Elis FLONET FN50 Series User manual

ELIS PLZEŇ a. s.

Design, Assembly and Service Manual

Page 1 of 32

Electromagnetic flowmeter FLONET FN50xx.1

ELIS PLZEN a. s., Lucni 425/15, 301 00 Plzen, Czech Republic, Phone: +420/377 517 711, fax: +420/377 517 722 Es90716K

Electromagnetic Flowmeter

FLONET FN50xx.1

ELIS PLZEŇ a. s.

Design, Assembly and Service Manual

Page 2 of 32

Electromagnetic flowmeter FLONET FN50xx.1

ELIS PLZEN a. s., Lucni 425/15, 301 00 Plzen, Czech Republic, Phone: +420/377 517 711, fax: +420/377 517 722 Es90716K

ELIS PLZEŇ a. s.

Design, Assembly and Service Manual

Page 3 of 32

Electromagnetic flowmeter FLONET FN50xx.1

ELIS PLZEN a. s., Lucni 425/15, 301 00 Plzen, Czech Republic, Phone: +420/377 517 711, fax: +420/377 517 722 Es90716K

Content

1. APPLICATION ...............................................................................................................................................4

2. MEASUREMENT PRINCIPLE ......................................................................................................................4

3. TECHNICAL DESCRIPTION.........................................................................................................................5

3.1. GENERAL................................................................................................................................................................... 5

3.2. METER DESIGN........................................................................................................................................................... 5

3.3. PROTECTION OF METERS AGAINST UNPROFESSIONAL HANDLING..................................................................................... 7

4. TECHNICAL PARAMETERS.........................................................................................................................8

4.1. FLOW SENSOR............................................................................................................................................................ 8

4.1.1. Selection of correct sensor size........................................................................................................................ 8

4.1.2. Operational pressure of measured liquid........................................................................................................ 12

4.1.3. Material of electrodes..................................................................................................................................... 12

4.1.4. Selection of sensor lining ............................................................................................................................... 12

4.1.5. Dimensions of flangeless sensor ISX.Mxx (for heat meters).......................................................................... 13

4.1.6. Dimensions of flanged sensor IS0.Mxx (for heat meters)............................................................................... 14

4.1.7. Dimensions of flangeless sensor ISX.1xx ..................................................................................................... 15

4.1.8. Dimensions of flanged sensor ISX.1xx........................................................................................................... 16

4.1.9. Technical data of sensor................................................................................................................................ 17

4.2. ELECTRONIC UNIT BOX .............................................................................................................................................. 18

4.2.1. Electronic unit specifications.......................................................................................................................... 18

5. METER APPLICATION RULES ............................................................................................................... 19

5.1. SENSOR PLACEMENT IN PIPING................................................................................................................................... 19

5.2.SENSOR EARTHING ................................................................................................................................................... 21

6. FLOWMETER INSTALLATION AND OPERATIONAL START................................................................. 22

6.1. SENSOR INSTALLATION.............................................................................................................................................. 22

6.2. ELECTRIC CONNECTIONS OF ELECTROMAGNETIC FLOWMETER ....................................................................................... 22

6.2.1. Connection to power source........................................................................................................................... 22

6.2.2. Output signal connections.............................................................................................................................. 23

6.3. OPERATIONAL START ................................................................................................................................................ 24

7. OPTIONAL SETTINGS............................................................................................................................... 24

7.1. Samples............................................................................................................................................................ 24

7.2. Pulse output OUT1............................................................................................................................................ 25

8. ERROR REMOVAL AND METER REPAIR PROCEDURES FN50X0....................................................... 25

8.1. FLOW-METERREPAIR PROCEDURE................................................................................................................. 26

9. PACKAGING............................................................................................................................................... 27

10. PRODUCT ACCEPTANCE....................................................................................................................... 27

11. WARRANTY CONDITIONS...................................................................................................................... 27

12. PRODUCT ORDERING ............................................................................................................................ 28

ELIS PLZEŇ a. s.

