Elka T 3000 User manual

Installation and operating instructions

Barriers T 3000 - T 3500

Part 1

Installation

Translation of original installation and operating instructions

D-ID: V1_0 – 02.15

ELKA-Torantriebe GmbH u. Co. Betriebs KG Phone: +49-(0) 48 61 - 96 90-0

Dithmarscher Str. 9 Fax: +49-(0) 48 61 - 96 90-90

Germany Internet: www.ELKA-Torantriebe.de

T 3000 - T 350

0

1

Index of contents

1Preface 3

1.1General notes 3

1.1.1Symbol explanation 4

1.2Copyright 4

1.3Information regarding installation instruction 4

2Safety 5

2.1General notes on safety 5

2.2Notes on safety for the operation 5

2.3Notes on safety for the operation with radio remote control 5

2.4Intended use – Vehicle traffic 6

2.5Danger, which could emanate from the site of operation 6

2.6Non-factory technical alterations and extensions 6

2.7Personnel requirements – professional skills, knowledge and

qualifications 7

2.8Personal protective equipment 7

3Transportation and storing 9

3.1Transportation inspection 9

3.2Scope of delivery T 3000-3500 9

3.3Storing 9

3.4Lifting heavy loads 10

4Declaration of incorporation 11

4.1Installation information for partly completed machinery 12

4.2Declaration of conformity 12

4.3Name plate 12

5Function description 13

6Technical data T 3000-3500 14

7Installation T 3000-3500 16

7.1Tools 16

7.2Mounting dimensions 17

7.3Foundation 18

7.4Opening / closing the housing 20

7.5Boom connector 22

7.5.1Installation – Boom connector left side 23

7.6Barrier boom 24

7.7Balancing springs 25

7.8Opening and closing times 27

T 3000 - T 350

0

2

8Terminal row 29

8.1Interior view 29

8.2Mains connection 29

8.3Controller terminal row 30

8.4Circuit diagram 33

9Barrier maintenance 40

10Layout (exploded drawing) 41

T 3000 - T 350

0

3

1 Preface

1.1 General notes

These operating instructions must be available on site at all times. It should be

read thoroughly by all persons who use, or service the appliances. Improper

usage or servicing or ignoring the operating instructions can be a source of

danger for persons, or result in material damage. If the meaning of any part of

these instructions isn’t clear, then please contact ELKA-Torantriebe GmbH u.

Co. Betriebs KG before you use the appliance.

This applies to all setup procedures, fault finding, disposal of material, care

and servicing of the appliance. The accident prevention regulations and

applicable technical regulations (e.g. safety or electrical) and environment

protection regulations of the country in which the appliance is used also apply.

All repairs on the appliances must be carried out by qualified persons. ELKA-

Torantriebe GmbH u. Co. Betriebs KG accepts no liability for damage which is

caused by using the appliance for purposes other than those for which it is

built.

ELKA-Torantriebe GmbH u. Co. Betriebs KG cannot recognise every possible

source of danger in advance. If the appliance is used other than in the

recommended manner, the user must ascertain that no danger for himself or

others will result from this use. He should also ascertain that the planned use

will have no detrimental effect on the appliance itself. The appliance should

only be used when all safety equipment is available and in working order. All

faults which could be a source of danger to the user or to third persons must

be eliminated immediately. All warning and safety notices on the appliances

must be kept legible.

All electrical periphery equipment which is connected to the appliance must

have a CE Mark, which ensures that it conforms to the relevant EEC

regulations. Neither mechanical nor electrical alterations to the appliance,

without explicit agreement of the manufacturer, are allowed. All alterations or

extensions to the appliance must be carried out with parts which ELKA-

Torantriebe GmbH u. Co. Betriebs KG have defined as suitable for such

alterations, and be carried out by qualified personnel. Please note that with

any alteration of the product, no matter whether mechanical or electrical, the

warranty expires and the conformity is revoked. Only the use of ELKA

accessories and original ELKA spare parts is allowed. In case of any

contravention ELKA disclaims liability of any kind.

INFORMATION!

The operation of the system within CEN countries must also be conformant

with the European safety-relevant directives and standards.

