8

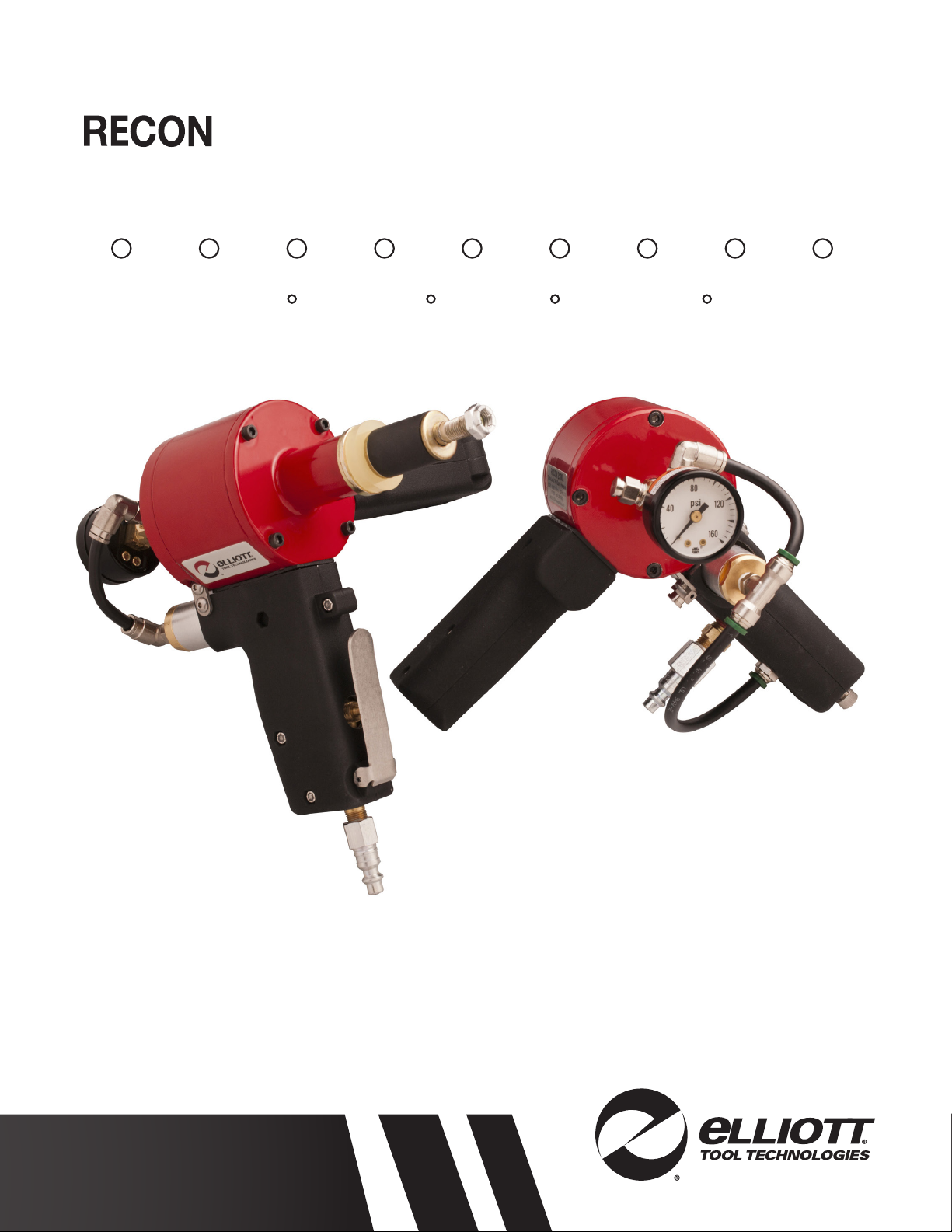

RECON 2500 Tube Leak Test Gun

OPERATION INSTRUCTIONS

The RECON 2500 Test Guns come as a set. This set is comprised of: an air injection gun and a

plugging gun. The air injection gun can be differentiated from the plugging gun because it incorporates

the valve block and air regulator.

1. Attach air supply to both guns. The RECON 2500 test guns will be operational on plant air

supplies ranging from 40 to 125 psi (2.7 to 8.6 Bar) at a minimum of 5 cfm. The maximum

test pressure of the tube is dependent on the tube ID and the air supply pressure (see

Table 1).

2. On the air injection gun, turn the adjusting nut on the air regulator counterclockwise to set

the tube testing pressure to zero.

