ELME FC1 User manual

un

- 1 -

Index

A quality choice

2

General instructions and warnings ...

3

..............................

4

Technical ...............................

4

Illuminating lamp replaci..................................

4

Installing the new machine

5

Cleaning

6

First Class Millennium ..

7

How to start the production of slush, sherbets or

cold drinks with FC Millennium

11

Old machine disposal

12

FCW installation ............................

13

Pressure switch refit procedure

13

Cotter pin substitution ..

14

Problem Solving

16

Warranty certificate

20

Millennium Electric system

21

Refrigerating system

22

Exploded view

23

Codes description

24

- 2 -

ENGLISH

A quality choice

Elmeco business is

managed in according

with rulesof Vision 2000

and ISO14001

Elmeco

200014001

These instructions are

also available in

electronic format on

our website.

Choosing Elmeco, and in

particular First Class, the new

and only multifunctional

machine with double augers,

demonstrates your attention to

innovation. Thanks for

understanding the importance of

working with a company that

does not consider “quality” as an

abstract word. For Elmeco

quality is a concrete

commitment. It actually means

to clinch the attention to the

innovation that characterized us

as the creators of the first slush

machine and that today confirms

our leadership in the technical

forefront. For our company

“Quality” also means working

trying to always improve from a

management and organizational

point of view following the

Vision 2000 certification, and it

finally means to care about the

customers and to dedicate

investments and resources to

continuously meet their needs.

On the other hand, for those who

decided to choose Elmeco,

quality means being able to work

with reliable and lasting

products, to count on a precise

and qualified assistance in order

to work with increasing

satisfaction and earnings.

Elmeco

a

Elmeco

2000

.

Elmeco

a

.

- 3 -

ENGLISH

General instruction and

warnings

This appliance is not intended for use

by persons (including children) with

reduced physical, sensory or mental

capabilities, or lack of experience and

knowledge, unless they have been

given supervision or instruction

concerning use of the appliance by a

person responsible for their safety.

Children should be supervised to

ensure that they do not play with the

appliance.

Before switching on themachine

carefully read the information in this

service manual; this way you will be

able to install, use and maintain the

machine. Keep the use and assembly

instructions, even for the next buyer.

The manufacturer declines any

responsibility for damages deriving

from the non-observance of the

following instructions.

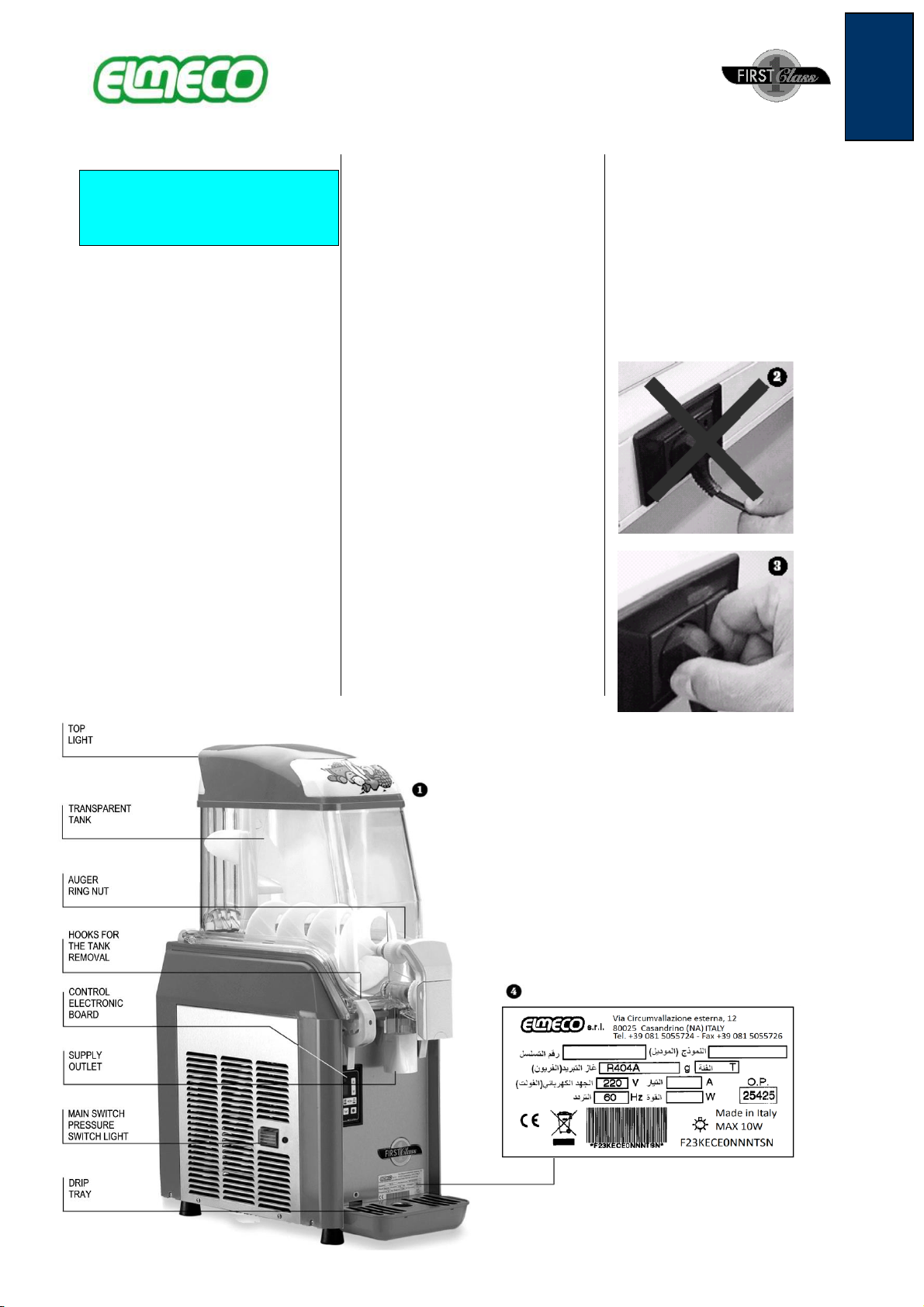

Install the machine according to the

assembly instructions. The power

supply must correspond to the data on

the plate on the front side of the

machine behind the drip tray (pic. 1).

WARNING: When positioning the

appliance, ensure the supply cord is

not trapped or damaged.

WARNING: Do not locate multiple

portable socket-outlets or portable

power supplies at the rear of the

appliance.

.

.

.

(

- 4 -

ENGLISH

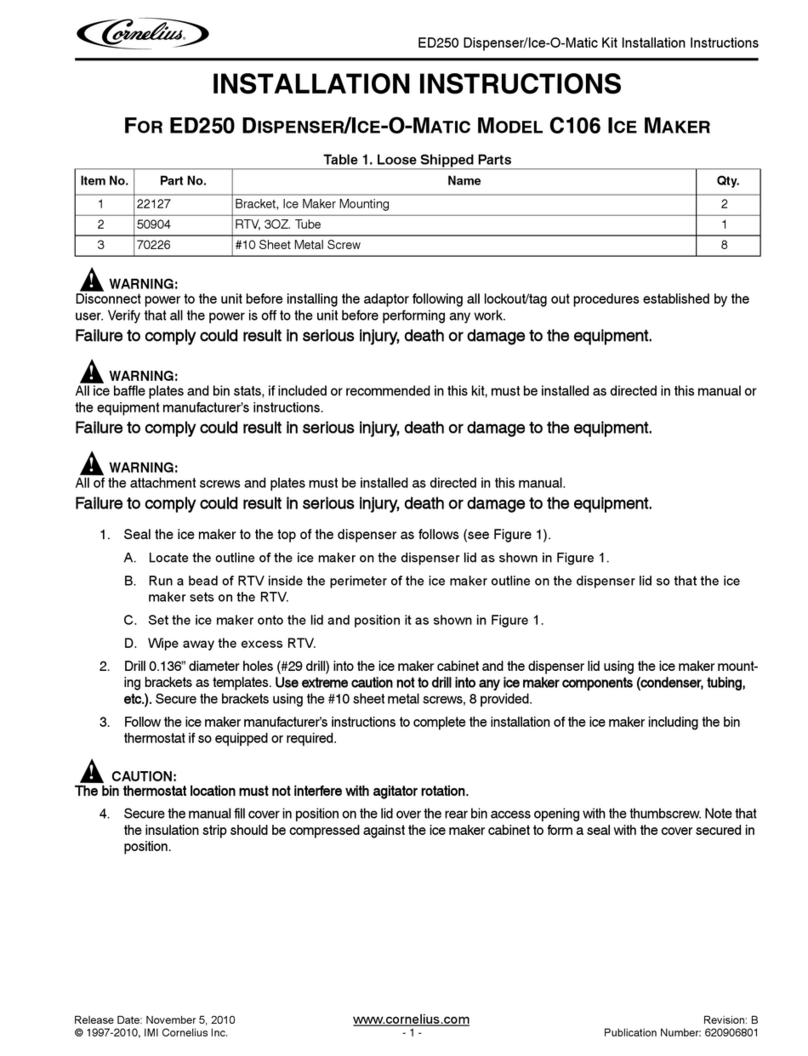

During maintenance and cleaning, or

in case of bad functioning, disconnect

the machine from the power plug (by

pulling the plug and not the cable) (pic.

