Assa Abloy SARGENT FIREGUARD 2499 User manual

Other Assa Abloy Door Opening System manuals

Assa Abloy

Assa Abloy Besam SW200i US Manual

Assa Abloy

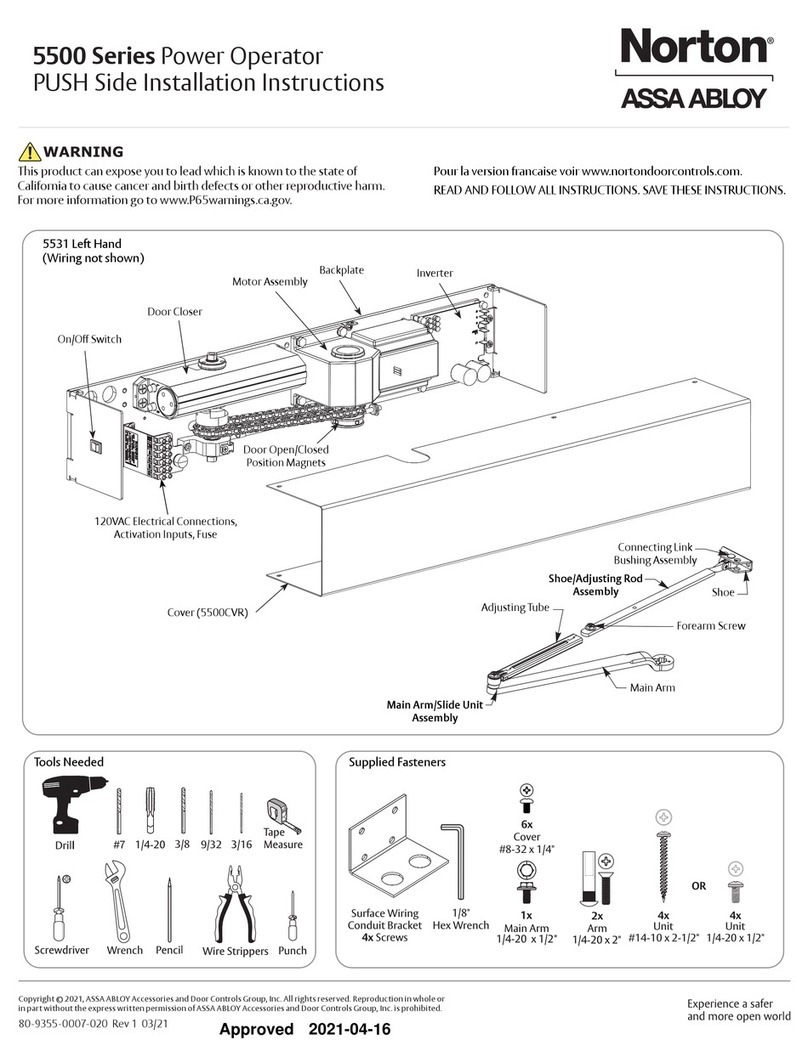

Assa Abloy Norton 5500 Series User manual

Assa Abloy

