Ellard Spider Operating and maintenance instructions

Installation Manual

Spider

Ellard Ltd 19-10-2018

Installation of the automatic door should be completed by an appointed distributer

or professional installation personnel.

Installation must be performed by professional installation personnel according

to local legislation and standards.

Refer to this manual for maintenance purposes.

This equipment has been conformed to the protection requirements of the

following directives:

2006/95/EEC( Low Voltage Directive) LVD

89-336 EEC (Electromagnetic Compatibility) EMC

2006/42/EC(Machine Directive)

EN16005:2012

Contents

Page

Safety Precautions………………………………………………………….1-2

Components of Mechanism………………………………………… ……. 3

Sectional View of Track and Cover……………………………………….4

Installation Process………………………………………………………… 5

Product features……………………………………………………………. 6

Components List…………………………………………………………… 7

Recommended Tools……………………………………………………….8

Adjustment of Hanger……………………………………………………… 8

Track Cutting and Installation……………………………………………...9

Component Positions –Left Opening…………………………………… 10

Component Positions –Right Opening………………………………….. 11

Component Positions –Bi –partition…………………………………..... 12

Installation of Motor, Controller and Idler Pulley………………………... 13

Adjustment of Idler Pulley…………………………………………………. 14

Installation of Stops………………………………………………………… 14

Lock and Release (Optional)……………………………………………...15-16

Installation of Sensor………………………………………………………. 17

Connection of Motor, Controller and Power Switch…………………….. 17

Terminal Details of Controller…….........................................................18

Learning Cycle Setting ……………………………………………………..18

Connection and Wiring……………………………………………………. 19-21

Spider Web (Function Selector)…………………………………………...22-23

Spider Web (Data Adjuster)………………………………………………..23-25

Spider Web (Password Setting)…………………………………………...25-26

Spider Web (Production Date)……………………………………………. 27

Spider Web (Working Times)…………………………………………….. 27

Spider Web (Battery Back Up Status)…………………………………… 28

Spider Web (Language Setting)………………………………………….. 28

Description of Operation………………………………………………...... 29

Troubleshooting……………………………………………………………. 30-31

Safety Precautions

The contents and categories a user must abide by are presented and described by the following

graphic expressions.

Warning

Warning

Misuse may cause injury even death to the operator.

Caution

Misuse may cause injury or physical loss to the operator.

Prohibited actions. Compulsory actions.

Installation and adjustment must be carried out according to the Installation Manual.

Failure to observe the correct installation and adjustment process could lead to

electric shocks or components becoming loose.

To reduce the risk of injury, no unauthorized personel must pass through the

automatic door to enter the work site and alternative access should br sought.

No modification the components must be carried out.

Never use apower supply beyond the stipulated voltage or frequency stated in this

manual.

Opening sensorsshould be set and adjusted so that the opening area of the door

will fall into the range of detection without any blind spots.

Failure to give propper adjustment could cause injury to personnel.

Detection range of photocell

Safety Precautions

1

15cm and more 15cm and more 15cm and more 15cm and more

1m and more

1m and more1m and more

1m and more

12cm and more 12cm and more 12cm and more 12cm and more

Door leaf

Door leaf

detection range of the sensor

detection range of the sensor

detection range of the sensor

detection range of the sensor

less than the size of a passer-by

Side screen safety sensors should be set and adjusted to give protection at the

outer most travel points of the door.

Failure to give propper adjustment could cause injury to personnel.

Safety Precausions

Safety Precautions

1

Caution

2

Never use the door in a place which is subject to dampness, vibration or corrosive gas,

as this may result in accidents such as fire, electric shocks or loose components.

To prevent finger traps allow a space of >25mm between the fully opened door edge

and upright column.

Never disconnect the power when the door is in operation, this may cause injury to

pedestrians.

Apply visual aids to door leaves, otherwise this may cause injury to pedestrians that

may of lost sight of the door leaf (s).

Never install an electric device with a capacity of >DC24V 300mA to the controller,

otherwise it will result in the controller being overloaded.

Other precautions

To prevent failure do not install a door leaf that exceeds the specified weight.

Battery Installation

- Ensure batteries are fully charged before instllation.

- The service life of the batteries is between 3-5 years at an ambient temperature of 0℃-40 ℃.

Excessive temperature variations will reduce the battery performance.

- If after installation and charging, the battery produces a fault,check the battery shelf life

If the shelf life has expired, replace it immediately.

-It is recconmended to perform a battery inspection every 6 month intervals.