2 and 3 pag.3).

Only specialized and authorized staff

can repair the machine. Not perfect

repairing can be dangerous for the

user. Contact Elmeco for information

concerning the closer authorized

assistance centre.

For correct operation use the machine

at maximum temperature of 43°C and

minimum 27°C.

For safe operation the maximum tilt of

the appliance is 1,5 degree towards

the front side (outlet).

The appliance is not suitable for

installation in an area where a water

jet could be used.

The appliance is only to be installed in

locations where its use and

maintenance is restricted to trained

personnel.

pag 3).

Elmeco

.

°C °C.

).

a

.

.

Important security

rules

•Do not touch the machine when

you have wet hands and/or feet.

•Do not use the machine with bare

feet.

•Do not allow children or

incompetent people to use the

machine.

•Do not leave the machine

exposed to atmospheric agents.

•Do not pull the power supply cable

to disconnect the machine from

the electric power.

•Do not remove the panels before

disconnecting the machine from

the electric power.

•This appliance is intended to be

used in household and similar

applications such as

staff kitchen areas in shops,

offices and other working

environments;

farm houses and by clients in

hotels, motels and other

residential type environments;

bed and breakfast type

environments;

catering and similar non-retail

applications.

•"

.

•"

.

•"

.

•"

.

•"

.

•"

.

•

:

.

Technical assistance

The repairing of the machine must be

carried out by an authorized service

centre, using only original spare parts.

If the supply cord is damaged, it must

be replaced by the manufacturer, its

service agent or similarly qualified

persons in order to avoid a hazard

.

a

Illuminating lamps

replacing

In case of replacing of the lamp follow

the procedure:

1. Switch off the machine;

2. Remove the top light complete

cover from the transparent tank;

3. Separate the top light from the

transparent lamp glass;

4. Change the old illuminating lamp

with new one (12Vac -10watt);

5. Assembly the top light with the

transparent lamp glass;

6. Reposition the top light complete

cover on the transparent tank.

1 2

3

4

Vac -10 5 6

The Supplier is reserved to bring alterations without notice.

The relevant data the power are indicative. To do reference to the data of plate data restored on the machine.

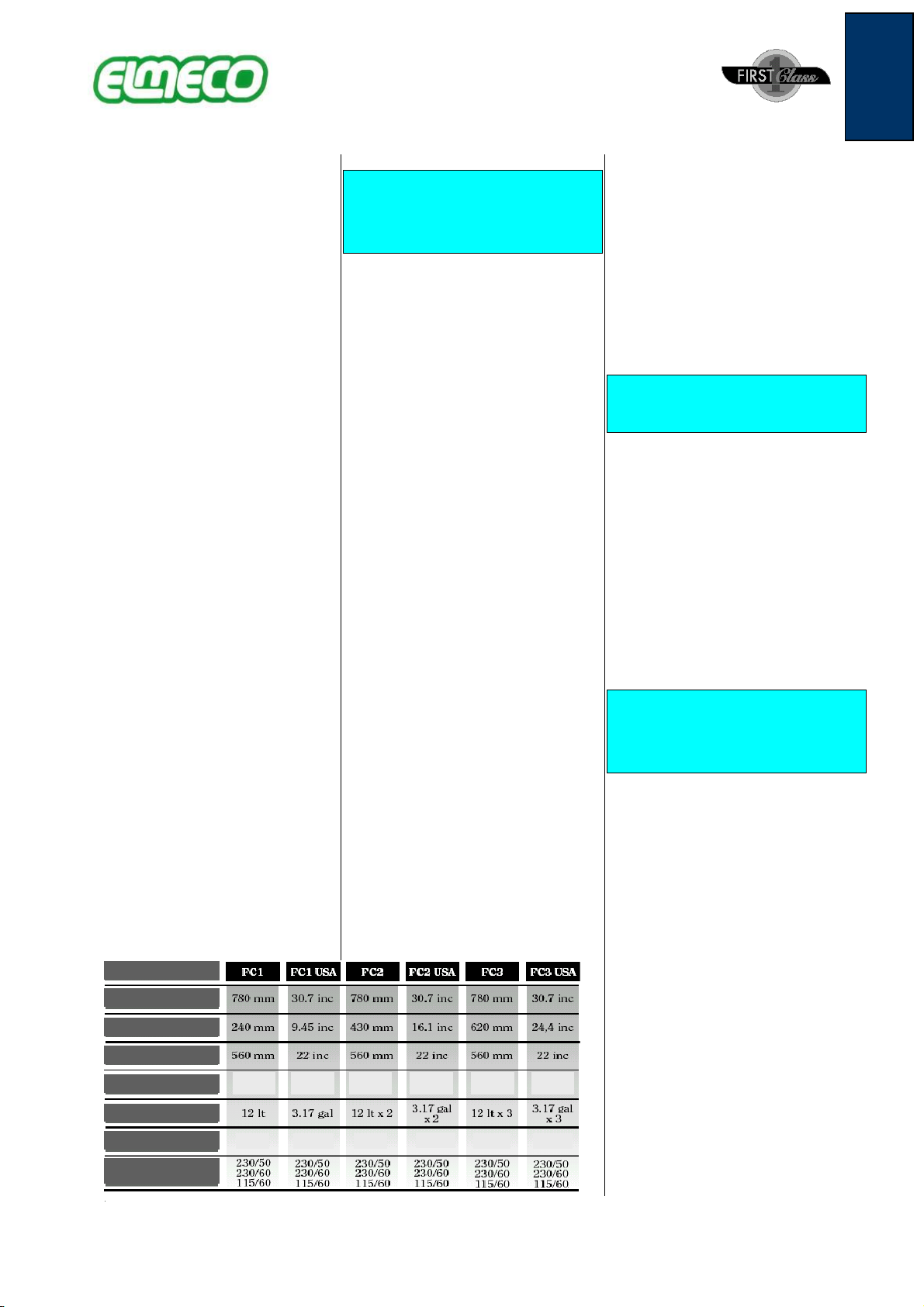

450 w

0,61 hp

900 w

1200 w

0,61 hp

0,61 hp

MODEL

HEIGHT

VOLTAGE HZ

POWER

CAPACITY

WEIGHT

DEPTH

WIDTH

32 kg

71 lb

54 kg

119 lb

67 kg

148 lb

- 5 -

ENGLISH

Installing the new machine

This machine for the production of cold

drink, slush, and sherbets grants the

absolute homogeneity of the product

and the possibility to regulate its

density thanks to an innovative

electronic control. Before installing the

machine, verify that:

•First Class is not placed by an heat

source;

•The machine has not been

damaged during transportation. In

case of doubt, contact the supplier;

•The power supply system is

endowed with a grounding that

respects the rules of law;

•The power supply system capacity

is adequate to the maximum power

of the machine, as indicated on the

plate (pic. 4 pag.3).

In case of doubt, contact only qualified

staff.

In order to install the machine,

carefully read the following

instructions.

:

•"

•"

•"

a

•"

).

.

.

Warnings

This machine is only for the use it has

been manufactured for. Any other

usage is to be considered as improper

and dangerous.

