ELM AM852 User manual

AM852 Veterinary Anaesthesia machine User’ Manual

2

Contents

1.Introduction......................................................................................................4

1.1About AM852......................................................................................................... 4

1.2Symbols used in the manual and device.................................................................. 4

2.Control section of anaesthetic system.............................................................7

2.1Anaesthetic control system...................................................................................... 7

2.2Assembly of respiration system...............................................................................9

2.3Exhaust emission................................................................................................... 10

2.4Control Evaporator.................................................................................................11

2.5Instructions for filling the AVDD.......................................................................... 12

3. Assembly of whole set..................................................................................15

3.1Respiratory system installation..............................................................................15

4. Pre-use Test..................................................................................................16

4.1Test interval............................................................................................................16

4.2Check the system................................................................................................... 17

4.3Test gas supply pipe............................................................................................... 17

4.4Test flowrate control.............................................................................................. 18

4.5Evaporator Installation...........................................................................................19

4.6Test Respiration system......................................................................................... 20

5. Installation and Replacing............................................................................22

5.1Install absorber.......................................................................................................22

5.2 Replace absorbent................................................................................................. 22

6. Cleaning and Sterilization............................................................................ 23

6.1Cleaning and sterilization of Anaesthesia workstation surface............................. 23

6.2Cleaning and sterilization of reusable rubber corrugated tube and manual

breathing bag...............................................................................................................23

6.3Cleaning and sterilization of inspiration and expiratory unidirectional valve.......24

6.4Cleaning and sterilization of absorber................................................................... 24

7. User’s maintenance.......................................................................................25

7.1Maintenance schedule............................................................................................25

7.2Maintenance of anaesthetic evaporator..................................................................25

7.3Maintenance of flowmeter..................................................................................... 26

7.4Maintenance of inspiration and expiratory unidirectional valve........................... 26

8.Trouble shooting............................................................................................27

9. Operation Principle.......................................................................................28

دﯾﯾﺎﻣرﻓ ﮫﻌﺟارﻣ.WWW.ELM-FAN.IRتﯾﺎﺳ ﮫﺑ رﺗﺷﯾﺑ دراوﻣ دوﻠﻧاد یارﺑ

To download more items, go to ELM-FAN.IR

AM852 Veterinary Anaesthesia machine User’ Manual

3

9.1Diagram of system drive air circuit....................................................................... 28

10. Technical Specification.............................................................................. 30

11. Detailed list of host machine, accessories, and consumer goods.............. 34

12. Guarantee....................................................................................................35

دﯾﯾﺎﻣرﻓ ﮫﻌﺟارﻣ.WWW.ELM-FAN.IRتﯾﺎﺳ ﮫﺑ رﺗﺷﯾﺑ دراوﻣ دوﻠﻧاد یارﺑ

To download more items, go to ELM-FAN.IR

AM852 Veterinary Anaesthesia machine User’ Manual

4

1.Introduction

1.1About AM852

AM852 is an anaesthetic transportation system, and it may carry out the

following functions:

Provide manual ventilation for the animal in an operation.

Supply the animal with oxygen in an operation.

Supply the animal with anaesthetic gases of accurate and steady

concentration in an operation.

Absorb carbon dioxide exhaled by the animal in an operation.

1.2Symbols used in the manual and device

Warning and Note show the possible risks if you disobey the declarations in this

manual. Please read and abide by all the warnings and cautions seriously.

Warning: Indicate the possible injury to operators or animal.

Note: Indicate the possible damage to the device.

Importance: similar to a commentary, but with emphasis meaning.

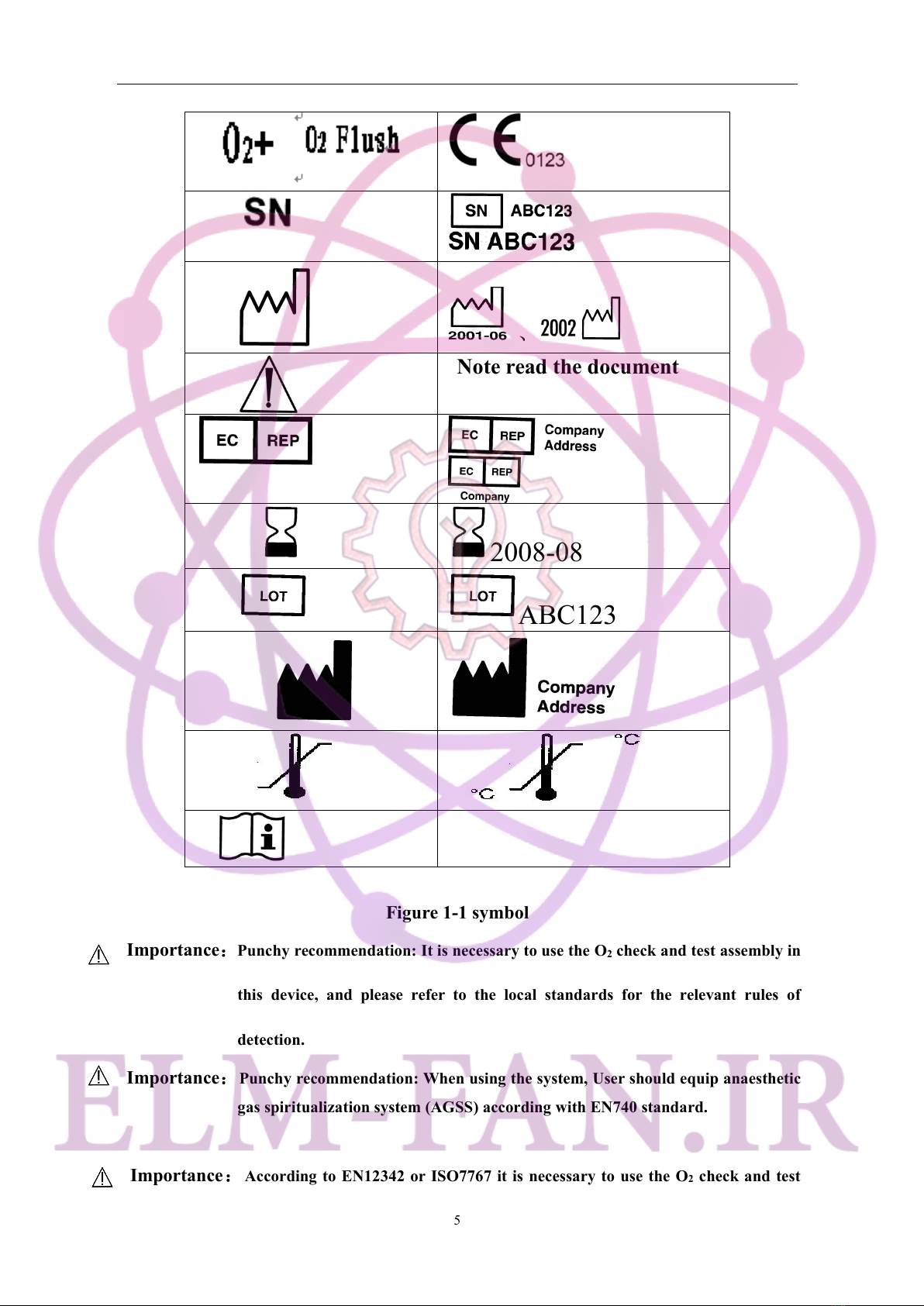

There are other symbols also used in the device or AM852 user’s manual to replace

text statement, including:

دﯾﯾﺎﻣرﻓ ﮫﻌﺟارﻣ.WWW.ELM-FAN.IRتﯾﺎﺳ ﮫﺑ رﺗﺷﯾﺑ دراوﻣ دوﻠﻧاد یارﺑ

To download more items, go to ELM-FAN.IR

AM852 Veterinary Anaesthesia machine User’ Manual

5

、

Note read the document

2008-08

ABC123

Figure 1-1 symbol

Importance:Punchy recommendation: It is necessary to use the O2check and test assembly in

this device, and please refer to the local standards for the relevant rules of

detection.

Importance:Punchy recommendation: When using the system, User should equip anaesthetic

gas spiritualization system (AGSS) according with EN740 standard.

Importance:According to EN12342 or ISO7767 it is necessary to use the O2check and test

دﯾﯾﺎﻣرﻓ ﮫﻌﺟارﻣ.WWW.ELM-FAN.IRتﯾﺎﺳ ﮫﺑ رﺗﺷﯾﺑ دراوﻣ دوﻠﻧاد یارﺑ

To download more items, go to ELM-FAN.IR

AM852 Veterinary Anaesthesia machine User’ Manual

6

and the CO2check and test (according to EN864 or ISO9918) in this device.

User should equip CO2check and test according with EN740 standard.

Importance :According to the stipulation of European standards EN740 and international

standards IEC 60601-2-13/ISO8835-1, it is essential to check and test the

anesthetic (according to ISO11196) when using Anaesthesia evaporator. User

should equip Anaesthesia evaporator monitor according with EN740 standard.

Warning: Please read this manual in detail and master the content before operating the

product.

Warning:Ensure the avirulence of air feed tube, bag and breathing loop assembly, and the

followings must not emerge:

·Cause allergic reactions in the animal’s body.

·React with Anaesthesia gas or anesthetic to produce dangerous byproducts.

Warning:The danger of explosion. Ensure not to use flammable anesthetic in AM852 system.

Warning:Do not use anlistatig breathing tube or face mask. It is possible to cause burning

when using this species of breathing tube or face mask near surgery equipments of

high frequency.

Warning:In order to protect the animal, the following must be ensured.

·Ensure the operations of all life supports and monitor assembly are proper.

·Ensure manual ventilation equipment convenient .

Warning :If the anaesthetic system is to be equipped with an anaesthetic ventilator, the

anaesthetic ventilator shall comply with the requirements of ISO 8835-5.

Warning: a malfunction of central gas supply system may cause more than one or even all

devices connected to it to stop their operation simultaneously.

