SEA VERG 24V User manual

VERG 24V BARRIER

General features

VERG 24V is an electro-mechanical barrier (2, 3, 4, 5 m)

recommended for the automation of access points which

require a high opening/closing speed (parking lots,

motorways, airports, etc.) and frequent use features. The

automation includes an anti-crush security system with

adjustable sensitivity, which guarantees a barrier force

value not exceeding 15 kg, thus protecting people and

objects from any accidents. A highly reliable slowdown

device guarantees the total control of the forces of inertia.

The emergency batteries guaranty at least 15 opening

cycles (depending on the installed accessories) in case of

power failure and a release system allows the manual

opening in case of emergency.

English

Sistemi Elettronici

di Apertura Porte e Cancelli

International registered trademark n. 804888

®

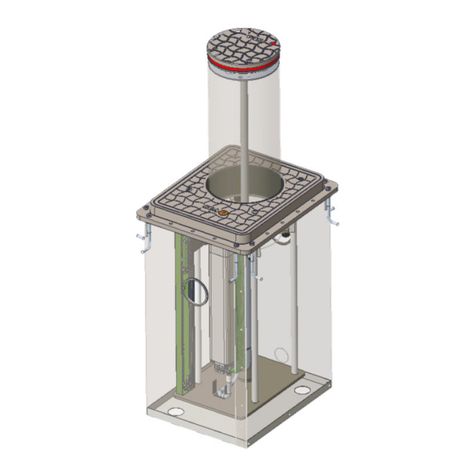

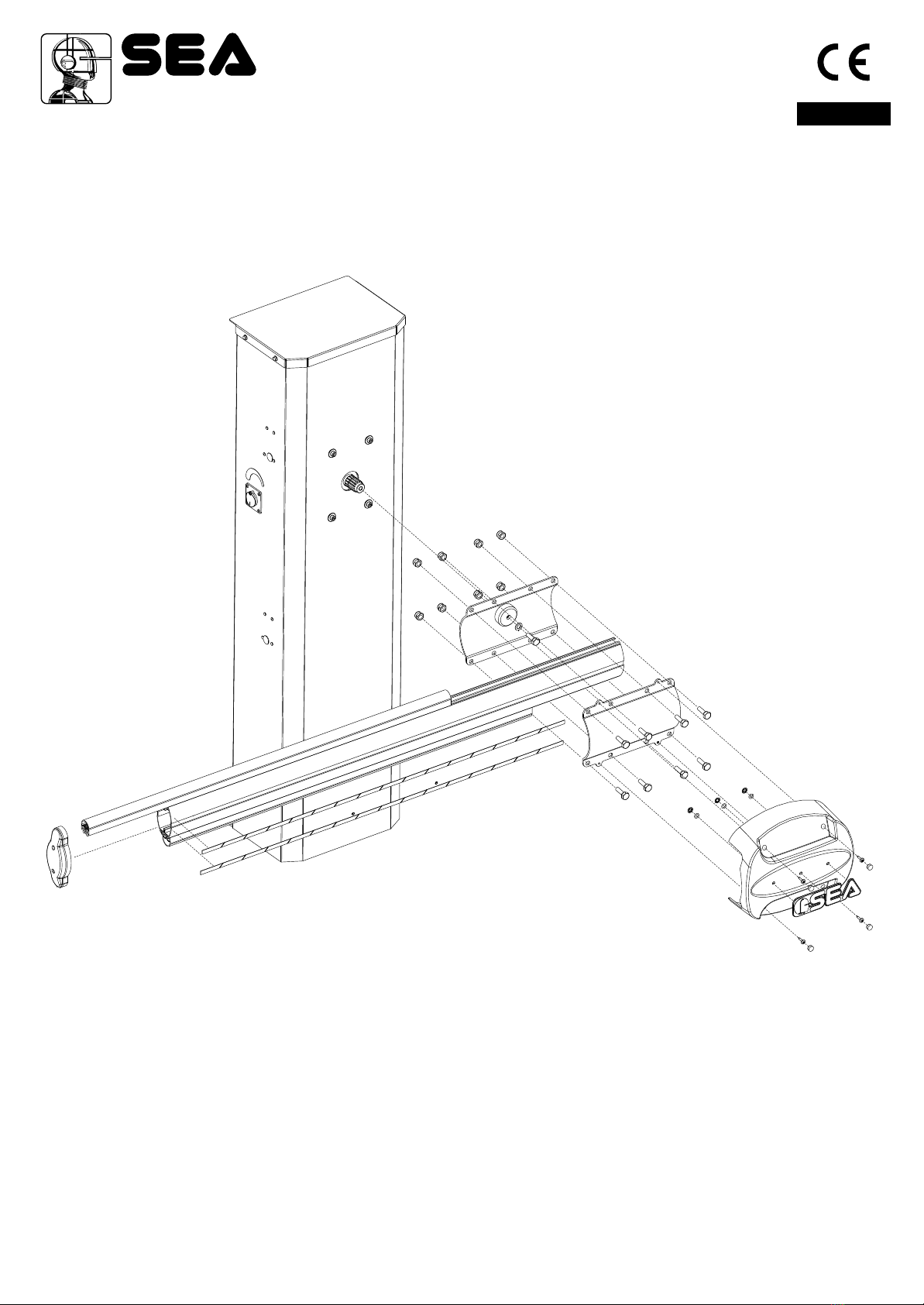

The automation system is composed of the following elements:

1 Adjustable mechanical stop

2 Manual release with key

3 Galvanised steel rocker arm.

4 VERG 24V, casing cover with lock and DIN key

5 Balancing spring.

6 Electronic control unit.

7 Foundation plate out of galvanized steel

8 Emergency batteries 2x12V 2Ah.

9 24V - 2400 rpm electric motor

10 Reduction gear

11 Cataphoresis-treated and polyester painted VERG 24V casing, for outside, protects

all included mechanical and electronic devices from fire, flood, lightning, etc.

Predisposed for the application of photocells, key switch, proximity reader. Stainless

steel casing available on request.

12 Battery charger circuit

Main components:

1) Adjustable mechanical stop

2) Manual release system

3) Rocker arm

4) VERG 24V casing cover

5) Balancing spring

6) Electronic control unit

7) VERG anchoring plate (optional)

8) Emergency batteries 2x12V 2Ah (optional)

9) 24V electric motor

10) Gearbox

11) VERG casing

12) Battery charger circuit (optional with battery kit)

