ELMON 41-822 User manual

ELMON rail 41-822 ELMON rail 41-322

Safety relais

Operang Manual (see last page for validity)

ELMON rail 41-822 / ELMON rail 41-322 Safety Relais

English

Page 03-14

U.S. Edion 2017

© ASO GmbH

Übergabedokumenta on / Documenta on / Documenta on de

data on / Documentazione di consegna / Documenta e

Anlagenbeschreibung / Descrip on / Descrip on du système / Descrizione impianto / Beschrijving van de

installa e

Anlagenart / Type of plant / Sorte du système / Tipo d’impianto / Type installa e

Hersteller / Manufacturer / Fabricant / Produ ore / Fabrikant

Seriennummer / Serial number / Numéro de série / Numero di serie / Seriennummer

Datum der Inbetriebnahme / Commissioning date / Date de mise en marche / Data della messa in funzione /

Datum van de ingebruikname

Aufstellort / Site of installa on / Lieu de montage / Luogo d’installazione / Opstellingsplaats

Verwendete Steuerung / Control unit / Commande u lisée / Centralina di comando ado ata /

Gebruikte besturing

Zusatzkomponenten / Addi onal components / Composants supplémentaires / Componen ausiliari /

Bijkomende componenten

Funk onsprüfung / Func onal test / Contrôle de fonc on / Controllo funzionale / Func econtrole

Sicherheitssensoren reagieren auf Betä gung / Safety sensor response to actua on /

Le senseur de sécurité réagit à l’ac onnement / Il sensore di sicurezza reagisce all’azionamento /

Veiligheidssensor reageert op ac vering

Sicherheitssensoren reagieren auf Zuleitungsunterbrechung / Safety sensor response to supply

line interrup on / Le senseur de sécurité réagit à l’interrup on de l’alimenta on / Il sensore di

sicurezza reagisce all’interruzione di collegamento / Veiligheidssensor reageert op onderbreking

van de toevoerleiding

ok

Name der ausführenden Firma / Owner / Nom de la société exécutrice / Nome della di a esecutrice /

Naam van de uitvoerende fi rma

Name des Installateurs / Installer / Nom de l’installateur / Nome dell’installatore / Naam van de installateur

Datum / Date / Date / Data /

Datum Unterschri / Signature / Signature / Firma /

Handtekening

ok

ELMON rail 41-822 / ELMON rail 41-322

Safety relais

3

1. Table of Contents

1. Table of Contents . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2. General safety regulaons and protecon measures . . . . . . . 4

3. General and funcon descripon . . . . . . . . . . . . . . . . . . 5

4. Intended use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

5. Applicaon example. . . . . . . . . . . . . . . . . . . . . . . . . . 6

6. Device overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

6.1 Versions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

6.2 Signal indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

6.3 Connecon terminals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

6.4 DIP switch for conguring the operang mode . . . . . . . . . . . . . . . . . 8

7. Operang modes . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

7.1 Safety output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

7.2 Automac reset . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

7.3 Fault self-retaining – manual reset . . . . . . . . . . . . . . . . . . . . . . . . 8

7.4 Signaling output without any delay (RLU) . . . . . . . . . . . . . . . . . . . . 8

7.5 Signaling output delayed (RL) . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

8. Mechanical mounng . . . . . . . . . . . . . . . . . . . . . . . . . 9

9. Electrical connecon . . . . . . . . . . . . . . . . . . . . . . . . . 9

9.1 Supply voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

9.2 Connecon of sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

9.3 Connecon of mulple sensors per sensor circuit. . . . . . . . . . . . . . . . 9

9.4 Connecon of control circuits . . . . . . . . . . . . . . . . . . . . . . . . . . 10

9.5 Connecon Reset. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

9.6 Connecon of signaling contact. . . . . . . . . . . . . . . . . . . . . . . . . 10

10. Commissioning and funcon tesng . . . . . . . . . . . . . . . . .11

11. Fault diagnosis . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

12. Decommissioning and disposal. . . . . . . . . . . . . . . . . . . .11

13. Technical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

14. Warnings and Disclaimers. . . . . . . . . . . . . . . . . . . . . . .13

15. EC Declaraon of Conformity . . . . . . . . . . . . . . . . . . . . .14

4

Safety relais

2. General safety regulaons and protecon measures

• The manufacturer and user of the system/machine on which the protection system is used are

responsible for coordinang and adhering to all applicable safety rules and regulaons under their own

responsibility.