Assa Abloy SARGENT 351 User manual

Assa Abloy

Assa Abloy Adams Rite 3700 User manual

Assa Abloy

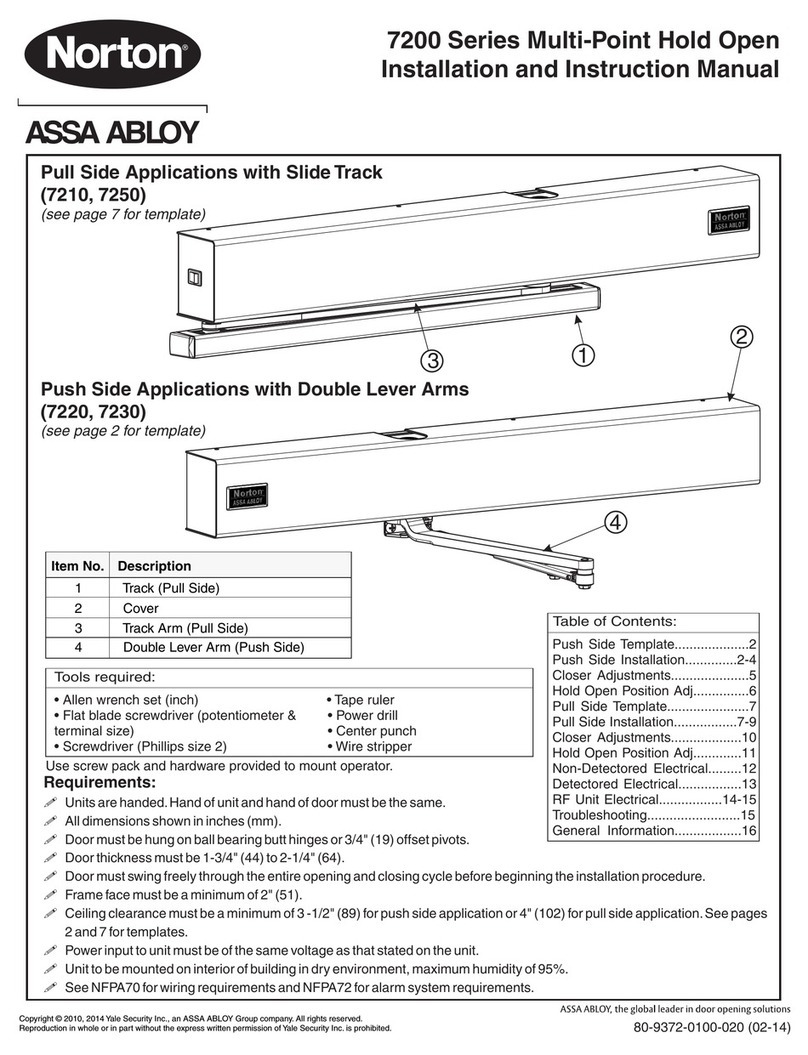

Assa Abloy Norton 7200 Series Quick guide

Assa Abloy

Assa Abloy Sargent FIREGUARD 2408 Series User manual

Assa Abloy