Design, Assembly and Service Manual

Page 4 of 32

Electromagnetic flowmeter FLONET FN50xx.1

ELIS PLZEN a. s., Lucni 425/15, 301 00 Plzen, Czech Republic, Phone: +420/377 517 711, fax: +420/377 517 722 Es90716K

1. APPLICATION

The FLONET FN50xx.1 electromagnetic flowmeter has been designed to measure volume flow rates of

electrically conductive liquids in closed piping systems. It enables flow measurement with high accuracy in a

wide range of flow rates (0.05 to 10 m/s) unlike the previous type FLONET FN20xx.1 (range 1:100) in

extended range 1:200.

It is supplied in a compact design (dismountable piece of flow sensor and electronic unit) as a “blind”

(without a display) low-cost flowmeter for heat and cold measurement systems.

There is also a remote design of this flowmeter with a junction box on the top of chimney connected

to a cable with an electronic unit fitted with L-shaped steel angle bracket at the other end of the cable.

Power supply range is 230 VAC (or110 VAC). The flowmeter has only one galvanic isolated passive pulse

output OUT1.

The basic parameters can be set during activation process using special USB channel and sw FLOSET (it

isn’t standard in a delivery) .

2. MEASUREMENT PRINCIPLE

The function of an electromagnetic flowmeter is based on Faraday’s induction law. The meter sensor

consists of a non-magnetic and non-conductive tube with two embedded measuring electrodes to pick up the

induced voltage. To create an alternating magnetic field, two coils are fitted onto the tube in parallel with the

plane defined by the active parts of the measuring electrodes. Now if a conductive liquid flows across

magnetic field B, voltage Uwill appear on the measuring electrodes proportional to the flow velocity v and

the conductor length l.

U = B x l x v

Uinduced voltage

B magnetic flux density

l distance between the measuring electrodes

v liquid flow velocity

As the magnetic flux density and distance between the electrodes are constant, the induced voltage is

proportional to the liquid flow velocity in the tube. The value of the volume flow rate can then be readily

determined as a product of the flow velocity and square section of the tube, Q = v x S.

ELIS PLZEŇ a. s.

Design, Assembly and Service Manual

Page 5 of 32

Electromagnetic flowmeter FLONET FN50xx.1

ELIS PLZEN a. s., Lucni 425/15, 301 00 Plzen, Czech Republic, Phone: +420/377 517 711, fax: +420/377 517 722 Es90716K

3. TECHNICAL DESCRIPTION

3.1. General

The electromagnetic flowmeter consists of a sensor through which the measured liquid flows and an

electronic unit where the low-level signal from the sensor is modified to a standardized form suitable for

further processing in various industrial electronic devices. The output signal is proportional to the volume

flow rate of the measured liquid. The only factor limiting the application of electromagnetic flowmeters is the

requirement that the measured liquid shall be conductive and non-magnetic. The electromagnetic flowmeter

can be designed as a compact or remote device. The meter sensor is with different type of lining (hard

rubber, soft rubber and special hard rubber for drinking water, PTFE or E-CTFE), with electrodes from

different material and in flanged or wafer (flangeless) version.

Cold meters always must be in a remote design!

The reason is a risk of moisture condensation inside of the cooled electronic unit in a compact design that

can be caused by drawing in a surrounding air.

Flow meters for heat meters in a compact design may have a sensor with a prolonged chimney (made of

stainless material). Such a sensor can measure media with temperatures up to 150ºC provided that the

sensor and pipeline are thermally insulated and the ambient temperature doesn’t exceed 60ºC.

When choosing a sensor for cold or heat measurement, physical parameters of lining must be taken into

account –see 4.1.4 Selection of flow sensor lining

3.2. Meter design

Compact design solution for a flangeless sensor and associated electronic unit

Compact design solution for a flanged sensor with associated electronic unit

ELIS PLZEŇ a. s.