دﯾﯾﺎﻣرﻓ ﮫﻌﺟارﻣ.WWW.ELM-FAN.IRتﯾﺎﺳ ﮫﺑ رﺗﺷﯾﺑ دراوﻣ دوﻠﻧاد یارﺑ

To download more items, go to ELM-FAN.IR

AM852 Veterinary Anaesthesia machine User’ Manual

7

2.Control section of anaesthetic system

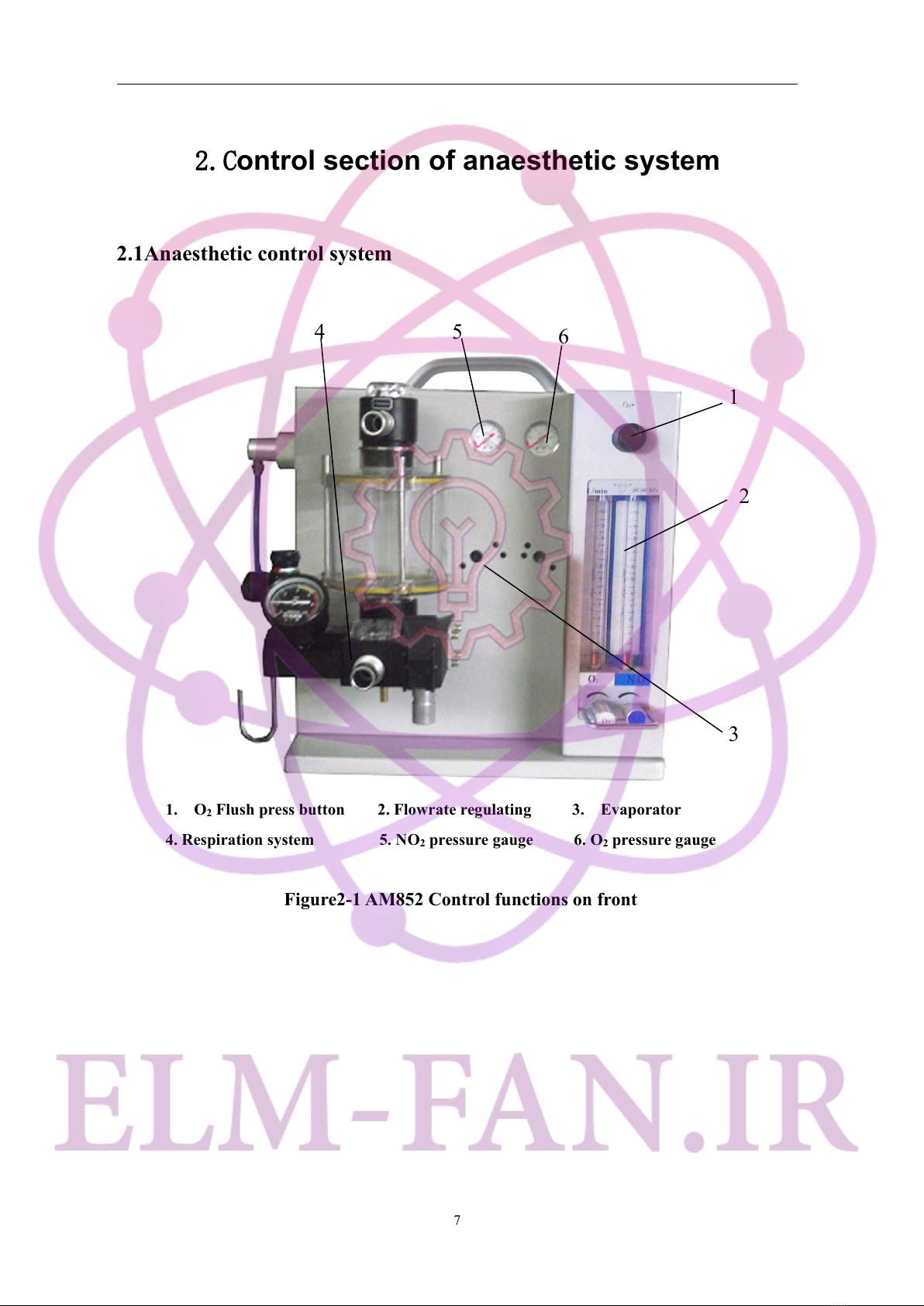

2.1Anaesthetic control system

1. O2Flush press button 2. Flowrate regulating 3. Evaporator

4. Respiration system 5. NO2pressure gauge 6. O2pressure gauge

Figure2-1 AM852 Control functions on front

3

2

1

6

5

4

دﯾﯾﺎﻣرﻓ ﮫﻌﺟارﻣ.WWW.ELM-FAN.IRتﯾﺎﺳ ﮫﺑ رﺗﺷﯾﺑ دراوﻣ دوﻠﻧاد یارﺑ

To download more items, go to ELM-FAN.IR

AM852 Veterinary Anaesthesia machine User’ Manual

8

Items Remark

1 O2flush button Press O2flush button to provide high flowrate O2to respiration

system

2 Flowrate regulating Revolving control button anti-clockwise will augment flowrate

and revolving control button clockwise will decrease flowrate.

1. Pipeline gas linker(O2) 2. Pipeline gas linker(NO2)

Figure 2-2 AM852 Functions on back

1

2

دﯾﯾﺎﻣرﻓ ﮫﻌﺟارﻣ.WWW.ELM-FAN.IRتﯾﺎﺳ ﮫﺑ رﺗﺷﯾﺑ دراوﻣ دوﻠﻧاد یارﺑ

To download more items, go to ELM-FAN.IR

AM852 Veterinary Anaesthesia machine User’ Manual

9

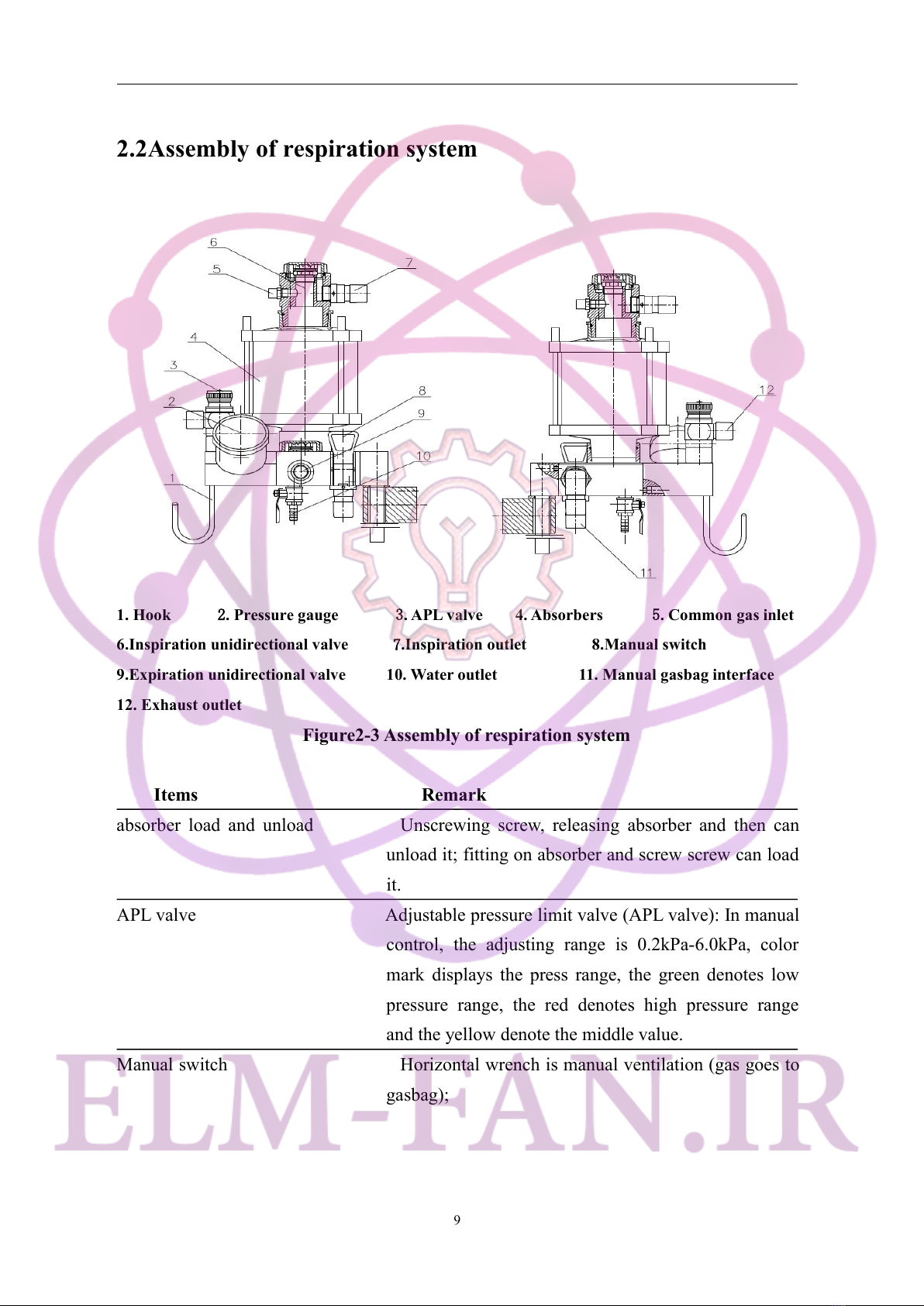

2.2Assembly of respiration system

1. Hook 2. Pressure gauge 3. APL valve 4. Absorbers 5. Common gas inlet

6.Inspiration unidirectional valve 7.Inspiration outlet 8.Manual switch

9.Expiration unidirectional valve 10. Water outlet 11. Manual gasbag interface

12. Exhaust outlet

Figure2-3 Assembly of respiration system

Items Remark

absorber load and unload Unscrewing screw, releasing absorber and then can

unload it; fitting on absorber and screw screw can load

it.

APL valve Adjustable pressure limit valve (APL valve): In manual

control, the adjusting range is 0.2kPa-6.0kPa, color

mark displays the press range, the green denotes low

pressure range, the red denotes high pressure range

and the yellow denote the middle value.