Assa Abloy RIXSON 91DCP User manual

Assa Abloy

Assa Abloy h.e.s. 9100 Series Manual

Assa Abloy

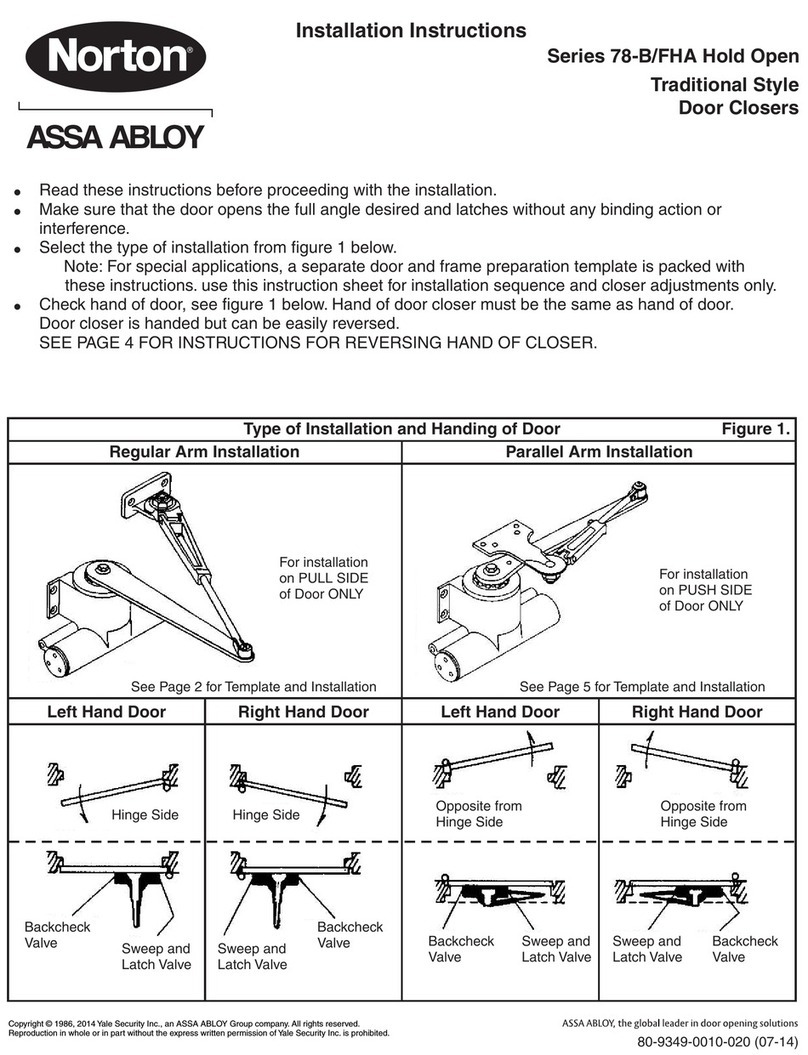

Assa Abloy Norton 78-B/FHA Hold Open Series User manual

Assa Abloy

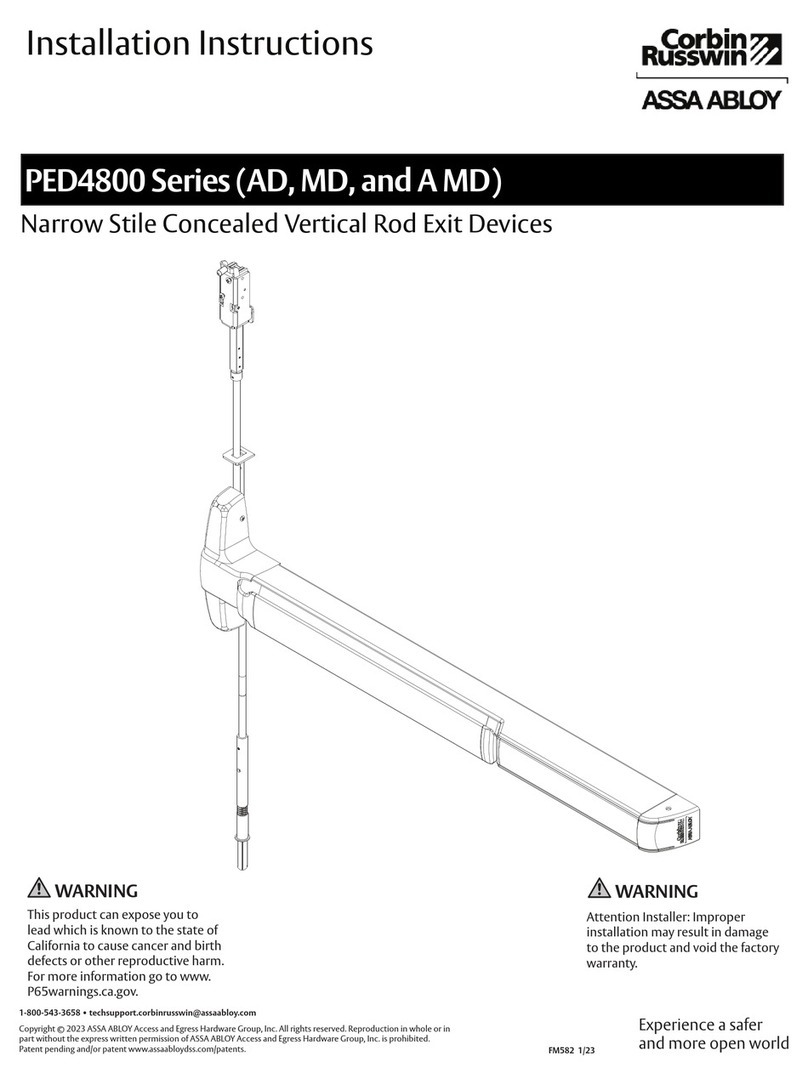