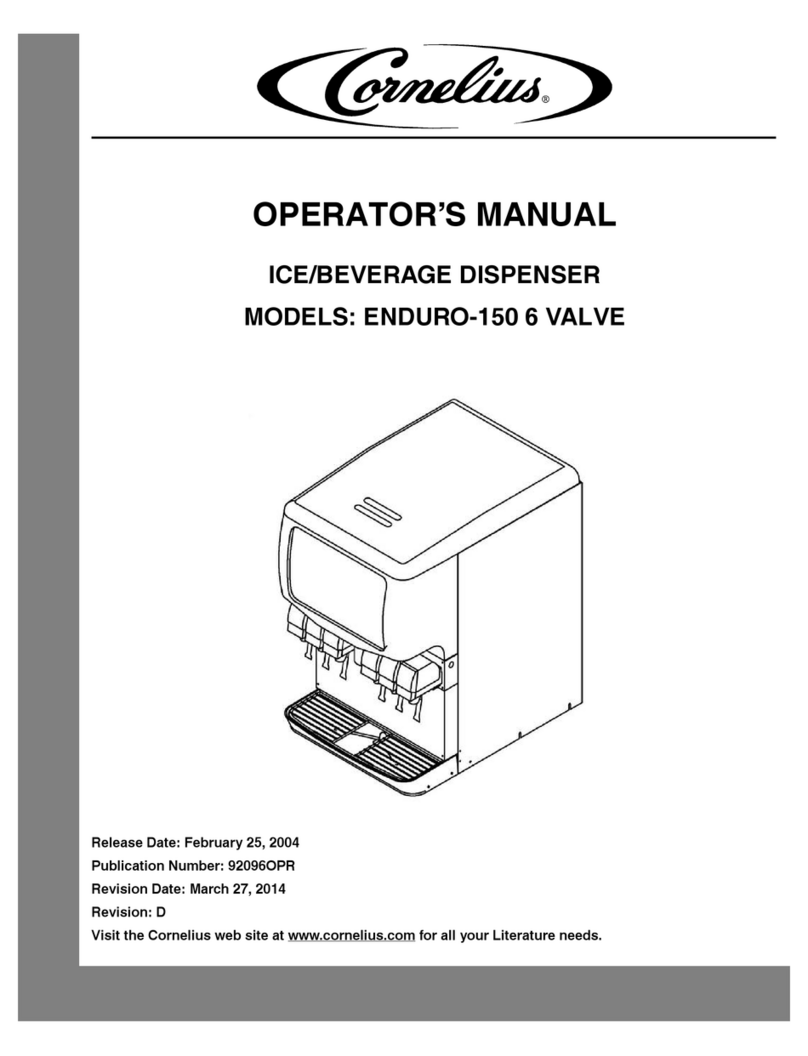

Machine description (pic. 1 pag.3):

•Top light

•Transparent tank

•Auger ring nut

•Hooks for the tank removal

•Control electronic board

•Supply outlet

•Main switch

•Pressure switch light

•Drip tray

•Plate data

.):

•"

•"

•"

•"

•"

•"

•"

•"

•"

•"

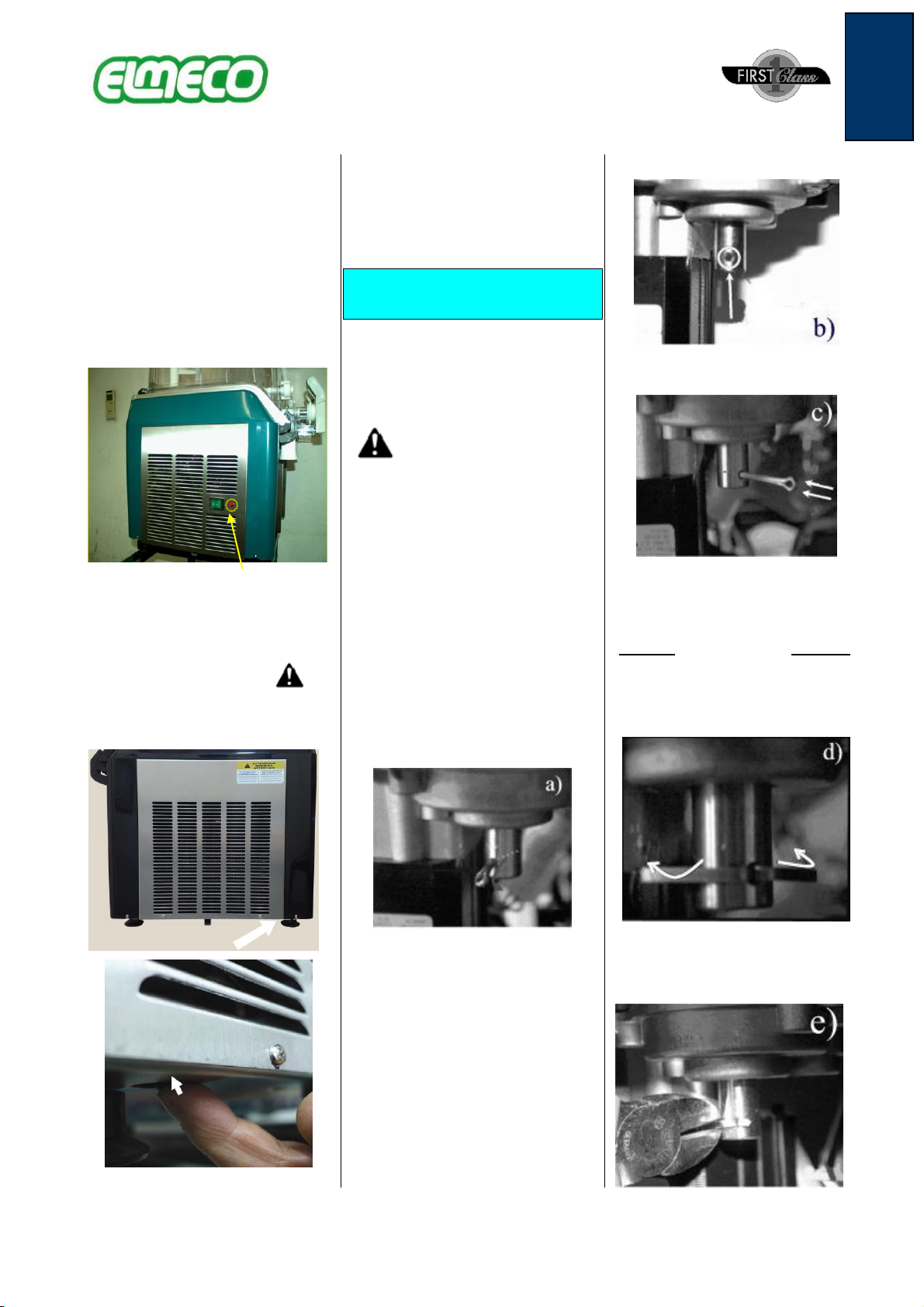

Installation

It is suggested that the machine is

installed only by qualified staff. A

wrong installation can cause damage

to people or things, for which things

the manufacturer declines any

responsibility. Once the machine is

unpacked, verify the integrity of the

machine. The packaging elements

(plastic bags, expanded polystyrene,

nails, etc.) must not be left at children

reach as they might be dangerous.

Remove the protection plastic stripes

also from the internal side of the grids.

We do not recommend to connect the

machine through adaptors, multiple

plugs and/or extensions. If necessary,

use only materials that conform to the

safety rules in force, as for the current

intensity up to what indicated onthe

plate (pic. 4 pag.3).

Place the machine so as to avoid any

heat source to be close to the grids.

Verify that there is a free space of 25

cm at least around the machine (pic. 5

in appendix-25).

After connecting the machine to the

power supply and switching on the

main switch, verify that air comes out

from the side grids (pic. 6 in appendix-

25).

polystyrene

.

(

a

Lid stickers

All refrigerators are equipped with 2

stickers for each single lid. The

stickers must be applied as showed in

the pictures:

:

Right usage

Before switching on themachine, it is

necessary to clean it as indicated in

".

- 6 -

ENGLISH

Cleaning

Cleaning is very important for the life

and maintenance of the machine; we

recommend to periodically clean the

parts that are in contact with the

product using the following procedure.

Warning! The appliance must not be

cleaned by a water jet.

Warning! Switch off the main switch

and disconnect the power plug (pic.

7 in appendix-25) before starting

any operation.

Use a solution of cold water and

sodium hypochlorite (bleach) with a 10

grams (1/2 spoon) for 1 liter of water

ratio. Rinse with lukewarm water.

Warning! A greater quantity of

beach could damage the material of

the auger.

Warning! If the plastic parts are

washed in the dishwashing

machine, verify that the temperature

is not higher than 60°C or 140°F,

because they could be damaged.

Do not use any abrasive powder.

.

.

.

a

hypochlorite ( a 10

.

.

°C

°F .

.

Tank cleaning procedure

See the picture at the end of this

manual.

•Empty the tanks by opening the

outlets and blocking them (pic. 8

in appendix-25), moving the little

letter from the left to the right.

•Remove the lamp (pic. 9 in

appendix-25), pour water in the

tanks and then empty them.

•Remove the auger ring nut (pic.

10 and 11 in appendix-25).

•Remove the tank unscrewing the

hooks grips (pic. 12 in appendix-

25), if present, and opening the

hooks (pic. 13 in appendix-25); lift

the tank as shown in pic. 14 and

15 in appendix-25.

•Unscrew the ring nut (pic. 16 in

appendix-25) in order to remove

the vertical auger (pic. 17 in

appendix-25).

