97627C (Rev. G - 04/02)

EZOTL8_1, EZODTL_A

Page 3

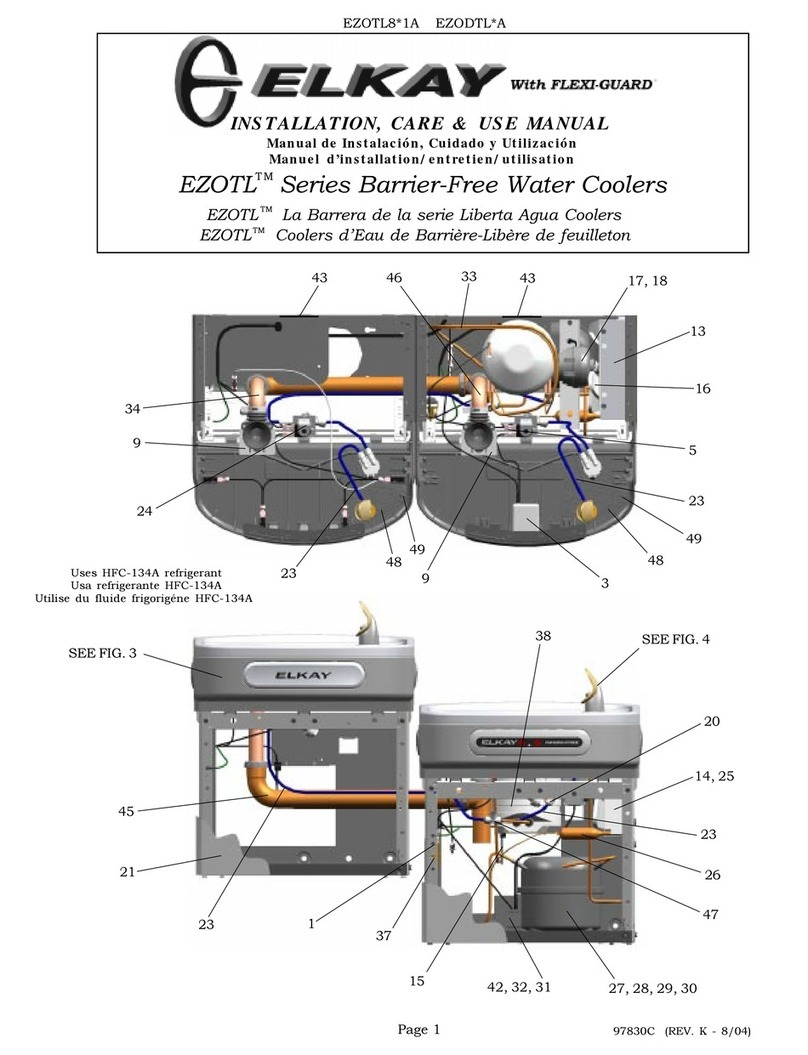

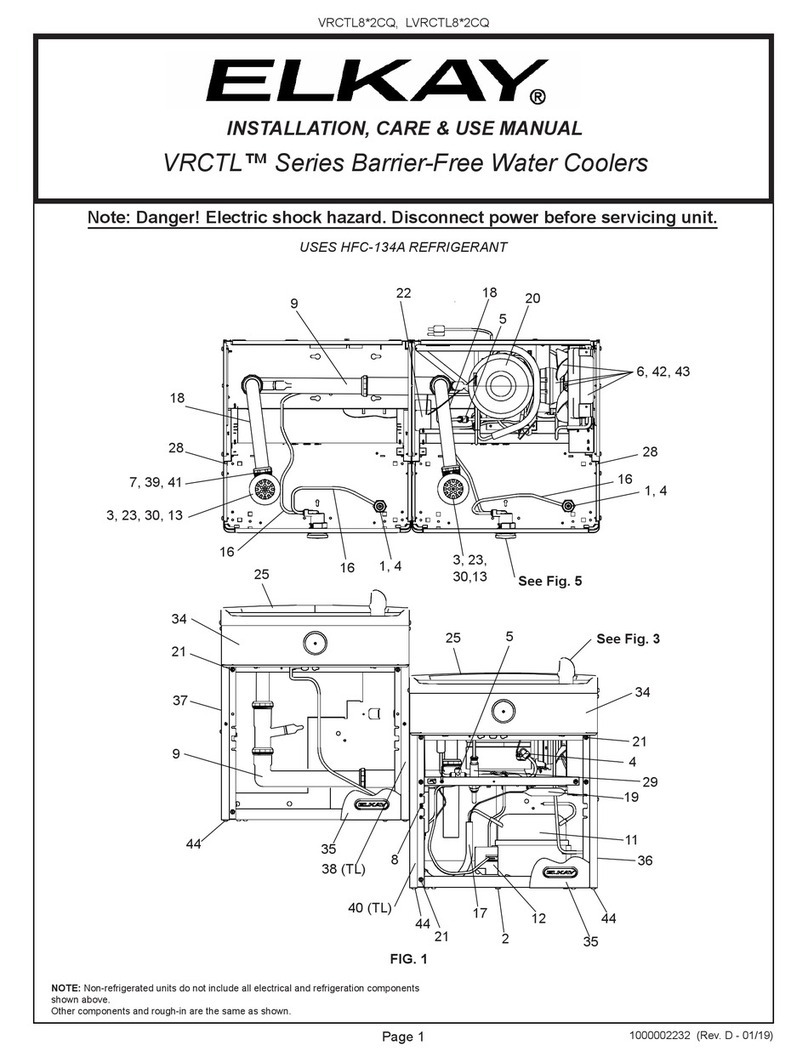

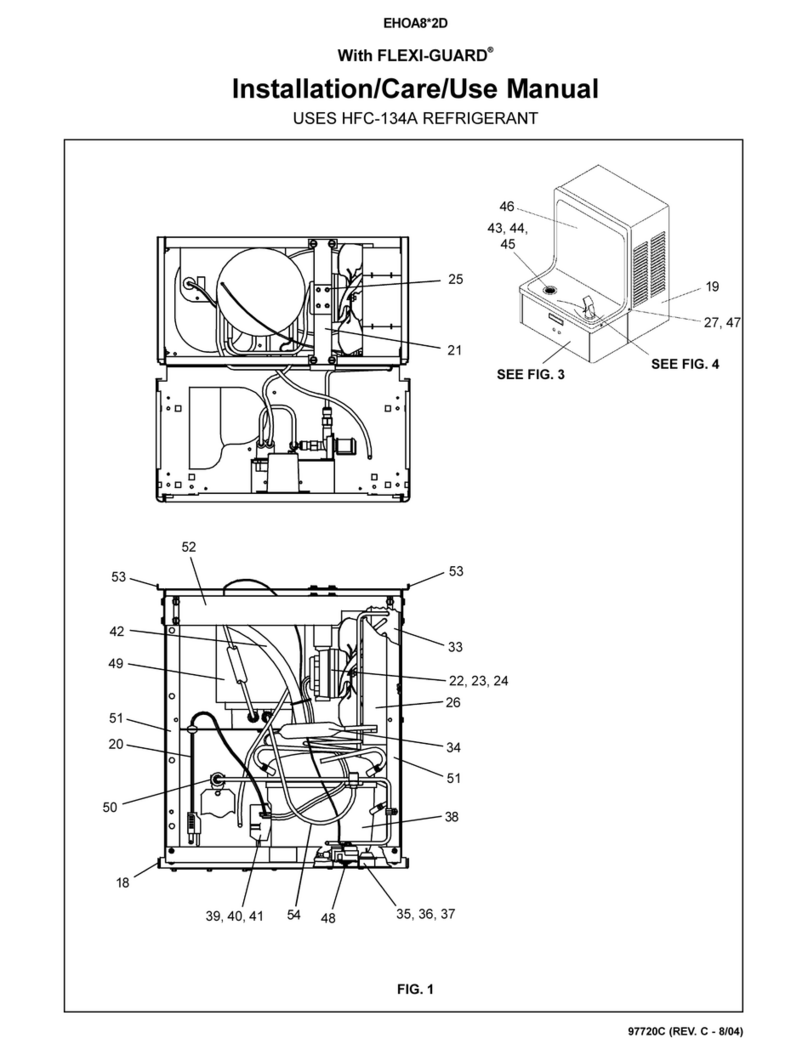

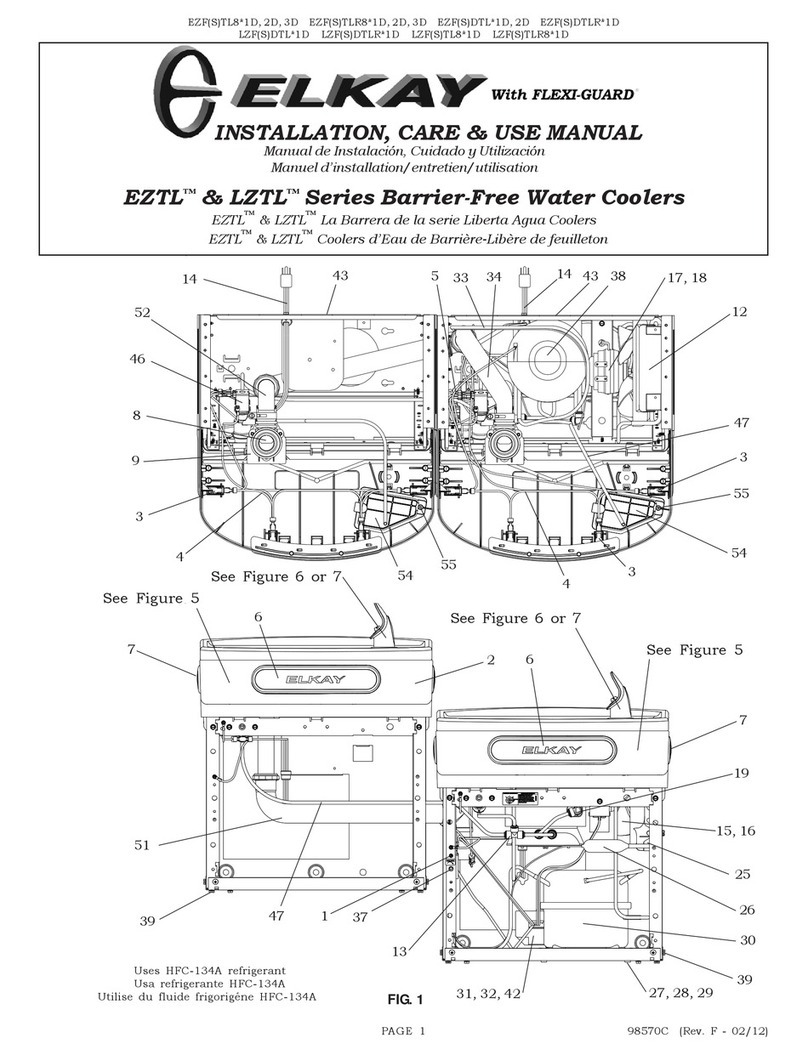

HANGER BRACKETS & TRAP

INSTALLATION

1) Remove hanger bracket fastened to back of cooler by removing one (1) screw.

2) Mount the hanger bracket as shown in Figure 2.

NOTE: Hanger Bracket MUST be supported securely. Add fixture support carrier if wall will not provide

adequate support. Anchor hanger securely to wall using all six (6) 1/4 in. dia. mounting holes.

IMPORTANT:

5-7/8 in. (150mm) dimension from wall to centerline of trap must be maintained for proper fit.

INSTALLATION OF COOLER

3) Hang the cooler on the hanger bracket. Be certain the hanger bracket is engaged properly in the slots

on the cooler back as shown in Figure 2.

4) Remove the six (6) screws holding the lower front panel at the bottom of cooler. Remove the front

panel by pulling straight down and set aside.

5) Connect water inlet line--See Note 4 of General Instructions.

6) Install trap. Remove the slip nut and gasket from the trap and install them on the cooler waste line

making sure that the end of the waste line fits into the trap. Assemble the slip nut and gasket to the trap

and tighten securely.

IMPORTANT: If it is necessary to cut the drain, loosen the screw at the black rubber boot and remove tube,

check for leaks after re-assembly.

7) Plug in electrical power.