Assa Abloy Corbin Russwin ED4000 Series User manual

Assa Abloy

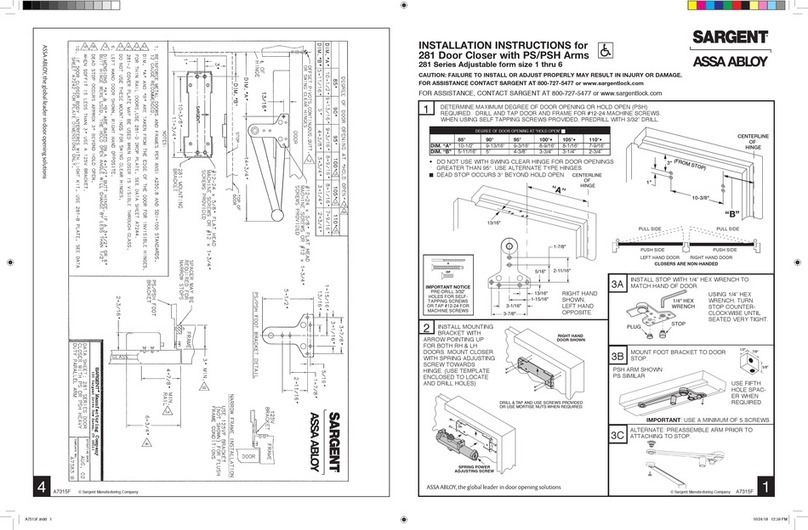

Assa Abloy Sargent 281 Series User manual

Assa Abloy

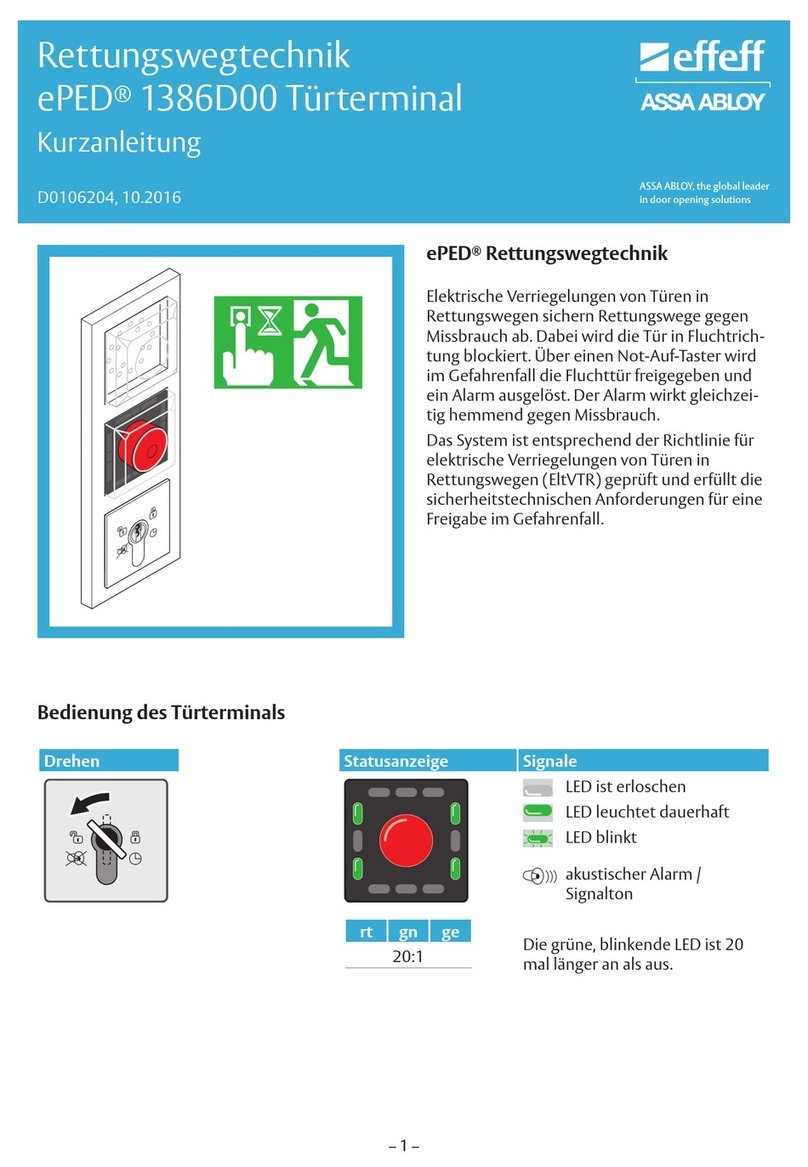

Assa Abloy effeff ePED 1386Z1LB7 04S0 Series Reference guide

Assa Abloy

