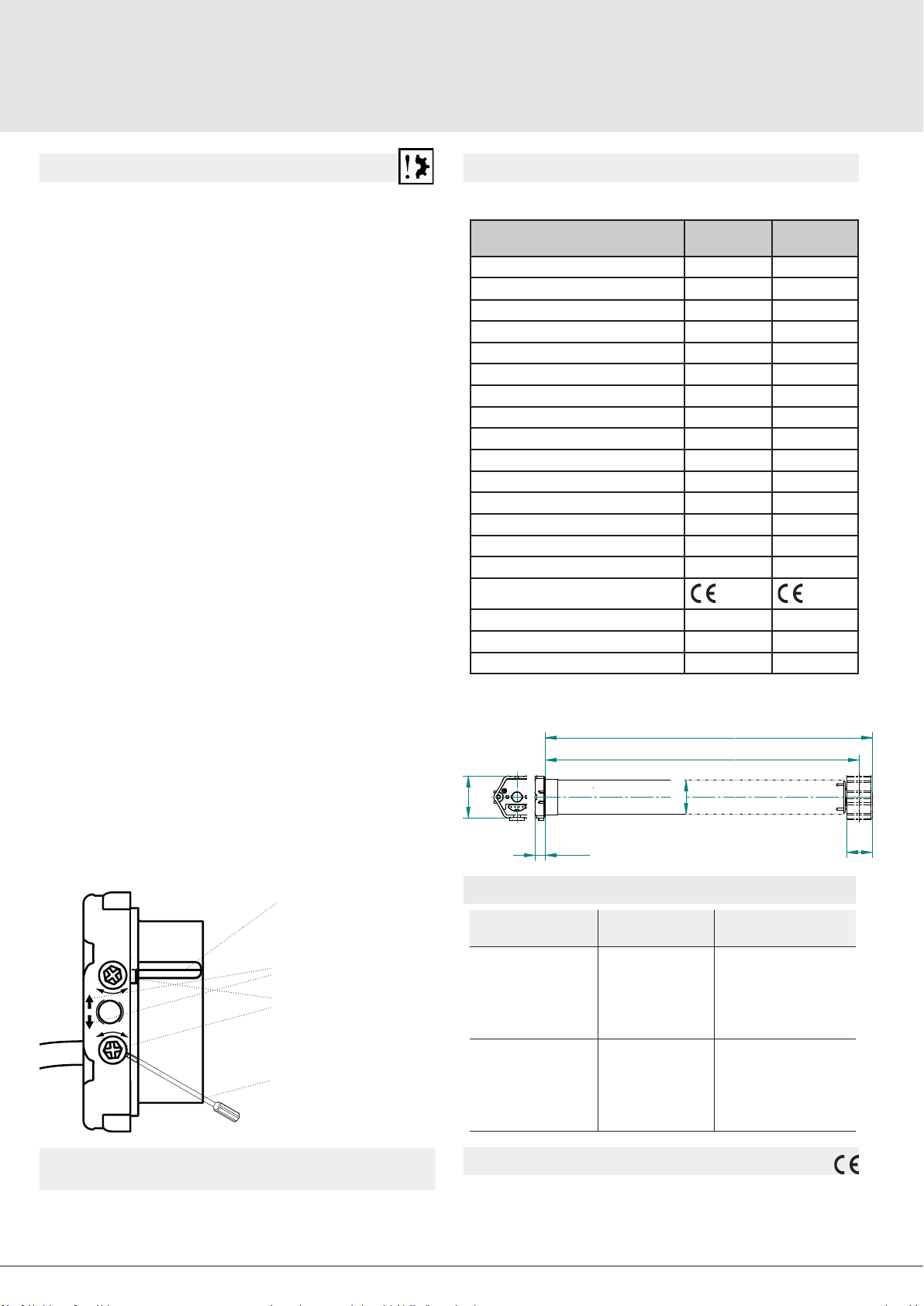

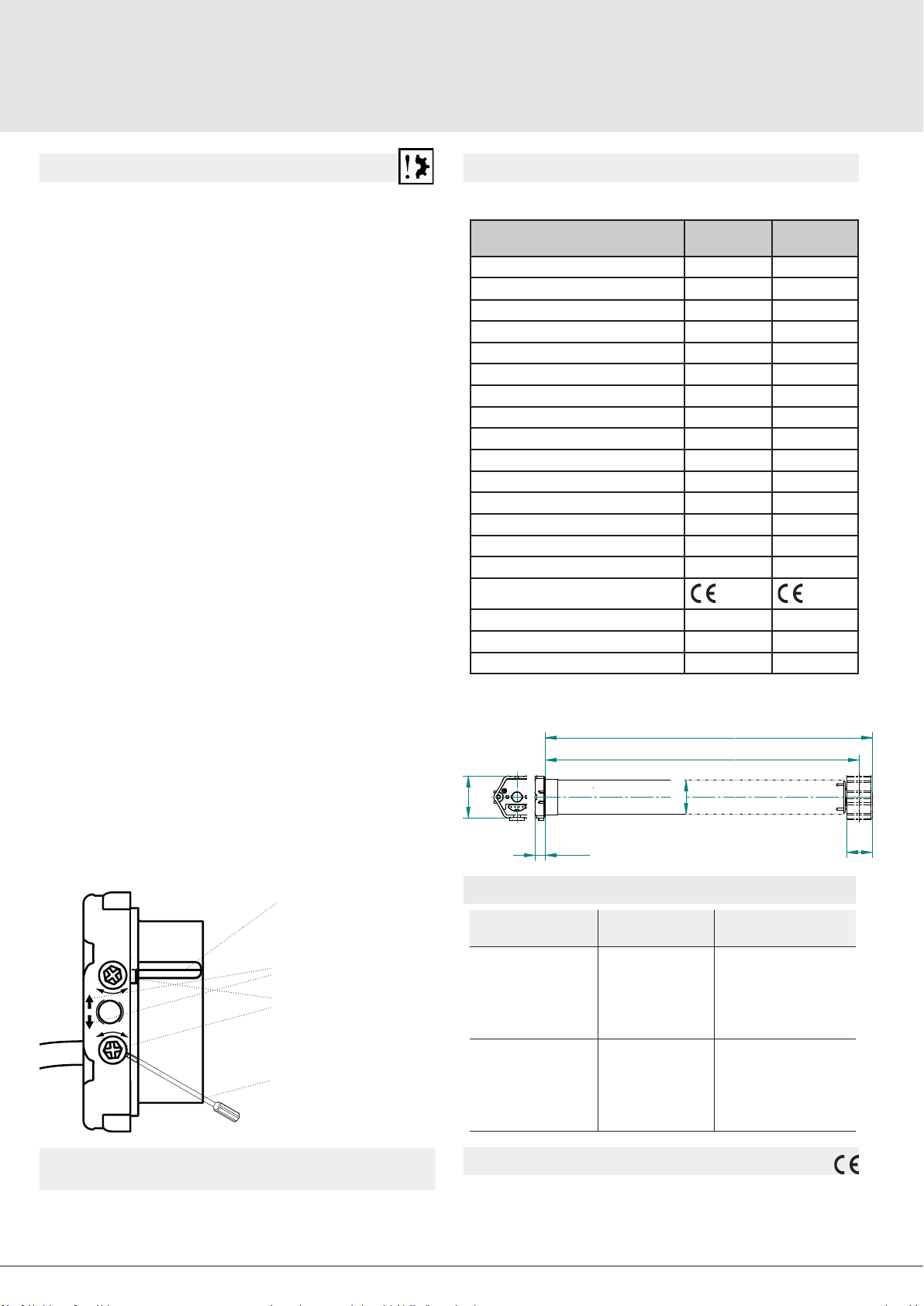

Technical data and dimensions

The technical data specified is subject to tolerance factors

(according to applicable standards).

Size / Type VariEco M10

DC

VariEco M12

DC

Rated voltage [V] 12 (DC) 12 (DC)

Noiseless soft brake

Rated torque [Nm] 10 12

Rated speed [rpm] 16 16

Rated current [A] 4.0 3.5

Rated power consumption [W] 48 42

Shaft diameter [mm] 50 50

Protection class (IP) 44 44

Limit switch range (revolutions) 35 35

Operating time (min S2) 10 10

Length C [mm] 477 497

Length D [mm] 460 480

Length E [mm] 14 14

Weight [kg] 1.6 1.7

Ambient operating temperature [

°C

] -20 ... 60 -20 ... 60

Conformity

Protection class II

Plug-in connecting cable [m] 3.0 3.0

Item number 34 621.0101 34 611.0101

EU Conformity

elero hereby declares that this device is in compliance with all

applicable regulations of the Machinery Directive 2006/42/EC.