•Remove the horizontal auger; this

way the inox side of the tank is

completely open and ready to be

cleaned (pic. 18 and 19 in

appendix-25).

•Remove the outlet (pic. 20, 21, 22,

23 in appendix-25) and the tank

gasket (pic. 24 in appendix-25):

•Remove the lever cover (pic.

20 in appendix-25) by

and remove the lever (pic. 21

in appendix-25);

•Rotate the ring nut clockwise

(pic. 22 e 23 in appendix-25)

and pull the outlet.

•Dip the dismantled parts in the

solution of water and bleach.

•Wash and dry.

•Wet the gasket before inserting it

in place (pic. 24 in appendix-25),

be careful to place the gasket joint

in one of the back corners of the

tank in the proper allocation.

•Reassemble everything.

•When you put the tank back in its

place verify that the low tension

contact wires are in the guides of

the terminal board. If they are not,

the lamp and the augers will not

work (pic. 25 in appendix-25).

•Connect the machine to the power

supply. Warning!

Any time the covers (lamp) are

removed, for security reasons, the

augers and the cooling system will

stop working.

.

•"

.

•"

.

•" ).

•"

.

•"

).

•"

inox

).

•" ):

•"

•"

e 23

.

•"

.

•"

.

•"

.

•"

.

•"

).

•"

.

!

.

- 7 -

ENGLISH

Condenser cleaning

procedure

Remove the side panel of the 2 or 3

tanks machine, or the back panel of

the one tank machine by unscrewing

the screws on the bottom and clean

the radiator with a soft brush or (if

possible) with compressed air.

a

.

Outlet restriction

First Class has an accessory called

Restriction (pic. 28 in appendix-25), it

is a shaped piece that is applied on the

ending part of the transparent tank

outlet. It has the following advantages:

•The product, liquid (clod drink) or

semi-liquid (low density slush), is

canalized directly in the glass;

•The restriction is easy to pull out,

therefore, it is possible to easy

wash the ending part of the outlet

without having to dismantle the

whole transparent tank, with a

consequent decrease of the

machine cleaning times. In

summary, the only part which is

not refrigerated, where an

accumulation of the product is

more likely to happen, can be now

removed and washed.

This restriction has some gaskets

(O-ring) that must be wet with water

before inserting them on the outlet

terminal part. This is to make the

introduction easier and to avoid that O-

ring goes outside their proper

locations.

On the restriction there is the image of

an arrow and of a glass that, while

inserting it, must face the operator.

a

•

•

a

. a

.

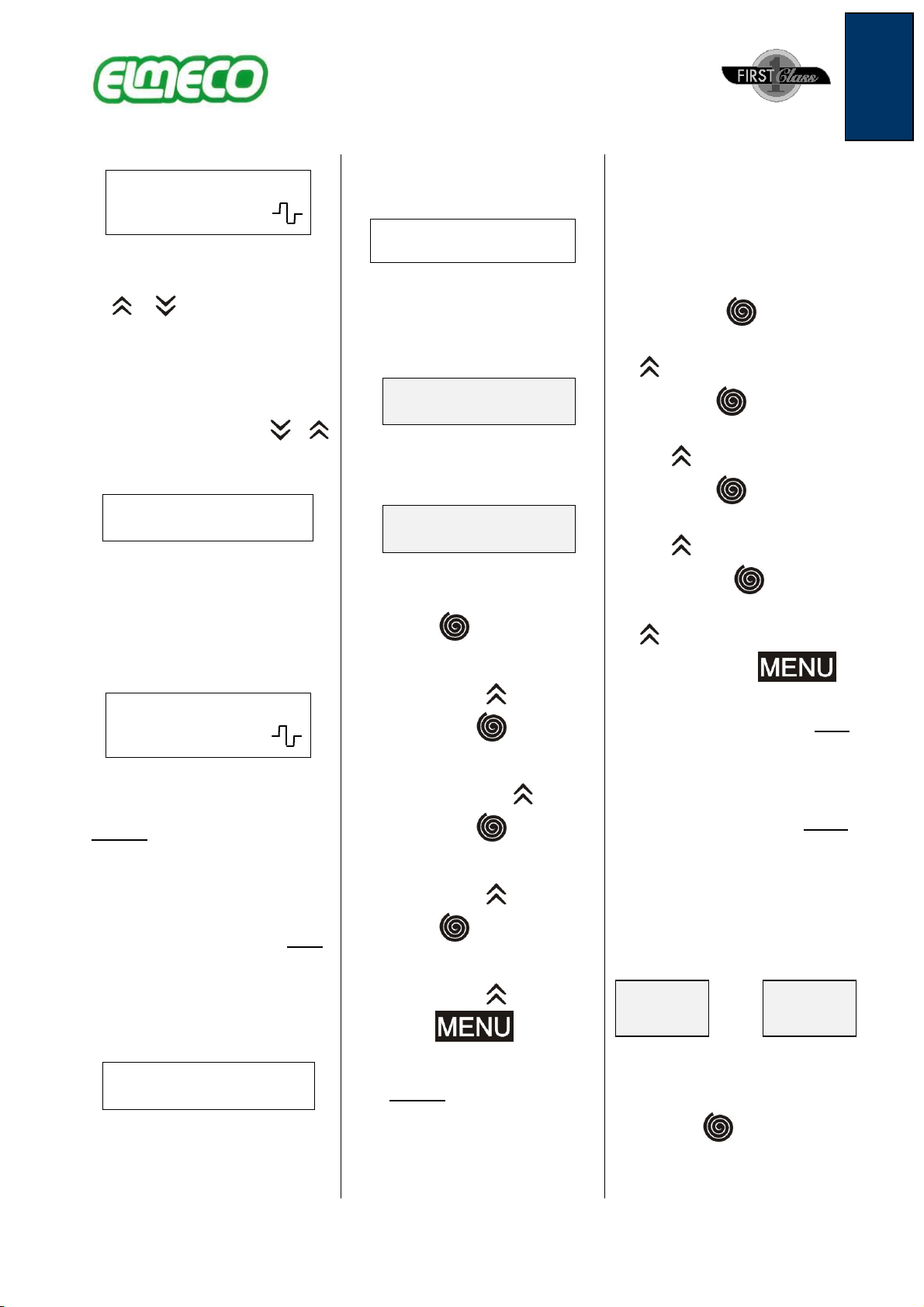

First Class Millennium

controls and signals

When you switch on the electronic

board, the display will show

SLUSH / MACHINE

V.30E

Where 0.15 indicates the tank review

number.

FC Millennium has a BASIC version

that only has the electronic board like

the one shown before, and an

ADVANCED version that has an

additional electronic kit in the machine

with additional features connected to

time.

Warning: The screen with the “/”

symbol indicates that the values are

shown alternatively.

After the screen shown above the

initial screen will be displayed:

.

a

san

.

.

:

StandBy

Press

WARNING: The electronic board will

keep the settings it had when the

machine was switched off.

.

When the tank is in stand-by mode,

the augers and the cooling system are

off. The augers and the gear motor

can be turned on by pressing the

button. The screen will show:

:

Motor on

Press < <> >

If you press the button, the

screen will display as follows:

::

- 8 -

ENGLISH

COLD

Y

(where Y is a variable number

between 2 and 5 for Cold Drink Mode,

which indicates the temperature in °C

at which the product must be

prepared).

Using and you can increase

or decrease the temperature of the

product. The recommended

temperature is 4°C.

If you press the button, the

screen will display as follows:

( a

°C

).

°C.

SLUSH

*X

(where X is a variable number

between 1 and 9 and indicates the

density of the slush). If you use the

and buttons it is possible to

increase or decrease the slush density

value.

(a

.

Warning: If, when the electronic

board is in Slush Mode, the product

temperature is greater than 5°C, the

following screen will be displayed:

°C

:

Auto / Setting / Wait

*X

This screen indicates that the

calibration process is taking place. The

calibration process will take one

minute to complete.

.

If you press the button (Cooling

off- cold drink- slush) you can switch

the machine functioning modes

alternatively. Each time you press the

button, the different screens of cold

drink slush and cooling off alternate.

In this latter position only the augers

rotate and no other action is taken.

.

If you press the auger rotation key

, the display will appear as

follows:

::

StandBy

Press

By holding the button for

one second you will enter the

selection menu.

Please note that unless you give any

further instruction to the electronic

board in more 10 seconds time, the

display will automatically go back to

the initial screen.

.

.

This screen allows you to turn ON or

OFF the light in the lid, by pressing the

and buttons of the electronic

board.

.

LAMP

OFF / ON

In this screen you can activate or

deactivate the bypass function by

pressing the increase and

decrease keys.

..