Design, Assembly and Service Manual

Page 6 of 32

Electromagnetic flowmeter FLONET FN50xx.1

ELIS PLZEN a. s., Lucni 425/15, 301 00 Plzen, Czech Republic, Phone: +420/377 517 711, fax: +420/377 517 722 Es90716K

Example of flowmeter assembly in the remote design version

Dimensions of the box to accommodate the flowmeter in the compact design version

ELIS PLZEŇ a. s.

Design, Assembly and Service Manual

Page 7 of 32

Electromagnetic flowmeter FLONET FN50xx.1

ELIS PLZEN a. s., Lucni 425/15, 301 00 Plzen, Czech Republic, Phone: +420/377 517 711, fax: +420/377 517 722 Es90716K

3.3. Protection of meters against unprofessional handling

The meter shall be provided with an assembly seals after installation, which can do duly authorized

organization, which is trained from the producer.

Placement of official and assembly seals on meters.

ASSEMBLY

SEAL

ELIS PLZEŇ a. s.

Design, Assembly and Service Manual

Page 8 of 32

Electromagnetic flowmeter FLONET FN50xx.1

ELIS PLZEN a. s., Lucni 425/15, 301 00 Plzen, Czech Republic, Phone: +420/377 517 711, fax: +420/377 517 722 Es90716K

4. TECHNICAL PARAMETERS

4.1. Flow sensor

The sensor environment must be free of any strong magnetic fields.

4.1.1. Selection of correct sensor size

The following table shows minimum and maximum flow rates for various sensor sizes and flow velocities

ranging from 0,05 to10 m/s. The best operational properties will be achieved at the flow-velocity range of 0.5

to 5 m/s. For lower flow velocities, the measurement accuracy is worse while at higher flow velocities the

turbulences at contact edges may cause undesirable interference.

Minimum and maximum flow rates for various sensor sizes

Qmin corresponds to flow velocity 0.05 m/s

Qmax corresponds to flow velocity 10.0 m/s

DN

l / s

m3 / h

Qmin

Qmax

Qmin

Qmax

15

0.0072

1,8

0,026

6,5

20

0,013

3,3

0,048

12

25

0,025

5

0,09

18

32

0,04165

8,33

0,15

30

40

0,0625

12,5

0,225

45

50

0,1

20

0,36

72

65

0,16665

33,33

0,6

120

80

0,25

50

0,9

180

100

0,38885

77,77

1,4

280

125

0,5972

119,44

2,15

430

150

0,90275

180,55

3,25

650

200

1,597

319,4

5,75

1150

250

2,5

500

9

1800

300

3,5

700

12,6

2520

350

4,86

972

17,5

3500

400

6,25

1250

22,5

4500

500

10

2000

36

7200

600

11,1

2778

40

10000

700

15,5

3889

56

14000

800

20,0

5000

72

18000

ELIS PLZEŇ a. s.

Design, Assembly and Service Manual

Page 9 of 32

Electromagnetic flowmeter FLONET FN50xx.1

ELIS PLZEN a. s., Lucni 425/15, 301 00 Plzen, Czech Republic, Phone: +420/377 517 711, fax: +420/377 517 722 Es90716K

The basic parameters of flow meters for heat/cold meters are designed in compliance of standard EN1434

(OIML R 75).

Below is issued ratio of following flow rates:

qs

= 2

qp

Size DN

Overload

flow

qs[m3/h]

Permanent

flow

qp[m3/h]

Min. flow

qi[m3/h]

Ratio

qp/pi

15

6,5

3

0,0163

200

20

12

6

0,0300

25

18

9

0,0450

32

30

15

0,0750

40

45

23

0,1125

50

72

36

0,1800

65

150

75

0,3750

80

180

90

0,4500

100

280

140

0,70

125

430

215

1,08

150

650

325

1,6

200

1 150

575

2,9

250

1 800

900

4,5

300

2 520

1 260

6,30

350

3 500

1 750

9

400

4 500

2 250

11

500

7 200

3 600

18,0

600

10 000

5 000

25

700

14 000

7 000

35

800

18 000

9 000

45

Data in the table are valid for accuracy higher than ±2% in range qmin x% ≤ qi≤ qs

Legend:

qs = overload (maximum) flow rate of a measured liquid

qp= permanent (nominal) flow rate of a measured liquid

qi= min flow rate for an accuracy of measurement

ELIS PLZEŇ a. s.

