ELETTROQUADRI MP2 User manual

ELETTROQUADRI

SINCE 1983

TRANSLATION OF THE ORIGINAL INSTRUCTIONS

ENGLISH

2023- rev. 2.9

USER, MAINTENANCE AND

INSTALLATION MANUAL

MICROPROCESSOR SYSTEM

MP2

REVISION INDEX REASON FOR REVISION DATE OF REVISION

2.9 Updated text 18/04/2023

ELETTROQUADRI

SINCE 1983

S 0

INSTALLATION, USE AND MAINTENANCE MANUAL

3 / 54

MP2 rev. 2.9

MP2

© ELETTROQUADRI S.r.l.

C

1 G .......................................................................................5

1.1. Installaon Manual...................................................................................................................5

1.1.1. Reproducon limits and copyright................................................................................................ 5

1.1.2. Updates ......................................................................................................................................... 5

1.1.3. Care of the instrucons................................................................................................................. 5

1.1.4. How to print the Instrucon Manual ............................................................................................ 5

1.2. How to use this manual............................................................................................................6

1.2.1. Page layout.................................................................................................................................... 6

1.2.2. Symbols ......................................................................................................................................... 7

1.2.3. General definions........................................................................................................................ 7

1.3. Manufacturer's data.................................................................................................................8

1.4. Aer-sales assistance ...............................................................................................................8

1.5. Warranty ..................................................................................................................................8

1.6. Tesng ......................................................................................................................................8

2 S ...............................................................................................................9

2.1. Reference standards applied....................................................................................................9

2.2. Safety warnings ........................................................................................................................9

2.2.1. General warnings .......................................................................................................................... 9

2.2.2. Warnings for Installer safety ......................................................................................................... 9

2.3. Idenficaon of operang personnel.....................................................................................10

2.3.1. Personal Protecve Equipment ................................................................................................... 11

2.4. Correct use .............................................................................................................................11

2.5. Incorrect use...........................................................................................................................11

2.6. Residual risks ..........................................................................................................................11

3 I....................................................................................................13

3.1. First connecon (tensioning the installaon).........................................................................13

3.2. Inspecon control ..................................................................................................................15

3.2.1. INSPECTION CONTROL WITH BILM3/BILM4 SWITCH .................................................................. 15

3.2.2. INSPECTION CONTROL WITH BILM5 SWITCH (with paramater Nc = YES) ................................... 15

3.3. Reset condions .....................................................................................................................16

4 P ................................................................................................17

4.1. General warnings ...................................................................................................................17

4.2. Programming the board .........................................................................................................17

4.2.1. MP2 board dip switches.............................................................................................................. 18

4.2.2. Board display............................................................................................................................... 18

4.3. Programming the MP2 board.................................................................................................20

4.4. Further board funcons .........................................................................................................32

4.4.1. LE selection - Fault log reading.................................................................................................... 32

4.4.2. Fo selecon - Omnibus procedure .............................................................................................. 32

4.4.3. Ec selection - Travel limit test .................................................................................................... 32

4.4.4. In selecon - Uncontrolled movement test................................................................................. 32

4.4.5. PA selecon - Commissioning...................................................................................................... 32

5 D ....................................................................................................33

5.1. General warnings ...................................................................................................................33

5.2. Fault table and fault finding ...................................................................................................33

ELETTROQUADRI

SINCE 1983

S

0

INSTALLATION, USE AND MAINTENANCE MANUAL

4 / 54 MP2 rev. 2.9

MP2

© ELETTROQUADRI S.r.l.

