Eljen GSF A42 User manual

Geotextile Sand Filter

CORPORATION

Innovative Onsite Products & Solutions Since 1970

Indiana

Design & Installation Manual

www.eljen.com

June 2018

2018 Indiana Design and Installation Manual 2 www.eljen.com

Table of Contents

SUBJECT PAGE

GLOSSARY OF TERMS .............................................................................................................................. 4

GSF SYSTEM DESCRIPTION ..................................................................................................................... 5

1.0 CONDITIONS FOR USE ........................................................................................................................ 6

1.1 SYSTEM DESIGN .................................................................................................................................. 6

2.0 SUBSURFACE TRENCH AND SINGLE LATERAL BED DESIGN AND INSTALLATION .................... 8

2.1 SUBSURFACE TRENCH AND SINGLE LATERAL BED DESIGN EXAMPLE ................................... 11

2.2 SUBSURFACE TRENCH AND SINGLE LATERAL BED DESIGN INSTALLATION STEPS .............. 13

3.0 SUBSURFACE BED DESIGN AND INSTALLATION .......................................................................... 15

3.1 SUBSURFACE BED DESIGN EXAMPLE ............................................................................................ 17

3.2 SUBSURFACE BED DESIGN INSTALLATION STEPS ...................................................................... 19

4.0 SLOPED SUBSURFACE BED DESIGN AND INSTALLATION ........................................................... 21

4.1 SLOPED SUBSURFACE BED DESIGN EXAMPLE ............................................................................ 23

4.2 SLOPED SUBSURFACE BED DESIGN INSTALLATION STEPS ...................................................... 26

5.0 ELEVATED SAND MOUND DESIGN AND INSTALLATION ............................................................... 28

5.1 ELEVATED SAND MOUND DESIGN EXAMPLE ................................................................................ 30

5.2 ELEVATED SAND MOUND INSTALLATION STEPS.......................................................................... 34

6.0 ABOVE GRADE BED DESIGN AND INSTALLATION ......................................................................... 35

6.1 ABOVE GRADE BED DESIGN EXAMPLE .......................................................................................... 37

6.2 ABOVE GRADE BED DESIGN INSTALLATION STEPS .................................................................... 39

7.0 SLOPED ABOVE GRADE BED DESIGN AND INSTALLATION ......................................................... 41

7.1 SLOPED ABOVE GRADE BED DESIGN EXAMPLE .......................................................................... 43

7.2 SLOPED ABOVE GRADE DESIGN INSTALLATION STEPS ............................................................. 46

8.0 DOSING DISTRIBUTION REQUIREMENTS ....................................................................................... 47

9.0 PRESSURE DISTRIBUTION REQUIREMENTS ................................................................................. 48

10.0 PUMP CONTROLS ............................................................................................................................ 50

11.0 SYSTEM VENTILATION .................................................................................................................... 50

12.0 INSPECTION/MONITORING PORT .................................................................................................. 51

13.0 INDIANA GSF REGISTRATION FORM ............................................................................................. 52

GSF DRAWINGS AND TABLES

DRAWINGS

FIGURE 1: GSF SYSTEM OPERATION .................................................................................................... 5

FIGURE 2: SEQUENTIAL LOADING DIAGRAM ......................................................................................... 7

FIGURE 3: SUBSURFACE A42 TRENCH CROSS SECTION .................................................................... 8

FIGURE 4: SUBSURFACE B43 SINGLE LATERAL BED CROSS SECTION ............................................. 8

FIGURE 5: PLAN VIEW – 450 GPD – B43 –SINGLE LATERAL BED SYSTEM ......................................... 12

FIGURE 6: SECTION VIEW – B43 – SINGLE LATERAL BED SYSTEM – ≤ 0.5% SLOPE ........................ 12

FIGURE 7: SECTION VIEW – B43 – SINGLE LATERAL BED SYSTEM – 0.5 – 15% SLOPE .................. 12

FIGURE 8: SUBSURFACE BED CROSS SECTION ................................................................................. 15

FIGURE 9: PLAN VIEW – 600GPD – A42 – BED SYSTEM – ≤ 0.5% SLOPE ........................................... 18

FIGURE 10: CROSS SECTION VIEW – 600 GPD – A42 – BED SYSTEM – ≤ 0.5% SLOPE .................... 18

FIGURE 11: SUBSURFACE SLOPED BED CROSS SECTION ................................................................ 21

FIGURE 12: PLAN VIEW – 450 GPD – A42 – BED SYSTEM – 0.5 – 15% SLOPE .................................... 25

FIGURE 13: CROSS SECTION VIEW – 450 GPD – A42 – BED SYSTEM – 0.5 – 15% SLOPE ................ 25

FIGURE 14: ELEVATED SAND MOUND CROSS SECTION .................................................................... 28

FIGURE 15: CROSS SECTION – MOUND SYSTEM ................................................................................. 29

FIGURE 16: PLAN VIEW – MOUND SYSTEM .......................................................................................... 29

FIGURE 17: CROSS SECTION – MOUND SYSTEM ................................................................................. 33

FIGURE 18: PLAN VIEW – MOUND SYSTEM .......................................................................................... 33

2018 Indiana Design and Installation Manual 3 www.eljen.com

Table of Contents

FIGURE 19: PLAN VIEW – 600 GPD – APPLICATION AREA MOUND SYSTEM ..................................... 33

FIGURE 20: SUBSURFACE BED CROSS SECTION ............................................................................... 35

FIGURE 21: PLAN VIEW – 600GPD – A42 – BED SYSTEM – ≤ 0.5% SLOPE ......................................... 38

FIGURE 22: CROSS SECTION VIEW – 600 GPD – A42 – BED SYSTEM – ≤ 0.5% SLOPE ..................... 38

FIGURE 23: SLOPED ABOVE GRADE BED CROSS SECTION .............................................................. 41

FIGURE 24: PLAN VIEW – 450 GPD – A42 – BED SYSTEM – 0.5% - 6% SLOPE .................................... 45

FIGURE 25: CROSS SECTION VIEW – 450 GPD – A42 – BED SYSTEM – 0.5% - 6% SLOPE ................ 45

FIGURE 26: PRESSURE PIPE PLACEMENT ............................................................................................ 48

FIGURE 27: PRESSURE CLEAN OUT ..................................................................................................... 49

FIGURE 28: CONTOURED TRENCH INSTALLATION ............................................................................. 49

FIGURE 29: GSF WITH 4” VENT EXTENDED TO CONVENIENT LOCATION......................................... 50

FIGURE 30: MONITORING WELL FOR SAND-SOIL INTERFACE .......................................................... 51

TABLES

TABLE 1: SPECIFIED SAND SIEVE REQUIREMENTS ............................................................................. 4

TABLE 2: SYSTEM GUIDANCE CHART ..................................................................................................... 7

TABLE 3: GSF TRENCH AND SINGLE LATERAL BED SIZING CHART .................................................. 10

TABLE 4: GSF SUBSURFACE BED SIZING CHART ................................................................................ 16

TABLE 5: GSF SLOPED SUBSURFACE BED SIZING CHART ................................................................ 22

TABLE 6: N VALUE FOR MOUNDS ........................................................................................................... 30

TABLE 7: MINIMUM ELEVATED SAND MOUND BASAL AREA REQUIRED ........................................... 32

TABLE 8: GSF ABOVE GRADE BED SIZING CHART ............................................................................... 36

TABLE 9: GSF SLOPED ABOVE GRADE BED SIZING CHART ............................................................... 42

2018 Indiana Design and Installation Manual 4 www.eljen.com

Glossary of Terms

A42 Module 48” x 24” x 7” (L x W x H)

B43 Module 48” x 36” x 7” (L x W x H)

Cover Fabric The geotextile cover fabric (provided by manufacturer) that is placed over

the GSF modules. Barrier material cannot be substituted.