11

6

1

3

4

5

7

8

9

10

11

2

12

Cod. 67411465 Rev.00 - 12/2012

TECHNICAL FEATURES

Supply voltage

Motor power supply

Motor power

Motor speed

Working temperature

Opening/closing time

Protection class

Manual release system

Usage frequency

Anti-crushing device

Holding block

Slowdown

Barrier body treatment

Weight

Electronic equipment

INSTALLATION INSTRUCTIONS

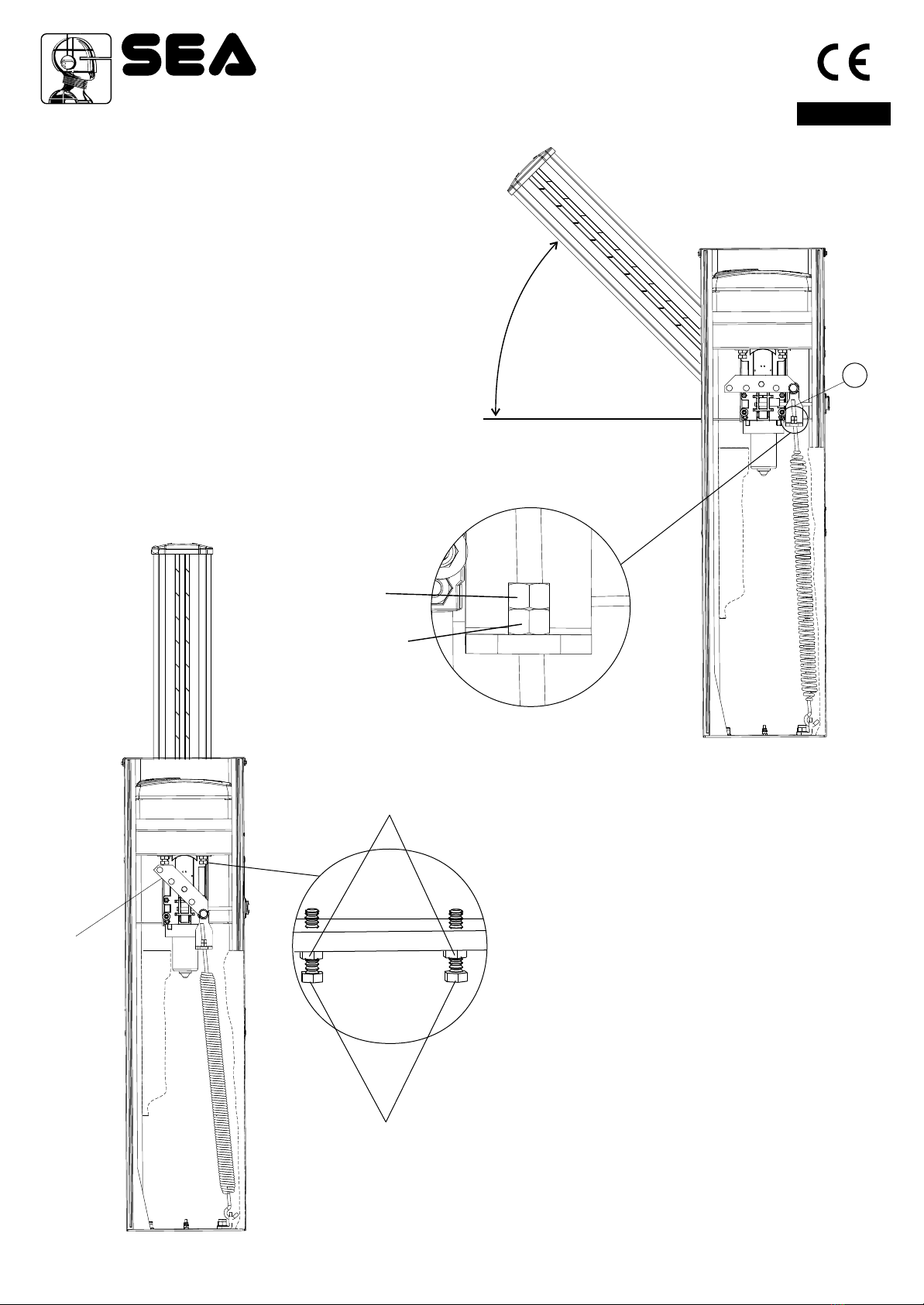

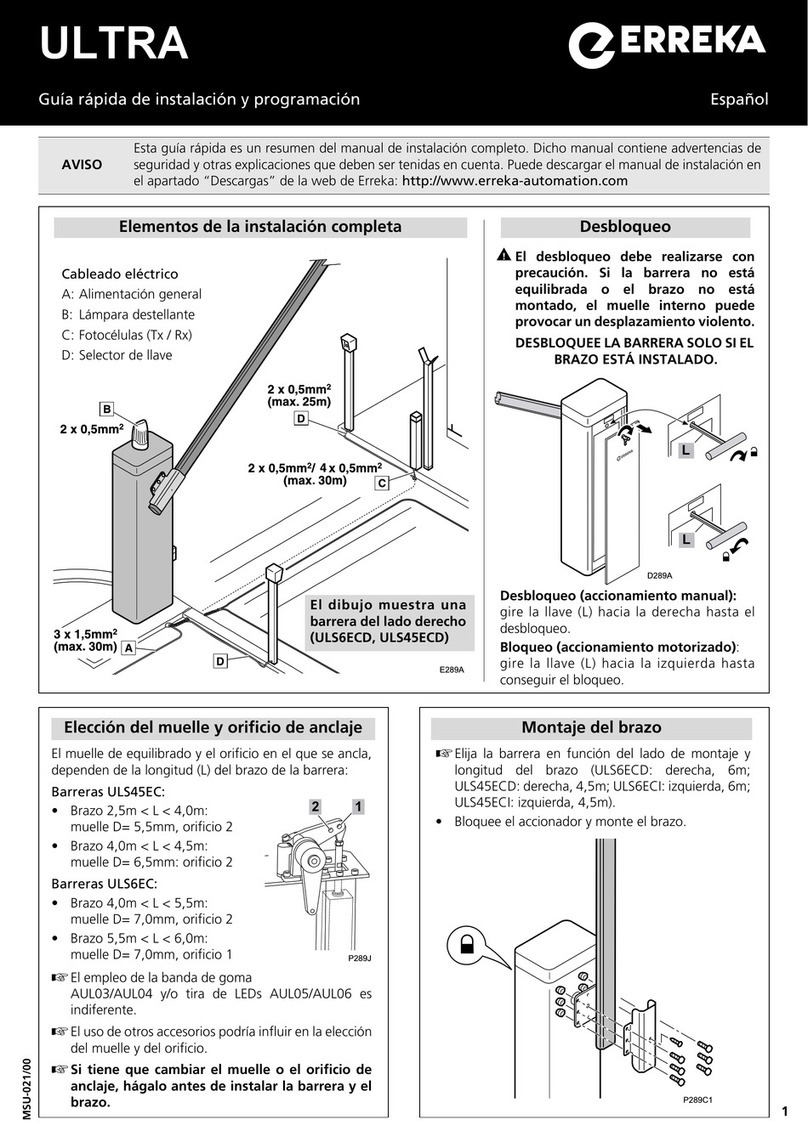

1) Spring position

Thanks to its high flexibility, the barrier you are installing can be closed

on the right-hand or left-hand side of the post, according to your needs.

e.g. if the spring is on the right-hand side, the guard closes on the left

(see Fig. 2).

English

Sistemi Elettronici

di Apertura Porte e Cancelli

International registered trademark n. 804888

®

Fig.2

Fig.1

Opening on the right Opening on the left

12

230 V~ ± 5% - 50/60 Hz 115 V~ ± 5% - 50/60 Hz

24Vdc

60 W

2400

-20° + 55°C

IP55

Yes

60%

A

Yes

E

39 kg

USER 1 24V

RPM

Adjustable

mmeter

lectronic