We reserve the right to make technical improvements without prior notice.

T 3000 - T 350

0

4

1.1.1 Symbol explanation

Remarks regarding the safety of persons and the gate opener itself are

marked by special symbols. These remarks have to be absolutely observed in

order to avoid accidents and material damage.

DANGER!

…points to an imminent dangerous situation, which can cause death or

serious injuries if it is not avoided.

WARNING!

…points to a potentially dangerous situation, which can cause death or

serious injuries if it is not avoided.

ATTENTION!

…points to a potentially dangerous situation, which can cause minor or

slight injuries if it is not avoided.

ATTENTION!

…points to a potentially dangerous situation, which can cause property

damage if it is not avoided.

REMARK!

Important notice for installation or functioning.

1.2 Copyright

The operating manual and the contained text, drawings, pictures, and other

depictions are protected by copyright. Reproduction of any kind – even in

extracts – as well as the utilization and/or communication of the content

without written release certificate are prohibited. Violators will be held liable for

damages. We reserve the right to make further claims.

1.3 Information regarding installation instruction

This document is to be used as installation instruction for partly completed

machinery (according to machinery directive 2006/42/EG, article 13, (2)).

T 3000 - T 350

0

5

2 Safety

2.1 General notes on safety

The valid regulations and standards have to be observed during installation

and operation, e.g. DIN EN 13241-1, DIN EN 12445, DIN EN 12453 etc. Only

the use of spare parts made by the original manufacturer is allowed.

Do not put a defective barrier into operation.

After set-up (installation) every user of the equipment has to be instructed

about the operation and function of the barrier.

In order to reduce the risk potential related to the movement of the barrier

boom, additional optical and/or acoustical warning devices should be installed.

2.2 Notes on safety for the operation

Children and not instructed persons are not allowed to operate the barrier.

No persons, objects, or animals are allowed within the range of the barrier

movement during opening or closing.

Never reach into moving parts of the barrier.

Drive through the barrier only after complete opening.

The barrier has to be secured depending on the type of usage, corresponding

to the valid standards and regulations.

The safety devices have to be checked regularly for functioning according to

the standards and regulations, at least twice a year.

2.3 Notes on safety for the operation with radio remote

control

The radio remote control should only be used, if the area of movement of the

barrier is always completely visible by the operator and thus it is assured, that

no person, object, or animal is present within this range of movement.

The radio remote control transmitters have to be carefully kept, so that an

unintentional use is impossible.

Radio remote controls should not be operated at radio-technical sensitive

locations, like airports or hospitals.

Interferences by other (properly operated) radio communication installations,

which are used within the same frequency range, cannot be ruled out.

T 3000 - T 350

0

6

2.4 Intended use – Vehicle traffic

The operational safety can only be ensured when the barrier is used as

intended.

After installation, the barriers of the series T 3000-3500 serve as passage

control of vehicle paths.

CAUTION!

Danger of impact and crushing!

With inadequate safety measures the movement of the barrier boom can

result in impact or crushing points between the boom and solid objects within

the movement area.

In order to reduce the potential danger during the barrier boom movement,

additional optical and/or acoustic warning devices should be installed.

The controller is a product component and serves to control the barrier.

Any use above and beyond the above mentioned use is prohibited and

constitutes improper use.

2.5 Danger, which could emanate from the site of operation

The barriers T 3000-3500 operate with moving parts.

WARNING!

Rotating and/or linear movable components can cause serious injuries.

Do not reach into moving parts or handle any moving components during

operation.

Turn the appliance off before any maintenance work, repair work or other

work and secure it against unintentional restarting.

2.6 Non-factory technical alterations and extensions

Non-factory technical alterations and/or extensions may result in hazards as

well as interfere with the function of the barrier.

DANGER!

Danger through voltage!

Risk of death by electric shock!

Technical alterations may only be performed by skilled personnel and only

according to the manufacturer’s instructions.

CAUTION!

Danger of injury through defective components!

Mechanical and electrical alterations can influence the functioning of the

barrier!

Technical alterations may only be performed by skilled personnel and only

according to the manufacturer’s instructions.

T 3000 - T 350

0

7

CAUTION!