Design Flow The estimated peak flow that is used to size a GSF system is 150 gallons

per day per bedroom.

GSF Unit The Eljen Geotextile Sand Filter Modules and the minimum 6-inch (for

subsurface trench or bed) or minimum 12-inch (for above grade or

elevated sand mound) sand layer at the base and 6 inches along the sides

of the modules.

GSF Module The individual module of a GSF system. The module is comprised of a

cuspated plastic core and geotextile fabric.

Specified Sand To ensure proper system operation, the system MUST be installed using

Indiana Department of Transportation Specification 23 (INDOT SPEC 23)

sand AND must be used in accordance with ISDH Rule 410 IAC 6-8.3 (80)

(j) or ISDH Rule 410 6-10.1 (88) (j). Ask your material supplier for a sieve

analysis to verify that your material meets the required specifications.

Please place a prominent note to this effect on each design drawing.

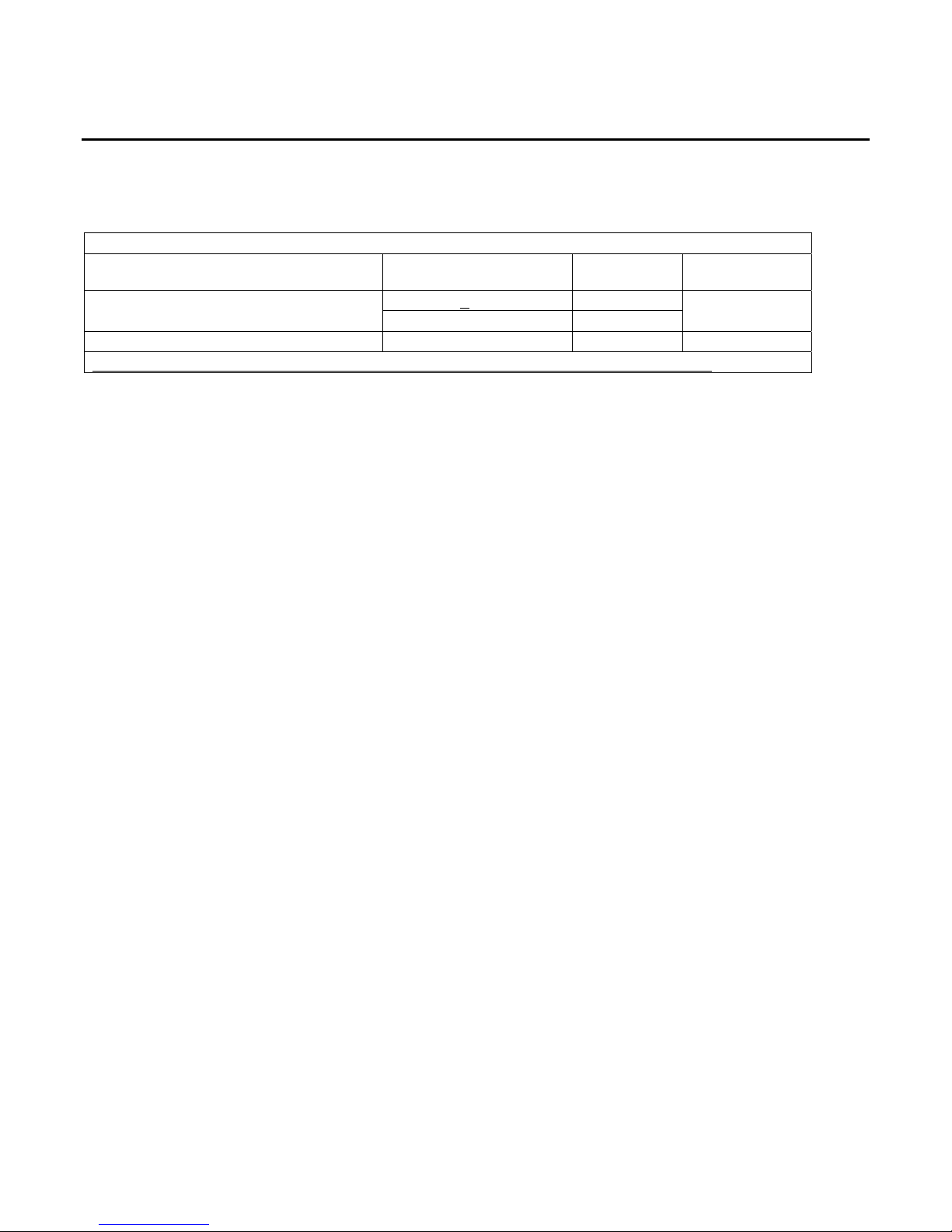

TABLE 1: SPECIFIED SAND SIEVE REQUIREMENTS

INDIANA DEPARTMENT OF TRANSPORTATION

SPECIFICATION 23 SAND

Sieve Size Sieve Square

Opening Size

Specification

Percent Passing

(Wet Sieve)