START UP

Also See General Instructions

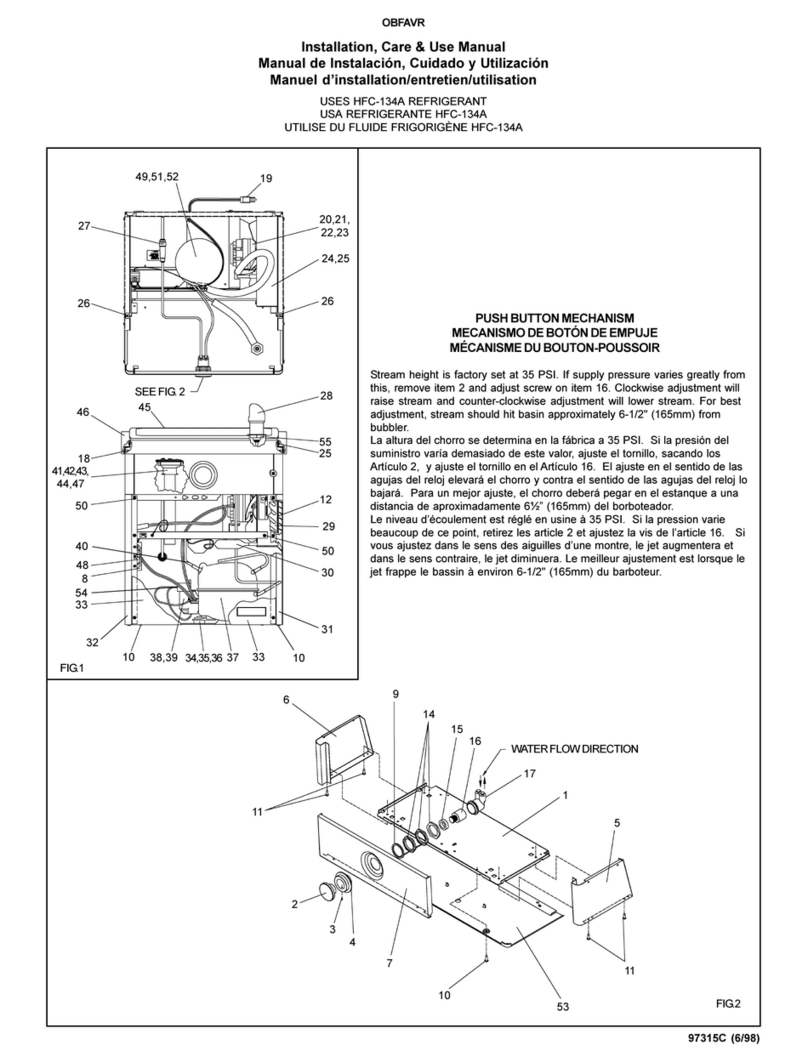

8) Stream height is factory set at 35 PSI. If supply pressure varies greatly from this, adjust screw located

on the right knee clearence area. CW adjustment will raise stream and CCW adjustment will lower

stream. For best adjustment, stream should hit basin approximately 6-1/2 (165mm) from bubbler on

the downward slope of the basin.

NOTE: If continuous flow occurs at the end of the compressor cycle, turn cold control (Item 37) counter-

clockwise 1/4 turn.

9) Replace the front panel ensuring that the metal wrapper is secured inside of the upper shroud.

Replace all six screws previously removed.

10

NOTE:

WHEN INSTALLING REPLACEMENT BUBBLER

AND PEDESTAL, TIGHTEN NUT (ITEM 10) ONLY

TO HOLD PARTS SNUG IN POSITION.

DO NOT OVER TIGHTEN.