Malfunctioning of the barrier!

Mechanical and electrical alterations can influence the functioning of the

barrier!

Technical alterations may only be performed by skilled personnel and only

according to the manufacturer’s instructions.

2.7 Personnel requirements – professional skills, knowledge

and qualifications

WARNING!

Risk of injury through inadequate qualification!

Improper handling during installation, maintenance, repair work or dismantling

can result in personal injury and/or property damage.

Work during installation, maintenance, repair and dismantling must be

performed by skilled personnel only.

Specialist - is a person with suitable professional training, knowledge and

experience, who can recognize and avoid danger.

Instructed person - is a person, which was instructed in the operation and

use of the barrier.

2.8 Personal protective equipment

During installation, maintenance, repair work and dismantling of the barrier

suitable personal protective equipment must be worn.

CAUTION!

Bruising/jamming/driving over (e.g. by material handling equipment,

industrial trucks) the feet, contusion by falling heavy objects, cutting

injuries by stepping into pointed/sharp objects.

Foot injuries

Wearing of suitable safety shoes during the installation, maintenance,

repair work and dismantling protects against serious foot injuries with long-

lasting consequences.

CAUTION!

Falling heavy objects hitting the head

Head injuries

Wearing of a suitable safety helmet during the installation, maintenance,

repair work and dismantling protects against serious head injuries with

long-lasting consequences.

CAUTION!

Cutting injuries resulting from pointed/sharp objects

Hand injuries

Wearing of suitable safety gloves during the installation, maintenance,

repair work and dismantling protects against serious hand injuries with

long-lasting consequences.

T 3000 - T 350

0

8

CAUTION!

Injuries resulting from drilling chips or saw dust

Eye injuries

Wearing of suitable safety goggles during the installation and repair work

protects against serious eye injuries with long-lasting consequences.

T 3000 - T 350

0

9

3 Transportation and storing

3.1 Transportation inspection

The shipment has to be inspected for transportation damage immediately after

receipt. In case of any damage record the type and extent on the delivery

receipt or refuse acceptance.

Inform ELKA-Torantriebe immediately in the event of damage.

In case the above points are not observed claims will be denied due to

insurance regulations.

3.2 Scope of delivery T 3000-3500

Drawing 1

Scope of delivery:

1x barrier model T 3000-3500

1x barrier boom

2x keys (in a pouch) for the access panel

1x accessory box with:

-2x warning signs "No passage for pedestrians"

-1x steel screw incl. washers and nut for the boom connection

-1x boom connector incl. fastening screws

3.3 Storing

The barrier has to be stored as follows:

CAUTION!

Do not expose the barrier to aggressive substances.

CAUTION!

Do not expose the barrier to heat sources.

T 3000 - T 350

0

1

0

CAUTION!

Storage temperature -30°C to +70°C / -22°F to +158°F.

3.4 Lifting heavy loads

WARNING!

Risk of injury by lifting heavy loads!

Lifting heavy loads may cause serious injuries.

Never lift the barrier single-handedly.

To lift the barrier, use a suitable lifting device.

Wear suitable safety shoes.

Barrier model Weight barrier

without boom

[kg]

Weight round

boom

[kg]

Total

[kg]

T 3000 58 2.4 60.4

T 3500 58 2.8 60.8

Table 1

T 3000 - T 350

0

11

4 Declaration of incorporation

Drawing 2

T 3000 - T 350

0

1

2

4.1 Installation information for partly completed machinery

The partly completed machinery must not be put into service until the

final machinery into which it has to be incorporated has been declared

inconformity with the provisions of the machinery directive.

The safety functions of the controller comply with EN ISO 13849-1:2008 Kat.2

PLc.

According to EC Directive 2006/42/EG the mains supply has to be equipped

with an all-pole circuit breaker.

WARNING!

Danger through voltage!

Danger of an electric shock.

Only certified electricians (VDE 0100) should connect the controller to the

mains supply.

According to DIN EN 12453, for an application with passenger traffic,

depending on the type of use and type of activation, suitable safety devices

have to be installed additionally, in order to provide the minimum level of

protection.