6 .........................................................................45

6.1. General warnings ...................................................................................................................45

6.2. Insulaon test.........................................................................................................................45

6.3. Switch funcons .....................................................................................................................45

UM/DM reed......................................................................................................................................... 45

RZA / RZB reed switch contacts............................................................................................................. 45

DMS / DMD reed switch contacts ......................................................................................................... 46

Slowdown / phase plug control at the top and lowest floors (CRS / CRD) ............................................ 46

6.4. Board technical specificaons................................................................................................46

MP2 BOARD .......................................................................................................................................... 46

EXP expansion boards ........................................................................................................................... 47

P2C minirelay posion boards (with decimal output - one row per floor)............................................ 47

PUC mini-relay posion boards (for coded display) .............................................................................. 47

ACF board.............................................................................................................................................. 48

DUPLO connecon board (only with separate “arriving” indicaons for the two cabinets)................. 48

TPX connecon diagram........................................................................................................................ 48

CABSER/CABEXT board ......................................................................................................................... 48

6.5. MP2 board lay-out..................................................................................................................49

LED on MP2 board................................................................................................................................. 49

6.6. Manoeuvres ...........................................................................................................................51

Single call manoeuvre or collecve down manoeuvre.......................................................................... 51

Collecve up/down manoeuvre............................................................................................................ 51

6.7. Connecons for Duplo/Duplex/Triplex/Quadruplex manoeuvres .........................................52

ELETTROQUADRI

SINCE 1983

G 1

5 / 54

INSTALLATION, USE AND MAINTENANCE MANUAL

MP2

MP2 rev. 2.9

© ELETTROQUADRI S.r.l.

1

GENERAL INFORMATION

1.1. I M

The Installaon manual is an integral part of the board and must be kept with care and accompany the board throughout its

enre life cycle, right up to final scrapping.

The manual has been drawn up by the Manufacturer to provide all the necessary informaon to those authorized to interact

with the machine during its expected service life: buyers, installers, expert operators and specialized technicians.

ELETTROQUADRI S.r.l. declines all liability for improper use of the board and for damages caused as a result of operaons not

considered in this manual or in any case unreasonable.

1.1.1. R

Reproducon of the manual, even paral, and distribuon by any means, unless expressly authorized by the Manufacturer, is

prohibited.

Any unauthorized reproducon will be prosecuted in the manner and mes prescribed by the laws in force.

© ALL RIGHTS RESERVED: copyright on this manual belongs to ELETTROQUADRI S.r.l.

Reprinng, reproducon and translaon, even paral, are prohibited without the wrien authorizaon of ELETTROQUADRI S.r.l.

The manual cannot be transferred to third pares for viewing without the wrien authorizaon of ELETTROQUADRI S.r.l.

1.1.2. U

Illustraons of the board are provide for explanatory purposes only and are not binding for the Manufacturer. The manufacturer

reserves the right to make any changes to components, parts and/or supplies for the purpose of making improvements or for

any other reason, without having to update this manual unless said changes alter machine operaon and/or safety.

IMPORTANT

The Manufacturer reserves the right to make changes without prior noƟce.

IMPORTANT

Any addiƟons to the manual which the manufacturer deems appropriate to send to users must be kept together

with the manual, becoming an integral part thereof.

1.1.3. C

The Installaon manual must be kept by a person responsible for said task, in a suitable place, so that it is always available for

consultaon in opmum condion.

It must always be easy to find and consulted by the skilled operators and must always accompany the board in the case of

transfer or resale.

CAUTION

The manual must be kept with care and replaced if it deteriorates and/or becomes illegible.

1.1.4. H I M

CAUTION

ELETTROQUADRI S.r.l. shall not be held liable for any misinterpretaƟon of the informaƟon contained herein if

prinƟng has not been executed correctly.

ELETTROQUADRI

SINCE 1983

G

1

6 / 54

INSTALLATION, USE AND MAINTENANCE MANUAL

MP2

MP2 rev. 2.9

© ELETTROQUADRI S.r.l.

1.2. H

The encharged operators must, under their own responsibility, read this manual carefully before using and programming the

board.

IMPORTANT

Keep this manual for the board's whole life cycle in a known and easily accessible place, so that it is always

available when needed.

1.2.1. P

The logic applied to the page layout of these instrucons is presented and described below.