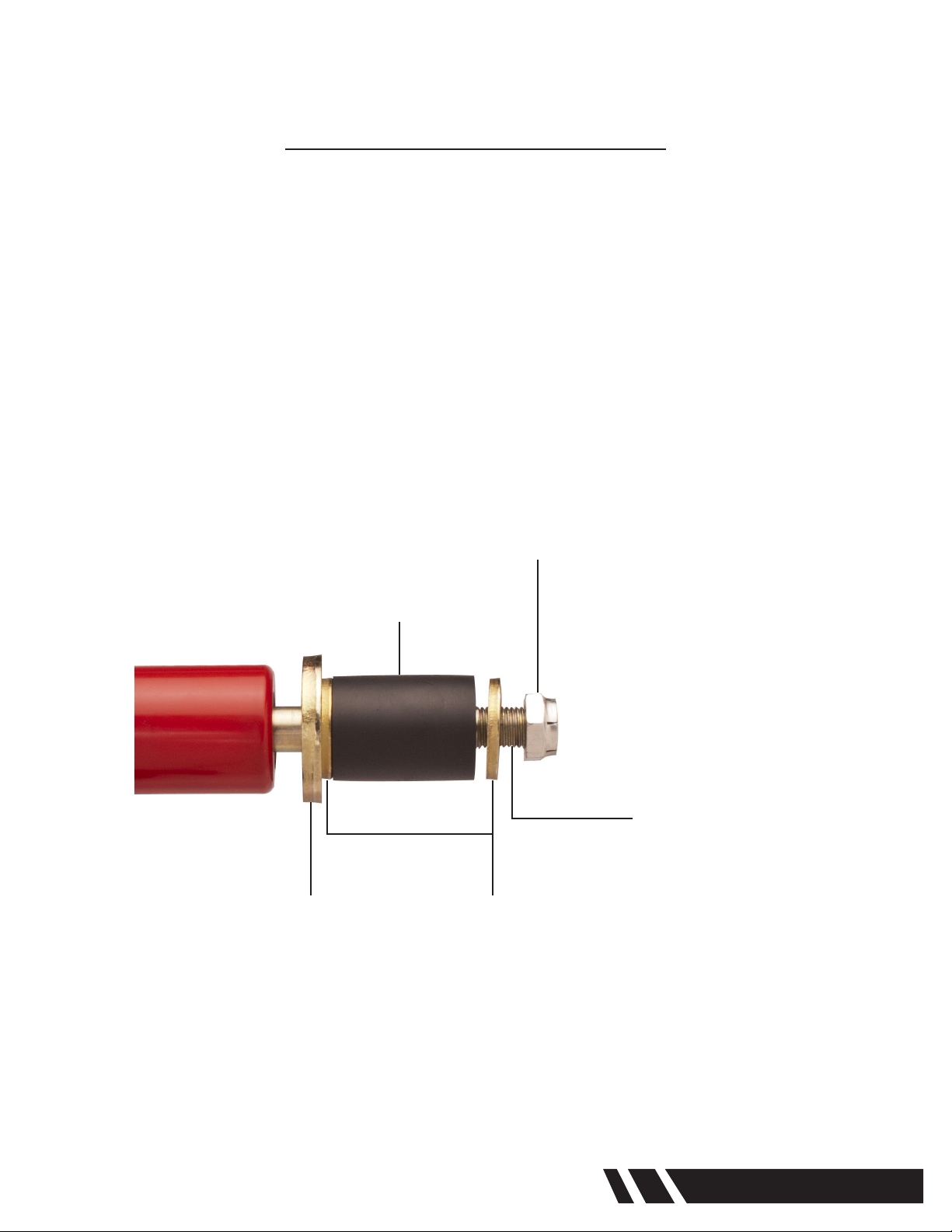

3. Insert the air injection gun into one end of the tube to be tested and the plugging gun into

the other end. The seal should be fully into the tube and the backup washer should be

against the tube end.

4. Press the the top button for actuating the cylinder of the air injection gun, and press the

air control valve on the plugging gun and hold until the guns are rmly held in the tubes.

Release both buttons.

5. Press the the bottom button for pressurizing the tube on the air injection gun and adjust

the air regulator clockwise until the desired tube test pressure is achieved (use Table 1 for

maximum tube test pressures available).

NOTE: The air pressure regulator must be readjusted if testing different size tubes or if air

supply pressure changes.

6. Both injection gun and plugging gun operators should observe the pressure gage on their

respective guns. Any decrease in the pressure will indicate a leaking tube.

7. Press the bleed valve on the injection gun between the gage and the cylinder body to

bleed off the air pressure in the tube. After the tube test pressure has bled to zero, press

the bleed valve on both guns to release the pressure in the cylinder and relax the seals.