ByPass

OFF / ON

This screen allows you to turn ON or

OFF the Low Level control function

to no.1, when the level probe is not

covered with product for more than 20

minutes); you can do that by pressing

the increase key or the decrease

key.

.

LowLevel

OFF / ON

If you add some product (liquid that

touches the level probe), the function

will be deactivated and the slush

preparation will reach the density value

that was previously set on the

electronic board. When this function is

active, you will see the following

display:

:

- 9 -

ENGLISH

Please/refill/LOWLEVEL

*1L

This screen allows you to activate

(LOCK) or deactivate (UNLOCK) the

by pressing

the or buttons. This function is

suitable in self-service places, in order

to avoid people from changing the

values set.

.

KeyBoard

UNLOCK / LOCK

When the keyboard is locked, the

the display as shown on the screen

below:

a "

:

SLUSH

*X

If the machine is turned OFF and ON,

the electronic board will be in LOCK

position again.

Warning: The keyboard lock can be

activated if the electronic board is

in “Standby" or “MotorOn” mode.

.

"MotorOn".

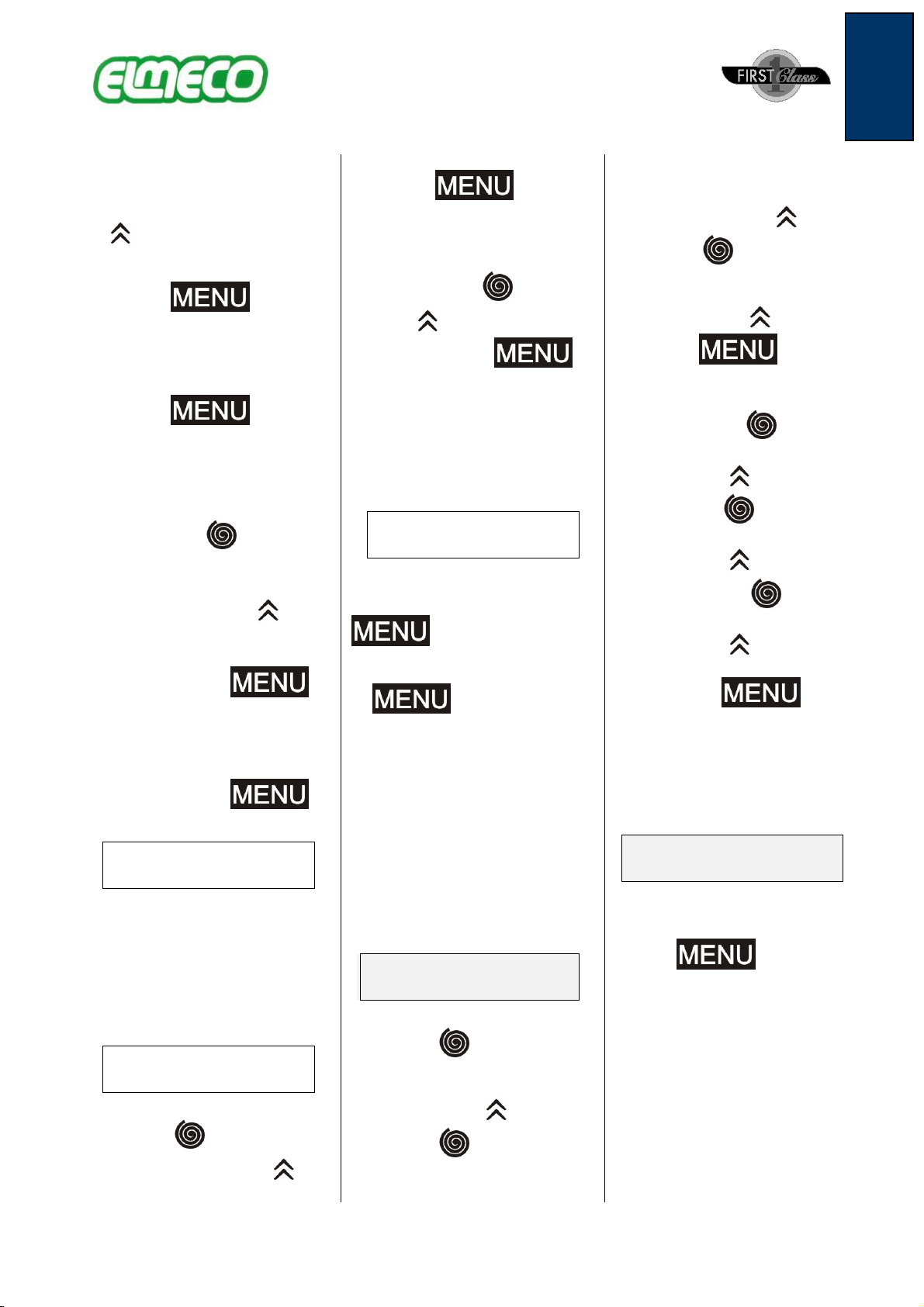

Turning OFF and ON of the washing

function.

..

Washing

OFF / ON

If the function is active, the electronic

board will show the screen below:

::

Washing

In this condition all buttons and the

cooling functions are NOT active, a pat

from the MENU button.

, a

.

TIME

hh:mm

This screen shows the time set on the

machine.

.

TIME

hh:mm

If it is different from the place where

the machine is installed, you can

change it by following the steps below:

1) press the button;

2) the first value will start to blink. If

you want to change the value, you

need to press the button;

3) if you press the button;

4) the second value will start to blink.

If you want to change the value,

you need to press the button;

5) if you press the button;

6) the third value will start to blink. If

you want to change the value, you

need to press the button;

7) press the button;

8) the fourth value will start to blink. If

you want to change the value, you

need to press the button;

9) press the button to

exit this function. The time will be

saved.

Warning: During the time

adjustment, the date (MM/DD/YY)

will appear on the upper line. It can

be different from the date of the

place where the machine is

installed, but the machine will work

without any problem.

NOTE: First Class Millennium

BASIC does not display this screen

and all other screens here reported

in the dotted square. These will only

be active in the ADVANCED version.

:

1; 2

3 4

;

5; 6

;

7; 8

;

9

..

.

.

Defrost function: On the screen you

can see the defrost ON and OFF time.

.

If the two values are the same, the

function is deactivated. In order to

change the ON and OFF time, follow

the steps below:

1) press the button;

DEFROST

ON 00:00

DEFROST

OFF 00:00

- 10 -

ENGLISH

2)

start to blink. If you want to change

the value, you need to press the

button;

3) repeat the steps 1) and 2) until all

ON values are set;

4) press the button to

exit the

5) . repeat the steps 1) and 2) until all

OFF values are set;

6) press the button to

exit the change function. The time

will be then saved.

:

1; 2

; 3

;

4

5.

;

6

..

Max Temp

NO/YES

In this screen you can activate or

deactivate the Critical Temperature

Control function. When the critical

temperature value is (NO), the function

is deactivate.

..

Max Temp

NO/YES

If you want to activate it, you need to:

1) press the button;

2) set the value pressing the

button;

3) press the button to

exit the change function.

:

1;

2

;

3

.

When you switch the machine on, if

the product temperature is greater

than the one set, the display will blink

and show:

:

Product

T > 4

temperature. In order to stop the

warning signal, please press the

button.

"

.

In this screen you can activate or

deactivate the Cleaning warning

function. This function is used if the

user wants the machine to show a

clear warning on the display that

reminds to clean the machine. If the

Cleaning warning function is on (000d-

---) it is deactivated.

a

d ----)

..

CLEANING

000d - ---

In order to activate it:

1) press the button;

the first value will start to blink. If

you want to change the value, you

need to press the button;

2) press the button again;

3) the second value will start to blink.

If you want to change the value,

you need to press the button;

4) press the button;

5) the third value will start to blink. If

you want to change the value, you

need to press the button;

6) press the button to

exit the change function.

:

1;

;

2; 3

;

4

; 5

; 6

..

When the machine is turned on and

the values (---) are zero, the display

will blink showing the cleaning

warning:

::

CLEANING

REQUIRED

Clean the tank as described in the

usage manual pag. 6;

In order to stop the warning signal,

press the button; thus the

countdown will start again for the next

warning.

000d = time in days for the cleaning

warning to appear

- --- = countdown (day to the

warning)

- 11 -

ENGLISH

EXEMPLES:

100d = after 100 days the machine

will inform that it must be cleaned up

050d = after 50 days the machine

will inform that it must be cleaned up

007d = after 07 days the machine

will inform that it must be cleaned up.

.

000 d =

- --- =)

:

100 d =

050 d =

007 d =

.

For machines with auto refill set up

ONLY! (This should be ON only if the

machine has the auto refill installed).