Key:

A. MANUAL HEADING

B. FOOTNOTES

1. Manufacturer's logo

2. Board model

3. CHAPTER of the Installaon Manual secon - NUMBER and NAME

4. Type of manual

5. Board model and manual revision index

6. Number corresponding to the current page and total number of pages in the whole manual

7. Manufacturer's name and copyright

ELETTROQUADRI

SINCE 1983

G 1

7 / 54

INSTALLATION, USE AND MAINTENANCE MANUAL

MP2

MP2 rev. 2.9

© ELETTROQUADRI S.r.l.

1. Title Chapter Title.

(1.“Chapter number”)

1.1. Title Heading.

(1.“Chap. No.” 1.“Heading Number“)

1.1.1. Title Sub-heading.

(1.“Chap No.” 1.“Heading no.” (1.“Sub-heading number”)

1. list Numbered list, for idenfying operaons in succession.

• list Bullet points, for general lists.

The references inside the figures may consist of leers (A, B, C ...) or sequenal numbers (1, 2, 3 ...).

Each figure with a reference may be followed by a Key describing the indicated elements.

1.2.2. S

For the purpose of highlighng important parts of the text or important specificaons, certain symbols have been adopted, the

meaning of which is described below.

GENERIC HAZARD

Indicates situaƟons of potenƟal danger that, if overlooked, can seriously endanger people's health and safety.

GENERAL OBLIGATION

Indicates informaƟon or a precauƟon that must be observed to avoid operaƟons that may damage the board,

or in any case, a part of the text that deserves specific aƩenƟon.

IMPORTANT

Indicates technical informaƟon of parƟcular importance which should not to be overlooked.

ENVIRONMENTAL NOTE

Indicates the obligaƟon to dispose of waste materials in an ecological manner.

ELECTROCUTION HAZARD

Indicates situaƟons of potenƟal danger that can seriously endanger people's health and safety.

1.2.3. G

Some recurring terms in the manual are described to ensure a more complete understanding of their meaning.

ELETTROQUADRI S.r.l., the manufacturer of the aforemenoned board, will be referred to as the Manufacturer.

Danger zone:

any area inside and/or near the electric cabinet containing the board in which the presence of a person constutes a risk for the

health and safety of said person.

Exposed person:

any person who is completely or parally inside a danger zone.

Installer:

Skilled technician for board installing/programming.

Maintenance personnel:

Person responsible for servicing and repairing the board.

ELETTROQUADRI

SINCE 1983

G

1

8 / 54

INSTALLATION, USE AND MAINTENANCE MANUAL

MP2

MP2 rev. 2.9

© ELETTROQUADRI S.r.l.

1.3. M'

ELETTROQUADRI S.r.l.

Via Puccini, 1

21050 Bisuschio (VA) - Italy

Tel. +39 0332 470049 - Fax. + 39 0332 474032

www.eleroquadri.net

1.4. A-

For any assistance, contact the Manufacturer's Assistance Service.

CAUTION

The Manufacturer declines all liability for accidents involving persons or things caused by a failure to observe

the instrucƟons and regulaƟons provided in this manual or the non-observance of the safety and accident

prevenƟon regulaƟons in force in the country of machine use.

1.5. W

The MP2 board warranty is valid for 1 year.

CAUTION

The Manufacturer declines all liability for accidents involving persons or things caused by a failure to observe

the instrucƟons and regulaƟons provided in this manual or the non-observance of the safety and accident

prevenƟon regulaƟons in force in the country of machine use.

1.6. T

The board was tested during the producon phases on the manufacturer's premises.

ELETTROQUADRI

SINCE 1983

S 2

9 / 54

INSTALLATION, USE AND MAINTENANCE MANUAL

© ELETTROQUADRI S.r.l.