3/8 inch 9.52 mm 100

No. 4 4.76 mm 95 - 100

No. 8 2.38 mm 80 - 100

No. 16 1.19 mm 50 - 85

No. 30 590 µm 25 - 60

No. 50 297 µm 5 - 30

No. 100 149 µm 0 - 10

No. 200 75 µm 0 - 3

2018 Indiana Design and Installation Manual 5 www.eljen.com

GSF System Description

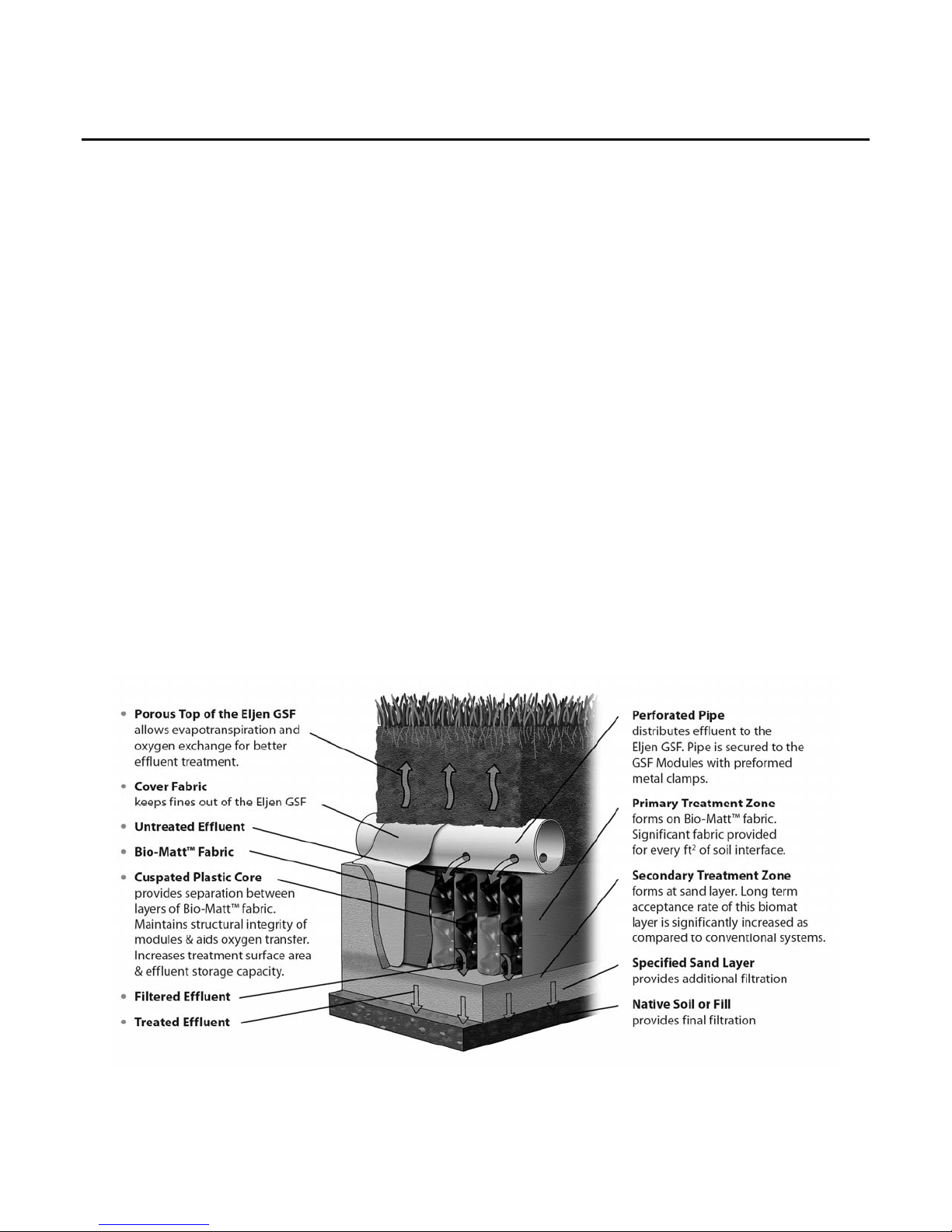

Primary Treatment Zone

Perforated pipe is centered above the GSF module to distribute septic effluent over and into corrugations

created by the cuspated core of the geotextile module.

Septic effluent is filtered through the Bio-Matt (geotextile) fabric. The module’s unique design provides

increased surface area for biological treatment that greatly exceeds the module’s footprint.

Open air channels within the module support aerobic bacterial growth on the modules geotextile fabric

interface, surpassing the surface area required for traditional absorption systems.

A cover fabric covers the top and sides of the GSF module and protects the Specified Sand and soil

from clogging, while maintaining effluent storage within the module.

Secondary Treatment Zone

▪ Effluent drips into the Specified Sand layer and supports unsaturated flow into the native soil. This Specified

Sand/soil interface maintains soil structure, thereby maximizing the available absorption interface in the native

soil. The Specified Sand supports nitrification of the effluent, which reduces oxygen demand in the soil, thus

minimizing soil clogging from anaerobic bacteria.

The Specified Sand layer also protects the soil from compaction and helps maintain cracks and crevices

in the soil. This preserves the soil’s natural infiltration capacity, which is especially important in finer

textured soils, where these large channels are critical for long-term performance.

Native soil provides final filtration and allows for groundwater recharge.

FIGURE 1: GSF SYSTEM OPERATION

2018 Indiana Design and Installation Manual 6 www.eljen.com

1.0 Conditions for Use

1.0.1 ALTERATION OF MODULES: GSF modules shall not be altered by cutting or any other type of physical

modification.

1.0.2 WATER SOFTENER BACKWASH: Water softener backwash shall be discharged to a separate soil

absorption field meeting all required state codes and local regulations.

1.0.3 SEPTIC TANK OUTLET FILTERS: Eljen requires the use of outlet filters on all tanks including single

compartment tanks, up-sized tanks or when the dwelling has a garbage disposal installed.

1.0.4 GARBAGE DISPOSALS: Eljen discourages the use of garbage disposals with septic systems. If a GSF

system is to be designed and installed with garbage disposals the following measures must be taken to prevent

solids from leaving the tank and entering the GSF system:

Increase the septic tank capacity by a minimum of 30% or

Installation of a second septic tank installed in series if a multi-compartment tank isn’t used

1.0.5 ADDITIONAL FACTORS AFFECTING RESIDENTIAL SYSTEM SIZE: Homes with expected higher than

normal water usage may consider increasing the septic tank volume as well as incorporating a multiple compartment

septic tank. Consideration for disposal area may be up-sized for expected higher than normal water use.

For example:

Luxury homes, homes with a Jacuzzi style tubs, and other high use fixtures.

Homes with known higher than normal occupancy.

1.1 System Design

1.1.1 REQUIREMENTS: GSF systems must meet ISDH Rule 410 IAC 6-8.3 except as outlined in this manual.

The sizing tables in this manual applies to residential systems of any size and

Commercial systems with daily design flows less than or equal to 750 GPD

Sizing examples are found in this manual. Please contact Eljen’s Technical Resource Department at 1-800-444-

1359 for design information on commercial systems and adhere to ISDH Rule 410 6-10.1.

1.1.2 NUMBER OF GSF MODULES REQUIRED: The tables found in this manual indicate the minimum number

of A42 or B43 modules allowed. Systems can always be designed beyond the minimum required number of

modules. The minimum design requirements per 150 gpd are 6 A42 modules or 6 B43 modules.

1.1.3 SUITABLE SITE AND SOIL CONDITIONS: The Eljen Modules may be designed for all sites that meet the

criteria described in the Indiana State Department of Health, Residential Onsite Sewage Systems, Rule 410 IAC 6-

8.3 (70-73) or ISDH Rule 410 6-10.1 (78-80).

1.1.4 SEQUENTIAL LOADING: Sequential distribution may only be utilized for sloping sites. Sequential

Distribution uses a distribution box equipped with speed levelers. The uppermost line of the system and the inlet

to the distribution box will be left open. Down slope lines from the distribution box will have the speed leveler at 9

o’clock. Figure 2 demonstrates this practice which will fully utilize the uppermost section of the system prior to

spilling effluent into a lower row of modules. This is for use on any site with greater than 0.5% slope and parallel

distribution cannot be used. These systems are approved in writing on a case by case basis by the Eljen Technical

Department.

2018 Indiana Design and Installation Manual 7 www.eljen.com

1.1 System Design

FIGURE 2: SEQUENTIAL LOADING DIAGRAM

GSF MODULES

LOWEST TRENCH

GSF MODULES

LOWER TRENCHES

GSF MODULES

UPPER MOST TRENCH

THE LOWEST TRENCH ALONG THE SLOPE

DOES NOT REQUIRE A DISTRIBUTION BOX, ALTHOUGH

RECOMMENDED WITH COMMERCIAL DESIGNS

FOR INSPECTION AND OBSERVATION

THE INVER OF DIAL-A-FLOW "B"

IS SET AT THE 9:00 POSITION

DIAL-A-FLOW FITTINGS ARE NOT INSTALLED

ON THE OVER FLOW LINE FROM A UPPER

DISTRIBUTION BOX

OR THE DISTRIBUTION PIPE

LEADING TO THE GSF MODULES

BA

DIAL-A-FLOW

INVERT SETTING

THE INVER OF DIAL-A-FLOW "B"

IS SET AT THE 9:00 POSITION

DIAL-A-FLOW FITTINGS ARE NOT

INSTALLED ON THE OVER FLOW LINE

FROM THE SEPTIC TANK

OR THE DISTRIBUTION PIPE

LEADING TO THE GSF MODULES

BA

B

A

1.1.5 SYSTEM GUIDANCE The chart below directs you to the appropriate section of this manual for the design

and installation of the system.