To prevent malfunction the equpment should be installed in an environment with ambient

temperature not exceeding 0℃-40℃

Always use the manufacturers brand of electonic lock to ensure correct operation

2

3

Motor

Stopper

Hanger

Belt connector

Idler pulley

Belt

Hanger

Stopper

Controller

Components of mechanism

Name of components

Belt connector

Spider web

F1

F3F2

SET

Components of Mechanism

3

Sectional view of track and cover

Sectional view

Caution: This view is not in a scale of 1:1.

4

80

175

114.7

15-30 Adjustable

5mm (nominal ref) gap between

bottom of door and

floor guide

h

20mm (nominal ref)

'h' = door height

Sectional View of Track and Cover

4

5

Installation process

Preparation

Foundation work

Main frame installation

Power supply wiring

Automatic door installation

Front (frame) assembly and installation

Installation of components of mechanism

Hanging the door leaves

Connection of power supply

Inspection after installation

Adjustment of operation

Inspection after adjustment of operation

Description of operation to user

Installation Process

5

6

Specifications Spider

Door leaf mode

Door leaf weight

Door leaf width

Voltage

Opening speed

Closing speed

Opening time

Manual open force

Motor

Operating temperature

Single-opening Double-opening

Max 200kg Max 2*180kg

DW=700-2500mm DW=600-1800mm

AC≤16.5±5%V DC≤24.5V

20-60cm/s (Adjustable)

20-60cm/s (Adjustable)

0-60second (Adjustable)