Manual switch Horizontal wrench is manual ventilation (gas goes to

gasbag);

دﯾﯾﺎﻣرﻓ ﮫﻌﺟارﻣ.WWW.ELM-FAN.IRتﯾﺎﺳ ﮫﺑ رﺗﺷﯾﺑ دراوﻣ دوﻠﻧاد یارﺑ

To download more items, go to ELM-FAN.IR

AM852 Veterinary Anaesthesia machine User’ Manual

10

2.3Exhaust emission

When using the system, exhaust emission should be carried out. User should equip AGSS

according with EN740 standard. Connect exhaust outlet of respiration system with AGSS

by exhaust emission tubes according with EN740 standard. See Fig. 2-4

1.Respiration system 2. Connecting tube 3. AGSS system

Fig 2-4 Connecting AGSS system

Warning: Never connect exhaust gas port with sub-atmospheric system directly. Orelse

leakage of breathing system generates.

دﯾﯾﺎﻣرﻓ ﮫﻌﺟارﻣ.WWW.ELM-FAN.IRتﯾﺎﺳ ﮫﺑ رﺗﺷﯾﺑ دراوﻣ دوﻠﻧاد یارﺑ

To download more items, go to ELM-FAN.IR

AM852 Veterinary Anaesthesia machine User’ Manual

11

2.4Control Evaporator

Please refer to the evaporator operation manual to find the more details .

1 .drug-adding knob 2.lock knob 3. concentration panel

4. viewing window 5.drug-releasing port

Figure 2-5 Control Evaporator

Items Remarks

1Drug-adding knob Anticlockwise rotate screw cap to unload it, and the drug

can be put in, clockwise rotate screw cap to airproof.

2Lock knob Press this button, and rotate concentration control switch

to set anaesthetic concentration.

5Drug-releasing port You could see the Drug-releasing knob inside the evaporator

when you rotate the drug-adding knob to unload it. Unload

the drug-releasing knob, and release the drug.

دﯾﯾﺎﻣرﻓ ﮫﻌﺟارﻣ.WWW.ELM-FAN.IRتﯾﺎﺳ ﮫﺑ رﺗﺷﯾﺑ دراوﻣ دوﻠﻧاد یارﺑ

To download more items, go to ELM-FAN.IR

AM852 Veterinary Anaesthesia machine User’ Manual

12

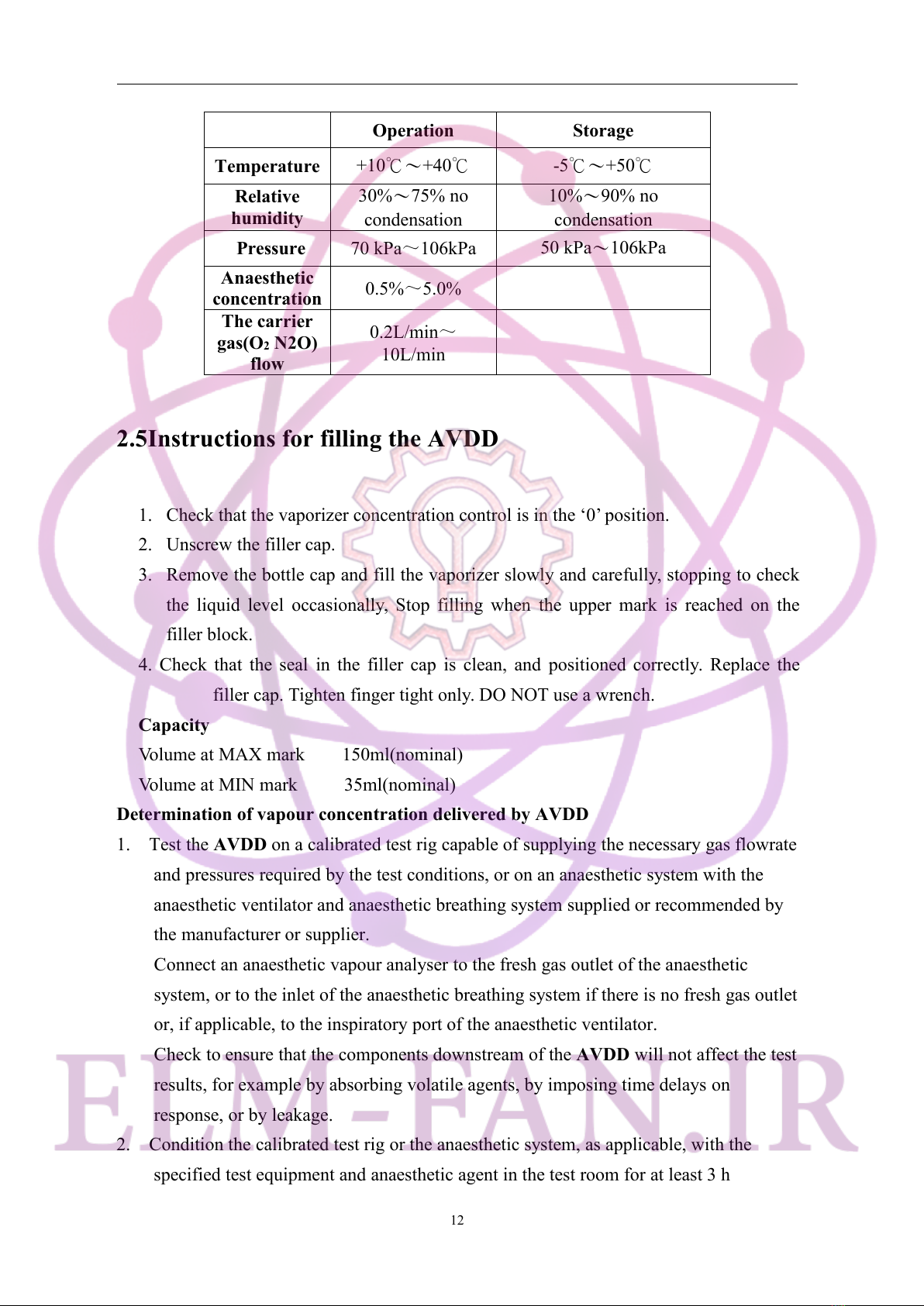

Operation

Storage

Temperature

+10℃~+40℃

-5℃~+50℃

Relative

humidity

30%~75% no

condensation

10%~90% no

condensation

Pressure

70 kPa~106kPa

50 kPa~106kPa

Anaesthetic

concentration

0.5%~5.0%

The carrier

gas(O2N2O)

flow

0.2L/min~

10L/min

2.5Instructions for filling the AVDD

1. Check that the vaporizer concentration control is in the ‘0’ position.

2. Unscrew the filler cap.

3. Remove the bottle cap and fill the vaporizer slowly and carefully, stopping to check

the liquid level occasionally, Stop filling when the upper mark is reached on the

filler block.

