Page 3 1000002234 (Rev. A - 11/14)

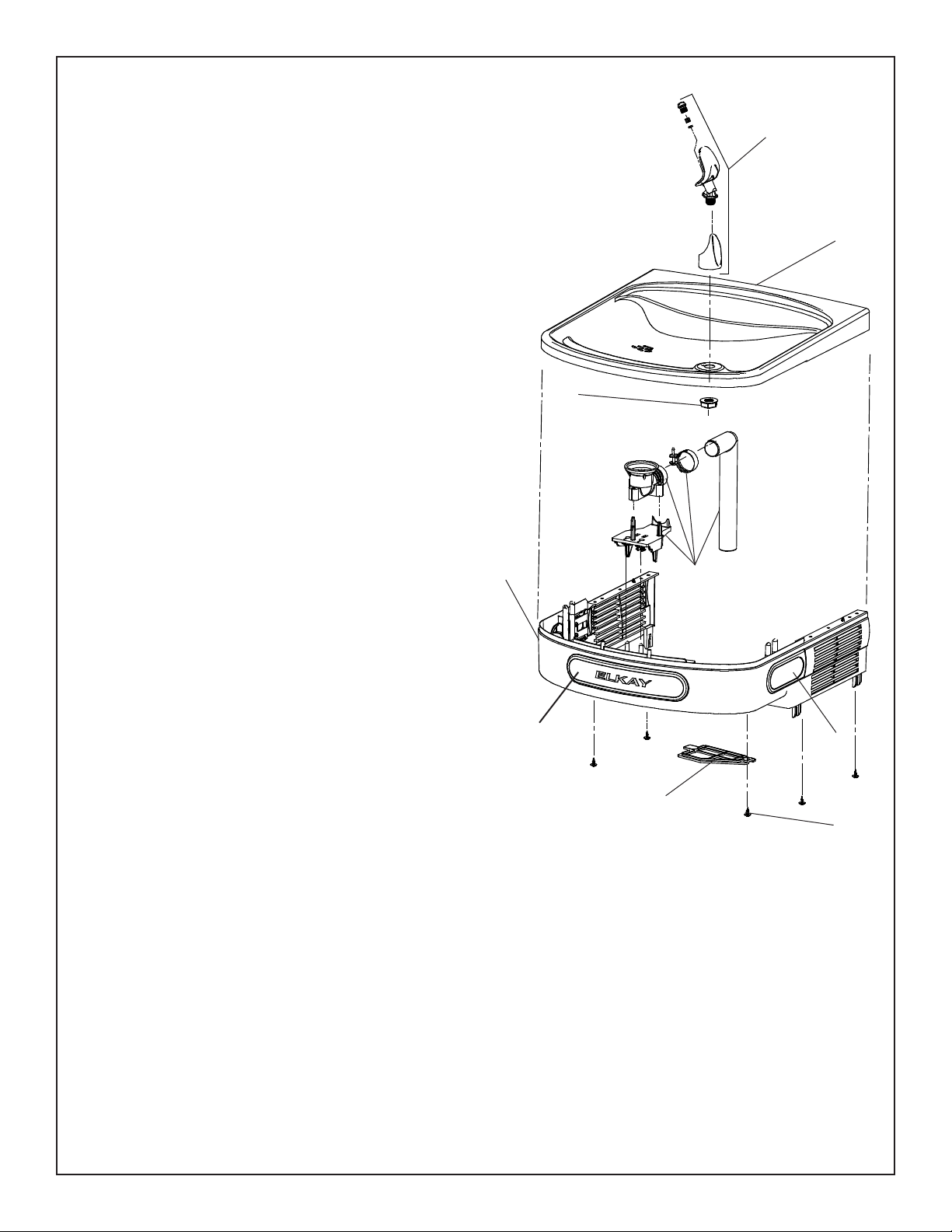

EZFS8*2FQ, LZFS8*2FQ

Lower and Upper Shroud

To access the refrigeration system and plumbing connections, remove four screws from bottom

of cooler to remove the lower shroud. To remove the upper shroud for access to the pushbars,

regulator, solenoid valve or other components located in the top of the unit, remove lower shroud,

disconnect drain, remove four screws from tabs along lower edge of upper shroud, unplug two wires

and water tube.

Switches Behind the Push Bar

The regulator, in an EZ cooler is always held fully open by the use of a single regulator nut (See Fig.

6). Water is not dispensed until the pushbar is depressed to activate a switch which then opens

a solenoid valve. When installing the regulator nut, the regulator spring must be depressed while

turning the nut.

Single bar units will have the same wiring as side push bar units but will not have the extra leads

attached to sidebars.

To remove sidebars, from the inside compress the ared tabs and pull out carefully. To reinstall side

pushbars, the front of the pushbar is inserted rst. While keeping the switch depressed, snap the

rear of the pushbar into position.

Service Instructions

12 - Bubbler

Assembly

Fig. 3

2

12

7

22

15

69

Bubbler

To remove the bubbler, rst disconnect the power supply. The underside of the bubbler can be

reached through the access panel (Item 7) on the underside of the upper shroud (Item 6). Remove

the access panel by removing the retaining screw. To remove the bubbler, loosen locknut from the

underside of the bubbler and remove the tubing from the quick connect tting per the Operation Of

Quick Connect Fittings section in the General Instructions. After servicing, replace the access panel

and retaining screw.