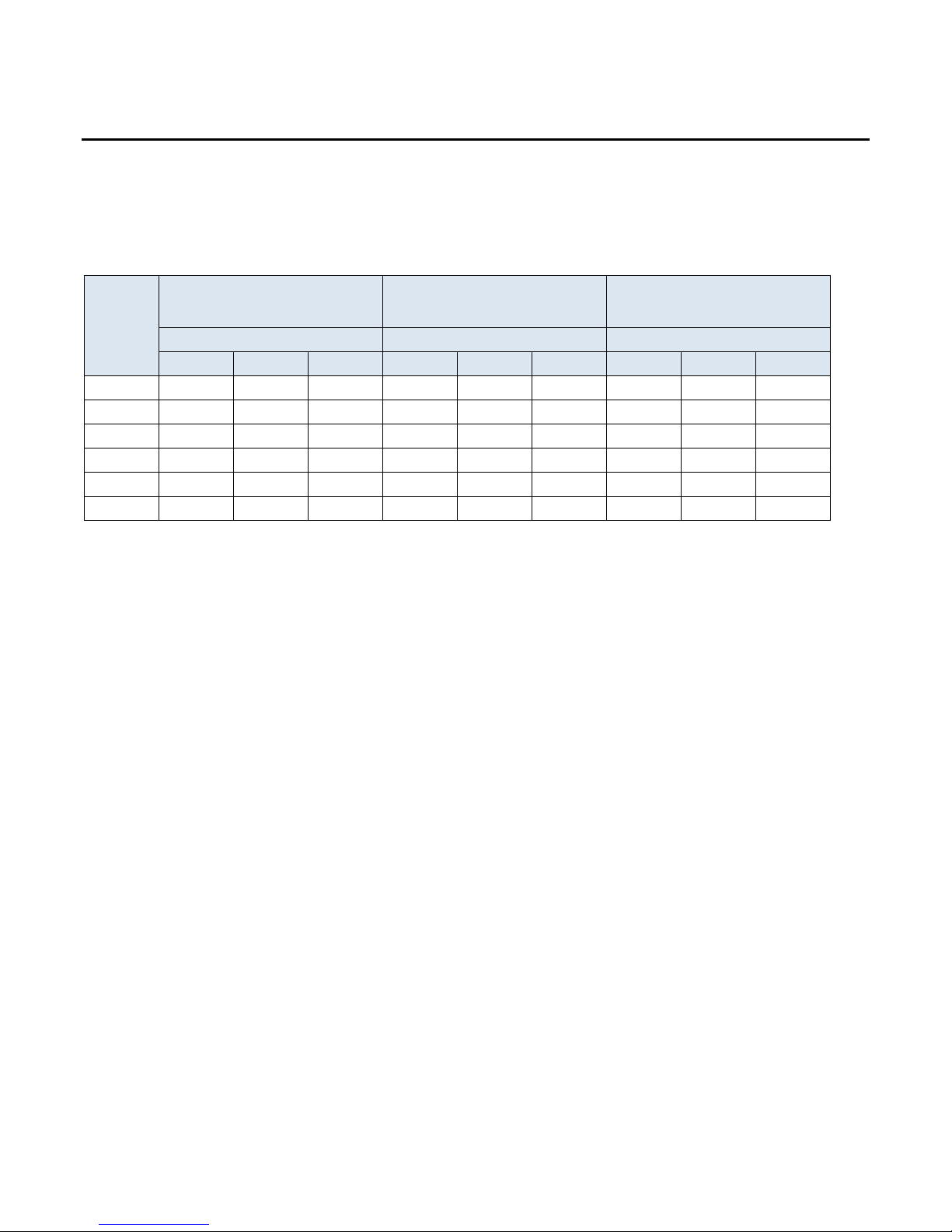

TABLE 2: SYSTEM GUIDANCE CHART

Minimum Depth of

Installation from Existing

Grade

Number of

Laterals per

Excavation

Slope Section Page

10 Inches or Greater

Single 0 – 15% Subsurface Trench and

Sin

g

le Lateral Bed 11

Multiple 0.0 - 0.5% Subsurface Bed 15

0.5 – 15% Sloped Subsurface Bed 21

Existing Grade

Single 0 - 6% Elevated Sand Mound 28

Multiple 0.0 - 0.5% Above Grade Bed 35

0.5 – 6% Sloped Above Grade Bed 41

Use the section above to go to the correct portion of this manual.

2018 Indiana Design and Installation Manual 8 www.eljen.com

2.0 Subsurface Trench and Single Lateral Bed Design and Installation

2.0.1 ACCEPTABLE METHODS OF DISTRIBUTION: Gravity, dosed and pressure distribution are acceptable.

2.0.2 MINIMUM DEPTH FROM ORIGINAL GRADE FOR SUBSURFACE SYSTEMS: The minimum depth for

subsurface systems is 10 inches from original grade to the sand/soil interface for the system.

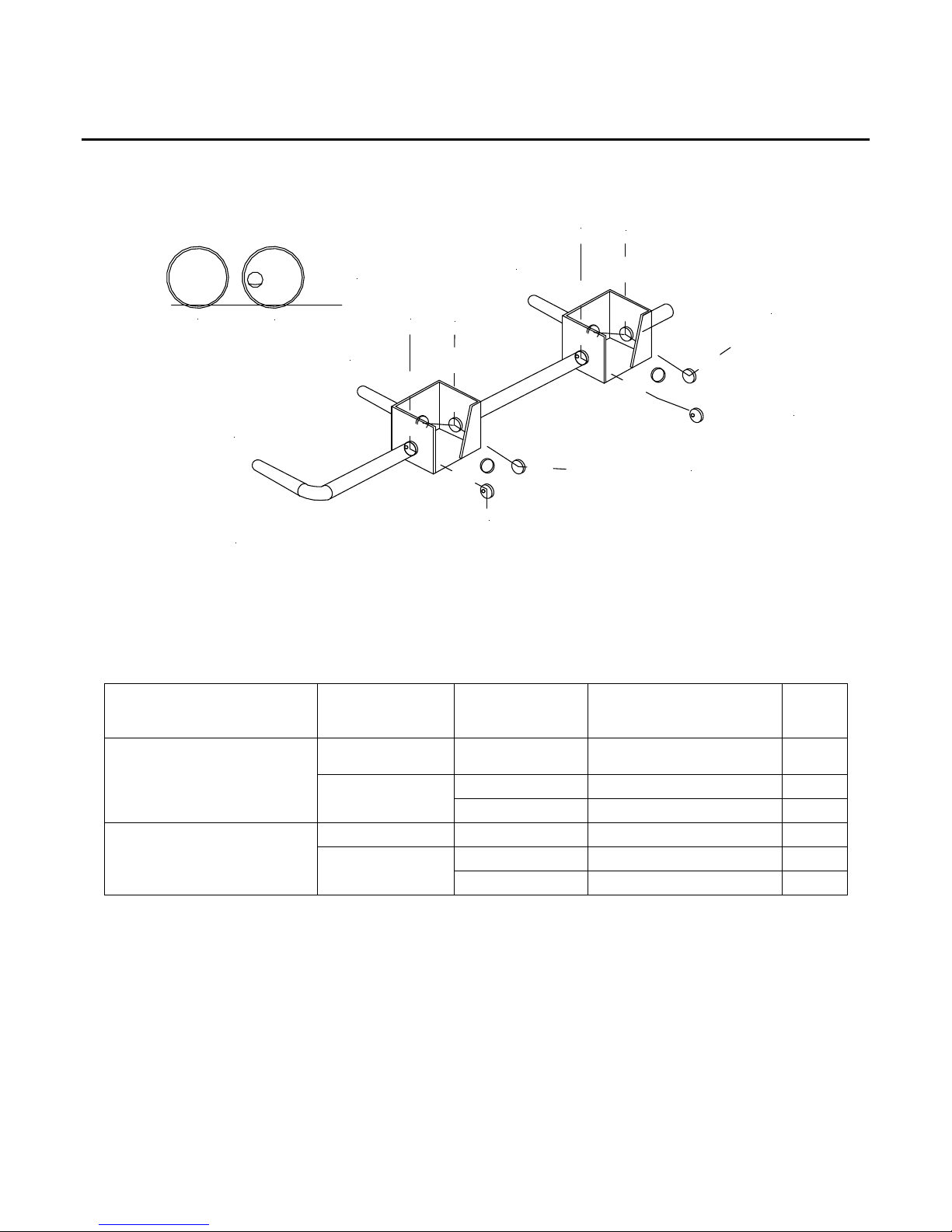

2.0.3 GENERAL CROSS SECTIONS

FIGURE 3: SUBSURFACE A42 TRENCH CROSS SECTION

SPECIFIED SAND

GEOTEXTILE FABRIC

FINAL GRADE

13"

36"

6"24"6"

6"

7"

MIN 12" OF

COVER SOIL

MATERIAL

MAXIMUM

TRENCH

DEPTH 36"

FIGURE 4: SUBSURFACE B43 SINGLE LATERAL BED CROSS SECTION

SPECIFIED SAND

GEOTEXTILE FABRIC

FINAL GRADE

13"

48"

6"36"6"

6"

7"

MIN 12" OF

COVER SOIL

MATERIAL

MAXIMUM

TRENCH

DEPTH 36"

All subsurface trenches and single lateral beds are required to have:

6 inches of Specified Sand at the edges of the GSF module.