• The protecon system guarantees funconal safety in combinaon with the superordinate control

system, but not the safety of the enre system/machine. Thus, a safety review of the enre system/

machine in accordance with machine direcve 2006/42/EC or relevant product standards is necessary

prior to use of the device.

• The operang instrucons must be permanently available at the operang locaon of the protecon

device. They must be thoroughly read and applied by every person who is tasked with the operaon,

maintenance or repair of the protecon device.

• The installaon and start-up of the protecon device may only be conducted by specialized personnel

who are familiar with these operang instrucons and the applicable regulaons on job safety and

accident prevenon. The instrucons in these operang instrucons must be followed and adhered to

uncondionally.

• Electrical work must only be carried out by skilled electricians. Safety regulaons for electrical engineering

and from the professional associaon must be followed.

• In case work has to be carried out on the switching device, it must be switched to a voltage-free posion

and checked for freedom from any voltage and secured against being switched back on again.

• If the potenal-free connecons of the safety switching contacts are supplied with a hazardous voltage

from an external source, it must be ensured that these are also switched o when working on the

switching device.

• The switching device does not contain any components that the user must service. Any warranty or

liability on the part of the manufacturer is forfeited in the event of any unauthorized modicaons or

repairs to the switching device.

• Auxiliary outputs must not execute any safety-orientated funcons. They are not fail-safe and are not

checked either by tesng.

The system must be checked for correct funcon in suitable intervals by qualied persons for

the standard-conform design of the safety system. The check must be documented in a way that

allows it to be traced at any me.

In the case of non-compliance or deliberate abuse, the manufacturer’s liability will cease.

!

ELMON rail 41-822 / ELMON rail 41-322

Safety relais

5

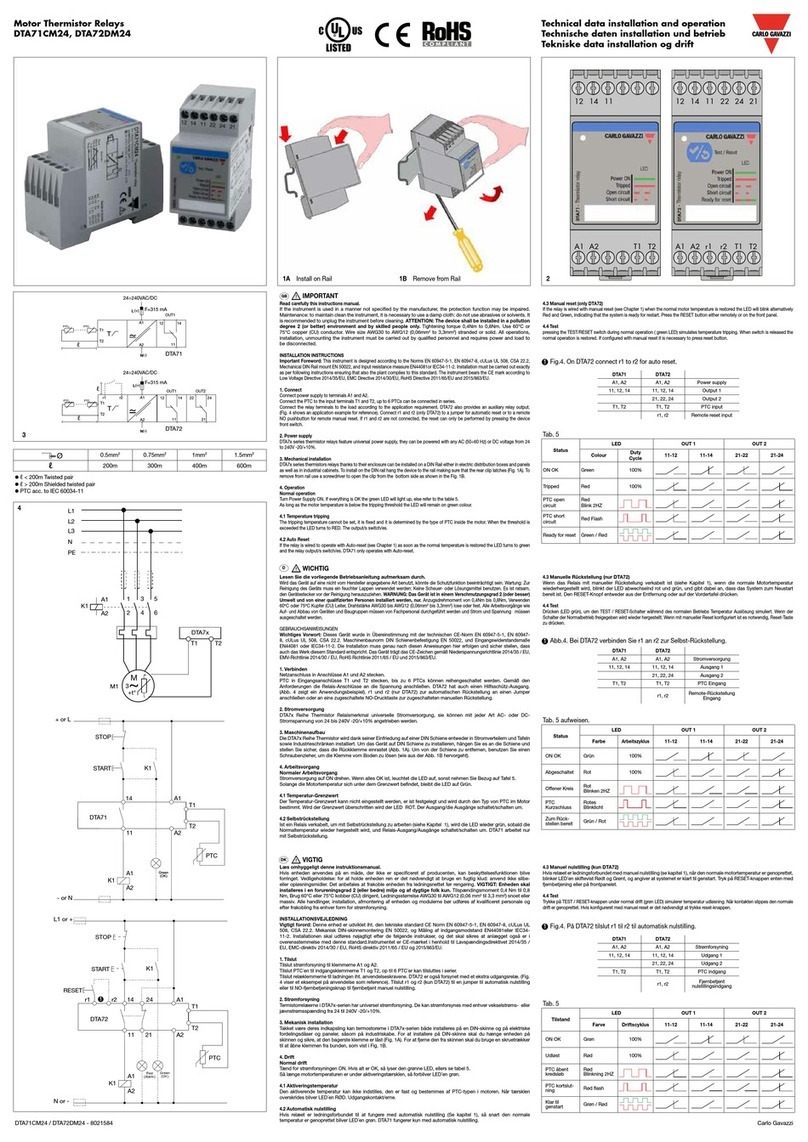

3. General and funcon descripon

The ELMON rail 41-822 (ELMON rail 41-322) switching device is used to evaluate sensors such as safety

contact mats, safety contact edges and safety bumpers for securing crush and shear locaons.