Design, Assembly and Service Manual

Page 10 of 32

Electromagnetic flowmeter FLONET FN50xx.1

ELIS PLZEN a. s., Lucni 425/15, 301 00 Plzen, Czech Republic, Phone: +420/377 517 711, fax: +420/377 517 722 Es90716K

The basic parameters of flow meters are designed in compliance of standard ISO 4064 (OIML R 49).

Below is issued ratio of following flow rates:

Q4

= 1.25

Q2

= 1.6

Q3

Q1

An accuracy complies of standard EN ISO 4064-1 (OIML R 49)

Values in the table are acc to standard ISO 4064-1 (OIML R 49).

-6

-4

-2

0

2

4

6

Q1 Q2 Q3 Q4

Relative error [%]

ELIS PLZEŇ a. s.

Design, Assembly and Service Manual

Page 11 of 32

Electromagnetic flowmeter FLONET FN50xx.1

ELIS PLZEN a. s., Lucni 425/15, 301 00 Plzen, Czech Republic, Phone: +420/377 517 711, fax: +420/377 517 722 Es90716K

Values of flow Q1, Q2, Q3a Q4 ,which apply to individual design variants and to dimensions, are written in the

table 2 below:

Table 2

Size DN

Over load

flow

Q4 [m3/h]

Permanent

flow

Q3 [m3/h]

Transition

flow

Q2 [m3/h]

Min. flow

Q1 [m3/h]

Insensitivity

[m3/h]

Q1 35%

Insensitivity

[m3/h]

Q1 50%

Ratio

Q3/Q1

15

6,5

5,2

0,0416

0,026

0,0091

0,013

200

20

12

9,6

0,0768

0,048

0,0168

0,024

25

18

14,4

0,1152

0,072

0,0252

0,036

32

30

24

0,192

0,12

0,042

0,06

40

45

36

0,288

0,18

0,063

0,09

50

72

57,6

0,4608

0,288

0,1008

0,144

65

120

96

0,768

0,48

0,168

0,24

80

180

144

1,152

0,72

0,252

0,36

100

280

224

1,79

1,12

0,392

0,56

125

430

344

2,75

1,72

0,602

0,86

150

650

520

4,16

2,6

0,91

1,3

200

1 150,0

920

7,36

4,6

1,61

2,3

250

1 800,0

1 440,0

11,52

7,2

2,52

3,6

300

2 520,0

2 016,0

16,13

10,08

3,528

5,04

350

3 500,0

2 800,0

22,4

14

4,9

7

400

4 500,0

3 600,0

28,8

18

6,3

9

500

7 200,0

5 760,0

46,08

28,8

10,08

14,4

600

10 000,0

8 000,0

64

40

14

20

700

14 000,0

11 200,0

89,6

56

19,6

28

800

18 000,0

14 400,0

115,2

72

25,2

36

Legend:

Q4overload (maximum) low (maximum)

Q3permanent (nominal) flow

Q2 transition flow

Q1min. flow for specific accuracy

ELIS PLZEŇ a. s.

Design, Assembly and Service Manual

Page 12 of 32

Electromagnetic flowmeter FLONET FN50xx.1

ELIS PLZEN a. s., Lucni 425/15, 301 00 Plzen, Czech Republic, Phone: +420/377 517 711, fax: +420/377 517 722 Es90716K

4.1.2. Operational pressure of measured liquid

The standard flow-sensor versions have the following pressure ratings:

Sensor size

Pressure rating

DN 15 to DN 50

PN 40 (4,0 MPa)

DN 65 to DN 200

PN 16 (1,6 MPa)

DN 250 to DN 800

PN 10 (1,0 MPa)

Relationship between operational pressure and temperature of the measured liquid.