6 inches of Specified Sand at the beginning and end of each GSF Row.

Minimum 6 inches of Specified Sand directly below the GSF module.

Minimum 12 inches of cover soil material above the 4-inch distribution pipe.

Maximum trench or single lateral bed depth from final grade is 36 inches.

2018 Indiana Design and Installation Manual 9 www.eljen.com

2.0 Subsurface Trench and Single Lateral Bed Design and Installation

2.0.4 VERTICAL SEPARATION TO SEASONAL HIGH-WATER TABLE OR LIMITING LAYER: Refer to section

Rule 410 IAC 6-8.3 70.b.5 for subsurface absorption systems or ISDH Rule 410 6-10.1 (61).

V

ertical Separation Distance

(

VSD

)

System Type Daily Design Flow Limiting

La

y

er

Seasonal High

Water Table

Subsurface Trench and Single Lateral

Bed System

>450 30” 24”

<450 24”

Pressure Distribution Any 24” 24”

VSD measured from the bottom of the excavated trench or bed for the subsurface s

y

stem.

2.0.5 DISTRIBUTION BOX: Parallel distribution is preferred. Sequential distribution may be utilized for sloping

sites and must conform to 1.1.4. Distribution boxes are required to be 5 feet from the proximal end of each soil

absorption field trench.

2.0.6 PARALLEL DISTRIBUTION: Parallel distribution is the preferred method of application to a gravity or pump

to gravity system. It encourages equal flows to each of the lines in the system. It is recommended for most trench

systems.

2.0.7 TRENCH LENGTH: Trenches will have a maximum of 100 ft in length unless pressure distribution is used per

410 IAC 6-8.3 (74) (r) or ISDH Rule 410 6-10.1 (82) (r).

2.0.8 EQUAL LENGTH: Trenches must be of equal length in order to provide equal distribution.

2.0.9 SPACING GUIDANCE BETWEEN TRENCHES AND SINGLE LATERAL BED ROWS: Ensure trenches are

of equal length throughout the system. If using the B43 in a single lateral bed system, ensure there is center to

center distance of 10 feet and 7.5 feet center to center distance for the A42 in a trench.

2.0.10 DISPERSAL AREA: Dispersal area requirements are located in IAC 6-8.3 (58) or ISDH Rule 410 6-10.1

(62).

2.0.11 MINIMUM SLOPE REQUIREMENTS: Maintain a 3:1 slope or gentler for all slopes off the application area.

2.0.12 SUBSURFACE DRAINS: If subsurface drains are utilized they must remain 10 feet from the edge of the

system sand perimeter.

2018 Indiana Design and Installation Manual 10 www.eljen.com

2.0 Subsurface Trench and Single Lateral Bed Design and Installation

2.0.13 SIZING GSF SYSTEMS:

TABLE 3: GSF TRENCH AND SINGLE LATERAL BED SIZING CHART

Soil

Loading

Rate

(gpd/sf)

Minimum Absorption Area

Required (Square Feet) A42 Modules per House B43 Modules per House

Bedrooms per House Bedrooms per House Bedrooms per House

3 4 5 3 4 5 3 4 5

1.2 252 335 419 21 28 35 18 24 30

0.75 402 536 670 34 45 56 26 34 42

0.6 503 670 838 42 56 70 32 42 53

0.5 603 804 1005 51 67 84 38 51 63

0.3 1005 1340 1675 84 112 140 63 84 105

0.25 1206 1608 2010 101 134 168 76 101 126

Notes:

The Minimum Absorption Area has been adjusted to reflect a 33% reduction in absorption field area.

Any jetted bath tub with a capacity greater than 125 gallons will be treated as an extra bedroom for the system sizing requirements per Rule

410 IAC 6-8.3.

A42 Modules have an effective area of 12 ft2/mod. B43 Modules have an effective area of 16 ft2/mod.

2018 Indiana Design and Installation Manual 11 www.eljen.com

2.1 Subsurface Trench and Single Lateral Bed Design Example

Example 1: Subsurface Trench (A42 Module) and Single Lateral Bed System (B43 Module)

House size: 3 Bedrooms

Design Flow: 450 gpd

Soil Loading Rate: 0.3 gpd/ft2

Absorption Field Type: Trench

Calculate Minimum Basal Area and Units Required

Refer to Table 3 for the minimum number of units and minimum sized basal area required for installation.

Calculate Minimum Trench Length

A42: 84 units x 4 ft/unit = 336 linear ft B43: 63 units x 4 ft/unit = 252 linear ft

Trench Width

A42: 3 ft B43: 4 ft

Final Dimension Layout

(Note: System layout and number of rows will vary based on site constraints)

A42 – Trench

Min. Product Length 336 ft

(note: 6 inches sand required at each end of trench

which makes the minimum trench length 337 ft)

Trench Width 3 ft

Minimum Number of Units 84 A42 Modules

Designed Absorption Area 1,011 ft2

B43 – Single Lateral Bed

Min. Product Length 252 ft

(note: 6 inches sand required at each end of trench

which makes the minimum trench length 253 ft)

Trench Width 4 ft

Minimum Number of Units 63 B43 Modules

Designed Absorption Area 1,012 ft2

345345345

0.3 1005 1340 1675 84 112 140 63 84 105

Soil

Loading

Rate

(gpd/sf)