Cataphoresis treated and polyester painted

128

56

1148

288

203

VERG 230V VERG 115V

Note: The frequency of

use is valid only for the

first hour at 20°C room

temperature.

OVERALL DIMENSIONS:

*To guarantee longer life of the barrier, SEA

recommend to adjust the speed giving an extra time

of at least 1 sec from the Max Speed as for this chart.

** SEA grant those performances only for the 1st

hour of operation. After 1 st hours cycles can drop

up to 50%. Cycles are granted only with slowdown

active. Periodically check the balance of the beam.

VERG 2mt 3mt 4mt 5mt

Max Speed* 2-3 sec 3-4 sec 4-5 sec 5-6 sec

Cycles** 60% 50% 45% 35%

BEAMS RECOMMENDED SPEED

Cod. 67411465 Rev.00 - 12/2012

Concrete

Foundation plate

to be levelled

60°~ clamp opening

Conduit

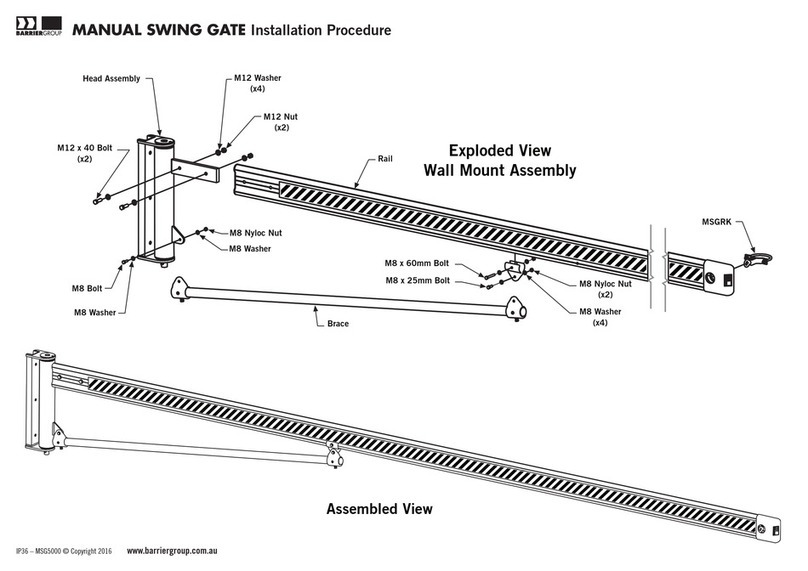

2) Foundation plate anchoring

−Make a 500 x 500 x 300 mm (depth) hole in

the ground.

−Widen the foundation plate clamps till they

reach approx. 60° (Fig. 3).

−Fill the hole with R425 concrete and place the

foundation plate as shown in Fig. 3.

−Accurately level the plate.