4.1.3. Material of electrodes

Measurement electrodes are made of stainless steel 1.4571 (316Ti). Some special applications require

use of higher-quality and more resilient materials. We provide electrodes made of Hastelloy C276, Tantalum,

Titanium and Platinum-Rhodium (PtRh10).

4.1.4. Selection of sensor lining

The sensors are produced with linings of different materials. Selection of lining material depends on

properties of measured liquid.

Soft rubber, low aggressive liquids, -35oC to 80ºC, higher content of abrasive particles

Hard rubber, low aggressive liquids, +5 to 80ºC

Special rubber for potable water, +5 to 80ºC

Teflon PTFE, aggressive liquids with operating temperature –20 to +110ºC, on request –35 to +150ºC

E-CTFE, operating temperature -20 to +110ºC, for dimensions over DN300, on request –35 to +130ºC

ELIS PLZEŇ a. s.

Design, Assembly and Service Manual

Page 13 of 32

Electromagnetic flowmeter FLONET FN50xx.1

ELIS PLZEN a. s., Lucni 425/15, 301 00 Plzen, Czech Republic, Phone: +420/377 517 711, fax: +420/377 517 722 Es90716K

4.1.5. Dimensions of flangeless sensor ISX.Mxx (for heat meters)

L

D

A

DN

M6

Flangeless sensor dimensions for various rated diameters (DN)

DN

D

A*

L

Hmotnost

[ kg ]

25

72

165

104

2

PN40

32

82

175

104

2

40

92

186

104

2

50

107

199

104

3

65

127

219

104

3

80

142

234

104

4

PN16

100

162

254

104

4

125

192

284

134

6

150

218

310

134

8

200

274

366

219

10

* Height is considered without the electronic unit, without the junction box respectively. Weight

of sensor has an indicative character.

ELIS PLZEŇ a. s.

Design, Assembly and Service Manual

Page 14 of 32

Electromagnetic flowmeter FLONET FN50xx.1

ELIS PLZEN a. s., Lucni 425/15, 301 00 Plzen, Czech Republic, Phone: +420/377 517 711, fax: +420/377 517 722 Es90716K

4.1.6. Dimensions of flanged sensor IS0.Mxx (for heat meters)

l

L

d

A

DN

D

M6

Dimensions of flanged sensor according to DN

Flanges according to the norm EN 1092-1

DN

D

d

A*

L

l

Weight

[ kg ]

15

95

62

x

200

66

2

20

105

62

x

200

66

2,5

25

115

72

187

200

96

3

PN40

32

140

82

206

200

96

4

40

150

92

216

200

96

4

50

165

107

230

200

96

6

65

185

127

251

200

96

9

80

200

142

267

200

96

14

PN16

100

220

162

287

250

96

16

125

250

192

317

250

126

19

150

285

218

347

300

126

25

200

340

274

405

350

211

41

PN10

250

395

370

487

450

211

54

300

445

420

542

500

320

77

350

505

480

591

550

320

92

400

565

530

649

600

320

116

500

670

640

759

600

320

167

600

780

760

877

600

320

288

700

895

880

997

700

420

356

PN6

800

975

960

1107

800

420

427

* Height is considered without the electronic unit, without the junction box respectively. Weight of flow

sensor has an indicative character.

ELIS PLZEŇ a. s.

Design, Assembly and Service Manual

Page 15 of 32

Electromagnetic flowmeter FLONET FN50xx.1

ELIS PLZEN a. s., Lucni 425/15, 301 00 Plzen, Czech Republic, Phone: +420/377 517 711, fax: +420/377 517 722 Es90716K

4.1.7. Dimensions of flangeless sensor ISX.1xx

L

A

D

DN

Dimensions of flangeless sensor according to DN

DN

D

A*

L

Hmotnost

[ kg ]

25

72

158

104

2

PN40

32

82

168

104

2

40

92

179

104

2

50

107

192

104

3

65

127

212

104

3

80

142

227

104

4

PN16

100

162

247

104

4

125

192

277

134

6

150

218

303

134

8

200

274

359

219

10

* Height is considered without the electronic unit, without the junction box respectively. Weight

of flow sensor has an indicative character.