<40N <50N

24V,100W brushless DC motor

-20℃~ +70℃

Product features

Intelligent micro control and precision machinery manufacturing

Smart self-learning system

Double track and rubber design, giving low noise & smooth open and closing

Powerful long life brushless DC motor

Easy access terminals to allow connection of full range of accesories

Monitored battery backup with optional opening programs, working times,

limit setting

3 wheel hanger design to prevent lifting

Monitored saftety sensor inputs

Door working cycle memory

Auxiliary Power

24V dc - 300mA Max Load

Product Features

Components List

7

Description Schematic diagram Quantity

Single-leaf Double-leaves

Motor

Idler pulley

Hanger

Belt connector

Stopper

Toothed Belt

Fastenings

Installation Manual

1 1

1 1

1 1

11

11

2 2

1 2

2 4

1 1

Controller

Spider web

F1

F3F2

SET

1 1

Components List

7

8

Recommended Tools

10mm

Y

Y

X

Y

4

5

13

B

B

A

+/-X

+/-Y

Adjustment of hanger

10/13mm

Recommended Tools

Adjustment of Hanger

8

9

80

175

114.7

80

175

114.7

5

5

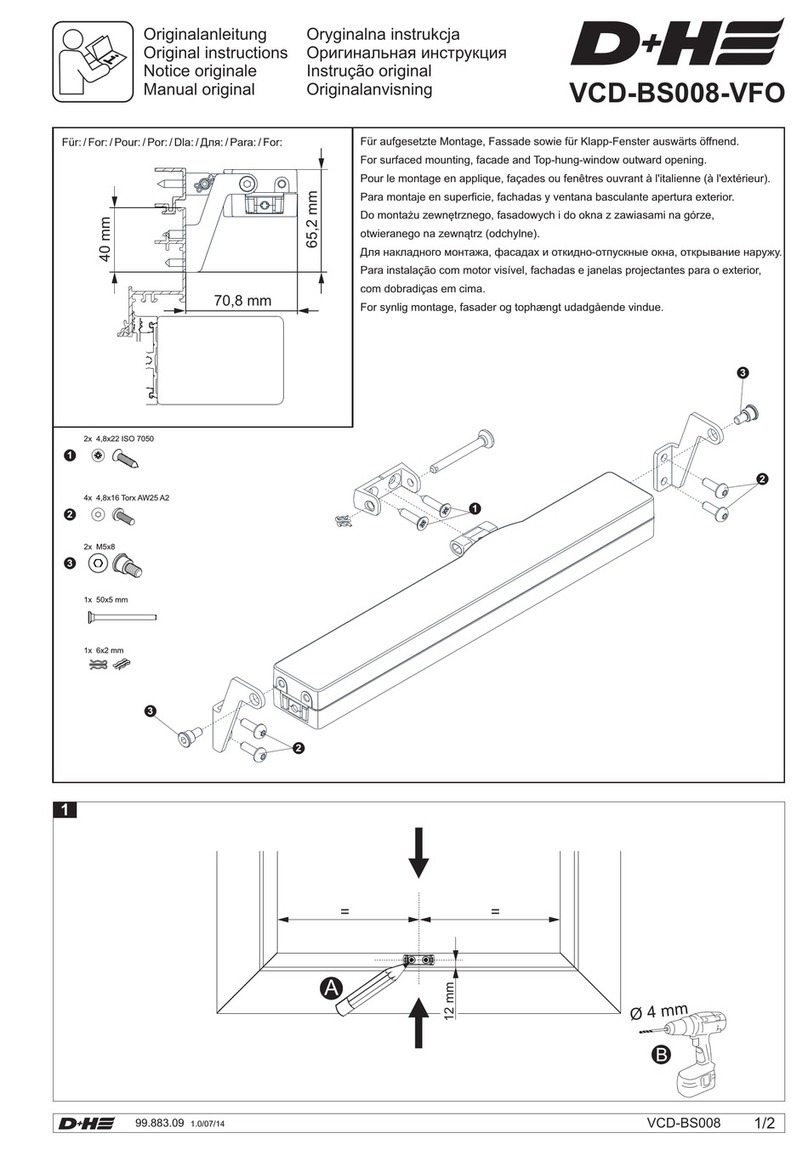

1.Frame door 2.Frameless door

Frame guider

Glass guider

Door height

(

DH

)

Door height

(

DH

)

20

20

Installation

Track's cutting and installation

Track Cutting and Installation

9

10

Components' position(left opening)

Header profile length L=

Opening travel

W=

Motor dimension M=

Belt length

f=

Trolley distance c=

1400 1600 1800 2000 2200 2400 2600

900 1000 1100 1200 1300 1400 1500

1045 1245 1445 1645 1845 2045 2245

2260 2660 3060 3460 3860 4260 4660

716 816 916 1016 1116 1216 1316

2800

1600

2445

5060

1416

3000

1700

2645

5460

1516 1616

3200

1800

2845

5860

Header profile length

Trolley distance

L=2W+200

f=2M+170

c=W-184

Belt length

L+10

L

208

165

70 418

M

c

W

30

150

Component Positions for Left Opening

10

11

Components' position(right opening)

Header profile length L=

Opening travel

W=

Motor dimension M=

Belt length

f=

Trolley distance c=

1400 1600 1800 2000 2200 2400 2600

900 1000 1100 1200 1300 1400 1500

1045 1245 1445 1645 1845 2045 2245

2260 2660 3060 3460 3860 4260 4660

716 816 916 1016 1116 1216 1316

2800

1600

2445

5060

1416

3000

1700

2645

5460

1516 1616

3200

1800

2845

5860

Header profile length

Trolley distance

L=2W+200

f=2M+170

c=W-184

Belt length

L+10

L

208

165

70 418

M

c

W

30

150

Component Positions for Right Opening

11

12

Components' position (bipartition)

L

L+10

208

165

70 418

M u

c

120

W

Header profile length

Motor dimension min

Deflection unit

Trolley distance

L=2W+20

M= W-210

u= W-190

c=W/2-184

Header profile length L=

Opening travel W=

Motor dimension min.580 M=

Deflection unit min.600 u=

Belt length f=

Trolley distance c=

1600 1800 2000 2200 2400 2600 3000 3200 3400 3800 4200 4600 5200 6200

790

580

600

2530

211

890

680

700

2930

261

800

990

780

3330

311

1090

880

900

3730

361

1190

980

1000

4130

411

1100

1290

1080

4530

461

1490

1280

1300

5330

561

1590

1380

1400

5730

611

1690

1480

1500

6130

661

1890

1680

1700

6930

761

2090

1880

1900

7730

861

2290

2080

2100

8530

961

2590

2380

2400

9730

1111

3090

2880

2900

11730

1361

Componen Positions for Bi-patition

12

1. Place the square-head boltsinto channel

2. Fix the motor as shown.

1. Place square-head bolts into channel.

2. Fix it as shown.

3. For specific installation position please refer

to page 3.