4. Check that the seal in the filler cap is clean, and positioned correctly. Replace the

filler cap. Tighten finger tight only. DO NOT use a wrench.

Capacity

Volume at MAX mark 150ml(nominal)

Volume at MIN mark 35ml(nominal)

Determination of vapour concentration delivered by AVDD

1. Test the AVDD on a calibrated test rig capable of supplying the necessary gas flowrate

and pressures required by the test conditions, or on an anaesthetic system with the

anaesthetic ventilator and anaesthetic breathing system supplied or recommended by

the manufacturer or supplier.

Connect an anaesthetic vapour analyser to the fresh gas outlet of the anaesthetic

system, or to the inlet of the anaesthetic breathing system if there is no fresh gas outlet

or, if applicable, to the inspiratory port of the anaesthetic ventilator.

Check to ensure that the components downstream of the AVDD will not affect the test

results, for example by absorbing volatile agents, by imposing time delays on

response, or by leakage.

2. Condition the calibrated test rig or the anaesthetic system, as applicable, with the

specified test equipment and anaesthetic agent in the test room for at least 3 h

دﯾﯾﺎﻣرﻓ ﮫﻌﺟارﻣ.WWW.ELM-FAN.IRتﯾﺎﺳ ﮫﺑ رﺗﺷﯾﺑ دراوﻣ دوﻠﻧاد یارﺑ

To download more items, go to ELM-FAN.IR

AM852 Veterinary Anaesthesia machine User’ Manual

13

at (20 ± 3) ° C, and maintain this temperature throughout the test procedure.

3. Fill the AVDD with the appropriate anaesthetic agent to approximately half of the

maximum usable volume, and leave it to stand for at least 45 min.

If the manufacturer recommends that when power is applied to the AVDD, a warm-up

period be allowed before use, power shall be applied for at least that period before

testing. This period may be within the 45 min.

4. With the AVDD control in the “Off”, “0” or, if applicable, “Standby” position, set the

gas flowrate through the anaesthetic system to (2 ± 0,2) l/min and adjust the

anaesthetic ventilator to give (15 ± 2) breaths/min at an I:E ratio of 1:2 ± 20 % with

the inspiratory flow control set to maximum.

For an anaesthetic system in which the fresh gas flow is determined by the anaesthetic

ventilator settings, set these to give a minute volume of (2 ± 0,2) l.

Introduce a maximum pressure fluctuation of (2 ± 0,3) kPa (above ambient) at the

fresh gas outlet, ensuring that the decay time during the expiration period (from

100 % of the fresh gas outlet pressure at the end of the inspiration period to 33 % of

this pressure) is less than 0,6 s.

Note: This can be achieved by using a test lung having a compliance of 0,2 l/kPa and an

appropriate resistance.

Maintain the pressure fluctuations for 3 min, and after that time measure the

concentration of anaesthetic vapour delivered over a further 1 min period while

maintaining the pressure fluctuation. Calculate the average vapour concentration in

the total delivered gas flow.

5. Repeat the procedure described in 4. with the AVDD set to each of the other settings,

and in the order given in Table 2-1. If the AVDD is not marked with the concentration

settings given in Table 101, use the nearest settings on the AVDD. If any setting

given in Table 101 is equidistant between settings on the AVDD, use the lower setting

on the AVDD.

Table 2-1 — Settings to be used for testing delivered concentration

Order of test

1

2a

3

4

5

6

7

Off, Standby, and zero, if separately marked

lowest graduation above zero

10 % FS

20 % FS

50 % FS

75 % FS

maximum graduation (full scale)

a If 10 % of full scale (FS) is the lowest graduation, step 2 is omitted.

6. Repeat the procedure in 4. and 5., using a fresh gas flowrate of (8 ± 0,8) l/min and a

دﯾﯾﺎﻣرﻓ ﮫﻌﺟارﻣ.WWW.ELM-FAN.IRتﯾﺎﺳ ﮫﺑ رﺗﺷﯾﺑ دراوﻣ دوﻠﻧاد یارﺑ

To download more items, go to ELM-FAN.IR

AM852 Veterinary Anaesthesia machine User’ Manual

14

pressure fluctuation at the fresh gas outlet of (5 ± 0,4) kPa.

For an anaesthetic system in which the fresh gas flowrate is determined by the

ventilator settings, set these to give a minute volume of (8 ± 0,8) l.

Vapour output during and after oxygen flush

*When the AVDD is tested as described in Determination of delivered vapour output

during and after oxygen flush , the output of anaesthetic vapour shall not increase by

more than 20 %.

Determination of delivered vapour output during and after oxygen flush

1. Follow the test procedure in.6. Instead of introducing a pressure fluctuation at the fresh

gas outlet, measure the output of anaesthetic vapour (concentration of vapour × volume

of gas) for 1 min before, during a 10s activation of the oxygen flush, and for 30s after

the oxygen flush activation.

Compare these three measurements, expressed as volume flowrate (volume of vapour

per unit of time).

Note: The volume of gas can be determined for example, by integrating flow or by collecting

the gas during the specified period.

2. Repeat the test procedure in 1. using a steady sub-atmospheric pressure of 10 kPa.

Compare these three measurements, expressed as volume flowrate (volume of vapour

per unit of time).

Warning: The evaporator isn’t adjusted in the range from 0 to the first scale, so this

range can not be used.

Warning: An ANAESTHETIC VAPOUR DELIVERY DEVICE used with the ANAESTHETIC SYSTEM

shall comply with ISO 8835-4.

دﯾﯾﺎﻣرﻓ ﮫﻌﺟارﻣ.WWW.ELM-FAN.IRتﯾﺎﺳ ﮫﺑ رﺗﺷﯾﺑ دراوﻣ دوﻠﻧاد یارﺑ

To download more items, go to ELM-FAN.IR

AM852 Veterinary Anaesthesia machine User’ Manual

15

3. Assembly of whole set

3.1Respiratory system installation

1. Common gas pipe 2. Holder 3.Respiration system

Fig. 3-1

Pipeline installation:

Fig. 3-2

1

2

3

دﯾﯾﺎﻣرﻓ ﮫﻌﺟارﻣ.WWW.ELM-FAN.IRتﯾﺎﺳ ﮫﺑ رﺗﺷﯾﺑ دراوﻣ دوﻠﻧاد یارﺑ

To download more items, go to ELM-FAN.IR

AM852 Veterinary Anaesthesia machine User’ Manual

16

4. Pre-use Test

4.1Test interval

Under the following condition,pre-use test should carry out:

1. Before the first pet use every day.

2. Before each pet use.

3. Test machine according to the request after service and maintenance.

Test item

Before the first

pet use every day

Before each pet use

Check system

applicable

-

Test pipe and gas cylinder

applicable

-

Test flowrate control

applicable

-

Install evaporator

applicable

-

Test respiration system

applicable

applicable

Warning: Do not put the machine into operation before you read and comprehend

the operation and maintenance of each parts.

