LZO8TL*1C, LZO8TL*2C, LZO8TL*3C

98399C (Rev. C - 03/09)

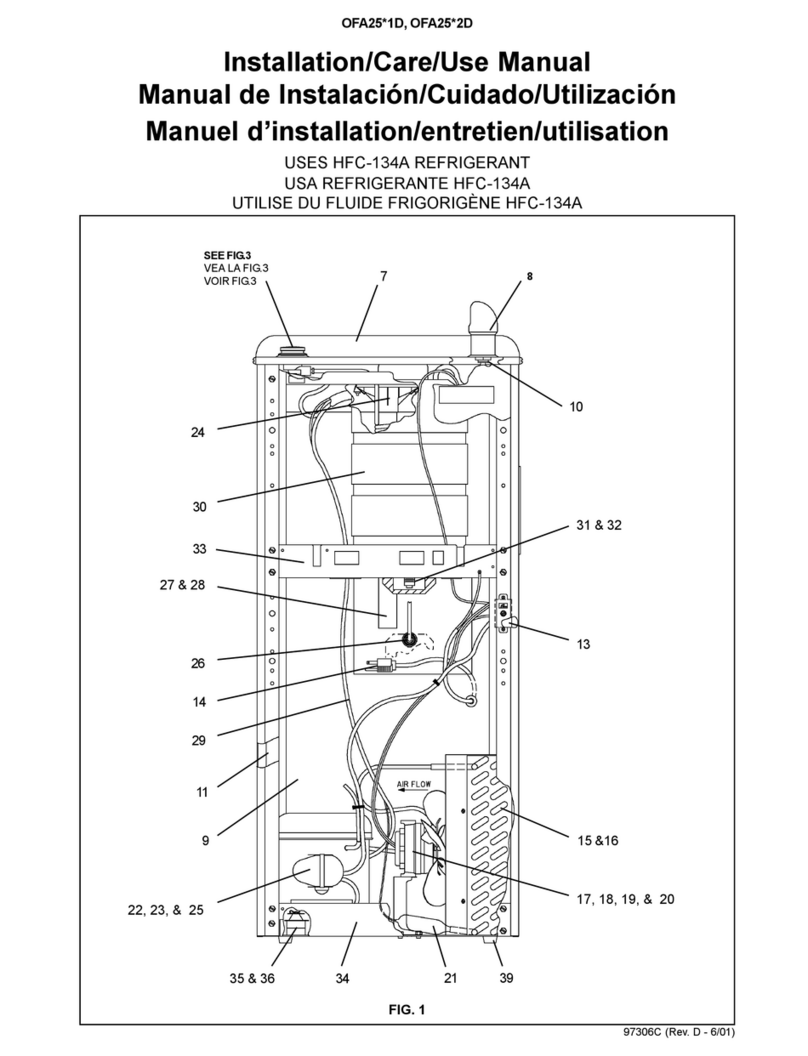

HANGER BRACKETS & TRAP

INSTALLATION

1) Remove hanger bracket fastened to back of cooler by removing one (1) screw.

2) Mount the hanger bracket as shown in Figure 2.

NOTE: Hanger Bracket MUST be supported securely. Add fixture support carrier if wall will not provide adequate support. Anchor hanger securely to wall

using all six (6) 1/4 in. dia. mounting holes.

IMPORTANT:

5-7/8 in. (150mm) dimension from wall to centerline of trap must be maintained for proper fit.

INSTALLATION OF COOLER

3) Hang the cooler on the hanger bracket. Be certain the hanger bracket is engaged properly in the slots on the cooler back as shown in Figure 2.

4) Remove the four (4) screws holding the lower front panel at the bottom of cooler. Remove the front panel by pulling straight down and set aside.

5) Connect water inlet line--See Note 4 of General Instructions.

6) Install trap. Remove the slip nut and gasket from the trap and install them on the cooler waste line making sure that the end of the waste line fits into the

trap. Assemble the slip nut and gasket to the trap and tighten securely. The purple jumper wire (item 48) from the right hand refrigerated unit is to be

connected to the the purple jumper wire (item 48) located on the non-refrigerated left hand unit by removing the protective end caps and connecting the

male and female terminal connectors.

IMPORTANT: If it is necessary to cut the drain, loosen the screw at the black rubber boot and remove tube, check for leaks after re-assembly.