ELIS PLZEŇ a. s.

Design, Assembly and Service Manual

Page 16 of 32

Electromagnetic flowmeter FLONET FN50xx.1

ELIS PLZEN a. s., Lucni 425/15, 301 00 Plzen, Czech Republic, Phone: +420/377 517 711, fax: +420/377 517 722 Es90716K

4.1.8. Dimensions of flanged sensor ISX.1xx

D

DN

l

L

d

A

Dimensions of flanged flow sensor according to DN

Flanges according to the norm ČSN EN 1092-1

DN

D

d

A*

L

l

Weight

[ kg ]

15

95

62

x

200

66

2,5

20

105

62

170

200

66

3

25

115

72

180

200

96

3

PN40

32

140

82

199

200

96

4

40

150

92

209

200

96

4

50

165

107

223

200

96

6

65

185

127

244

200

96

9

80

200

142

260

200

96

14

PN16

100

220

162

280

250

96

16

125

250

192

310

250

126

19

150

285

218

340

300

126

25

200

340

274

398

350

211

41

PN10

250

395

370

480

450

211

54

300

445

420

535

500

320

77

350

505

480

584

550

320

92

400

565

530

642

600

320

116

500

670

640

752

600

320

167

600

780

760

x

600

320

288

700

895

880

x

700

420

x

PN6

800

975

960

x

800

420

427

* Height is considered without the electronic unit, without the junction box respectively. Weight of flow

sensor has an indicative character.

ELIS PLZEŇ a. s.

Design, Assembly and Service Manual

Page 17 of 32

Electromagnetic flowmeter FLONET FN50xx.1

ELIS PLZEN a. s., Lucni 425/15, 301 00 Plzen, Czech Republic, Phone: +420/377 517 711, fax: +420/377 517 722 Es90716K

4.1.9. Technical data of sensor

Dimensions of sensor

Flangeless DN 25 to DN 200

Flanged DN 15 to DN 800

Operating pressure

PN 40 (4,0 MPa) for DN 15 to DN 50

PN 16 (1,6 MPa) for DN 65to DN 200

PN 10 (1,0 MPa) for DN 250to DN 800

Connection of sensor

Flangeless

Flanged

Earthing

Earthing electrode

Flow rate of measured liquid

0,05 m/s to 10 m/s (range 1:200)

Temperature of measured liquid

110oC

Up to 150ºC on a request (based on lining type and

when using sensor with prolonged chimney made of

stainless material) –see article 4.1.4

Minimum conductivity of measured liquid

20 μS/cm, based on agreement with manufacturer up

to 5 μS/cm

Lining

Soft rubber

Hard rubber

Rubber for potable water

Teflon PTFE

E - CTFE

Electrodes

Stainless steel 1.4571 (316Ti)

Hastelloy C276

Tantalum

Titanium

Platinum-Rhodium (PtRh10)

Ingress protection

IP 65

Storage temperature

-10ºC to +70ºC, at the max. relative humidity 70 %

ELIS PLZEŇ a. s.

Design, Assembly and Service Manual

Page 18 of 32

Electromagnetic flowmeter FLONET FN50xx.1

ELIS PLZEN a. s., Lucni 425/15, 301 00 Plzen, Czech Republic, Phone: +420/377 517 711, fax: +420/377 517 722 Es90716K

4.2. Electronic unit box

The signal-processing electronic unit is accommodated in a cast aluminum box coated on the surface with

paint of hue RAL 1017. The box is held by four (2x hexagonal head and 2x countersunk head) M5 bolts with

hexagonal socket heads. Inside the box is the terminal board accessible by removing the cover fastened by

4 bolts. The side of the box is equipped by cable glands. Prior to putting the meter in service, check the

correct sealing of all active glands, and tightening of the bolts holding the cover of the box.

The remote version of electronic unit is equipped with L- shaped angle bracket for wall mounting. Through

the cable bushing fitted at the angle bracket, the connecting cable connects electronic unit and junction box

of sensor.