In this screen you can activate or

deactivate the auto refill control signal.

.

AUTOFILL

ON / OFF

Alarms functions

First Class Millennium is endowed with

a direct signalling of the problems

found. When the electronic board

blinks, it indicates that there is an

active alarm. To see what alarm is,

please press the button

for 1 second.

section, you can see a complete list of

all possible alarms at pag. 16. If more

than one alarm is active, these will be

indicated with more messages that

appear alternatively.

a

a

.

Operator security

If you open the tank lifting the lamp,

the augers will stop.

.

Self-diagnostics

Consult the Problem Solving

Section.

.

Configuration memory

All the functioning modes and the

regulations set are registered in a non-

volatile memory which is active even

without power; therefore, when you

switch on the machine, the tank keeps

the configuration it had when you

switched it off, a part from the

keyboard lock (as already said).

a

, a .(

Minimum level signal

All machines are endowed with a

probe that detects the product

minimum level in the tanks. When the

product is below this level, the light of

the lamp starts blinking. If the product

level does not change, the light will

stop blinking after a minute.

a

.

How to start the

production of slush,

sherbets or cold drink

with First Class

Millennium

Clean themachine as described in the

previous paragraph.

Remove the covers and pour the mix

in the tanks.

.

.

Warning: the temperature of the

poured product must not be lower

than 10 °C in order to allow a

correct calibration of the electronic

kit that will be indicated as

described in the previous

paragraph.

°C

a

.

Warning: Don’t fill the tank with

only water. In case of freezing

product switch off the board until

the product will be liquid.

.

Warning: The service area is

restricted to persons having

knowledge and practical experience

of the appliance, in particular as far

as safety and hygiene are

concerned.

.

Warning: When switching on the

machine, the poured product must

not be lower than 10 °C in order to

allow a correct calibration of the

electronic kit.

°C a

.

Switch on the main switch (see pic. 7

in appendix-25).

Switch on the auger switch .

- 12 -

ENGLISH

).

.

The following screen will be displayed:

:

Motor On

Press < <> >

Press the button to select

slushcold drink

".

slush

increase the product density with the

button and decrease it with the

button.

.

SLUSH

* 5

Slush.

It is possible to change the product

density from 1 to 9 using the or

buttons to increase or decrease it

respectively.

.

.

cold drink

increase the product temperature with

the button and decrease it with the

button.

. .

COLD

5

Cold drink.

It is possible to change the product

temperature from +02 °C to +05 °C

using the or buttons to

increase or decrease it respectively.

CC

Warning: The recommended

temperature value is 4°C.

°C.

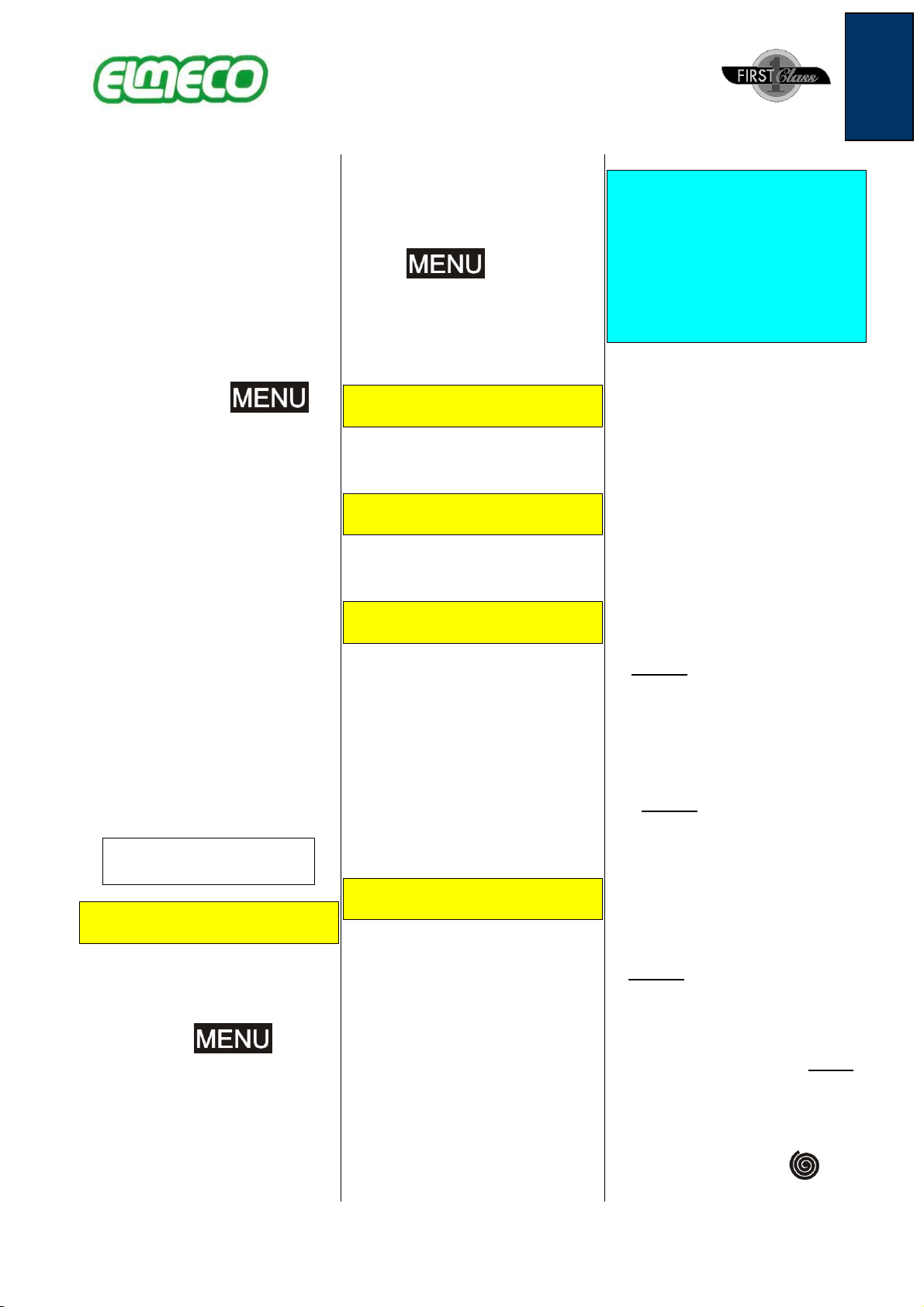

Here you are the table with the

correspondence between the values

mode and the °C/°F degrees.

°C/ °F.

Warning: in order to have slush or

cold drink, you need a small

quantity of sugar per liter. The

recommended quantity is generally

reported in the usage instructions.

In case of natural products, we

suggest to use a quantity that goes

from 12 and 22%.

a

If the horizontal auger is

blocked because of ice blocks due to a

lack of sugar or to other reasons, such

as foreign bodies in the tank, the

vertical auger can undergo a break.

a

a.

Warning: If the temperatures exceed

35°C Elmeco is not responsible for

the refrigerator performance (that

will be slower) and for the

correspondence between the

temperature selected on the

electronic board and the drink

temperature.

°C Elmeco

.

Old machine disposal

The out-of-use machines must be

disabled. Disconnect the plug from the

electrical network and cut the cable.

.

Ecological instructions

All refrigerating machines must be

disposed by the communal disposal

service or by an equivalent private

authorized company. Take care not to

damage the rigid tubes of the

refrigerator until they are taken back in

order to be carefully and ecologically

disposed.

All packaging materials used can be

disposed without any danger.

.

.

°C

°F

2

2 6

35.6 42.8

3

3 7

37.4 44.6

4

4 8

39.2 46.4

5

5 9

41.0 48.2

- 13 -

ENGLISH

FCW installation (water

cooling system)

If the First Class you bought is

endowed with the water cooling

system, it is necessary to follow these

instructions.

On the machine front side (outlet side)

There are some water exit (left) and

entrance pipes (right) as shown in the

pic. f .

The quantity of water necessary for the

functioning can change according to

the product cooling phases, with

higher values when starting the slush

production and values that are close to

zero when you want to keep the slush.

We therefore recommend to connect

the machine to the water network with

the maximum capacity, thus the

pressure switch valve (pic. g) in the

machine will regulate the flux

according the real necessity.

Important:

It is not possible to connect the FCW

water entrance with the input of

another machine based on a water

cooling system (series).

It is not possible to connect several

machines based on the water cooling

system on the same outlet.

.

)

.

f.

. g)

..

:

a ).

.

Pressure switch refit

procedure

Warning! The following steps

must be performed by qualified

personnel.