7) Plug in electrical power. Unit must have

electrical power to have water flow. START UP

Also See General Instructions

8) Stream height is factory set at 35 PSI. If supply pressure varies greatly from this, adjust screw located on the left side below the push bar assembly on

the crossbar. CW adjustment will raise stream and CCW adjustment will lower stream. For best adjustment, stream should hit basin approximately 6-

1/2” (165mm) from bubbler on the downward slope of the basin.

NOTE: If continuous flow occurs at the end of the compressor cycle, turn cold control (Item 38) counterclockwise 1/4 turn.

9) Replace the front panel ensuring that the metal wrapper is secured inside of the upper shroud. Replace all four screws previously removed.

Page 3

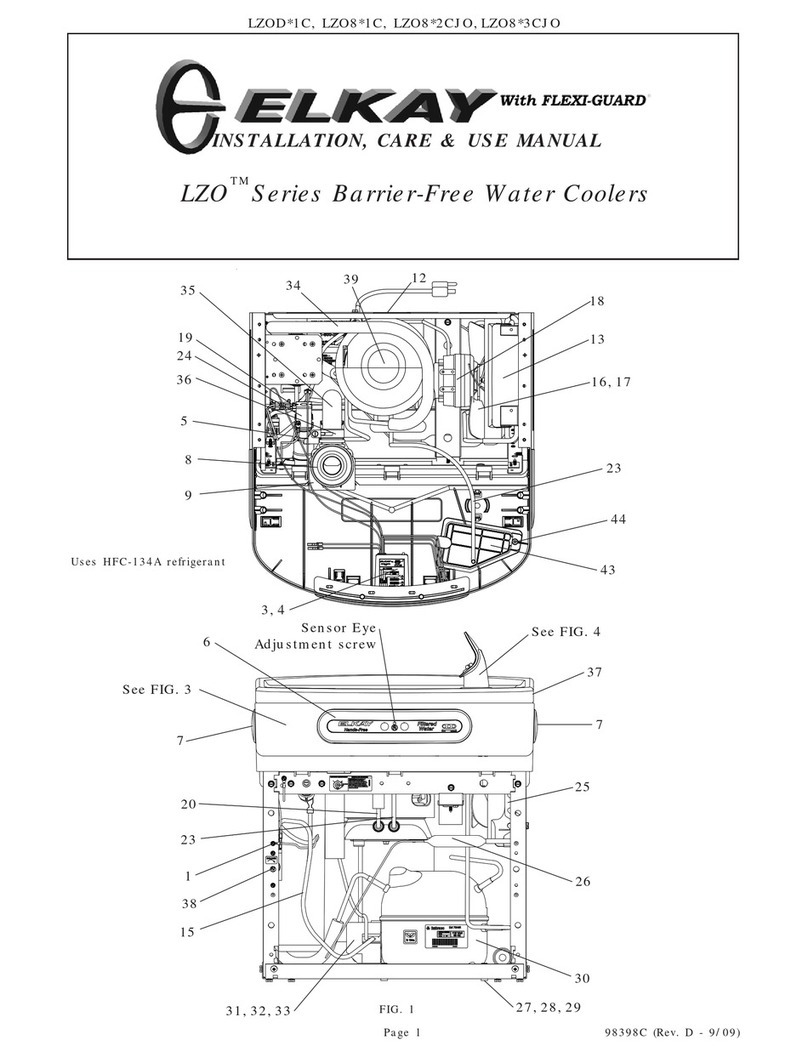

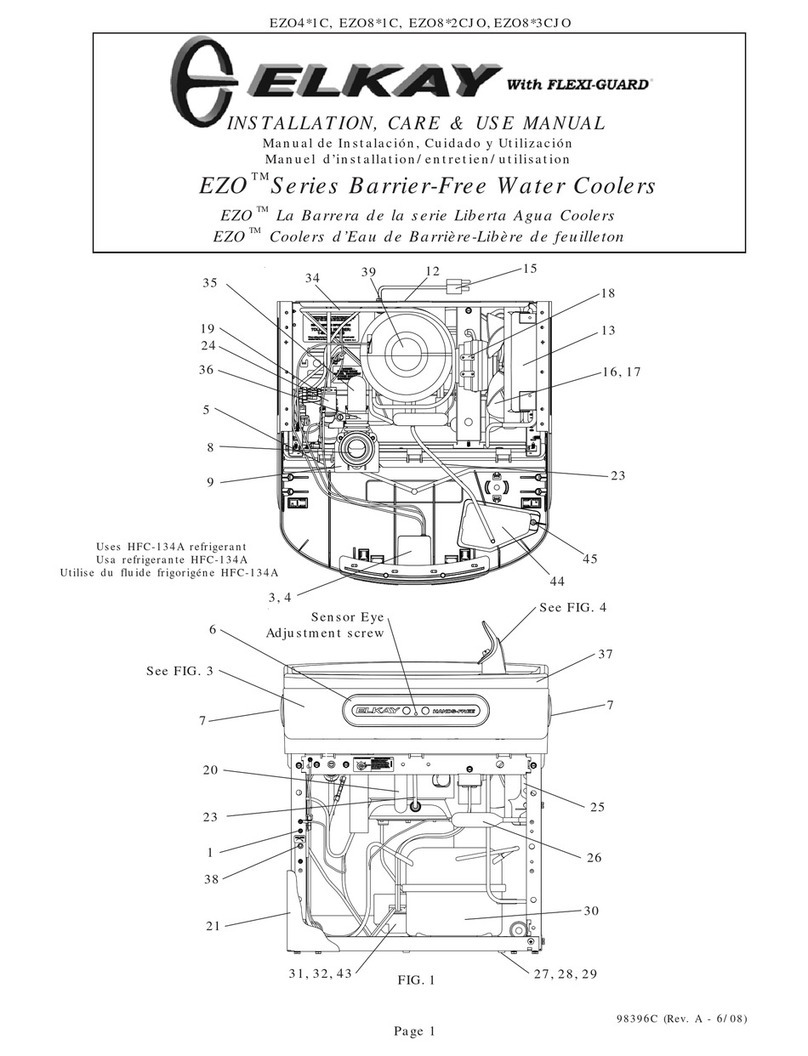

SENSOR RANGE ADJUSTMENT:

The electronic sensor used in this cooler is factory pre-set for a “visual” range of 36 inches (914 mm). If actual

range varies greatly from this or a different setting is desired, follow the range adjustment procedure below:

- Using a small tip screwdriver, locate range adjustment screw through the small hole between the sensor

lenses (See Page 1.) Turn this screw clockwise to increase range and counterclockwise to decrease range

(See Fig. 3).

CAUTION: Complete range of sensor (24-36 inches/610-1168mm) is only one turn of the adjusting

screw.

SENSOR WITH VISUAL FILTER MONITOR (VFM) – LZO SERIES:

The electronic sensor includes LED filter status indicators that are factory preset to monitor filter life. The sensor monitors the “ON” time of the water

valve solenoid and keeps track of total time water is dispensed. On LZOTL units, the sensor also monitors the water time on of the left hand unit

using a purple jumper wire. If the purple jumper wire is not installed, improper water usage will be calculated. There are (3) LED’s and indicates the