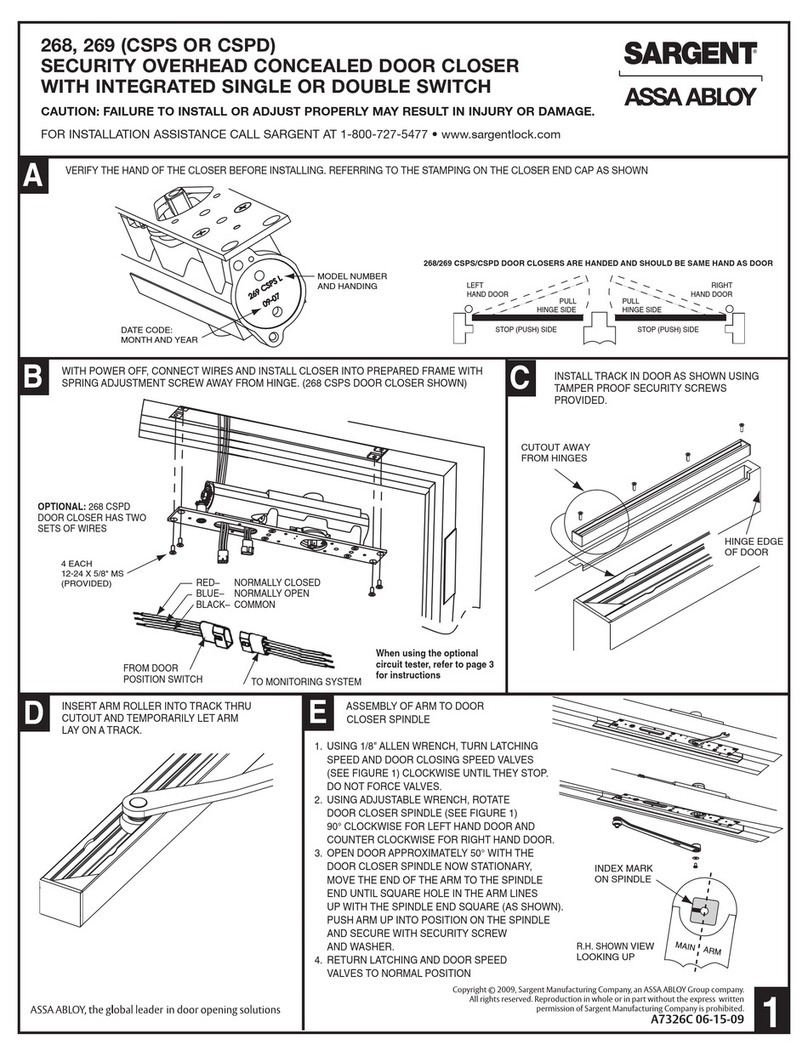

Assa Abloy SARGENT 268 Series User manual

Assa Abloy

Assa Abloy Norton 8000 Series User manual

Assa Abloy

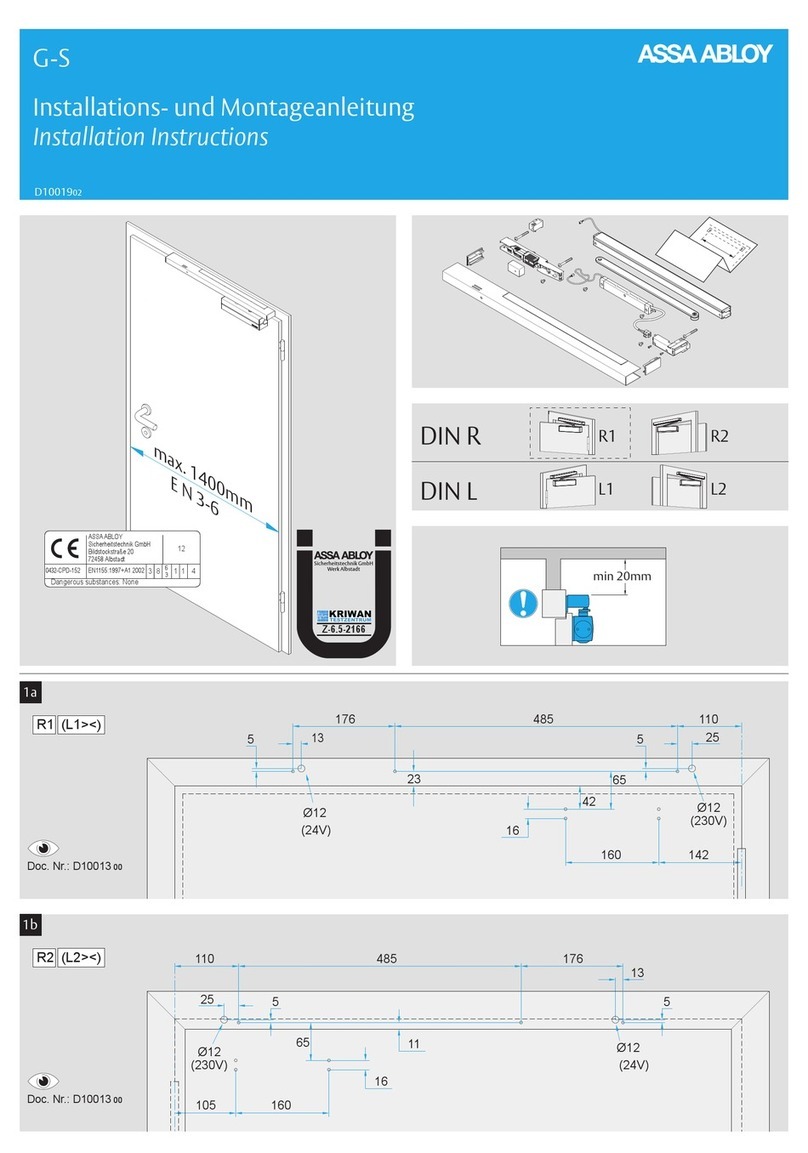

Assa Abloy G-S User manual

Assa Abloy

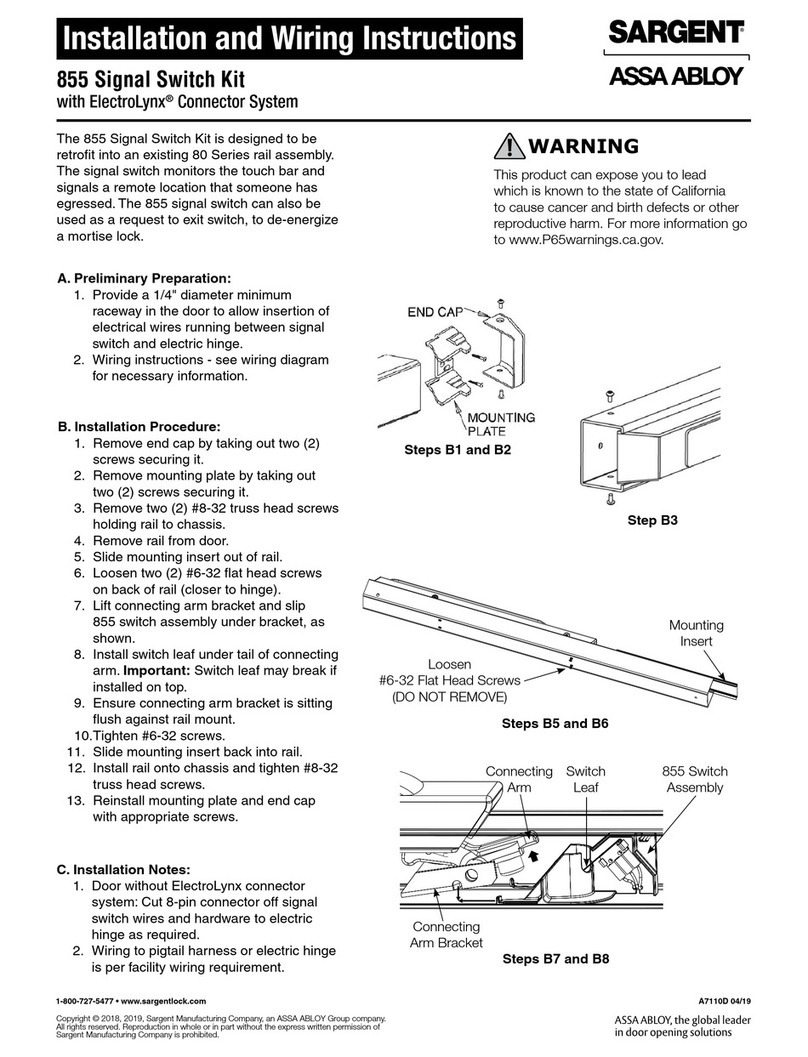