MP2

MP2 rev. 2.9

2 SAFETY

2.1. R

REFERENCE TITLE

EN 81-20:2020 Safety rules for the construcon and installaon of lis - Lis for transporng

persons and property - Part 20: Lis for persons and property accompanied by

persons

EN 81-50:2020 Safety rules for the construcon and installaon of lis - Checks and tesng - Part

50: Rules for the design, calculaon, checking and tesng of licomponents

UNI 10411-1:2021 Modificaons to electric lis not conforming with Direcve 95/16/EC

UNI 10411-2:2021 Modificaons to hydraulic lis not conforming with Direcve 95/16/EC

UNI 10411-3:2016 Modificaons to electric lis installed in conformity with Direcve 95/16/EC and

UNI EN 81-1

UNI 10411-4:2016 Modificaons to hydraulic lis installed in conformity with Direcve 95/16/EC and

UNI EN 81-2

UNI 10411-5:2017 Modificaons to electric lis installed in conformity with Direcve 95/16/EC or

Direcve 2014/33/EU and not conforming with UNI EN 81-1

UNI 10411-6:2017 Modificaons to hydraulic lis installed in conformity with Direcve 95/16/EC or

Direcve 2014/33/EU and not conforming with UNI EN 81-2

2.2. S

2.2.1. G

CAUTION

Consequently, any intervenƟon which alters board configuraƟon shall automaƟcally exonerate the

manufacturer from all liability.

Consequently, any use other than those indicated in this manual shall exonerate ELETTROQUADRI S.r.l. from all liability for

any risks which may occur.

2.2.2. W I

Before commencing work, the Installer must be fully knowledgeable of board funcon, configuraon, and technical

operang characteriscs.

CAUTION

Any work to be performed on the board requires maximum cauƟon from the Installer.

IMPORTANT

Works on the board must be performed in strict observance of operaƟonal competences. The Manufacturer

declines all liability for any failure to observe said competences.

ELETTROQUADRI

SINCE 1983

S

2

10 / 54

INSTALLATION, USE AND MAINTENANCE MANUAL

© ELETTROQUADRI S.r.l.

MP2

MP2 rev. 2.9

CAUTION

During operaƟons the operator must wear all the necessary Personal ProtecƟve Equipment (PPE).

CAUTION

The Installer must NEVER perform operaƟons or manoeuvres on his own iniƟaƟve which are not within his

sphere of competence and may jeopardize his own safety and that of others.

2.3. I

Operang personnel are the operators employed to perform installaon, programming and maintenance acvies

depending on specific skills and qualificaons, who, in all cases:

• are fully familiar with the instrucons provided in this document on which they have been specifically trained and

instructed;

• have gained sufficient experience and knowledge in the specific field of work.

When one of the following symbols is found at the start of a page or alongside a specific part of the text in this document,

it means the operaons described are the exclusive competence of a specific operator. The symbol also indicates the level

of qualificaon required for the specific operator in queson.

INSTALLER

Person with specific and cerfied technical qualificaons responsible for electrical work on the machine

who can, in complete autonomy:

• perform maintenance, disassembly, assistance, replacement and reassembly operaons on electrical

parts and equipment;

• pinpoint failures/electrical damage and determine the cause;

• perform calibraon operaons;

• envisage hazards deriving from these operaons.

ELETTROQUADRI's QUALIFIED TECHNICIAN

Expert technician employed by the manufacturer who is suitable and qualified to perform the same tasks

as the Installer.

The Expert Technician is able to perform specific acvies (e.g. mechanical, electrical and electronic) not

covered by the user's sphere of competence and which therefore cannot be executed autonomously (e.g.

supervision of installaon, tesng, adjustments, opmizaon, etc.).

The Manufacturer, if spulated in the contract with the user, may in any case guarantee, if needed, expert

technical intervenon via the aer-sales assistance service.

ELETTROQUADRI

SINCE 1983

S 2

11 / 54

INSTALLATION, USE AND MAINTENANCE MANUAL

© ELETTROQUADRI S.r.l.

MP2

MP2 rev. 2.9

2.3.1. P P E

PICTOGRAMS DESCRIPTION

SAFETY FOOTWEAR MUST BE WORN

PROTECTIVE GLOVES MUST BE WORN

PROTECTIVE CLOTHING MUST BE WORN

2.4. C

The MP2 board may ONLY be used in electrical licontrol cabinetsELETTROQUADRI S.r.l..