Bedrooms per House Bedrooms per House Bedrooms per House

Minimum Absorption Area

Required (Square Feet) A42 Modules per House B43 Modules per House

2018 Indiana Design and Installation Manual 12 www.eljen.com

2.1 Subsurface Trench and Single Lateral Bed Design Example

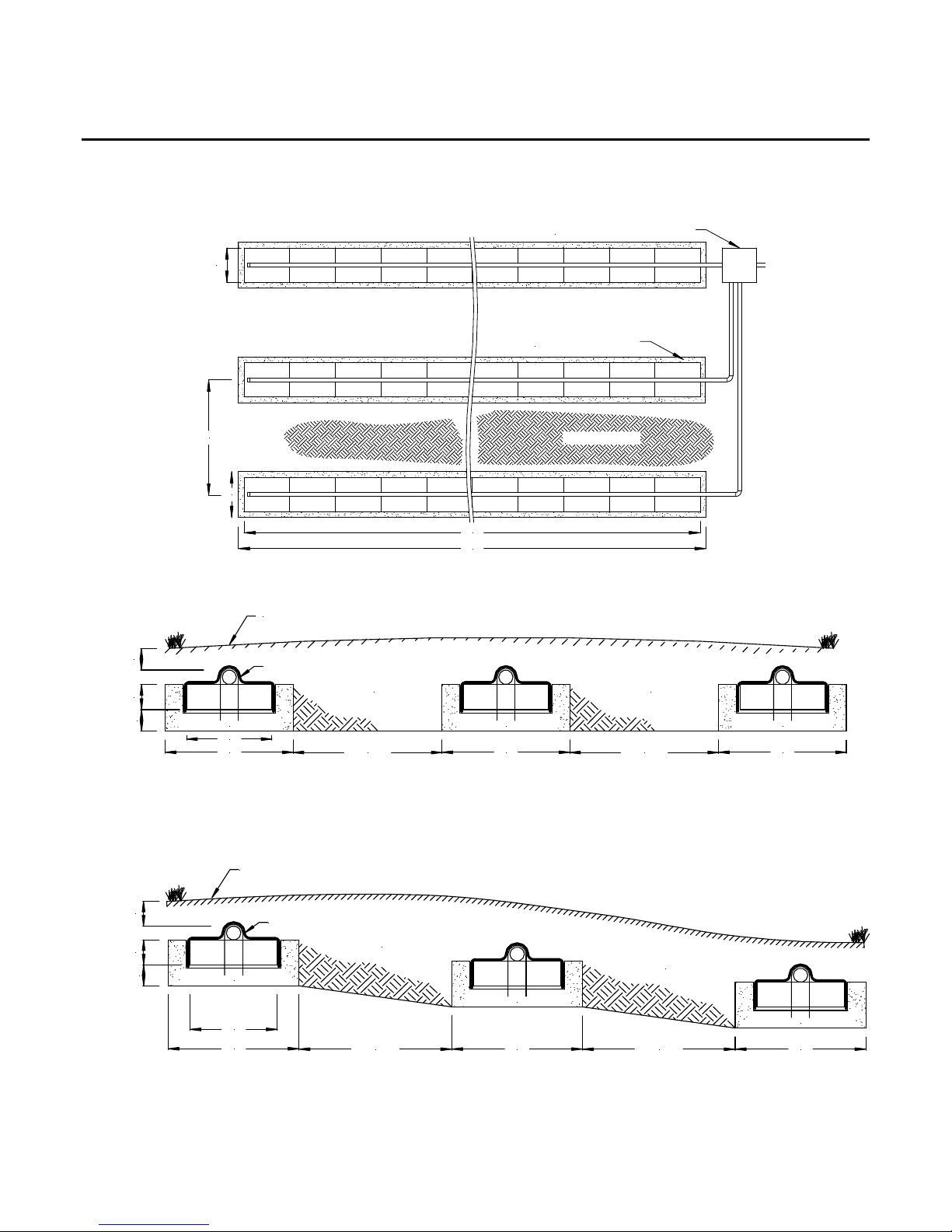

FIGURE 5: PLAN VIEW – 450 GPD – B43 –SINGLE LATERAL BED SYSTEM

NATIVE SOIL

DISTRIBUTION BOX

(MIN 5 FT FROM FIELD)

SPECIFIED SAND

4'

MIN 10'

3'

85'

84'

FIGURE 6: SECTION VIEW – B43 – SINGLE LATERAL BED SYSTEM – ≤ 0.5% SLOPE

48"

36"

GEOTEXTILE

FABRIC

FINAL GRADE

SPECIFIED SAND

7"

6"

MIN 12" OF

COVER SOIL

MATERIAL

48"

NATIVE SOIL

6' MIN

SPECIFIED SAND

48"

NATIVE SOIL

6' MIN

SPECIFIED SAND

Loading Rate 0.3 gpd/ft2, Design Flow 150 gpd x 3 Bedrooms = 450 gallons per day.

(21 Modules per Row)

FIGURE 7: SECTION VIEW – B43 – SINGLE LATERAL BED SYSTEM – 0.5 – 15% SLOPE

FINAL GRADE

7"

6"

MIN 12" OF

SOIL COVER

MATERIAL

NATIVE SOIL

6' MIN

GEOTEXTILE

FABRIC

SPECIFIED SAND

SPECIFIED SAND

48"

36"

48"

NATIVE SOIL

6' MIN

SPECIFIED SAND

48"

Loading Rate 0.3 gpd/ft2, Design Flow 150 gpd x 3 Bedrooms = 450 gallons per day.

(21 Modules per Row)

2018 Indiana Design and Installation Manual 13 www.eljen.com

2.2 Subsurface Trench and Single Lateral Bed Design Installation Steps

1. Ensure all components leading to the GSF system are installed properly. Outlet filters are required with the

GSF system. Connections of lines to tanks and distribution boxes must follow requirements of 410 IAC 6-8.3

or ISDH Rule 410 6-10.1.

2. Determine the number of GSF Modules required using Table 3.

3. Prepare the site. Do not install a system in saturated ground or wet soils that are smeared during excavation.

Keep machinery off infiltrative areas. Refer to IAC 6-8.3 or ISDH Rule 410 6-10.1 for all site preparation

requirements prior to site construction.

4. Plan all drainage requirements above (up-slope) of the system. Set soil grades to ensure that storm water

drainage and ground water is diverted away from the absorption area once the system is complete. All drainage

requirements shall be in accordance with 410 IAC 6-8.3 (59) or 410 6-10.1 (63).

5. Excavate the trench absorption area; scarify the receiving layer to maximize the interface between the native

soil and specified sand.

6. Minimize walking in the trench prior to placement of the specified sand to avoid soil compaction.

7. Place a minimum of 6 inches of Specified Sand in the absorption area and stabilize level. The first 6 inches of

sand immediately under and around the perimeter of the GSF system must be INDIANA DEPARTMENT OF

TRANSPORTATION (INDOT) SPECIFICATION 23 SAND. See Table 1 for more information on the sand and

sieve specifications.

8. Place GSF modules with PAINTED STRIPE FACING UP. Each row of modules is laid level in its length and

width, end to end, along their four-foot length on the Specified Sand layer. No mechanical connection is

required between modules.

9. A standard 4-inch perforated pipe, SDR 35 or equivalent is centered along the modules 4-foot length. Orifices

are set at the 4 & 8 o’clock position. All distribution piping must meet the requirements of ISDH Rule 410 6-8.3

Section 67 or ISDH Rule 410 6-10.1 Section 75.

10. All 4-inch pipes are secured with manufacturers supplied wire clamps, one per module.

11. (Pressure Distribution Systems) Insert a Sch. 40 pressure pipe which meets 410 IAC 6-8.3 (67) or ISDH Rule

410 6-10.1 (75), into the standard 4-inch perforated pipe. The pressure pipe orifices are set at the 12 o’clock

position as shown in Figure 26. Each pressure lateral will have a drain hole at the distal end of the lateral at

the 6 o’clock position. Each pressure lateral shall have a clean out at the end of the trench.

12. The 4-inch distribution pipe shall be capped or vented.

13. Cover fabric substitution is not allowed. The installer should lay the Eljen provided geotextile cover fabric

lengthwise down the trench, with the fabric fitted to the perforated pipe on top of the GSF modules. Fabric

should be neither too loose, nor too tight. The correct tension of the cover fabric is set by:

a. Spreading the cover fabric over the top of the module and down both sides of the module with the

cover fabric tented over the top of the perforated distribution pipe.

b. Place shovelfuls of Specified Sand directly over the pipe area allowing the cover fabric to form a

mostly vertical orientation along the sides of the pipe. Repeat this step moving down the pipe.

14. Place 6 inches of Specified Sand along both sides of the modules edge. A minimum of 6 inches of Specified

Sand is placed at the beginning and end of each trench.

2018 Indiana Design and Installation Manual 14 www.eljen.com

2.2 Subsurface Trench and Single Lateral Bed Design Installation Steps

15. Complete backfill with cover soil material to a minimum of 12 – 19 inches measured from the top of the 4-inch

distribution pipe. Fill must be clean, porous and able to sustain vegetation. Do not use wheeled equipment

over the system during backfill operation. A light track machine may be used with extreme caution, avoiding

crushing or shifting of pipe assembly.

16. Divert surface runoff from the system. Finish grade to prevent surface ponding. Topsoil and seed system area

to protect from erosion.

2018 Indiana Design and Installation Manual 15 www.eljen.com

3.0 Subsurface Bed Design and Installation

3.0.1 ACCEPTABLE METHODS OF DISTRIBUTION: Gravity, dosed and pressure distribution are acceptable.

3.0.2 MINIMUM DEPTH FROM ORIGINAL GRADE FOR SUBSURFACE SYSTEMS: The minimum depth for

subsurface systems is 10 inches from original grade. That is the start of the sand/soil interface for the system.