Assa Abloy Sargent 855 Assembly instructions

Assa Abloy

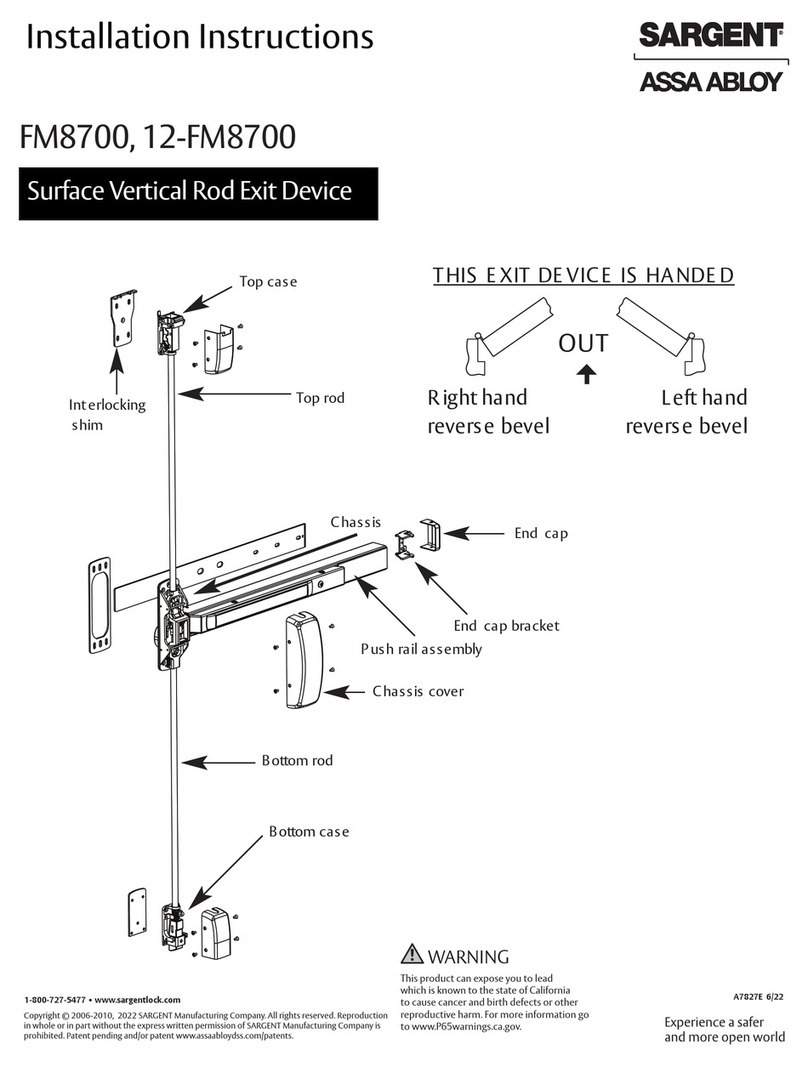

Assa Abloy SARGENT FM8700 User manual

Assa Abloy

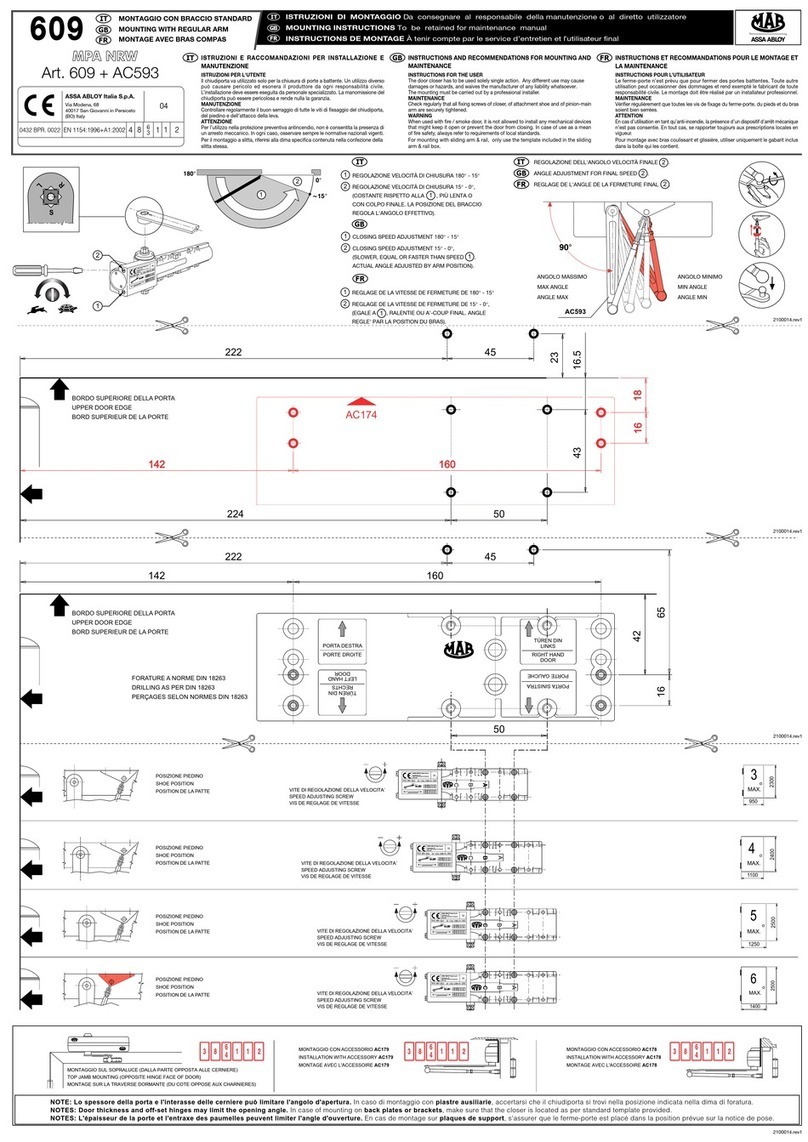

Assa Abloy MAB 609 + AC593 Instruction Manual

Assa Abloy