4.2 Declaration of conformity

After the installation an EG- declaration of conformity according to EC-

machinery directive 2006/42/EG for the complete system has to be issued by

the person responsible for the integration (according to product standard DIN

EN 13241-1).

4.3 Name plate

The name plate of the barrier is attached at the inside front of the barrier

housing.

T 3000 - T 350

0

1

3

5 Function description

Barriers serve as passage control of vehicle paths. By raising and lowering of

the barrier boom the passage is granted or obstructed.

The controller offers the possibility to activate the barrier by radio remote

control.

The controller is able to observe the max. permitted force which was set

before in the learning sequence. If during the closing movement more force is

needed, the barrier reverses. Additionally several different safety features, e.g.

photoelectric barriers, can be connected.

CAUTION!

Danger of impact and crushing!

With inadequate safety measures the movement of the barrier boom can

result in impact or crushing points between the boom and solid objects within

the movement area.

In order to reduce the risk potential related to the movement of the barrier

boom, additional optical and / or acoustic warning devices should be

installed.

T 3000 - T 350

0

14

6 Technical data T 3000-3500

Range of application

Application for… Toll-station

Drive pulse

from...

TCP/IP

RS485

Push button, card reader, desktop panel etc.

Induction loops

Safety Force monitoring for barrier CLOSE

Emergency release / vandalism protection

Internal evaluation for safety contact profile (8.2kOhm)

Connection of external safety systems

Table 2

General data

Supply voltage 88~264VAC

47~63Hz

Power consumption Max. 1.4A (230VAC)

Max. 2.8A (115VAC)

Duty cycle 100%

Temperature range -30°C to +70°C / -22°F to +158°F

Controller MO 24

Housing dimensions (L/W/H) 360x300x1.100mm

Foundation (frost-free) 550x500x800mm

Boom connector Left or right

Housing Aluminium

Mechanics Steel, galvanized

Sound pressure level (distance 1m) ≤60 dB(A)

Degree of protection IP 54

Table 3

T 3000 - T 350

0

1

5

Model-related data T 3000 T 3500

Power consumption, max. [W] 210 180

Running time - standard, ca. [s] 0.9 1.3

Running time - fast, ca. [s] 0.6 0.9

Max. boom length [mm] 3,240 3,740

Effective boom length [mm] 3,000 3,500

Power reversal yes yes

Table 4

T 3000 - T 350

0

1

6

7 Installation T 3000-3500

7.1 Tools

Quantity Description

2 Open-end wrench 13mm

1 Open-end wrench 16mm

1 Open-end wrench 17mm

1 Open-end wrench 18mm

1 Open-end wrench 19mm

1 Allen key 6mm

1 Torque wrench (0-120Nm) 3/4"-square head

1 Bit 3/4", 10mm,

Length 100mm

1 Bit 3/4", 19mm,

Length 100mm

1 Right-angle screwdriver for hexagon socket

screws

4mm, long model

1 Right-angle screwdriver for hexagon socket

screws

6mm, long model

1 Screwdriver 0,6 x 3,5mm

1 Screwdriver PH2 x 100

1 Cutter knife 18mm

Table 5

T 3000 - T 350

0

1

7

7.2 Mounting dimensions

Drawing 3

T 3000 - T 350

0

1

8

7.3 Foundation

Basic requirements

Keep a safety distance of min. 500mm between all moving barrier parts

and surrounding objects like walls, fences etc. Please check the following

drawing.

Drawing 4

a = min. 500mm

T 3000 - T 350

0

1

9

Empty conduits

Use separate conduits for the power line and the control leads.

Use an additional (separate) conduit for each induction loop.

The distance between the conduits should be as large as possible.

Drawing 5

Requirements regarding the foundation

A minimum concrete strength class of C20/25 (or higher)

The use of heavy duty anchor bolts (M12).

Observe the foundation dimensions quoted in this manual. The installation

distance between the barrier housing and the foundation edge has to be

approx. 100mm.

WARNING!

Risk of injury by insufficient fastening!

Tilting barrier housings can result in severe injuries.

Before installation ensure a safe stand of the barrier housing.

Do not lean the barrier boom against a wall or similar before installation.

Store the boom horizontally only.