An ASO sensor can be connected to the switching device. The steady-state current monitoring of the sensor

is made possible by an integrated terminang resistor in the sensor.

Furthermore, the device can also evaluate a sensor in four-wire technology.

If the desired steady-state current ows, the safety relays are driven and the switching contacts closed. If

the sensor is operated or the sensor circuit is interrupted, the relay switching contacts open.

A signal output with potenal-free switching contacts is available. An operaon of the sensor causes a

reacon of the signal output in accordance with the DIP switch conguraon. The signal output must not

execute any safety-orientated funcons. It is not fail-safe and not checked by tesng either.

The switching device has been designed and type-approved in accordance with EN ISO 13849-1 “Safety-

related parts of control systems” for category 3 Performance Level e. For compliance with category 3, the

safety output is set up redundantly with two independent switching elements.

In addion the device has been type-approved according to EN 62061 “Funconal safety of safety-related

electrical, electronic and programmable electronic control systems“ and can meet a safety funcon up to

SIL 3.

The monitoring state of the sensor and the applied operang voltage are indicated by LED.

If there is a fault alarm, all safety outputs are inacve.

Installaon and electrical work must be performed by authorized electricians.

The unit can be used in a household environment as well as an industrial environment up to

an altude of 2000m above mean sea level. The unit must not be operated in areas with major

temperature changes.

!