* The middle hole of the plate must be used for

cable routing. Therefore, make sure that the

conduit connected to the hole complies with

current regulations, before filling the hole with

concrete.

Anchoring

nuts and

washers

Hole for the conduit containing

the electrical cables

3) Post anchoring on the foundation plate

−Place the casing so that the holes on the base match the

screws located on the foundation plate.

−Make sure that the conduit for the cables goes through

the large hole of the casing base.

−Insert the bracket for anchoring the spring: A in case of

left-hand mounting, B in case of right-hand mounting; the

bracket must always be positioned towards the inside as

in Fig.4

−Fix the casing on the foundation plate, screwing the

supplied nuts and washers carefully.

English

Sistemi Elettronici

di Apertura Porte e Cancelli

International registered trademark n. 804888

®

Fig.4

Fig.3

500

300

B

A

13

Cod. 67411465 Rev.00 - 12/2012

4) Fixation of the balance

−Carefully insert the roll bearing (A) into the hole 1 or 2 of

the balance in case of left-hand mounting; into hole 3 or 4

in case of right-hand mounting using hinge P and a nylon

hammer.

Attention: The choice of the hole varies according to the beam

length. (SEE BOARD)

−Lubricate with grease the bearing and the washers

.

−Mount the resting devices as shown in Fig. 5

during assembling

5) Mounting of the spring

−Anchor the spring on the bracket which has been mounted

before (S)

−Insert the rod of the spring into the bracket (B) and insert the

nuts (D) without tightening them.

OVAL BEAM

Length

(m)

3

4

5

Balance

position

1 / 4

1 / 4

1 / 4

Spring

(Ø mm)

6

7,5

8,5

Note: Strictly follow the opening time to avoid bad

working

Note: The springs and the bracket of anchorage are supplied with the

beam.

Opening

time

3

4

5

” ÷ 4”

” ÷ 5”

” ÷ 6”

English

Sistemi Elettronici

di Apertura Porte e Cancelli

International registered trademark n. 804888

®

Fig.6

A

P

Fig.5

P

A

1

2

3

4

B

D

S

Keep well

lubricated

with grease

14 Cod. 67411465 Rev.00 - 12/2012

6) Mounting of the oval beam

Note: For 4 and 5 m beams it is recommended to use the fork support or the flexible support.

English

Sistemi Elettronici

di Apertura Porte e Cancelli

International registered trademark n. 804888

®

Fig.7

15

Cod. 67411465 Rev.00 - 12/2012

7) Beam balancing

−Release the beam with manual release, so

that it is free to be opened and closed

manually (Fig.8).

−Place the beam at approx. 45°.

−Loosen or tighten the spring stretching nut

until the spring counterbalances the weight of

the 45° beam (Fig. 8). The best balancing

position is obtained when the beam reaches

the position shown in Fig. 8.

−After having obtained the balancing, lock the

nuts of the spring stretcher with the counter

nut and re-block the motor.

Should the balancing of the beam not be

perfect and the length of the spring stretcher

(T) be too long, cut it about half of its length.

Spring

nutstretching

Anchoring

lock nut

8) Beam levelling

Note: this operation must be carried out only if

the beam is not perfectly horizontal (closing

stage) or vertical (opening stage) at the end of its

stroke.

−Release the beam with the special manual

release so that it is free to open and close

manually.

−Release the screws of the limit switch on

unscrewing the nuts on the mechanical stops

(fig.9).

−Loosen or tighten the stop screws so that the

beam is released in its vertical position

(opening stage) (Fig. 9) and horizontal position

(closing stage).

−After having executed the levelling lock the

screws of the limit switch tightening the nuts on

the mechanical stops and re-lock the beam.

Stop adjustment

screws

Lock nuts

Rocker

arm

English

Sistemi Elettronici

di Apertura Porte e Cancelli

International registered trademark n. 804888

®

4°

5

T

Fig. 8

Fig.9

16 Cod. 67411465 Rev.00 - 12/2012

Battery charger

circuit

Note: For a longer duration of the battery it

is recommended to set the charging

current according to the following table:

Battery current (mA) Battery (Ah)

9) Battery charger circuit

English

Sistemi Elettronici

di Apertura Porte e Cancelli

International registered trademark n. 804888

®

GNDGND

GNDGND PSOLPSOL BATBAT 28V28V

++

SS

--

USER24

+ +

- -

= charge 200mA

Solar Panel

Batteries

GNDGND

+

Grey connector

CN1

= charge 360mA

= charge 800mA

~

~

~

12V12V 12V12V

12 or 16

7

2

800

360

200

Fig.10

17

Cod. 67411465 Rev.00 - 12/2012

10) Electrical system

Fig. 11 sketches the electrical system that the barrier requires.