1. Place square-head boltsinto channel.

2. Fix it as shown.

Installation of idler pulley

Installation of controller

Installation of motor

13

Installation of Motor

Installation of Controller

Installation of Idler Pulley

Installation of stopper

Adjustment of idler pulley

1. Loosen the 4(x) fastening bolts,then wind the adjusting screw clockwise

or anti-clockwise

2. Place the belt on pulley and tighten the adjusting bolt to give the correct tension.

3. Tighten the 4(x) fastening bolt to secure .

M6

14

Adjusting bolt

Adjusting plate

Fastening bolt

10mm

Adjustment of Idler Pulley

Installation of Stops

15

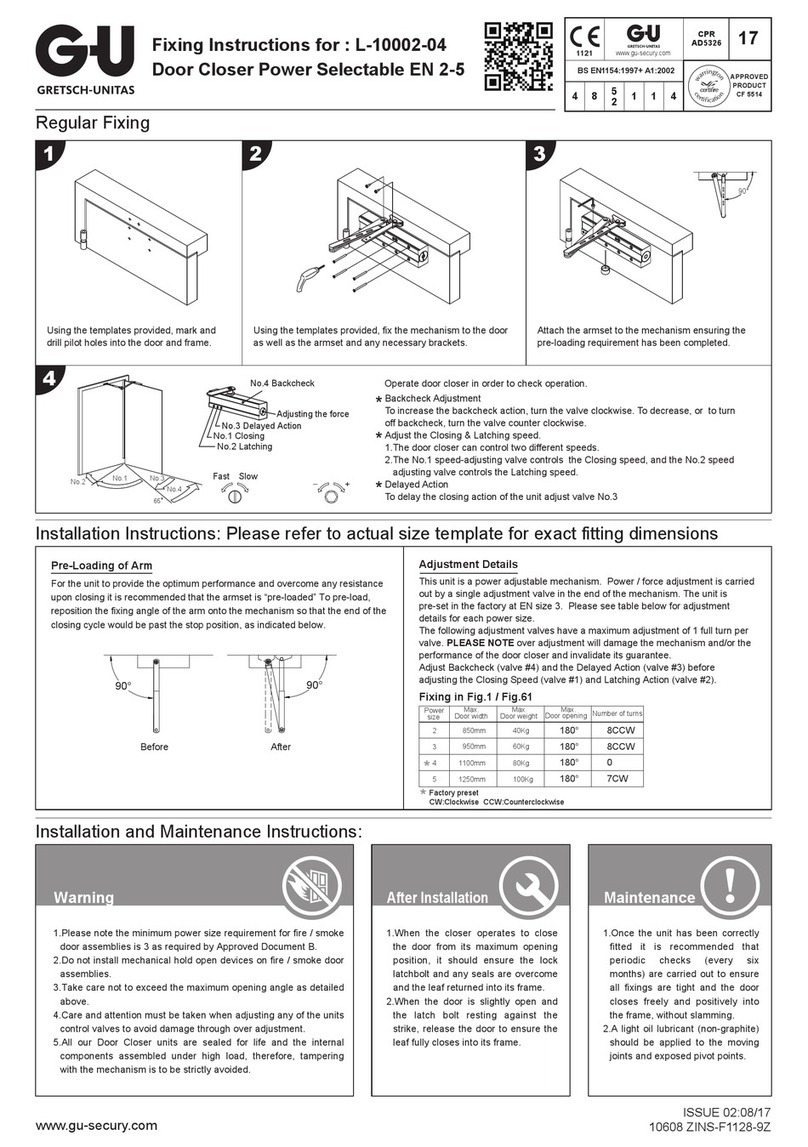

Lock and release (Optional)

Stop plate Interior manual release

5-10mm

Installaon of Electric lock

1.

Install the lock onto the rail according to picture

2.

Install the stop plate onto the hanger

to be locked)

3. Fully close

door, move the lock to the posion according to the picture.

The distance between lock plunger and stopplate should be 5-10mm

Close direcon

Lock

Lock

Stop plate Manual release

(interior)

Interior and Outdoor manual

release Electric lock

Outdoor manual

release(oponal)

Rope pipe

Wirerope 2pcs

Rope pipe

Refer to manual prior to applicaon,

1. Check component according to manual

2. Check the lock working condion and refer to circuit diagram before installing to door system

Operaonal principle: Power on -release Power off -lock

Working Voltage: 12V dc

Main components : 1. Lock, 2.Stop plate, 3. Interior manual release, 4.Outdoor manual release (oponal)

Interior Manual release Electric LOCK

Lock and Release (Optional)

15

16

Lock and release(Optional)

Installaon of interior manual release

M5

M5

Wirerope

Fit the Wirerope into the manual release according to picture Adjust the angle of the manual release according to picture,

Secure the Wirerope by ghtening the M5 screw

Red Black 1. Lock (-)

2. Lock (+)Control

Fit the Wirerope from this posion

Working Voltage:12V dc

Red:Positive (+)

Black:Negative (-)

Current:Start Current 0.9A,Working Current 0.3A

Main technical parameters

Lock and release(Optional)

Lock and Release (Optional)

16

17

Installation of sensor

Connection of motor,controller and power switch

H

LB

The sensor should be installed at the center of the door leaf.

The max installing height of sensor is 3m.

INPUT

AC100-250V

Installation of Sensor

17

Table of contents

Other Ellard Door Opening System manuals

Popular Door Opening System manuals by other brands

Dormakaba

Dormakaba TS 98 XEA Mounting instructions

MOX

MOX C40 Series Instruction and warnings for the installer

LARSON

LARSON SCREEN-AWAY quick start guide

Assa Abloy

Assa Abloy DC3210 Series installation instructions

Dormakaba

Dormakaba ED100 operating & maintenance manual

Optex

Optex ELITE PRO instruction manual