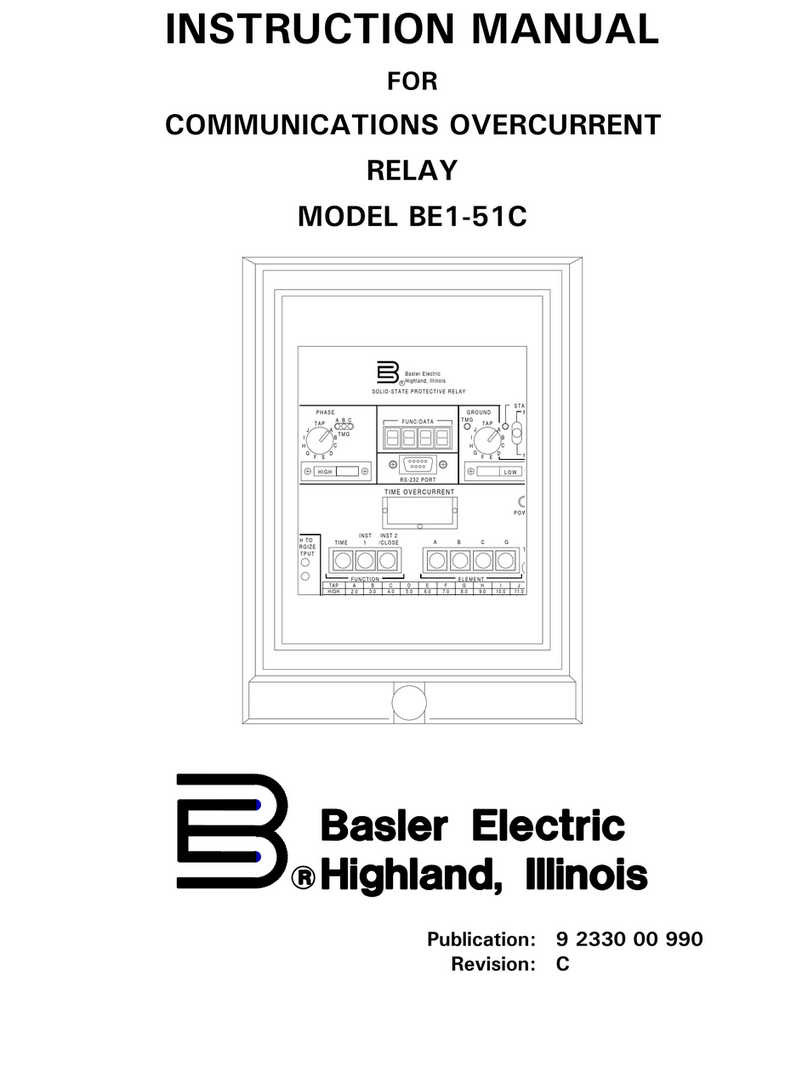

Funconal circuit diagram

Logic

Mode

Reset

R

+U2 AUX1

OUT

REL1

OUT

Reset

Manual Z1

Z2

X1

X2

X3

X4

SIG

A1

A2

B1

B2

31

32

13

14

23

24

24V AC/DC

REL2

OUT

ELMON rail 41-322: 230 V AC

(ELMON rail 41-822: 120 V AC)

6

Safety relais

4. Intended use

The switching device can only fulll its safety-relevant task, if it is used as intended within specicaons.

The intended use of the switching device is the use as a protecon system in connecon with safety contact

mats, safety bumpers and safety contact edges with 8.2 kΩ resistance for steady-state current monitoring.

It is not allowed to use the safety relay in heights over 2000 m above sea level or potenally explosive

atmospheres.

A dierent use or any use going beyond the intended use is not within specicaons. The manufacturer

does not accept any liability for any damage arising from use not within specicaons.

Any use for special applicaons requires prior release by the manufacturer.