The full text of the EU Declaration of Conformity is available

at the following Internet address: www.elero.de/downloads-

service/

Notes on troubleshooting

Fault Cause Remedy

• The drive does

not switch o

in the end posi-

tions via the limit

switches

• The limit

switch crown

is not being

driven

• Readjust instal-

lation and limit

switches via the

limit switch setting

screws

• Drive does not

react

• Temperature

limiter has

triggered

• Incorrect con-

nection

• Allow drive to cool

down. Tempera-

ture limiter is self-

resetting.

• Readjust connec-

tion

Manufacturer's

Service

elero GmbH

73278 Schlierbach

GERMANY

www.elero.de

If malfunctions have occurred or the

device has been damaged despite

proper handling, contact your contrac-

tor or dealer.

Adjustment of end positions

Important: The limit switch setting screws for the upper end

position and lower end position are assigned depending on

the parallelism of the rotating limit switch crown with the run-

ning direction arrow (see Figure).

The basic factory setting when delivered is centrally set at 5

revolutions.

6 revolutions of one of the two limit switch setting screws

corresponds to 1 revolution of the winding shaft.

Turning the limit switch setting screw from negative to positive

causes the travel path of the blind to increase.

Upper end position

1. Let the drive (with no connection to the blind) run in the

DOWN/CLOSE direction until it switches o automatically.

2. Attach the rolled-down blind to the shaft.

3. Push the UP button and keep this held down.

4. If the drive switches o before it reaches the desired end

position, turn the limit switch setting screw towards positive

until the desired blind position has been reached.

5. If the drive does not switch o automatically when the desi-

red end position has been reached, release the button. Run

the blind slightly in the other direction. Turn the correspon-

ding setting screw towards negative and approach the end

position again. Repeat this process until the desired end

position has been reached.

Lower end position

1. Push the DOWN/CLOSED button and keep this held down.

2. If the drive switches o before it reaches the desired end

position, turn the limit switch setting screw towards positive

until the desired blind position has been reached.

3. If the drive does not switch o automatically when the desi-

red end position has been reached, release the button. Run

the blind slightly in the other direction. Turn the correspon-

ding setting screw towards negative and approach the end

position again. Repeat this process until the desired end

position has been reached.

Checking the end positions

Allow the drive to run alternately in both directions until the

limit switch switches o. The electric cut-out must take place

before the blind has reached the end position of its mechani-

cal travel path.

If the blind is constantly operated as far as its end position,

there is a risk that the drive and/or blind will be damaged or

destroyed.

NOTE: The limit switch only functions if the drive has been in-

stalled properly in a winding shaft (prole tube or round tube).

Limit switch set-

ting screws

Setting tool

Limit switch crown with

drive lug

• Negative sense of rota-

tion (-) = shorter travel

• Positive sense of rotati-

on (+) = longer travel

Direction of travel arrows

D

C

14E=

381 364 339

391 374 349

456 439 414

466 449 424

486 469 444

526 509 484

546 529 504

RolTop M1,8/138 RH Neher 384493401 120 556 539 514

RolTop M1,8/138-868 RH Nehe r 384403406 120

55

C

D

14E=

12E=

45O

55O52,7

C

D

33

33

C

D

33

12E=

45O

45O45O

O52,7

C

D

33

45O

O57,5

19E=

C

D

33

45O

O57,5

19E=

381 364 339

391 374 349

456 439 414

466 449 424

486 469 444

526 509 484

546 529 504

RolTop M1,8/138 RH Neher 384493401 120 556 539 514

RolTop M1,8/138-868 RH Nehe r 384403406 120

55

C

D

14E=

12E=

45O

55O52,7

C

D

33

33

C

D

33

12E=

45O45O45O

O52,7

C

D

33

45O

O57,5

19E=

C

D

33

45O

O57,5

19E=

33

381 364 339

391 374 349

456 439 414

466 449 424

486 469 444

526 509 484

546 529 504

RolTop M1,8/138 RH Neher 384493401 120 556 539 514

RolTop M1,8/138-868 RH Nehe r 384403406 120

55

C

D

14E=

12E=

45O

55O52,7

C

D

33

33

C

D

33

12E=

45O45O45O

O52,7

C

D

33

45O

O57,5

19E=

C

D

33

45O

O57,5

19E=

±

±