elero KL/DMA User instructions

Other elero DC Drive manuals

elero

elero AeroTec 28 140.0001 User manual

elero

elero SunTop/Z M-868 User manual

elero

elero RolMotion M Product guide

elero

elero RolTop S Specification sheet

elero

elero VariEasy M10 SH Product guide

elero

elero RolTop-868 User manual

elero

elero JA Comfort series User manual

elero

elero SunTop Product guide

elero

elero SunTop/Z M RH User manual

elero

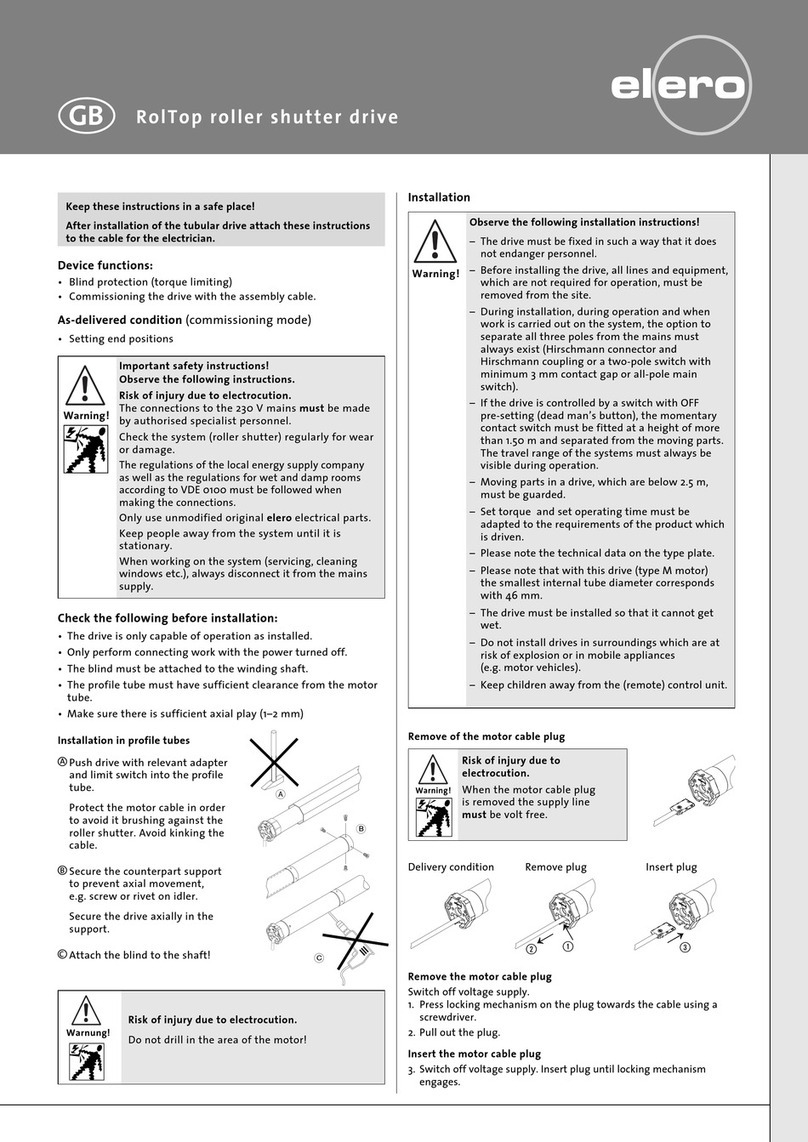

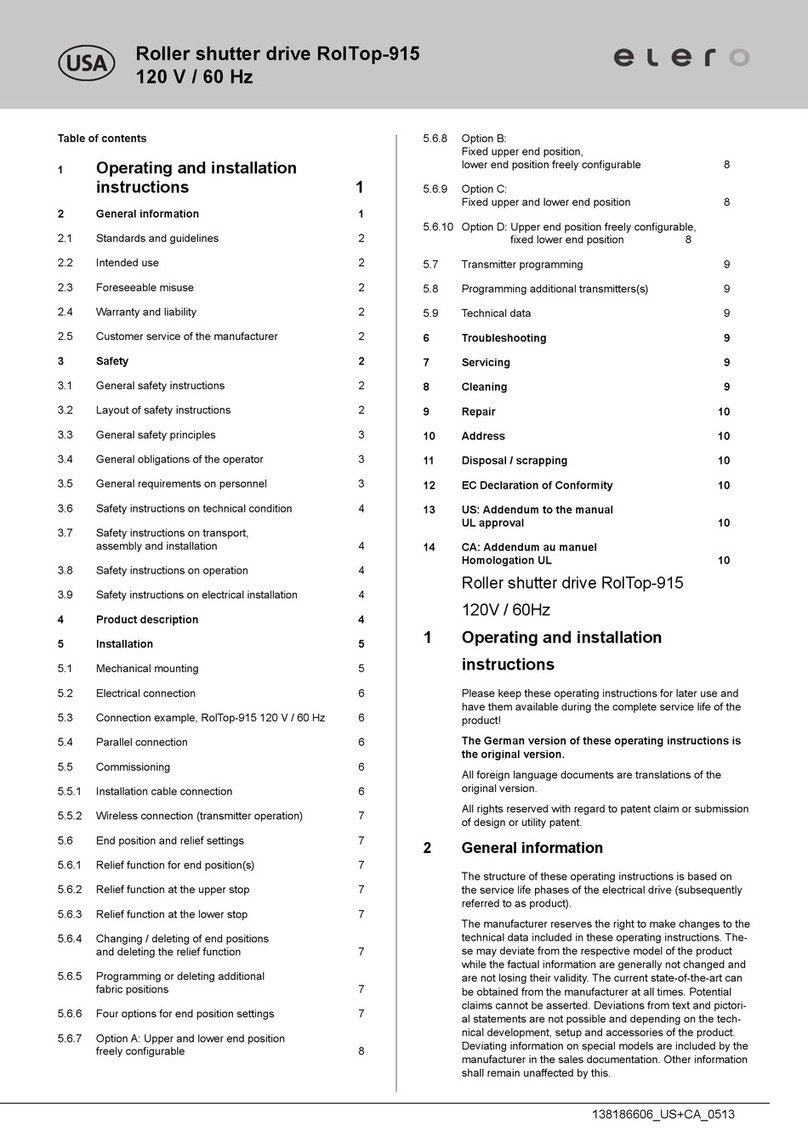

elero RolTop-915 User manual

elero

elero DFM 100 User manual

elero

elero SunTop-915 User manual

elero

elero SunTop-868 User manual

elero

elero Solar-Bundle DC User manual

elero

elero RolMotion/D+ M Series Product guide

elero

elero RolMotion/D+ M-868 Product guide

elero

elero CSM-868 User manual

elero

elero VariEco L RH Product guide

elero

elero VariEco M DC User manual

elero

elero CSM-F-868 User manual

Popular DC Drive manuals by other brands

HAUTAU

HAUTAU EA 500-300 Mounting and operating instructions

Dorner

Dorner 2200 series Operation & maintenance manual

Lenze

Lenze Global Drive 8200 vector Information for the operator of the machine/system

Wittenstein Alpha

Wittenstein Alpha CP Series operating manual

Danfoss

Danfoss VLT AutomationDrive FC 302 Design guide

SEW-Eurodrive

SEW-Eurodrive Movitrac 31 Series manual

TECHTOP

TECHTOP Topdrive350 Series Quick start up guide

ZIEHL-ABEGG

ZIEHL-ABEGG ZAdyn4C MRL Replacement manual

SEW-Eurodrive

SEW-Eurodrive MOVIMOT MMxD Series Compact operating instructions

Siemens

Siemens MICROMASTER 440 operating instructions

Rockwell Automation

Rockwell Automation Allen-Bradley PowerFlex 4 quick start

Geckodrive

Geckodrive GM215 manual