15

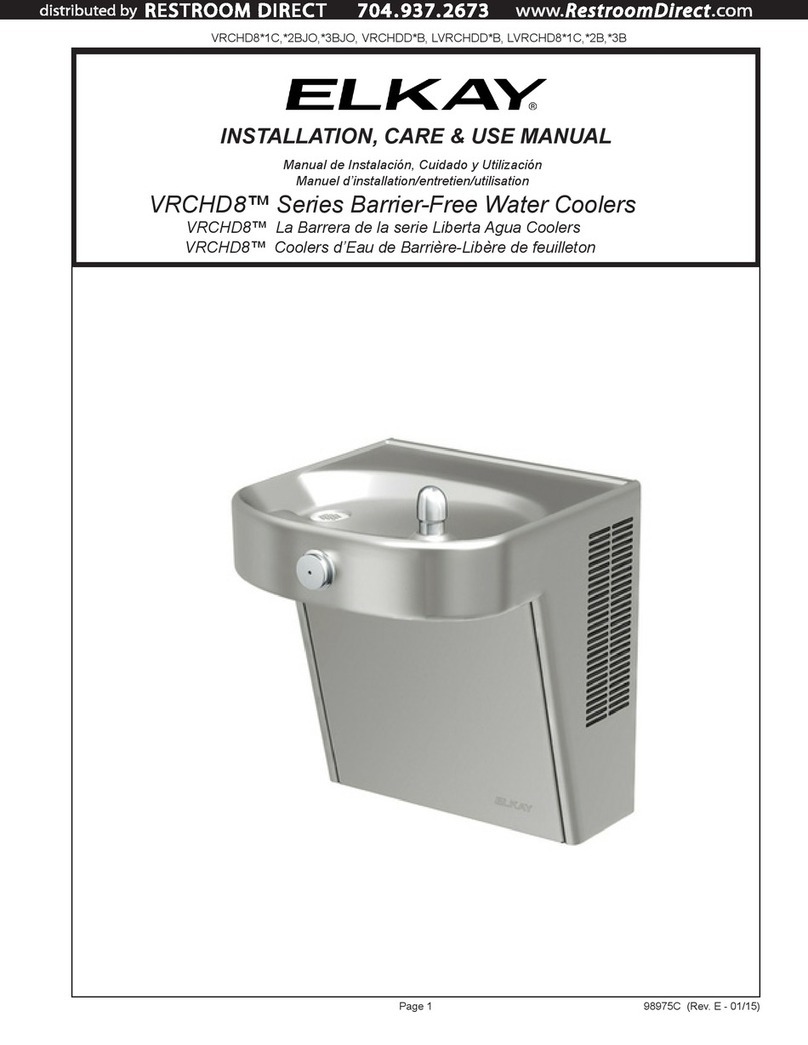

HANGER BRACKETS & TRAP

INSTALLATION

1) Remove hanger bracket fastened to back of cooler by

removing one (1) screw.

2) Mount the hanger bracket as shown in Figure 2.

NOTE: Hanger Bracket MUST be supported securely.

Add xture support carrier if wall will not provide

adequate support. Anchor hanger securely to wall

using all six (6) 1/4 in. dia. mounting holes.

IMPORTANT:

5-7/8 in. (150mm) dimension from wall to centerline

of trap must be maintained for proper t.

INSTALLATION OF COOLER

3) Hang the cooler on the hanger bracket. Be certain

the hanger bracket is engaged properly in the slots

on the cooler back as shown in Figure 2.

4) Remove the four (4) screws holding the lower front

panel at the bottom of cooler. Remove the front panel

by pulling straight down and set aside.

5) Connect water inlet line--See Note 4 of General

Instructions.

6) Install trap. Remove the slip nut and gasket from the

trap and install them on the cooler waste line making

sure that the end of the waste line ts into the trap.

Assemble the slip nut and gasket to the trap and

tighten securely.

IMPORTANT: If it is necessary to cut the drain, loosen

the screw at the black rubber boot and remove tube,

check for leaks after re-assembly.

7) Plug in electrical power. Unit must have

electrical power to have water ow.

START UP

Also See General Instructions

8) Stream height is factory set at 35 PSI. If supply pres-

sure varies greatly from this, adjust screw located on

the left side below push bar ass’y. on crossbar. CW

adjustment will raise stream and CCW adjustment will

lower stream. For best adjustment, stream should hit

basin approximately 6-1/2” (165mm) from bubbler on

the downward slope of the basin.

NOTE: If continuous ow occurs at the end of the com-

pressor cycle, turn cold control screw counterclock-

wise 1/4 turn.

9) Replace the front panel ensuring that the metal wrap-

per is secured inside of the upper shroud. Replace

all four screws previously removed.

Warm, soapy water or mild household cleaning products

can be used to clean the exterior panels of the EZ cool-

ers. Extra caution should be used to clean the mirror

nished stainless steel panels. They can be easily

scratched and should only be cleaned with mild soap and

water or Windex glass cleaner and a clean, soft cloth.

Use of harsh

chemicals or petroleum based or abrasive cleaners will

void the warranty.

CLEANING