When the pressure switch light, near

main switch in ON,

Pressure switch light

this indicates that the pressure switch

intervened to deactivate the

compressor. In order to refit this

device, it is important to follow the

instructions below:

1° Disconnect the power cable.

2° Push the pressure switch button

under the frame of the machine.

- 14 -

ENGLISH

In order to avoid this situation to

happen again, verify the correct

position of the machine asin the pic.5

pag.25 and/or clean the condenser as

described at pag.7.

,

::

1..

2

pag.7.

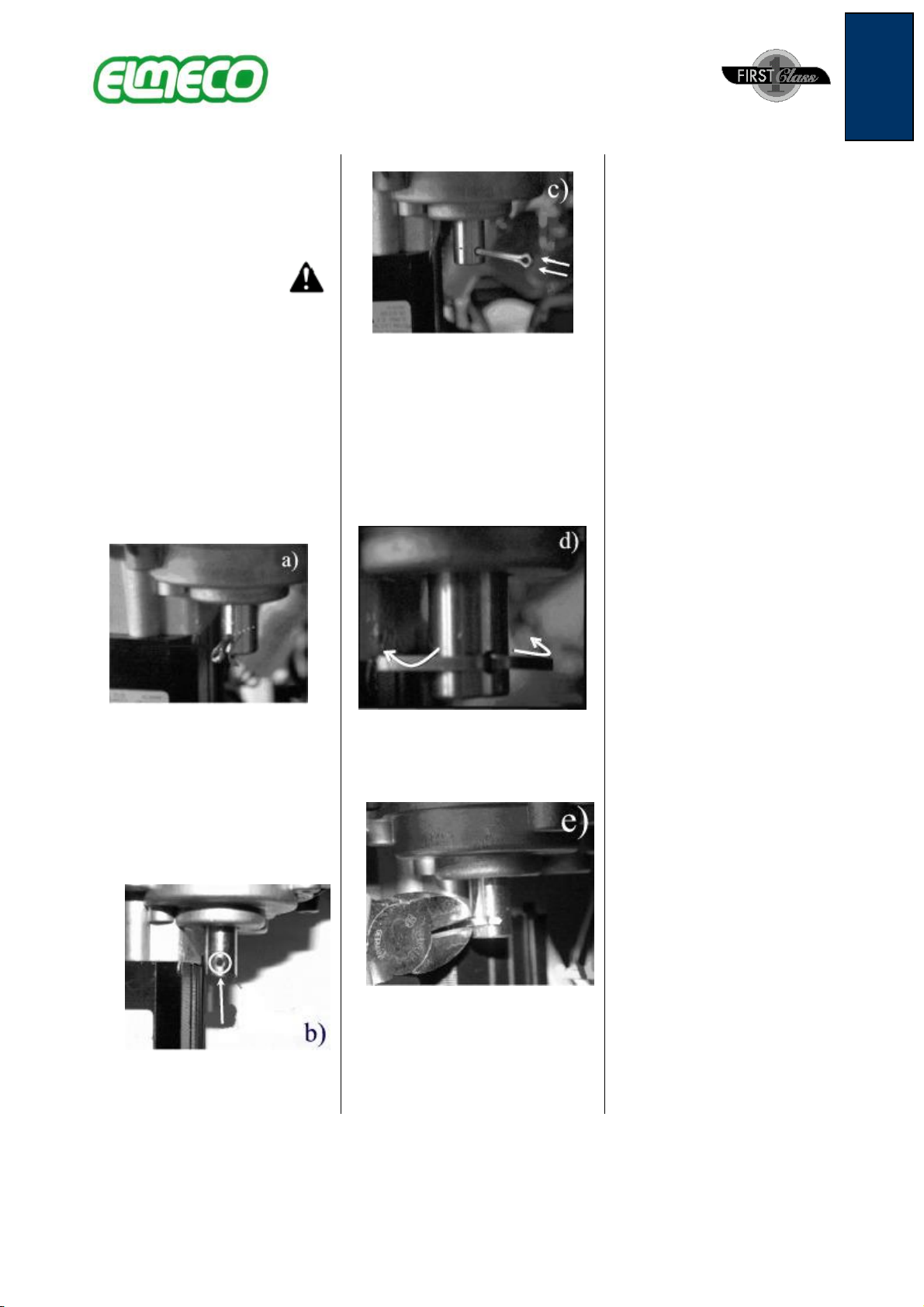

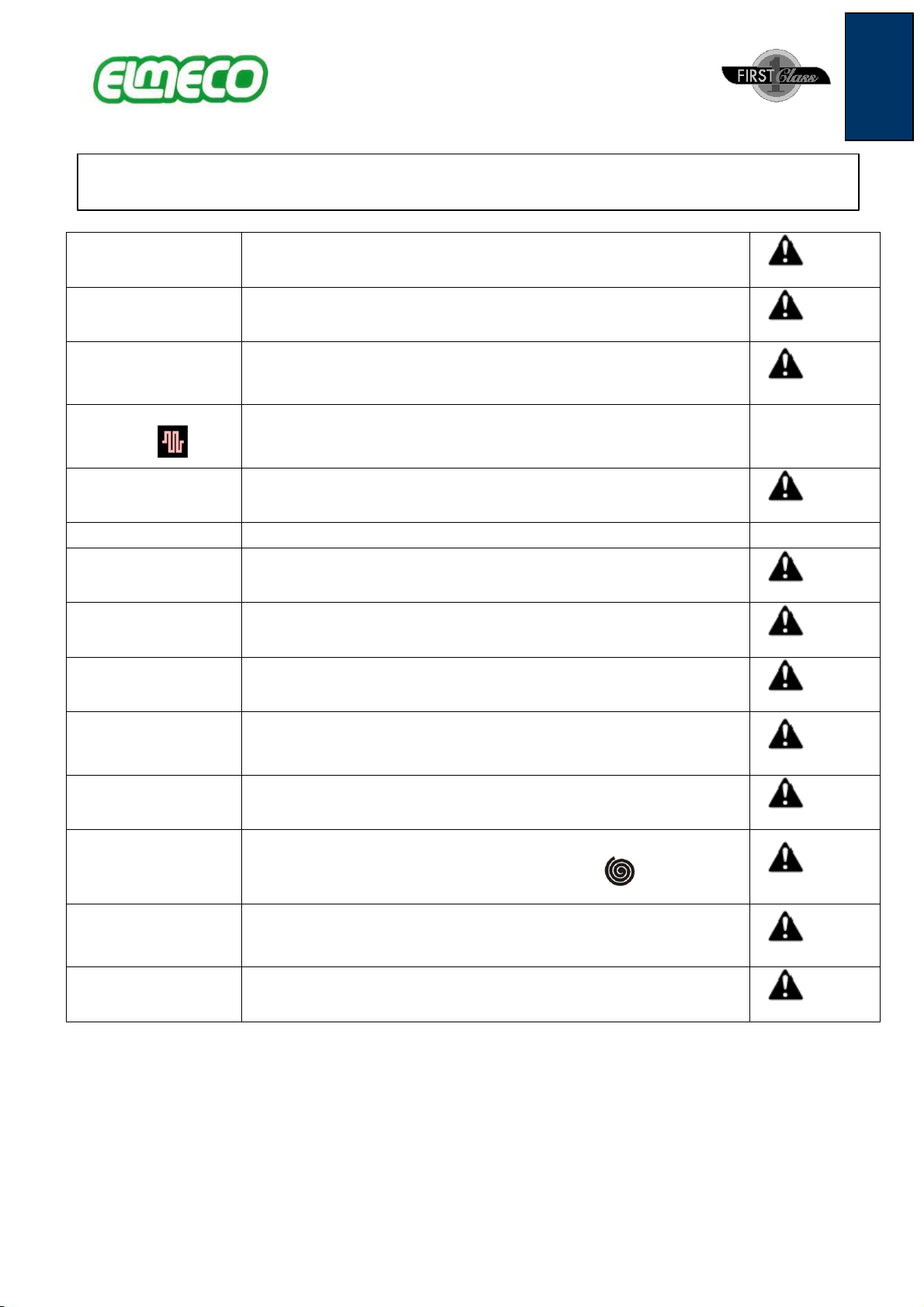

Cotter pin substitution

If the machine works but the augers do

not turn, it is possible that the cotter

pin, (item 35 of the exploded view in

appendix-23) that connects the gear

motor to the transmission shaft, broke

down.

Disconnect the power electric

cable

After removing the back and side

panels, you can see the breakdown

trying to lift the ring that fix the vertical

auger (item 28 of the exploded view in

appendix-23). It can happen that it is

blocked or that, if you lift it, it carries

away the transmission shaft with it

(item 29 of the exploded view in

appendix-23).

