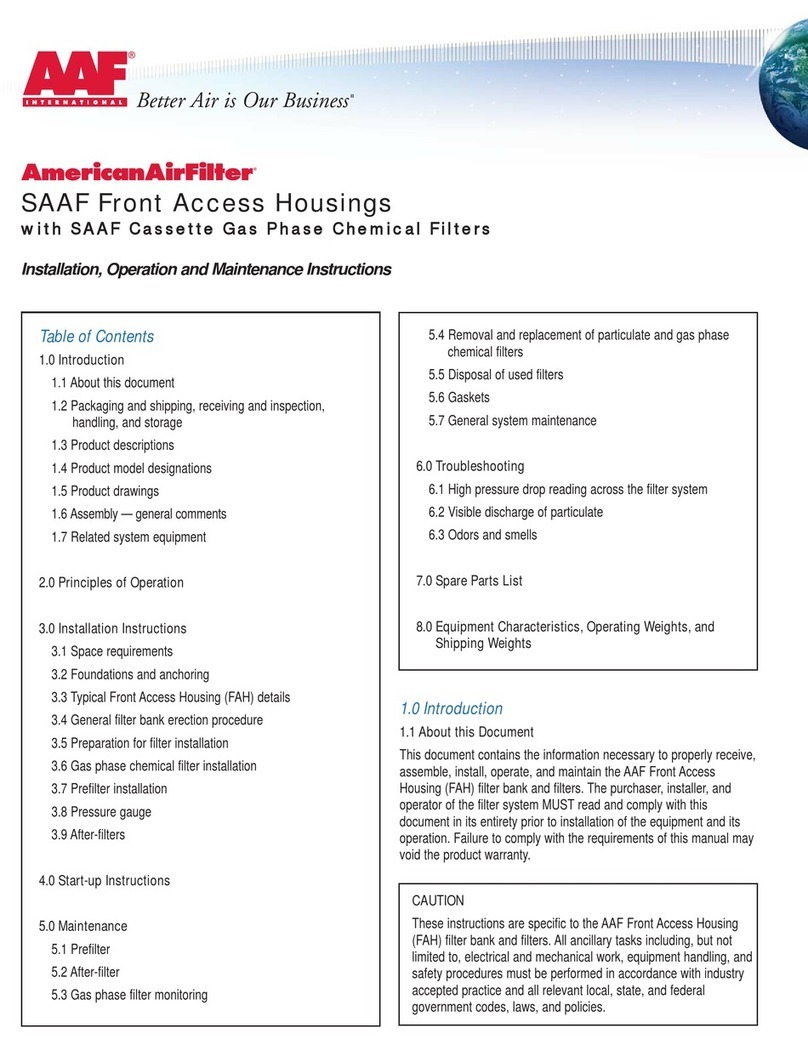

10

5.4 Disposal of Used Filters

Used chemical filtration media and particulate filters shall be

packaged and disposed of in full accordance with all required and

applicable laws and regulations. Consult with local environmental

control authorities such as local, state, and federal EPA & OSHA

authorities for direction. Material Safety Data Sheets (MSDS) are

available on all products supplied by AAF. Contact your AAF

representative for further information.

5.5 Cover Lid Sealing Gaskets

The proper maintenance of the cover lid sealing gaskets is critical to

the performance of the system. Check the gaskets carefully whenever

the gas phase chemical filters are replaced. If gaskets are worn,

frayed, or damaged in any way they should be replaced. Check the

seal between the lid and the tank whenever new SAAF chemical

media is installed.

5.6 General System Maintenance

Ducts, external PORTA-Scrubber surfaces, latches, blower, and

other system infrastructure should be checked at least every 6

months. Internal surfaces shall be examined whenever filters are

replaced. Examine all components for the following:

5.6.1 Cleanliness: Sweep and vacuum all standing dust or dirt in

the system. If using cleaning solvents, be mindful of the impact of

solvents on the performance and life of the chemical media and

take appropriate precautions to protect the system.

5.6.2 Water: The system should be completely dry at all times.

The presence of standing water, condensation, or dampness is

detrimental to the performance and life of the system. Determine

and remove the cause for the presence of water in the system, dry

the system, and examine all components for the presence of molds

and other biological growth. Remove all contamination, clean and

sterilize as necessary.

5.6.3 Filter System Integrity: Ensure that the unit contains the

appropriate filter elements, both particulate and gas phase, and

that these elements are correctly installed. Check for missing or

improperly installed components and review the system seals.

Check for air leaks at joints and seams and replace gaskets,

worn hardware, and seal with caulk as necessary.

5.6.4 Duct and System Integrity: Examine the entire system to

ensure that contaminated air cannot leak around the filter system.

Check all perimeter seals and repair as necessary.

5.6.5 Corrosion: If metal components are corroded repair the

corrosion and provide protective coatings as necessary. Be mindful

of the impact of painting on the performance and life of the

chemical media, and take appropriate precautions to protect the

system. Determine the source of the corrosion and rectify.

4.0 Start-Up Instructions

Immediately on start-up, examine the filter system for any apparent

air leaks or other anomalies. Air leaks may be detected by noise

or by use of a synthetic smoke puffing device at the external joints

and seams of the filter system installation. Correct or repair any

discrepancies, as necessary. Repeat this examination after

24 hours of operation and again after one week of operation.

5.0 Maintenance

5.1 PolyKlean Blue filter: A PolyKlean Blue pad has been included

as part of the system. Under normal conditions, the filter can be

expected to last for between 10 and 12 months before reaching

its final recommended capacity loading (see the AAF drawings

for details). However, this may vary under heavier or lighter

particulate loading conditions. At an air velocity of 75 feet per

minute the 2" deep PolyKlean Blue pad can be expected to have

an initial pressure drop in the range of less than 0.1" water gauge.

The recommended final pressure drop is 1.0 in. w.g.; however, it is

recommended that the PolyKlean Blue pad be replaced whenever

new chemical media is installed.

5.2 Chemical Media Monitoring

A discussion of sophisticated chemical media monitoring is beyond

the scope of this manual. At its most simple, when the system is

used to remove nuisance odors, the time to change out the chemical

media is when the odor begins to be regularly detected on the clean

side of the system. In more stringent applications, active real time

electronic and passive coupon corrosion monitoring systems are

available to determine the performance of the system. The remaining

life of the media can be determined by taking a sample of media and

returning it to AAF for analysis. Consult with your AAF representative

regarding active and passive monitoring systems and media sampling

for remaining life analysis.

5.3 Removal and Replacement of Particulate and Gas Phase

Chemical Media

Before removing activated carbon media, it is recommended the

media bed be grounded to release any electrostatic discharge.

Removal of filters will be the reverse of the installation process

described earlier in this manual. Filter and media replacement

will be carried out exactly the same as at initial installation detail with

use of manual or pneumatic methods. Reference appropriate safety

precautions related to specific gases being handled at the facility

and any operation instructions developed during the design phase

of the project.