4.2.1. Electronic unit specifications

Power source

85 to 305 VAC /47 ÷ 440 Hz

Power consumption

3 VA max.

Line fuse

T2 A

Electric shock protection according to standard

ČSN 332000-4-41

Automated disconnection from power source in TN-S

network

Cable bushing Pg9

For power supply cable with a diameter of 5 to 10 mm

Box material

Aluminum casting

Weight

0,4 kg

Ambient temperature

-5 °C to 55 °C (protected from direct sun light)

Storage temperature

-10 °C to 70 °C at relative air humidity not exceeding 70%

Flow velocity range

0,05 to 10 m/s

Maximum flow error

Acc to standard EN1434 or ISO4064-1 class 2 (standard)

0,2 % for 10 to 100 % Qmax (on request)

0,5 % for 5 to 100 % Qmax (on request)

Output 1 - passive output, insulated

Binary multi-function optocoupler 5-30 V / 50 mA

Frequency or pulse or binary *)

Serial communication ports

USB not insulated, only for service

Protection class

IP 65

*) A variant must be specified by an order. The calibration is done for a chosen output!

ELIS PLZEŇ a. s.

Design, Assembly and Service Manual

Page 19 of 32

Electromagnetic flowmeter FLONET FN50xx.1

ELIS PLZEN a. s., Lucni 425/15, 301 00 Plzen, Czech Republic, Phone: +420/377 517 711, fax: +420/377 517 722 Es90716K

5. METER APPLICATION RULES

5.1. Sensor placement in piping

No chemical injection or batching unit (such as chlorine compound injector) should be located at the input

side of the sensor. The insufficient homogeneity of the flowing liquid may affect the flow-rate values indicated

by the meter.

The meter performance will be the best if the liquid flow in the piping is well stabilized; therefore it is

necessary to observe specific rules for the sensor placement in piping. In the contact planes between the

sensor and the adjoining piping sections should be no edges as these would cause flow turbulence. Make

sure that straight piping sections are provided before and after the sensor; their required length is

proportional to the inner diameter of the piping concerned.

As required by clause 4.2.1 of standard EN 29104, the inner diameter of the connected pipe should not differ

by more than 3% from that of the sensor.

If more than one flow-disturbing element such as pipe bend or fitting are located near the sensor, the

required length of straight piping section on the sensor side concerned should be multiplied by the quantity

of such elements.

In the cases of bi-directional flow-rate measurement, the same conditions concerning flow stability shall be

met at the input and output sides of the sensor.

Required straight piping sections Pipe narrowing

In the cases where the pipe size larger than that of the meter sensor, it is necessary to use conical reduction

pieces with the angle of taper not exceeding 15° (see the picture). In the cases of bi-directional flow

measurement, the minimum length of straight piping sections on both sides is 5 DN. In horizontal sensor

installations, to prevent bubbling, use eccentrically-fitted reduction pieces (see standard EN ISO 6817).

Pipe narrowing sections with angles not exceeding 8° can be taken for straight sections.

In the cases where the liquid is pumped, the flow sensor shall always be placed at the output side of the

pump to prevent under pressure in the piping which might damage the sensor. The required length of the

straight piping section between the pump and sensor is then at least 25 DN.

Pump in the piping Closing valve in the piping

ELIS PLZEŇ a. s.

Design, Assembly and Service Manual

Page 20 of 32

Electromagnetic flowmeter FLONET FN50xx.1

ELIS PLZEN a. s., Lucni 425/15, 301 00 Plzen, Czech Republic, Phone: +420/377 517 711, fax: +420/377 517 722 Es90716K

For the same reason, the sensor shall be always placed before the closing valve in the piping.

The sensor can be fitted in the piping in either horizontal or vertical position. However, make sure that the

electrode axis is always horizontal and, if the sensor is mounted in a horizontal position, the flange section

for attachment of the electronic unit box faces upwards.