In the first case, it is necessary to

control that the transmission shaft

base is as high as the gear motor (exit

shaft). The lift pin could be in the hole

of the gear motor slow shaft but it

should be deformed or broken (see pic

.a)

In the second case, the hole in the

gear motor should be completely

empty and some remnants of the split

pin will certainly lie in the machine.

It is therefore necessary to install a

new split pin.

Place the transmission shaft so as its

hole is aligned with the one present on

the gear motor exit shaft; it should be

evident when they are aligned;

Insert the split pin as shown in the pic.

c;

verify that the head of the split pin, in

its rotation, does not touch the gear

motor and respects a minimum

distance.

Warning: do not reuse, in any case,

the old split pin

With the help of a pliers, fold the two

ends of the split pin downward as

indicated by the arrows in the pic. d;

Then, with nippers, cut the extremities

in excess in order to avoid a contact

with the gear motor during the rotation

(see pic. e).

- 15 -

ENGLISH

.

).

a)

.

a.

;

. c;

a.

a

. d;

a

a

. e).

- 16 -

ENGLISH

First Class Problem Solving

The electronic board displays "1

blinking"

Verifythat the cable connecting the electronic board to the gear motor magnetic revolution counter is

firmlyfixed to both elements. In case it needs to be substituted: disconnect the two connectors of the

old cable both from the reader and the electronic board; place the new cable with some insulating tape

or a small band on the existent electric installation.

Disconnect

the power electric cable

The electronic board displays "2

blinking"

Replace the cable that connects the thermostat probe to the electronic board verifying that there is not

oxide on it; if so, clean the contacts and if the problem still exists, it is necessary to substitute the

thermostat probe.

Disconnect

the power electric cable

The electronic board displays "8

blinking"

The electric power is not linear; there could a fluctuation of the entry tension due to tension changes, to

extensions or to multiple plugs to which First Class is connected. If the power tension is regular,

provide First Class with a single connection in order to solve the problem; if First Class in connected to

an autofill system, it is necessary to switch off and on First Class in order to make it work correctly

again.

Disconnect

the power electric cable

The tank does not make cold, the

cooling light is off

1. Switch off the slush machine with the main switch;

2. discharge the product, if it is cold, and put in the tank a product with a temperature higher than

15°C;

3. wait 5 minutes at least and switch on the machine again.

The electronics calibration is automatic.

The augers do not turn in the tank

and the electronic board does not

work properly.

The cotter pin (item 35 of the exploded view in appendix-23) broke down. For the cotter pin substitution

procedure see pag.14

Disconnect

the power electric cable

During the augers rotation you

can hear a creaking.

This noise derives from the vertical and horizontal augers gears. You can avoid this by simply go on

using the machine or putting some Vaseline on the plastic gears.

The machine does not make cold

and the slush and the pressure

switch light is ON.

The pressure switch intervened. In order to refit it see pag.13

Disconnect

the power electric cable

The MILLENNIUM electronic

board blinks. If you press the

MENU button for a second, it

ALARM THERMAL

Replace the cable that connects the thermostat probe to the electronic board verifying that there is not

oxide on it; if so, clean the contacts and if the problem still exists, it is necessary to substitute the

thermostat probe.

Disconnect

the power electric cable

The MILLENNIUM electronic

board blinks. If you press the

MENU button for a second, it

displays : "ALARM MOTOR"

Verifythat the cable connecting the electronic board to the gear motor magnetic revolution counter is

firmlyfixed to both elements. In case it needs to be substituted: disconnect the two connectors of the

old cable both from the reader and the electronic board; place the new cable with some insulating tape

or a small band on the existent electric installation.

Disconnect

the power electric cable

The MILLENNIUM electronic

board blinks. If you press the

MENU button for a second, it

displays : "ALARM VOLTAGE

The electric power is not linear; there could a fluctuation of the entry tension due to tension changes, to

extensions or to multiple plugs to which First Class is connected. If the power tension is regular,

provide First Class with a single connection in order to solve the problem; if First Class in connected to

an autofill system, it is necessaryto switch off and on First Class in order to make it work correctly

again.

Disconnect

the power electric cable

The MILLENNIUM electronic

board blinks. If you press the

MENU button for a second, it

displays : "ALARM LEVEL

Level probe (item 15 of the exploded view in appendix-23) missing or cover contact/level

probe/terminal board (item 37 of the exploded view in appendix-23) not correct.

Disconnect

the power electric cable

The MILLENNIUM electronic

board blinks. If you press the

MENU button for a second, it

displays : "ALARM REFILL

You can see this alarm only if the REFILL screen is ON. The alarm appear when the level probe does

not read the presence of the liquid in the tank, for longer than 2 minutes. In order to reset the alarm and

let the level control restart, switch off and on the electronic board with the button.

Disconnect

the power electric cable

The MILLENNIUM electronic

board blinks. If you press the

MENU button for a second, it

displays : "ALARM DATE

This alarm appear if the electronic board finds a problem on the date setting. In order to adjust the date

you need to use the programmer module.

NOTE. First Class Millennium Basic does not have this alarm.

Disconnect

the power electric cable

The MILLENNIUM electronic

board blinks. If you press the

MENU button for a second, it

displays: "ALARM SOLVED"

This window will show up when one or more alarms will be solved.

Disconnect

the power electric cable

- 17 -

ENGLISH

First Class Problem Solving

"

a

.

"

.

"

a

a autofill

.

e

1 2

aa°C3

.

.

.

a.

.

.

"

.

"

a

.

"

a

a autofill

.

"

.

"

. .

"

a

.

.

"

.

- 18 -

DICHIARAZIONE DI CONFORMITÀ

DECLARATION OF CONFORMITY

In accordo con la Direttiva Bassa Tensione 73/23 CEE, con la Direttiva 2004/108 CE (Direttiva EMC) e successivi emendamenti

integrate dalla marcatura Ce secondo la Direttiva 93/68 CEE.

According to the Low Voltage Directive 73/23/EEC, 2004/108 Direcive (EMC Directive) and subsequent amendments and

amended by the CE-marking Directive 93/68/EEC.

Tipo di apparecchio - Type of equipment: GRANITORE

Marchio Commerciale - Trademark ELMECO

Modello - Type designation FIRST CLASS 1 –FIRST CLASS 2 –FIRST CLASS 3

Costruttore - Manufacturer ELMECO

Indirizzo - Address VIA CIRCUMVALLAZIONE ESTERNA N. 12 80025 CASANDRINO (NA)

Telefono n° - Telephone no. 0039/081/5055724 - 5057068 - 5054028

Telefax n° - Telefax no. 0039/081/5055726

Le norme armonizzate o le specifiche tecniche (designazioni) che sono state applicate in accordo con le regole della buona arte in

materia di sicurezza in vigore nella CEE sono :

The following harmonized standards or technical specifications (designations) which comply with good engineering practice in

safety matters in force within the EEC have been applied :

Norme o altri documenti normativi Rapporto di collaudo-Schede Tecniche

standards or other normative documents Test report - Technical file

- EN 60335-1:2002 + A11:2004 + A1:2004 +A12:2006 +A2:2006 + A1/EC:2007 + A13:2008 + EC:2009 + EC:2010 +A14:2010

(Only cl. 19.11.4)

- EN 62233:2008

- EN 60335-2-24

- EN 55014-1:2006 + A1:2009

- EN 55014-2:1997 + A1:2001 +A2:2008

- EN 61000-3-2:2006 + A1:2009 + A2:2009

- EN 61000-3-3:2008

- EN 61000-3-11:2000

Informazioni ulteriori

Additional information

della CEE, si dichiara sotto la propria

responsabilità che gli apparecchi sono conformi alle esigenza essenziali previste dalle Direttive su menzionate.

As the manufacturer’s authorized established within ECC, We declare under out sole responsibility that the equipment follows the

provisions of the directive states above.

Data e luogo di emissione Nome e firma di persona autorizzata

Date and place of issue

NAPOLI

NAPLES

RUMOROSITÀ - NOISINESS - GERAUSCHPEGEL - BRUIT - RUIDOSO

Modello - Model - Muster - Modèle - Muestra

FC1

60.5 DB FC2

63.5 DB FC3

64 DB

Other manuals for FC1

3

This manual suits for next models

2

Table of contents

Other ELME Beverage Dispenser manuals

Popular Beverage Dispenser manuals by other brands

Perlick

Perlick HP15TS-3 A Series installation manual

Hoshizaki

Hoshizaki Lancer Mini Lady Installation, operation & service manual

Flavor Burst

Flavor Burst TS 80SS manual

Bartscher

Bartscher GE 21 instruction manual

Vinotemp

Vinotemp VT-WINED RAW4 owner's manual

FBD

FBD 77 Series Installation and operation manual