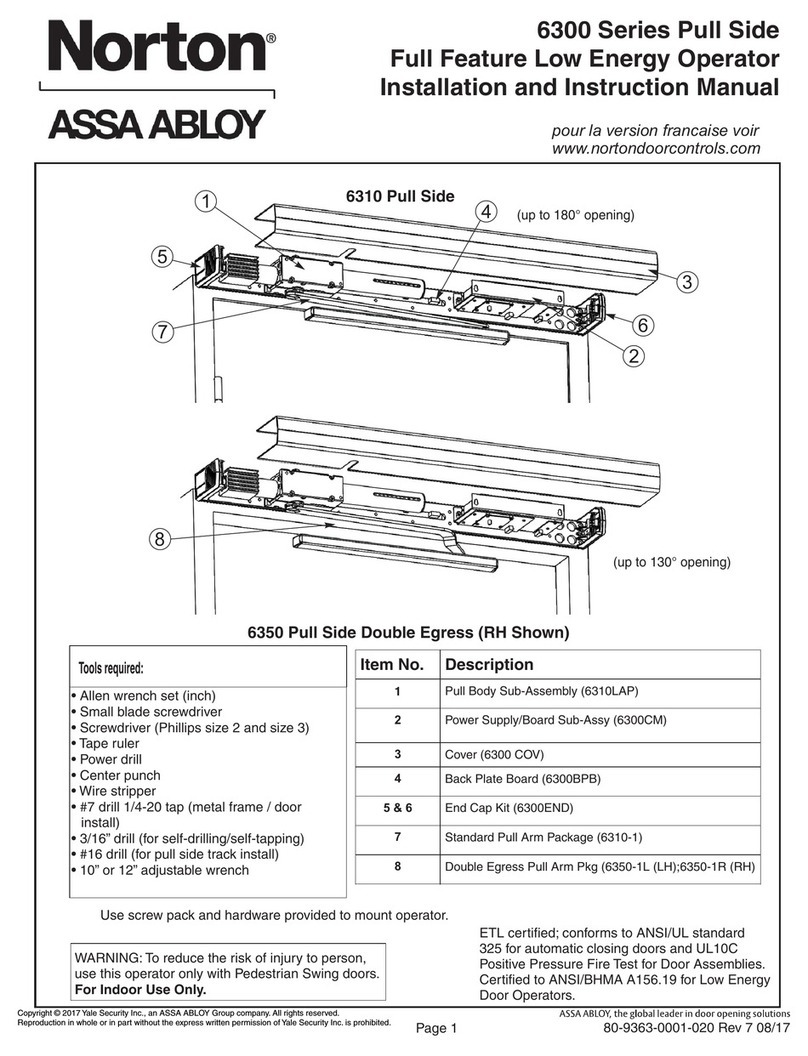

Assa Abloy Norton 6300 Series Quick guide

Assa Abloy

Assa Abloy SARGENT 351 Series User manual

Popular Door Opening System manuals by other brands

Stanley

Stanley MA900ñ Installation and owner's manual

WITTUR

WITTUR Hydra Plus UD300 Instruction handbook

Alutech

Alutech TR-3019-230E-ICU Assembly and operation manual

MPC

MPC ATD ACTUATOR 50 ATD-313186 Operating and OPERATING AND INSTALLATION Manual

GEZE

GEZE ECturn user manual

Chamberlain

Chamberlain T user guide