ELECTRODE

AXIS

Electrode axis Sensor mounted in a vertical position

In the cases where the sensor is mounted in a vertical position, the flow direction shall always be upwards.

Risk of liquid aeration Permanent flooding of sensor

To ensure correct meter function at all times, the measured liquid shall completely fill up the sensor and no

air bubbles shall be permitted to accumulate or develop in the sensor tube. Therefore the sensor shall never

be placed in the upper pocket of the piping or in a vertical piping section where the flow direction is

downwards.

In piping systems where complete flooding of the piping cannot always be guaranteed, consider placing the

sensor in a bottom pocket where full flooding is ensured.

If the sensor is located near a free discharge point, such point shall be by at least 2 DN higher than the top

part of the sensor.

This manual suits for next models

1

Table of contents

Other Elis Measuring Instrument manuals

Popular Measuring Instrument manuals by other brands

Bender

Bender ISOMETER isoHV425 operating manual

Bierer

Bierer HP72-DCXL operating instructions

Endress+Hauser

Endress+Hauser StamoLys CA 71 CU operating instructions

Draminski

Draminski HMM manual

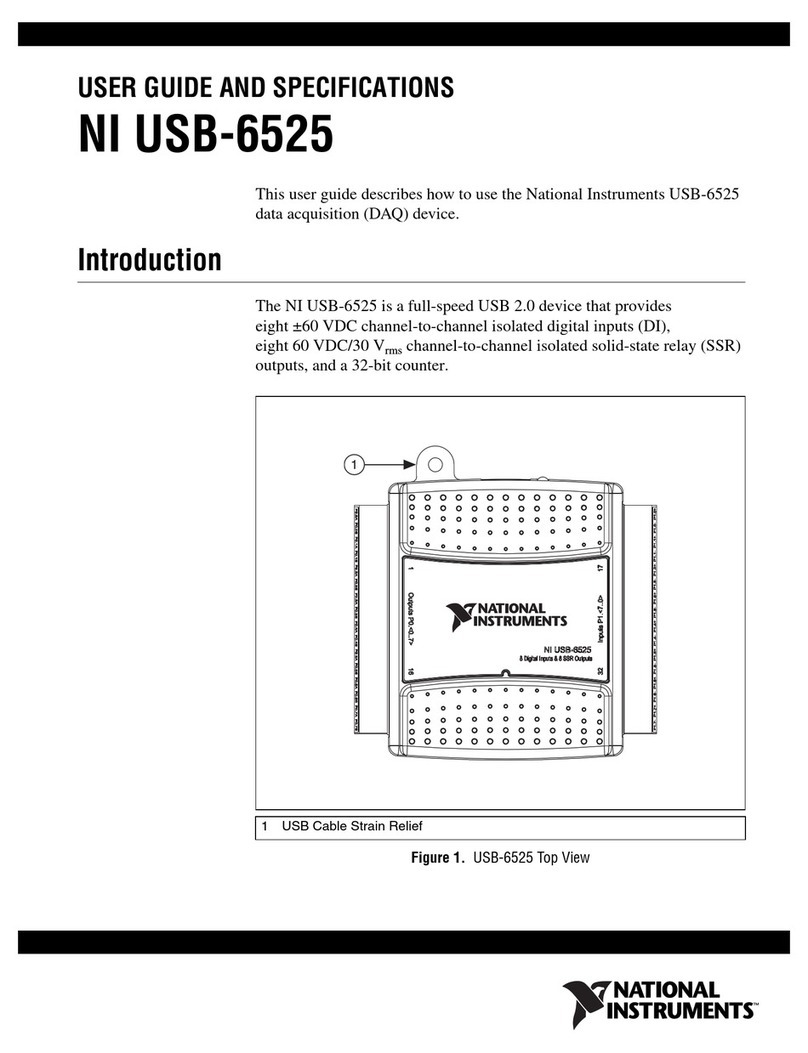

National Instruments

National Instruments 779640-01 user guide

Tektronix

Tektronix KEITHLEY 4200A-SCS-PKC quick start guide