following: Green LED (Good) indicates that the filter is operating within 0% - 80% of its life.

Yellow LED indicates that the filter is operating within 80% - 100% of its life.

Red LED (Replace) indicates that the filter needs to be replaced since it has reached end of filter life.

Once power is applied to the water cooler, if all three LED’s flash then the Green LED aluminates, this indicates that there is some filter usage memory

stored. When the Green LED comes on only, this indicates that the filter life is at absolute 0% of filter life. NOTE: You may have some very minimal

filter life in memory upon receiving water cooler due to factory functional testing.

NOTE: The filter status will be retained until reset (see resetting filter monitor). The filter monitor will retain its memory even during a loss

of power.

RESETTING VISUAL FILTER MONITOR (VFM):

In order to reset the visual filter monitor status LED’s, you must remove the access panel (item 45) underneath the front dispenser. With your finger

or straight blade screw driver, reach inside opening and depress the reset button located on the back of the sensor for a minimum of 1 second. (You

may need a flashlight) Reinstall access panel and the Green LED should be illuminated indicating that the visual filter monitor has been reset.

SENSOR CONTROL: If sensor fails to operate valve mechanism or operates erratically, check the following.

A. Ensure there are no obstructions within a 40 inch (1016mm) radius in front of cooler.

B. Check wire connections at the solenoid valve and sensor. CAUTION: Make sure unit is unplugged

before checking any wiring.

C. Ensure proper operation of solenoid valve. If there is an audible clicking sound yet no water flows,

look for an obstruction in the valve itself or elsewhere in the water supply line.