8. Remove the test guns and move on to the next tube. Mark each leaking tube encountered

for repair. The total operation should be completed in 5 to 10 seconds. Your actual testing

time will depend on the amount of time you choose to hold the pressure test.

9. Repeat steps 3 through 8 for each tube to be tested.

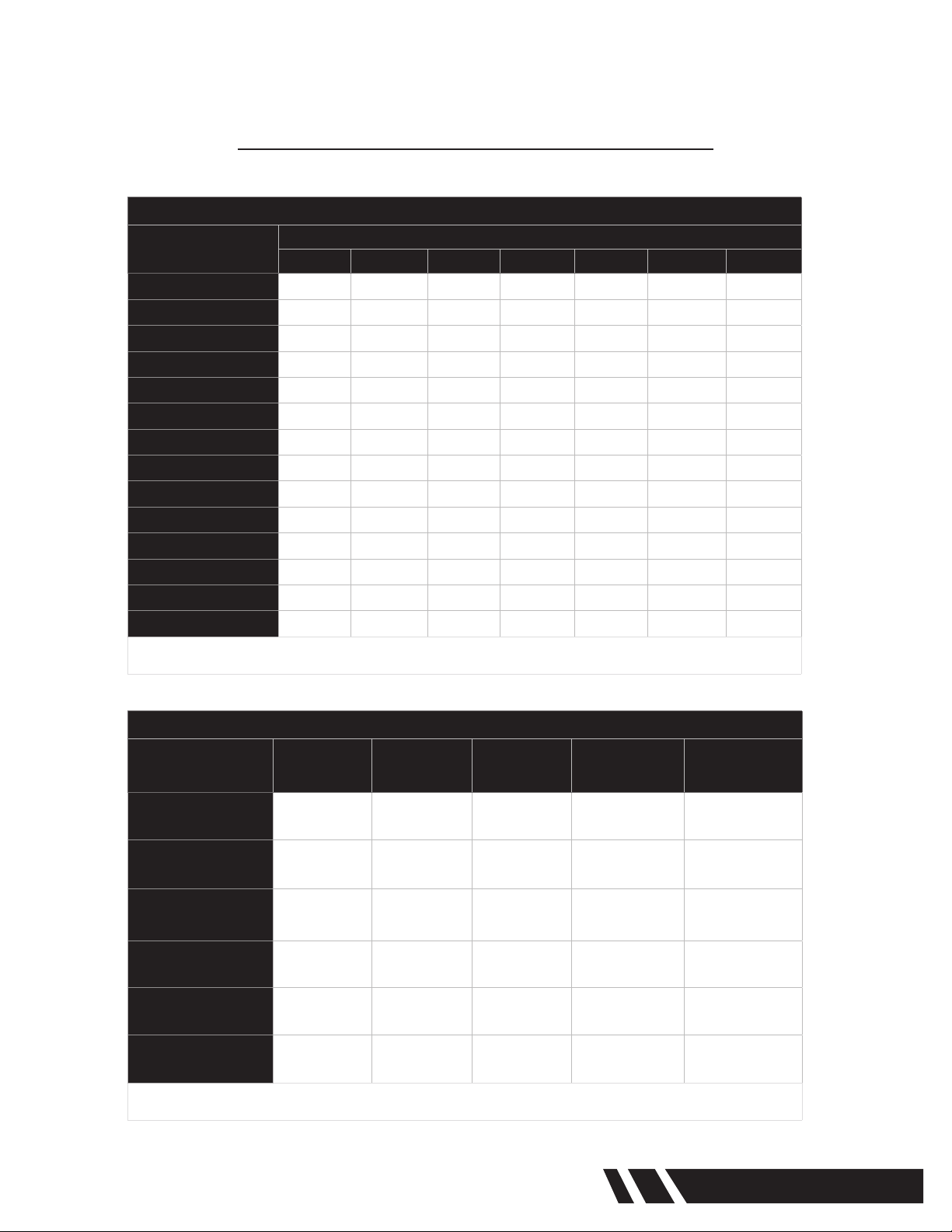

TABLE 1 – Maximum Tube Test Pressure Versus Air Supply Pressure And Tube ID

Nominal

Tube Size

Air Supply Pressure - PSI

40 60 80 100 125

Maximum Test Pressure - PSI

1-1/4” 40 60 80 100 125

1-1/2” 30 40 50 60 75

1-3/4” 20 30 40 50 60

2 15 20 25 30 35

2-1/4” 10 15 20 25 30

2-1/2” 5 10 15 20 25