.2.5 How to use the Couplant .........................................................................................7

1.1.2.6 Duplication of Reading.............................................................................................8

2. Technical Specifications ..........................................................................................................9

3. Measuring Principle................................................................................................................10

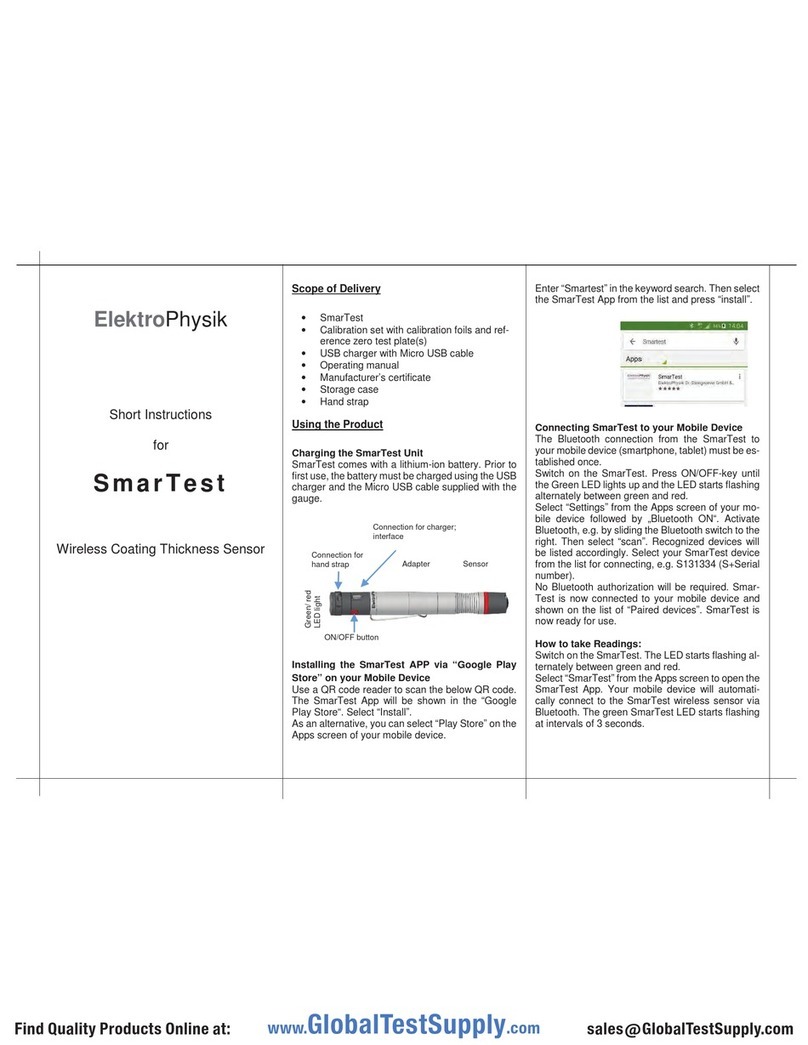

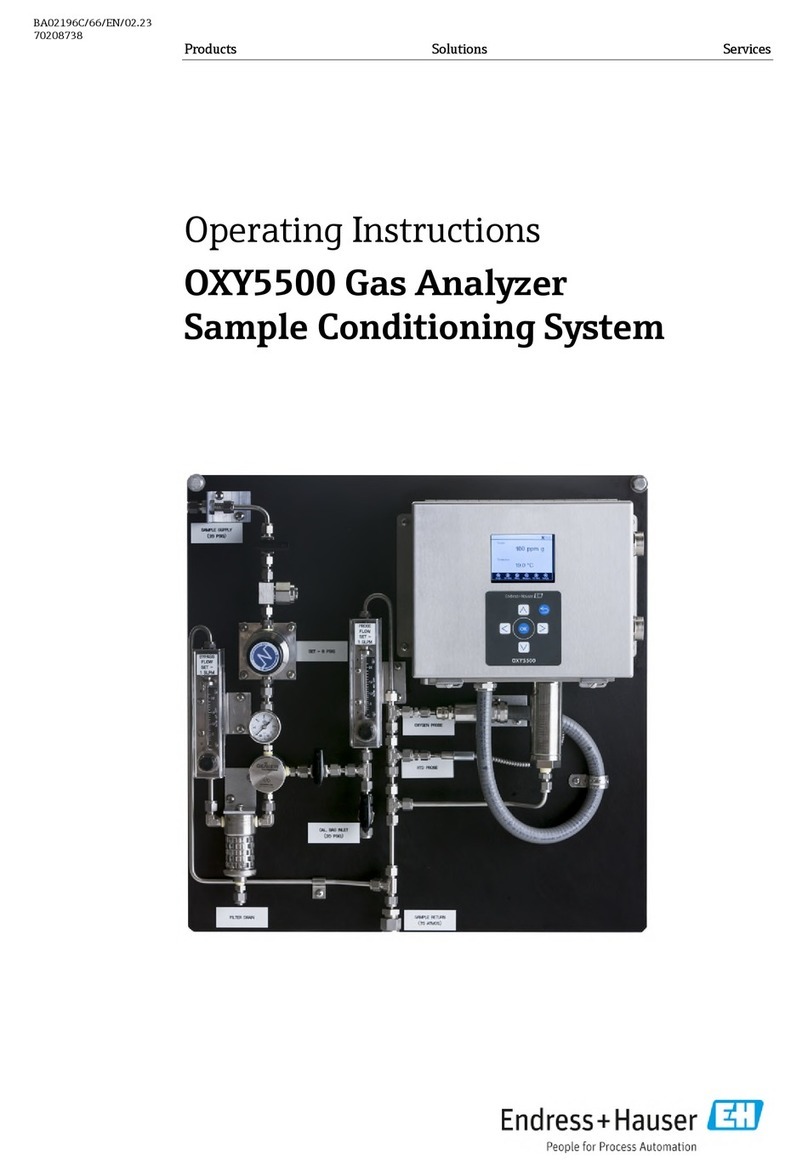

4. Description of the Gauge and Schedule of Supply...............................................................11

4.1 Description of the Gauge (Front and back Side)..................................................................11

4.2 Supply Schedule.................................................................................................................11

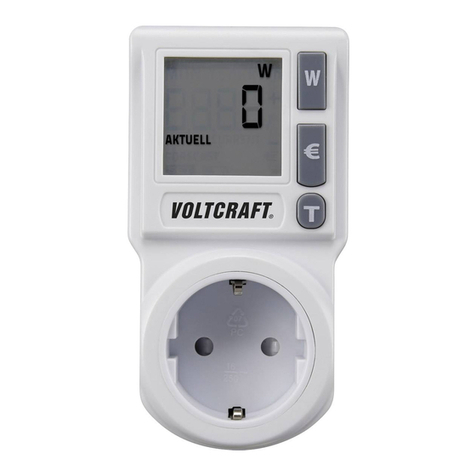

4.2 Display................................................................................................................................12

4.3 Keyboard.............................................................................................................................13

5. Preparing Measurement .........................................................................................................14

5.1 Preparing the Gauge...........................................................................................................14

5.2 Selection of the Transducer.................................................................................................14

5.3 Preparing the Surface of Measuring Object.........................................................................15

6. Operation.................................................................................................................................16

6.1 Switch ON...........................................................................................................................16

6.2 Taking Readings.................................................................................................................16

6.3 Calibration...........................................................................................................................17

6.3.1 Calibration...................................................................................................................17

How to calibrate MiniTest 430 / 440...................................................................................17

6.3.2 Determination of the Sound Velocity...........................................................................17