·All system connection.

·All warnings and notes.

·Operation method of each parts.

·Test method of each parts.

Before you use the system, should

·Complete all tests mentioned in this section.

·Test all other system parts.

دﯾﯾﺎﻣرﻓ ﮫﻌﺟارﻣ.WWW.ELM-FAN.IRتﯾﺎﺳ ﮫﺑ رﺗﺷﯾﺑ دراوﻣ دوﻠﻧاد یارﺑ

To download more items, go to ELM-FAN.IR

AM852 Veterinary Anaesthesia machine User’ Manual

17

4.2Check the system

Warning:

Ensure:

1. The equipment is in good condition.

2. All parts are connected correctly.

3. Respiration circuit and pipes are connected correctly and in good conditions,

and there are enough absorbent in absorber.

4. Lock evaporator to correct position and fill enough anaesthetic.

5. The connection and pressure of gas supply system are correct.

6. If there are spare gas cylinders, the valve of gas cylinder which is connected

to the system should be closed.

Warning: When use pipe to provide air, the spare gas cylinder should not be open so

as to avoid that supply gas exhaust result in storing supply shortage when

pipeline is in trouble.

7. The contingency equipment have already been prepared and in good

condition.

8. The equipment used to maintain airway, tracheal intubatton and manage

device have already been prepared and in good condition.

9. Applicable anaesthetic and contingency drug have already been prepared.

10. Anaesthesia gas spiritualization system has been connected correctly and in

good condition.

11. Ensure truckles are not loose and brake has been locked, can not move.

4.3Test gas supply pipe

Warning: In order to prevent the equipment being damaged:

·Open gas cylinder valve slowly

·Do not take flowrate control forcefully.

1.Cut off all air feed linkages and close all gas cylinder valves.

If the values of pipe and gas cylinder pressure gauge are not zero,

then:

دﯾﯾﺎﻣرﻓ ﮫﻌﺟارﻣ.WWW.ELM-FAN.IRتﯾﺎﺳ ﮫﺑ رﺗﺷﯾﺑ دراوﻣ دوﻠﻧاد یارﺑ

To download more items, go to ELM-FAN.IR

AM852 Veterinary Anaesthesia machine User’ Manual

18

·Feed into O2

·Set flowrate control on middle range.

·Ensure all of the pressure gauges be reset to zero, except O2.

·Cut off O2 feed.

·Ensure O2 pressure decline to zero gradually. With the pressure

debase, the low pressure alarm should ring.

2. Connect pipeline supply air.

3. Check whether the pipe pressure is coincident with the request of the region

where the user locates in.

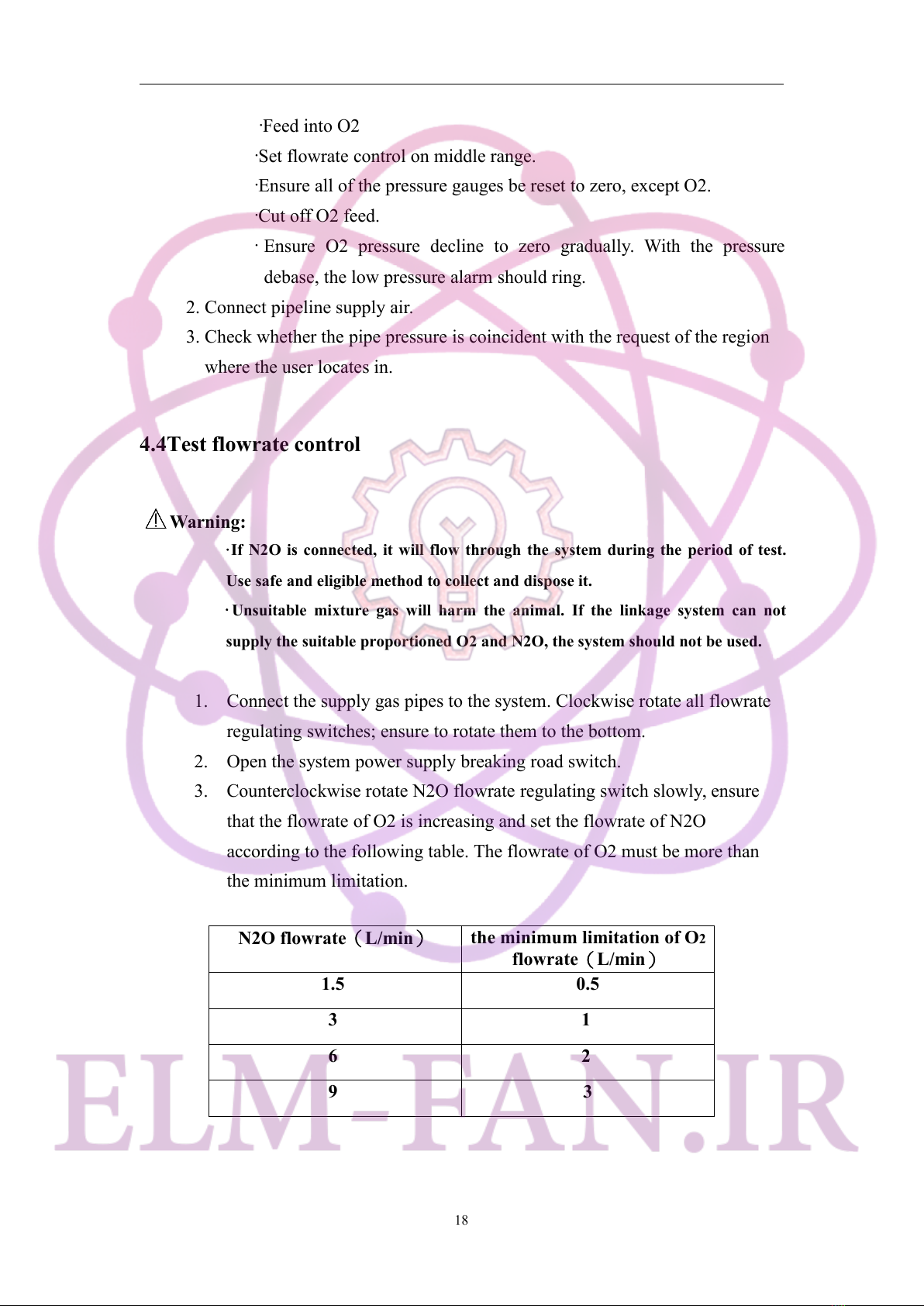

4.4Test flowrate control

Warning:

·If N2O is connected, it will flow through the system during the period of test.