Install the barrier housing as specified.

Use the recommended heavy duty anchor bolts M12, at least M10 is

required.

During maintenance check the housing for correct fastening on the

foundation.

This manual suits for next models

1

Table of contents

Other Elka Automatic Barrier manuals

Popular Automatic Barrier manuals by other brands

fadini

fadini VIGILO 2250 instruction manual

DoorHan

DoorHan Barrier PRO Series installation manual

Nice

Nice LBar Instructions and warnings for installation and use

ZKTeco

ZKTeco SBTL2000 instructions

BFT

BFT OMEGA PS XTREME 36 Installation and user manual

O&O

O&O NIGHT&DAY.3 Instructions for installation, use and maintenance

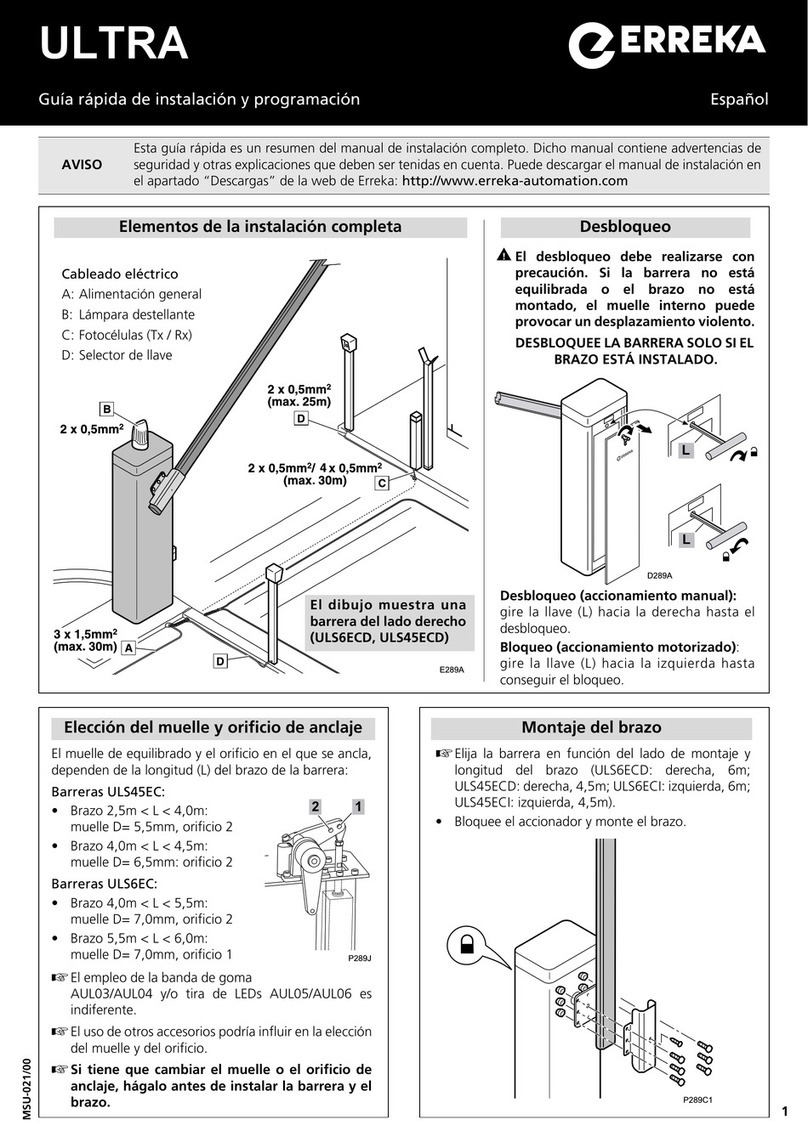

Gerreka

Gerreka ULTRA Quick installation and programming guide

BFT

BFT OMEGA ES GIOTTO ULTRA 36 Installation and user manual

Stagnoli

Stagnoli DAPHNE 6 instructions

Nice

Nice X-Bar Instructions and warnings for installation and use

RITE-HITE

RITE-HITE Wheel-Lok MWL-1300 owner's manual

Palfinger

Palfinger ILSL 30 owner's manual