6.3.2.1 How to determine the Sound Velocity.......................................................................18

6.3.3 Calibration of the Transducer....................................................................................18

6.4 User Menu ..........................................................................................................................19

6.4.1 Measuring Mode (Meas. Mode) ..................................................................................19

6.4.1.1 MiniTest 430..........................................................................................................19

6.4.1.2 Operating modes of MiniTest 440..........................................................................21

6.4.1.2.1 I-E mode.............................................................................................................21

6.4.1.3.2 Echo-Echo mode................................................................................................22

6.4.2 Sound Velocity............................................................................................................23

6.4.2.1 Materials................................................................................................................23

6.4.2.2 Setting Sound Velocity (vel. custom) .....................................................................24

6.4.3 Measuring Unit............................................................................................................25

6.4.4. Data Memory .............................................................................................................25

6.4.4.1 Select a Batch (MiniTest 430 / 440).......................................................................26

6.4.4.2 Delete a Batch (MiniTest 430 / 440).......................................................................26

6.4.5 Gain Setting................................................................................................................27

6.4.6 Switch Off Mode..........................................................................................................27

6.4.7 Contrast......................................................................................................................28

6.4.8 Language....................................................................................................................28

6.4.9 Gauge Data ................................................................................................................28

6.4.10 Standard Setting.......................................................................................................28

6.5 Data Processing..................................................................................................................28