Use safe and eligible method to collect and dispose it.

·Unsuitable mixture gas will harm the animal. If the linkage system can not

supply the suitable proportioned O2 and N2O, the system should not be used.

1. Connect the supply gas pipes to the system. Clockwise rotate all flowrate

regulating switches; ensure to rotate them to the bottom.

2. Open the system power supply breaking road switch.

3. Counterclockwise rotate N2O flowrate regulating switch slowly, ensure

that the flowrate of O2 is increasing and set the flowrate of N2O

according to the following table. The flowrate of O2 must be more than

the minimum limitation.

N2O flowrate(L/min)

the minimum limitation of O2

flowrate(L/min)

1.5

0.5

3

1

6

2

9

3

دﯾﯾﺎﻣرﻓ ﮫﻌﺟارﻣ.WWW.ELM-FAN.IRتﯾﺎﺳ ﮫﺑ رﺗﺷﯾﺑ دراوﻣ دوﻠﻧاد یارﺑ

To download more items, go to ELM-FAN.IR

AM852 Veterinary Anaesthesia machine User’ Manual

19

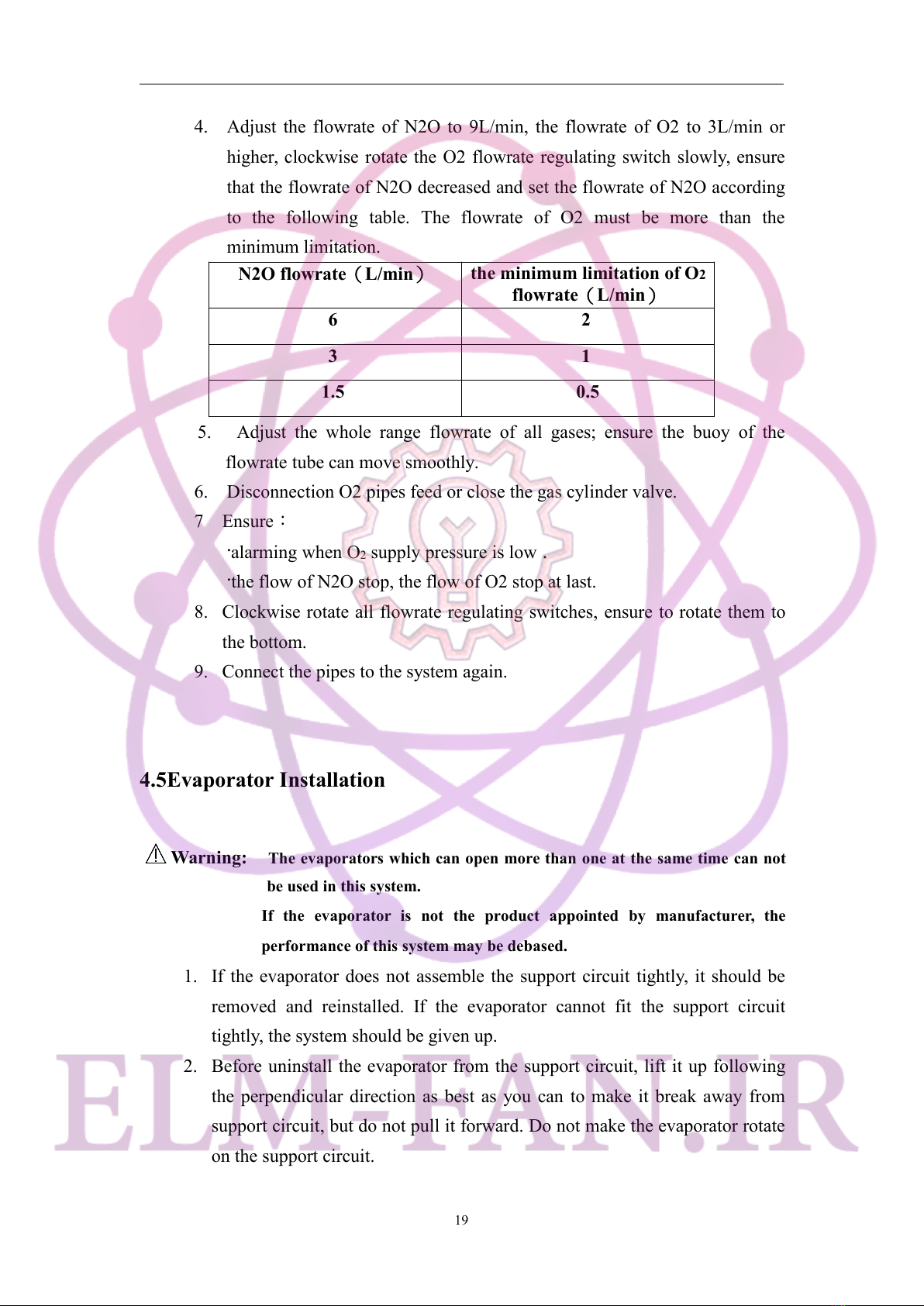

4. Adjust the flowrate of N2O to 9L/min, the flowrate of O2 to 3L/min or

higher, clockwise rotate the O2 flowrate regulating switch slowly, ensure

that the flowrate of N2O decreased and set the flowrate of N2O according

to the following table. The flowrate of O2 must be more than the

minimum limitation.

N2O flowrate(L/min)

the minimum limitation of O2

flowrate(L/min)

6

2

3

1

1.5

0.5

5. Adjust the whole range flowrate of all gases; ensure the buoy of the

flowrate tube can move smoothly.

6. Disconnection O2 pipes feed or close the gas cylinder valve.

7 Ensure:

·alarming when O2supply pressure is low .

·the flow of N2O stop, the flow of O2 stop at last.

8. Clockwise rotate all flowrate regulating switches, ensure to rotate them to

the bottom.

9. Connect the pipes to the system again.

4.5Evaporator Installation

Warning: The evaporators which can open more than one at the same time can not

be used in this system.

If the evaporator is not the product appointed by manufacturer, the

performance of this system may be debased.

1. If the evaporator does not assemble the support circuit tightly, it should be

removed and reinstalled. If the evaporator cannot fit the support circuit

tightly, the system should be given up.

2. Before uninstall the evaporator from the support circuit, lift it up following

the perpendicular direction as best as you can to make it break away from

support circuit, but do not pull it forward. Do not make the evaporator rotate

on the support circuit.