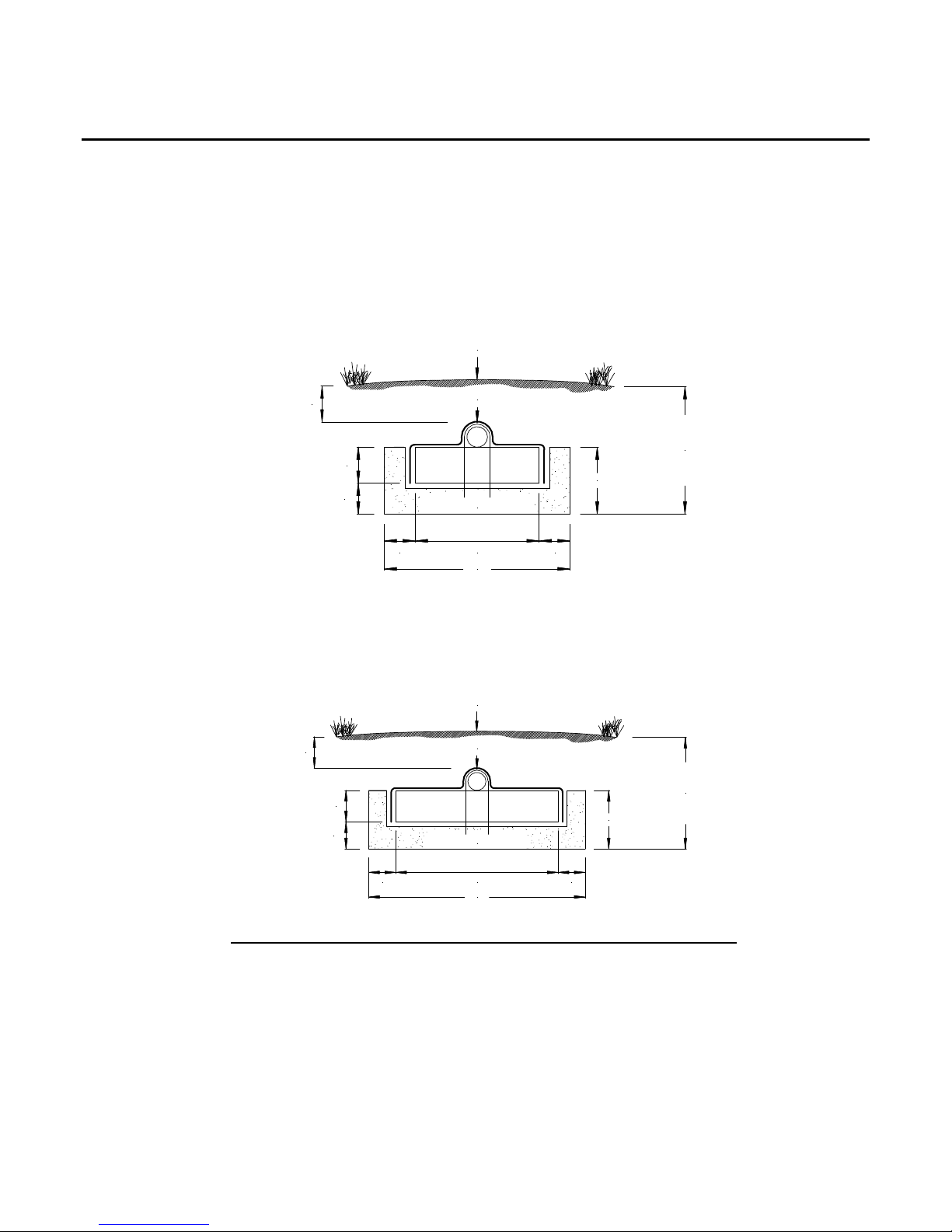

3.0.3 GENERAL CROSS SECTION

FIGURE 8: SUBSURFACE BED CROSS SECTION

SPECIFIED SAND

12" MIN - 19" MAX

OF COVER SOIL

MATERIAL

13"

ORIGINAL GRADE

FINAL GRADE

All subsurface bed systems are required to have a minimum of:

6 inches of Specified Sand at the edges of the GSF module.

6 inches of Specified Sand at the beginning and end of each GSF Row.

6 inches of Specified Sand directly below the GSF module.

Minimum 12 inches of cover soil material above the 4-inch distribution pipe

Maximum excavation depth from final grade is 36 inches.

3.0.4 VERTICAL SEPARATION TO SEASONAL HIGH-WATER TABLE OR LIMITING LAYER: Refer to section

Rule 410 IAC 6-8.3 70.b.5 for subsurface absorption systems or ISDH Rule 410 6-10.1 (61).

V

ertical Separation Distance

(

VSD

)

System Type Daily Design Flow Limiting

La

y

er

Seasonal High-Water

Table

Subsurface Bed >450 30” 24”

<450 24”

Pressure Distribution Any 24” 24”

VSD measured from the bottom of the excavated bed for the subsurface s

y

stem.

3.0.5 DISTRIBUTION BOX: Parallel distribution is preferred. Sequential distribution may be utilized for sloping

sites and must conform to 1.1.4. Distribution boxes are recommended to be 5 feet from the proximal end of each

soil absorption field row as per Rule 410 IAC 6-8.3 Section 75.i or ISDH Rule 410 6-10.1 Section 74. This may be

amended to shorter distance per the designer.

3.0.6 PARALLEL DISTRIBUTION: Parallel distribution is the preferred method of application to a gravity or pump

to gravity system. It encourages equal flows to each of the lines in the system. It is recommended for most bed

systems.

3.0.7 ROWS REQUIRED: All bed systems shall have a minimum of two rows of modules.

3.0.8 ROW LENGTH: Rows will have a maximum of 100 ft in length unless pressure dosed per 410 IAC 6-8.3 (74)

(r) or ISDH Rule 410 6-10.1 (82) (r).

3.0.9 EQUAL LENGTH: Rows must be of equal length in order to provide equal distribution.

2018 Indiana Design and Installation Manual 16 www.eljen.com

3.0 Subsurface Bed Design and Installation

3.0.10 DISPERSAL AREA: Dispersal area requirements are located in IAC 6-8.3 (58) or ISDH Rule 410 6-10.1

(62).

3.0.11 MINIMUM SLOPE REQUIREMENTS: Maintain a 3:1 slope or gentler for all slopes off the application area.

3.0.12 SUBSURFACE DRAINS: If subsurface drains are utilized they must remain 10 feet from the edge of the

system sand perimeter.

3.0.13 SIZING GSF SYSTEMS:

TABLE 4: GSF SUBSURFACE BED SIZING CHART

Soil

Loading

Rate

(gpd/sf)

Minimum Basal Area

Required (Square Feet) A42

Modules

per Room

B43

Modules

per Room

Bedrooms per House

3 4 5

1.2 252 335 419 6 6

0.75 402 536 670 8 7

0.6 503 670 838 9 8

0.5 603 804 1005 11 9

0.3 1005 1340 1675 12 10

0.25 1206 1608 2010 13 11

Notes:

The Minimum Basal Areas have been adjusted to reflect a 33% reduction in absorption field area.

Any jetted bath tub with a capacity greater than 125 gallons will be treated as an extra bedroom for the system sizing requirements per Rule

410 IAC 6-8.3.

3.0.14 SYSTEM LENGTH AND WIDTH: Best engineering practices should be used when construction the bed

systems. Rule IAC 6-8.3 (79) (2) and ISDH Rule 410 6-10.1 (87) (b) states the dimensions of the bed shall be as

long and narrow as the site allows.

3.0.15 BED DESIGN: For beds with less than a 0.5% slope, evenly distribute the bed laterals in the basal area. A

minimum separation distance between laterals for A42’s is 3’ and a minimum separation distance between laterals

of 4’ for B43’s.