2.5. I

The board MUST NOT be used:

• for any uses other than those described in heading 2.4 "Correct use".

2.6. R

Even when the safety regulaons and rules of board use are observed as indicated in this manual, the following residual

risks need to be noted:

Residual risk of electrocuƟon

Risk of electrocuon relang to all parts which remain live when the cabinet is opened.

ELETTROQUADRI

SINCE 1983

PAGE LEFT INTENTIONALLY BLANK

S

2

12 / 54

INSTALLATION, USE AND MAINTENANCE MANUAL

© ELETTROQUADRI S.r.l.

MP2

MP2 rev. 2.9

ELETTROQUADRI

SINCE 1983

I 3

13 / 54

USER, MAINTENANCE AND INSTALLATION MANUAL

© ELETTROQUADRI S.r.l.

MP2

MP2 rev. 2.9

3 INSTALLATION

3.1. F ( )

To move the plaorm inside the sha, before the safety contacts are installed,

→make the following connecons::

• R, S, T, GND, (neutral).

• Hoist motor.

• Rope: brake.

• Variable speed drive: hook the shielded cable up between the enclosure and the hoist motor.

• Hydraulic: solenoid valves.

• For the Commissioning Kit, refer to the wiring diagram for the system in queson.

IMPORTANT

For the numbers of the terminals, refer to the system's wiring diagram.

→jumper the terminals:

• For RM mini-contactor excitaon.

• To bypass the safety chain contacts.

N.B.: some terminals are oponal, if they are not present go to the next terminal.

• Oponal : 24 VDC bi-stable.

NORMAL

INSPECTION

ELETTROQUADRI

SINCE 1983

I

3

14 / 54

USER, MAINTENANCE AND INSTALLATION MANUAL

© ELETTROQUADRI S.r.l.

MP2

MP2 rev. 2.9

• For moving the car up.

• For moving the car down.

IMPORTANT

For the response to the up/down control, refer to “InspecƟon control”.

CAUTION

Before puƫng into operaƟon remove all jumpers previously wired.

NORMAL

INSPECTION

NORMAL

INSPECTION

DOWN

UP

ELETTROQUADRI

SINCE 1983

I 3

15 / 54

USER, MAINTENANCE AND INSTALLATION MANUAL

© ELETTROQUADRI S.r.l.

MP2

MP2 rev. 2.9

3.2. I

3.2.1. INSPECTION CONTROL WITH BILM3/BILM4 SWITCH

The inspecon control is acvated by seng the switch from “NOR” to “ISP” posion. The RM mini-relay is energized

and sends the informaon that inspecon control has been acvated to terminal J11/6(RM) of the board; “HH” signal

will appear on board display.

The contactors are controlled by the board which actuates the control signals received from the inspecon control

panel:

• Inputs J7/1(▼) and J7/2(▲) receives the control signals from the “down” and “up” buons (if both signals are

present, no control signal is output).

• The “down” and “up” buons, via their diodes, terminal 2A or BSQ/BQD and the RM contact, power the safety chain;

the board checks for voltage at input J7/8 (led D3) and outputs the close doors signal.

• When full closure of the safety chain is confirmed via the pick-up point at input J7/10 (led D4), the slide and contactors

are acvated.

• Depending on the signals at inputs J7/1(▼) and J7/2(▲) the board acvates the high speed+down outputs (GV+D) or

high speed+up outputs (GV+S) and monitors their excitaon and de-excitaon as in normal operaon.

• To prevent repeated jog operaon in a single direcon of travel and immediate reversal of direcon, a delay of 1

second has been introduced between the release of a buon and the response of the board to the next operaon of

the same or another direcon buon.

• The faults indicaon is also acve during the inspecon acvity.

• The run of the car is limited by CRS and CRD mechanical switches or by bistable CRSB / CRDB switches at the top and

boom floors.

• Once the inspecon is completed, the car, if it has been moved, resets to the lowest floor, or to its former desnaon.