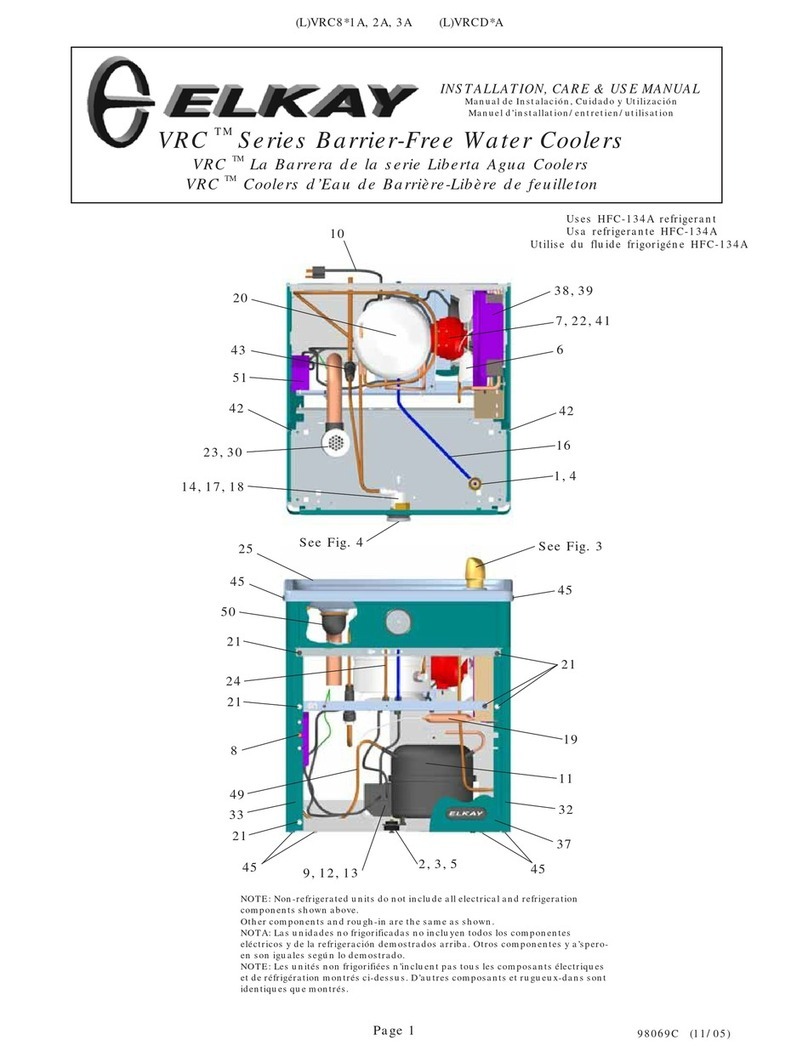

FIG.3

40

39

BASIN

ESTANQUE

BASSIN

22 41

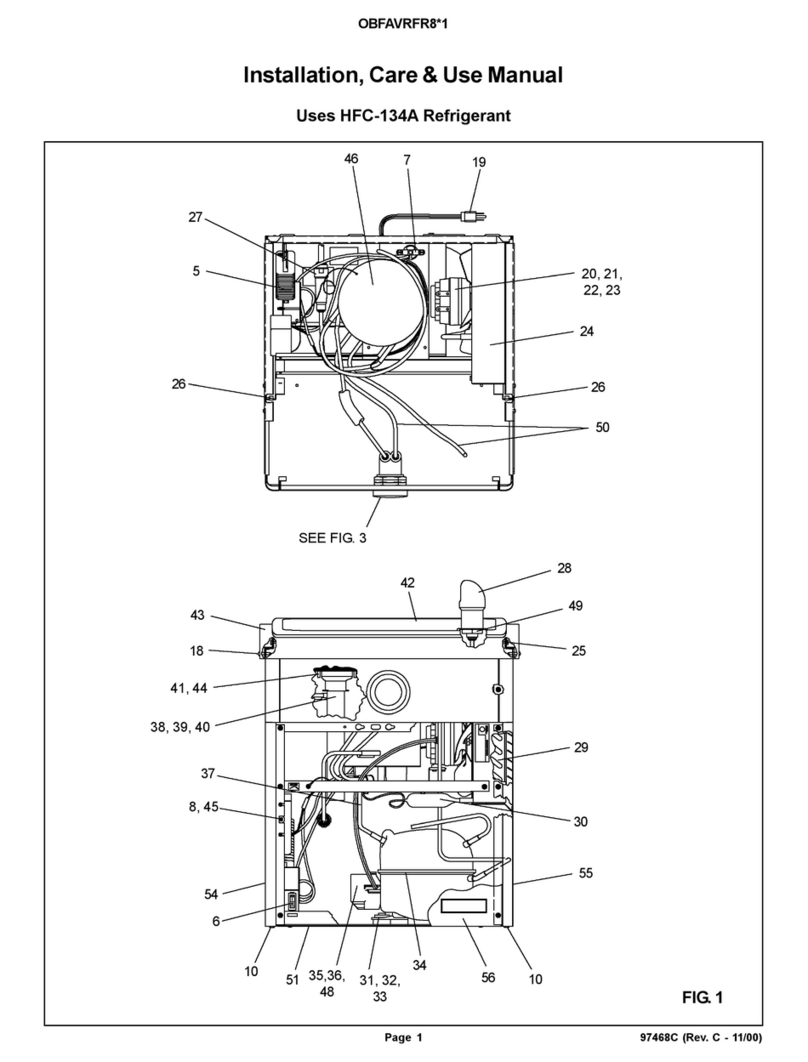

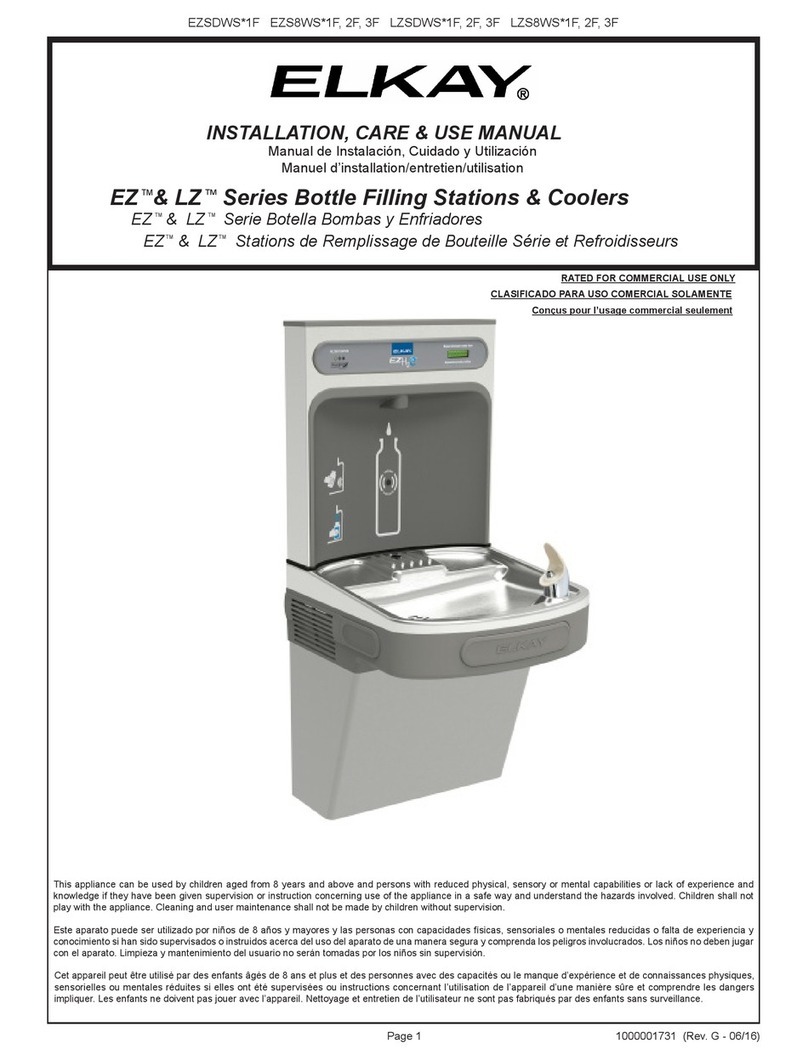

SENSOR RANGE ADJUSTMENT: The electronic sensor used in this cooler is factory pre-set for a

"visual" range of 36 inches (914 mm). If actual range varies greatly from this or a different setting is

desired, follow the range adjustment procedure below:

A. Disassemble the unit.

B. Using a small tip screwdriver, rotate range adjustment screw clockwise to increase range and

counterclockwise to decrease range (See Fig. 4).

CAUTION: Complete range of sensor (24-28 inches/610-711mm) is only one turn of the adjusting

screw.

C. Re-assemble the unit.

SENSOR CONTROL: If sensor fails to operate valve mechanism or operates erratically, check the

following.

A. Ensure there are no obstructions within a 40 inch (1016mm) radius in front of cooler.

B. Check wire connections at the solenoid valve and sensor. CAUTION: Make sure unit is unplugged

before checking any wiring.

C. Ensure proper operation of solenoid valve. If there is an audible clicking sound yet no water flows,

look for an obstruction in the valve itself or elsewhere in the water supply line.