2018 Indiana Design and Installation Manual 17 www.eljen.com

3.1 Subsurface Bed Design Example

Example 2: Subsurface Bed System – A42 Modules – 0.0 – 0.5% Slope

House size: 4 Bedrooms

Design Flow: 600 gpd

Soil Loading Rate: 0.3 gpd/ft2

Absorption Field Type: Bed

Site Slope: Less than 0.5%

Calculate Minimum Basal Area and Units Required

Refer to Table 4 for the minimum number of units and minimum basal area required for installation.

Units required per bedroom x bedrooms = Total units required

A42: 12 units/bedroom x 4 bedrooms = 48 A42s B43: 10 units/bedroom x 4 bedrooms = 40 B43s

Calculate Minimum Bed Basal Area Length

For This Example, Assume the Number of Bed Rows Equals Two (this encourages the longest and

narrowest subsurface bed design):

Modules per row: Modules Needed ÷ Rows

A42: 48 units ÷ 2 rows = 24 modules per row

A42: 24 units x 4 ft/unit +1 ft = 97 linear ft

B43: 40 units ÷ 2 rows = 20 modules per row

B43: 20 units x 4 ft/unit +1 = 81 linear ft

Calculate Bed Basal Area Width

a) Minimum A42 Basal Area Width

a) A42: Rows x 3 ft = 2 x 3 ft = 6 ft

or

b) Proposed Basal Area Width

b) Minimum Basal Area ÷ Length of System

b) A42: 1340 ft2 ÷ 97 ft = 13.8 ft,

b) round to 14 ft

A42: Use greater width of a or b: 14 ft

a) Minimum B43 Basal Area Width

a) B43: Rows x 4 ft = 2 x 4 ft = 8 ft

or

b) Proposed Basal Area Width

b) Minimum Basal Area ÷ Length of System

b) B43: 1340 ft2 ÷ 81 ft = 16.5 ft,

b) round to 17 ft

B43: Use greater width of a or b: 17 ft

Determine Lateral Spacing

Lateral to Lateral Spacing = Bed Width ÷ Rows

A42: 14 ft ÷ 2 rows = 7 ft B43: 17 ft ÷ 2 rows = 8.5 ft

Upper Edge to Lateral Spacing = Lateral to Lateral Spacing ÷ 2

A42: 7 ft ÷ 2 = 3.5 ft B43: 8.5 ft ÷ 2 = 4.25 ft

345

0.3 1005 1340 1675 12 10

Soil

Loading

Rate

(gpd/sf)

Minimum Basal Area Required

(Square Feet)

Bedrooms per House

A42

Modules per

Room

B43

Modules per

Room

A42 B43 A42 B43

Slope Lateral to Lateral SpacingUpper Edge to Lateral Spacing

Lessthanor

Equalto0.5%

Lateral to Lateral Spacing ÷ 2 Basal Area width divided by

number of rows

3.1 Subsurface Bed Design Example

Final Dimension Layout

(Note: System layout and number of rows will vary based on site constraints)

A42

Basal Area Length: 97 ft

Basal Area Width: 14 ft

Minimum Number of Units: 48 A42 Modules

Center to Center Spacing: 7 ft

Edge to Center Spacing: 3.5 ft

Designed Basal Area: 1,358 ft2

B43

Bed Length: 81 ft

Bed Width: 17 ft

Minimum Number of Units: 40 B43 Modules

Center to Center Spacing: 8.5 ft

Edge to Center Spacing: 4.25 ft

Designed Basal Area: 1,377 ft2

FIGURE 9: PLAN VIEW – 600GPD – A42 – BED SYSTEM – ≤ 0.5% SLOPE

SPECIFIED SAND

97'

96'

14'

3' 6"

7' DISTRIBUTION BOX

FIGURE 10: CROSS SECTION VIEW – 600 GPD – A42 – BED SYSTEM – ≤ 0.5% SLOPE

SPECIFIED SAND

3.5'7'3.5'

12" MIN - 19" MAX

OF COVER SOIL

MATERIAL

14'

13"

ORIGINAL GRADE

FINAL GRADE

2018 Indiana Design and Installation Manual 19 www.eljen.com

3.2 Subsurface Bed Design Installation Steps

1. Ensure all components leading to the GSF system are installed properly. Outlet filters are required with the

GSF system. Connections of lines to tanks and distribution boxes must follow requirements of 410 IAC 6-8.3

or ISDH Rule 410 6-10.1.

2. Determine the number of GSF Modules required using Table 4.

3. Prepare the site. Do not install a system in saturated ground or wet soils that are smeared during excavation.

Keep machinery off infiltrative areas. Refer to IAC 6-8.3 or ISDH Rule 410 6-10.1, for all site preparation

requirements prior to site construction.

4. Plan all drainage requirements above (up-slope) of the system. Set soil grades to ensure that storm water

drainage and ground water is diverted away from the system once it is complete. All drainage requirements

shall be in accordance with 410 IAC 6-8.3 (59).

5. Excavate the bed basal area; scarify the receiving layer to maximize the interface between the native soil and

specified sand.

6. Minimize walking in the excavated area prior to placement of the specified sand to avoid soil compaction.

7. Place a minimum of 6 inches of Specified Sand in the basal area and stabilize level. The first 6 inches of sand

immediately under and around the perimeter of the GSF system must be INDIANA DEPARTMENT OF

TRANSPORTATION (INDOT) SPECIFICATION 23 SAND. See Table 1 for more information on the sand and

sieve specifications.

8. Place GSF modules with PAINTED STRIPE FACING UP. Each row of modules is laid level in its length and

width, end to end, along their four-foot length on the Specified Sand layer. No mechanical connection is

required between modules.

9. A standard 4-inch perforated pipe, SDR 35 or equivalent is centered along the modules 4-foot length. Orifices

are set at the 4 & 8 o’clock position. All distribution piping must meet the requirements of ISDH Rule 410 6-8.3

Section 67 or ISDH Rule 410 6-10.1 Section 75.

10. All 4-inch pipes are secured with manufacturers supplied wire clamps, one per module.

11. (Pressure Distribution Systems) Insert a Sch. 40 pressure pipe which meets 410 IAC 6-8.3 (67) or ISDH Rule

410 6-10.1 (75), into the standard 4-inch perforated pipe. The pressure pipe orifices are set at the 12 o’clock

position as shown in Figure 26. Each pressure lateral will have a drain hole at the distal end of the lateral at

the 6 o’clock position. Each pressure lateral shall have a clean out at the end of the row.

12. The distribution pipe shall be capped or vented.

13. Cover fabric substitution is not allowed. The installer should lay the Eljen provided geotextile cover fabric

lengthwise down the row, with the fabric fitted to the perforated pipe on top of the GSF modules. Fabric should

be neither too loose, nor too tight. The correct tension of the cover fabric is set by:

a. Spreading the cover fabric over the top of the module and down both sides of the module with the

cover fabric tented over the top of the perforated distribution pipe.

b. Place shovelfuls of Specified Sand directly over the pipe area allowing the cover fabric to form a

mostly vertical orientation along the sides of the pipe. Repeat this step moving down the pipe.

14. Place 6 inches of Specified Sand along both sides of the modules edge. A minimum of 6 inches of Specified

Sand is placed at the beginning and end of each module row. A minimum of 12 inches of Specified Sand is

placed in between module rows.

2018 Indiana Design and Installation Manual 20 www.eljen.com

3.2 Subsurface Bed Design Installation Steps

15. Complete backfill with cover soil material to a minimum of 12 – 19 inches measured from the top of the 4-inch

distribution pipe. Fill must be clean, porous and able to sustain vegetation. Do not use wheeled equipment

over the system during backfill operation. A light track machine may be used with extreme caution, avoiding

crushing or shifting of pipe assembly.

16. Divert surface runoff from the system. Finish grade to prevent surface ponding. Topsoil and seed system area

to protect from erosion.

This manual suits for next models

1

Table of contents