3.2.2. INSPECTION CONTROL WITH BILM5 SWITCH ( N= YES)

The inspecon control is acvated by seng the switch from “NOR” to “ISP” posion. The RM mini-relay is energized

and sends the informaon that inspecon control has been acvated in response to the board inputs; the following

appear on the board display.

HH = No control panel under inspecon (if the chain confirms reseng in progress…)

H1 = Inspecon from car top.

H2 = Inspecon from panel

H3 = Inspecon from panel + car top.

H4 = Inspecon from pit

H5 = Inspecon from car top + pit

H6 = Inspecon from panel + pit

H7 = Inspecon from pit + car top + panel

HFLASHING = pit control panel inspecon acvaon memory: reset MP2 microprocessor board with RST key.

ELETTROQUADRI

SINCE 1983

I

3

16 / 54

USER, MAINTENANCE AND INSTALLATION MANUAL

© ELETTROQUADRI S.r.l.

MP2

MP2 rev. 2.9

3.3. R

In the sha, the board loses knowledge of the car posion under the following condions:

• Loss of power.

• Aer inspecon control (when the car has been moved).

• When reset buon on the board is acvated.

• Aer board programming sequence or mers adjustment.

• When CRS/CRD (or CRSB/CRDB) slowing down commands are acvated due to car out-of-step condion.

• Aer faults where reset to the lowest floor is needed.

The reset sequence will always bring the car to lowest floor; different condions are possible:

• Car already at the lowest floor (UM/DM led on and CRD or CRDB reset contact open): the reset happens without

moving the car.

• Car slightly higher than the lowest floor (CRD or CRDB reset contact open): the car moves down at low speed, and stops

when it encounters both magnec strips at the lowest floor level.

• Car in higher posion in the sha(CRD or CRDB reset contact closed): the car moves down at high speed, and stops

when it trips the lower CRD reset contact; it restarts down at low speed, and stops when it encounters both magnec

strips at the lowest floor level.

IMPORTANT

“ConƟnuous reset” (i.e. with stop and restart) can be set with parameter t0 (see par. 4.5. “Programming the

MP2 board”) by entering the car speed (in m/s), posiƟoning the DM slowdown strip at the boƩom floor (length

30 cm), and adjusƟng parameter P6 to delay acƟvaƟon (if necessary).

• Car slightly lower than lowest floor level (UM led on and CRD or CRDB reset contact open):

▪Hydraulic: the releveling circuit, if separate from the board.

▪Rope: the car moves up direcon at low speed and stops when it encounters both the magnec strips.

IMPORTANT

If the main floor is not the lowest floor, the reset described above will conclude with the car returning to the

main floor.

IMPORTANT

On shaŌencoder systems, the system resets at the closest floor.

ELETTROQUADRI

SINCE 1983

P 4

17 / 54

USER, MAINTENANCE AND INSTALLATION MANUAL

MP2

4 PROGRAMMING

4.1. G

INSTALLER

CAUTION

During operaƟons the operator must wear all the necessary Personal ProtecƟve Equipment (PPE).

RESIDUAL RISK OF ELECTROCUTION

Risk of electrocuƟon relaƟng to all parts which remain live when the cabinet is opened.

IMPORTANT

The Manufacturer declines all liability for operaƟons performed:

• by inadequate personnel;

• without observing the health and safety regulaƟons in force;

• without observing the procedures provided in these instrucƟons.

IMPORTANT

Before performing any procedure make sure you have read and understood all the various steps, seen all the

relaƟve images and adopted the safety and protecƟon measures described.