دﯾﯾﺎﻣرﻓ ﮫﻌﺟارﻣ.WWW.ELM-FAN.IRتﯾﺎﺳ ﮫﺑ رﺗﺷﯾﺑ دراوﻣ دوﻠﻧاد یارﺑ

To download more items, go to ELM-FAN.IR

AM852 Veterinary Anaesthesia machine User’ Manual

20

3. If more than one the evaporators can be opened at the same time, these

evaporators should be removed and reinstalled according to the operation

manual of evaporators.

4.6Test Respiration system

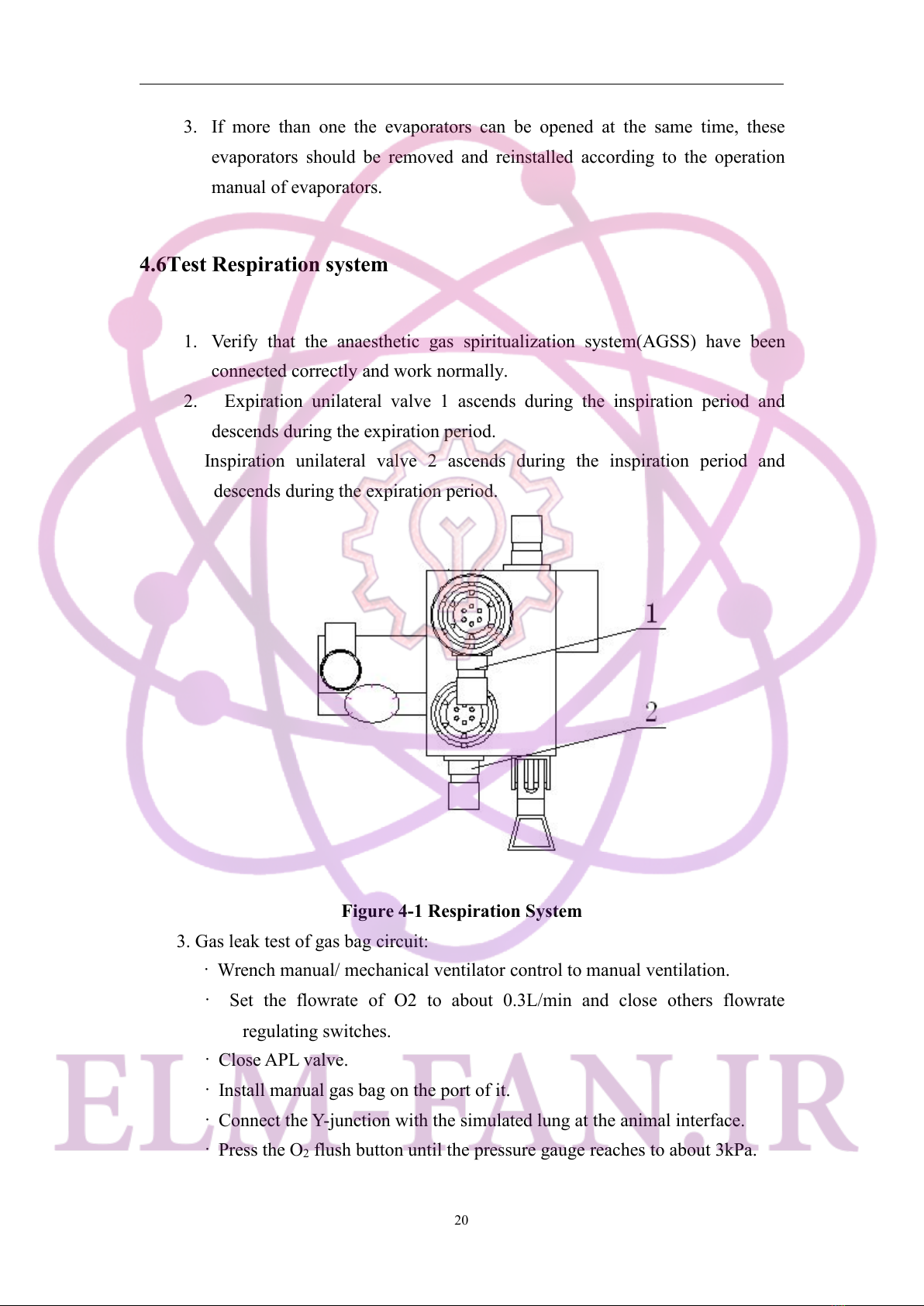

1. Verify that the anaesthetic gas spiritualization system(AGSS) have been

connected correctly and work normally.

2. Expiration unilateral valve 1 ascends during the inspiration period and

descends during the expiration period.

Inspiration unilateral valve 2 ascends during the inspiration period and

descends during the expiration period.

Figure 4-1 Respiration System

3. Gas leak test of gas bag circuit:

·Wrench manual/ mechanical ventilator control to manual ventilation.

·Set the flowrate of O2 to about 0.3L/min and close others flowrate

regulating switches.

·Close APL valve.

·Install manual gas bag on the port of it.

·Connect the Y-junction with the simulated lung at the animal interface.

·Press the O2flush button until the pressure gauge reaches to about 3kPa.

دﯾﯾﺎﻣرﻓ ﮫﻌﺟارﻣ.WWW.ELM-FAN.IRتﯾﺎﺳ ﮫﺑ رﺗﺷﯾﺑ دراوﻣ دوﻠﻧاد یارﺑ

To download more items, go to ELM-FAN.IR

AM852 Veterinary Anaesthesia machine User’ Manual

21

·The value of pressure gauge should not drop more than 0.3kPa within 20s,

if it is over this limit, that indicates gas leakage, the troubleshooting process

should be made.

4. Test the APL valve

·Close the APL valve completely.

·Set the flowrate of O2 to 3L/min.Close other gases and ensure that the value

of airway pressure do not over 7.5kPa. Certain pressure fluctuation is

normal circumstance.

·Open the APL valve completely.

·Ensure the value of airway pressure do not over 0.5kPa.

·Press the O2flush button and ensure that the value of airway pressure is

nearly 0.

Warning: If there were foreign bodies in respiration system, these will jam the gas

follow to the animal, this may cause injury or death to the animal Ensure

that there is no test plug or other foreign bodies in system.

دﯾﯾﺎﻣرﻓ ﮫﻌﺟارﻣ.WWW.ELM-FAN.IRتﯾﺎﺳ ﮫﺑ رﺗﺷﯾﺑ دراوﻣ دوﻠﻧاد یارﺑ

To download more items, go to ELM-FAN.IR

Table of contents

Popular Medical Equipment manuals by other brands

Avery Weigh-Tronix

Avery Weigh-Tronix Eyecon 9420 Quick reference guide

Stamina

Stamina Seated Inversion Therapy System owner's manual

Jula

Jula 951-106 User instructions

Labex

Labex INSPIRATION ELECTROLARYNX user manual

bort medical

bort medical 930 160 quick guide

Hill Laboratories

Hill Laboratories HA90D Reference manual