The two numbers located near the electrical cables indicate the cable number and section.

Captions:

1- VERG electronic control unit

2- Transmitting photocell

3- Receiving photocell

4- Key switch

5- Radio receiver

6- Flashing light

7- Push-button station

8- Differential switch

English

Sistemi Elettronici

di Apertura Porte e Cancelli

International registered trademark n. 804888

®

ACCESSORIES FOR VERG

FORK SUPPORT

BATTERY KIT

PHOTOCELLS

KEY SWITCH

WARNING LAMP

Fig.11

11

22

33

44

55

66

77

88

2x1

2x1

4x1

3x1,5

3x1

Fig.11

2X1 1xRG58

18 Cod. 67411465 Rev.00 - 12/2012

RELEASE LOCK

(Optional)

LED

LIGHTS KIT

NOTES

The electrical installation and the operation logics must comply with current regulations. Keep the power cables (motors, power supply)

separated from the control cables (push-buttons, photo-eyes, radio, etc.). Separate conduits should be used to prevent noise issues.

Note: Use “cable clips” and/or “duct/box pipes” fitting close to the control panel box so to protect the interconnection cables against pulling

efforts.

INTENDED USE

VERG system has been designed exclusively for the automation of barriers.

SPARE PARTS

The spare parts orders must be sent to:

SEA S.p.A. Zona Ind.le, 64020 S.ATTO Teramo Italy

SAFETY AND RESPECT FOR THE ENVIRONMENT

We recommend not to spoil the environment with product and circuit packing material.

STORAGE

STORAGE TEMPERATURE

Tmin

-30°C

Tmax

+60°C

Humiditymin

5% without condensation

Humiditymax

90% without condensation

The product must be handled using suitable means.

LONG-TERM STOPAND MAINTENANCE

The disassembly and/or stop and /or maintenance of the VERG automation system must be carried out by skilled and expert technicians.

GUARANTEE LIMITS

For the guarantee see the sales conditions on the official SEAprice list.

NOTE: THE MANUFACTURER SHALL NOT SHOULDER ANY RESPONSIBILITIES IN CASE OF DAMAGE CAUSED BY

INAPPROPRIATE, WRONG OR CARELESS USE.

SEA reserves the right to make all the necessary changes and modifications of the products and / or manuals without giving prior

notice.

English

Sistemi Elettronici

di Apertura Porte e Cancelli

International registered trademark n. 804888

®

11) Release system

To release operate as follows

- Turn the protection cap of the release.

- Insert the and turn it about 180° into

clockwise direction until the beam is released (Fig.

12).

- Open manually the beam.

To re-lock operate as follows

- Turn the into anti-clockwise direction

(Fig. 13).

- Extract the key.

- Re-close the protection cap.

T shaped key

T shaped key

PERIODICAL MAINTENANCE

All above mentioned operations must be executed exclusively by authorized installers.

Check the functionality of the release

Lubricate the bearing of the balance

Check the efficiency of the spring

Check the beam fixing screws and the balance and the casing

Check the integrity of the connexion cables

Check the efficiency of the batteries (where included)

Check and eventually adjust the value of intervention of the

anti-crash sensor.

Annually

Annually

Annually

Annually

Annually

Annually

Annually

To the attention of users and technicians

180°

Fig.12 180°

Fig.13

Release Lock

19

R

(OPTIONAL)

elease key with extractable cylinder

Release

Cod. 67411465 Rev.00 - 12/2012

Fig.14

Table of contents

Other SEA Automatic Barrier manuals

Popular Automatic Barrier manuals by other brands

Gerreka

Gerreka ULTRA Quick installation and programming guide

barrier

barrier SWING GATE INSTALLATION PROCEDURE

O&O

O&O NIGHT&DAY 35 Xtreme Instructions for installation, use and maintenance

DoorKing

DoorKing 1620 Series installation manual

nologo

nologo ACTIVE-A Series Manual and directions for the installer

PERCo

PERCo ST-02 Series Assembly and operation manual