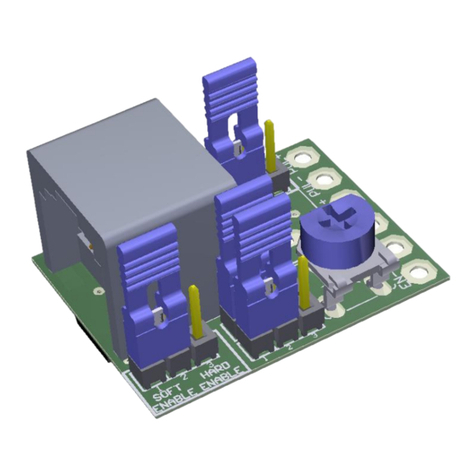

4.2. P

PROGR ENT/RST

M2A

01234567 01234567 01 234567

IA

IB

IC

ID

D1

D2

D3

D4

DM

UM

DMS

DMD

CCA

NF

FTA

FTB

CCS

CF1

CF3

CF2

CF5

CF4

DOB

DCB

SRV

FRM

OK

DS

DD

CP

APA

APB

S

D

PV

GV

PAT

AUX

LC

WD

FS

PR1

PR2

DPX

MPX

M1A

M1B M2B

1234 5 6 7 8910

11 12

1234 5 6 7 8910

11 12

RL1 RL2

PROGR

Select the opons in the item.

ENT/RST

Select an item and confirm the selected opons by

moving to the next item.

The display will show the items and their selected

opons alternately.

DISPLAY

ELETTROQUADRI

SINCE 1983

P

4

18 / 54

USER, MAINTENANCE AND INSTALLATION MANUAL

MP2

4.2.1. MP2

IMPORTANT

With non MP2/NR or MP2/ND boards.

1OFF Normal operaon.

ON Disables door opening.

2OFF Normal operaon.

ON Not used.

3OFF/ON Not used.

4OFF Stops at the last served floor.

ON Returns to the main floor or parks at a parking floor.

5OFF Park with doors open.

ON Park with doors closed.

6OFF/ON See par. 6.7.

7OFF/ON See par. 6.7.

8OFF/ON See par. 6.7.

4.2.2. B

Indicaon on the display Descripon

Program release version (e.g. “rl51”); displays on power up.

System reseng.

Floor posion indicator (e.g. “-1”).

Combinaon of leers and numbers for programming the board, mers and other

variables and funcons.

See par. “4.5. PROGRAMMING THE MP2 BOARD”.

Error message.

See par. “5.2. FAULT TABLE AND FAULT FINDING”.

Inspecon manoeuvre in progress.

Programming mode Pb→AC:

• front access only.

ELETTROQUADRI

SINCE 1983

P 4

19 / 54

USER, MAINTENANCE AND INSTALLATION MANUAL

MP2

Indicaon on the display Descripon

Programming mode Pb→AC:

• rear access only.

Programming mode Pb→AC:

• both accesses.

Programming mode PS:

• duplo/duplex/triplex/quadruplex: floors not served.

Normal operaon, actuaon:

• of a car call buon.

• of a floor call buon.

Normal operaon, actuaon:

• of the door open buon.

• of the photocells or mobile rib.

• of the overload.

• of machine room temperature.

Normal operaon:

• mer running.

ELETTROQUADRI

SINCE 1983

P

4

20 / 54

USER, MAINTENANCE AND INSTALLATION MANUAL

MP2

4.3. P MP2

Use the following keys to program the board: PROGR, ENT/RST.

There are three ways to access it:

• aer opening the automac valve VA (always present in the electrical cabinet);

• aer opening the safety chain switch IM (oponal);

• via inspecon of the manoeuvre cabinet (oponal).

Disconnect the call terminals before proceeding.

For example: open the automac valve VA, then hold down PROGR and aer 1 second press the key ENT/RST 4 mes: this

opens the MAIN MENU (the displays shows SP and the program code alternately).

IMPORTANT

To quit programming, simply close the automaƟc valve VA at any Ɵme.

IMPORTANT

Reset the board by holding the “RESET” buƩon down for 5 sec.

IMPORTANT

The programmed data MUST be confirmed with ENT/RST.

PROGR Press PROGR to change the program/move the dot/modify the parameter.

ENT/RST Press ENT/RST to enter the selected program/confirm the seng.

Key/Terminal block Funcon

M1A/0 + GND increments numerical values.

M1B/0 + GND decrements numerical values.

Table of contents

Other ELETTROQUADRI Computer Hardware manuals