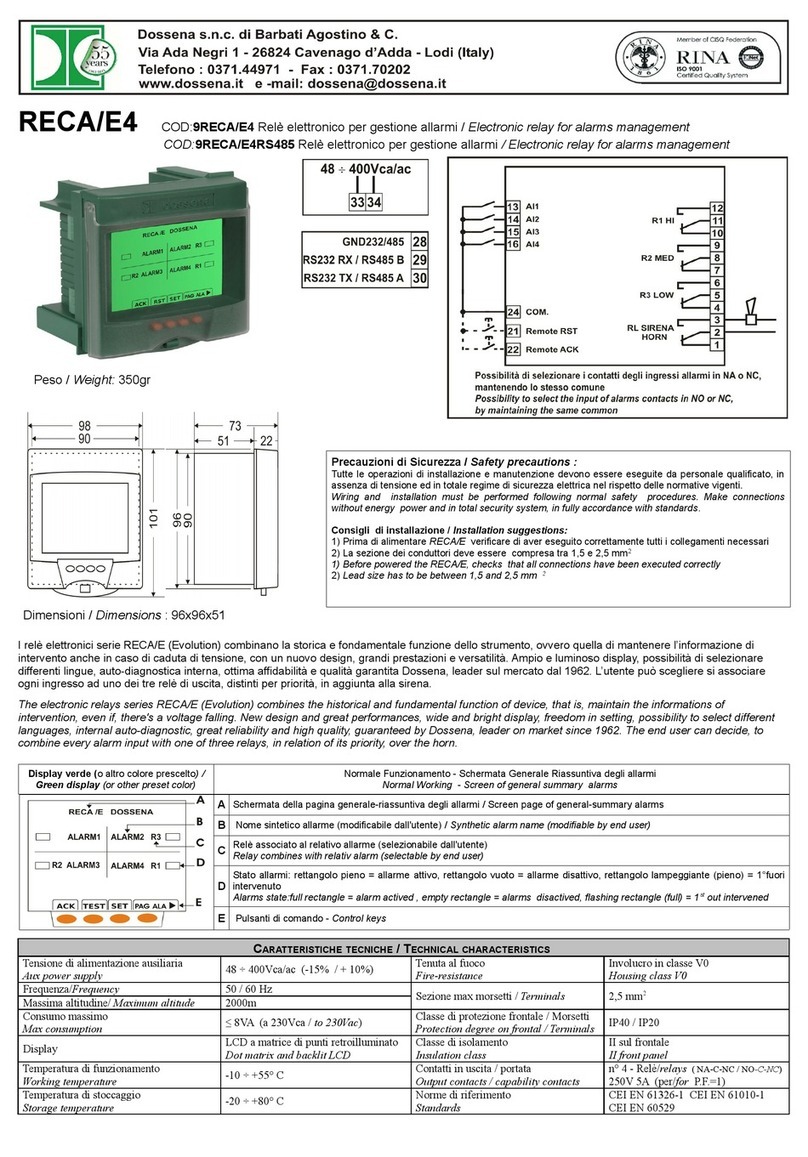

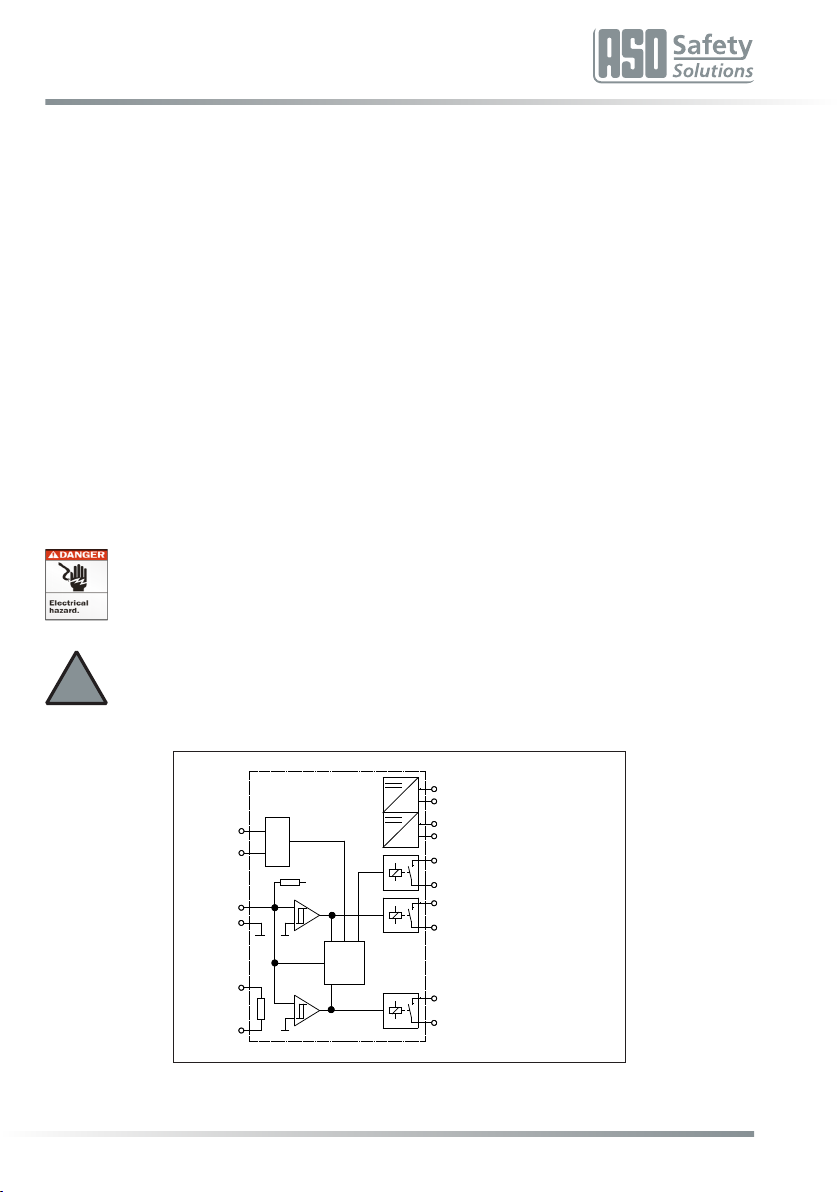

5. Applicaon example

Safety-orientated monitoring of a safety contact edge with start release via release pushbuon and separate

connuaon of the control circuits (category 3 compliant applicaon according to EN ISO 13849-1).

In order to check the funconality of the load breaking K1 and K2 relays the break contacts of these contactors

are integrated into the start circuit (Z1 Z2).

The signaling relay output is used to visualize the switching state of the safety contact strip.

Circuit diagram in voltage-free state. Sensor not operated.

1 Sensor (edge, mat or bumper)

2 Release key

+24V

M

13

14

K2

23

24

33

34

L1 L2 L3

31

8,2 ΚΩ

14

K1

24 34

13 23 33

2313X2X1B1 X4X3

S1

322414B2 Z2Z1

41

41

42

42

K2

K1 X1

Reset

0V

5.1 2-Wire Single Applicaon Example

ELMON rail 41-822 / ELMON rail 41-322

Safety relais

7

5.2 4-Wire Single Applicaon Example

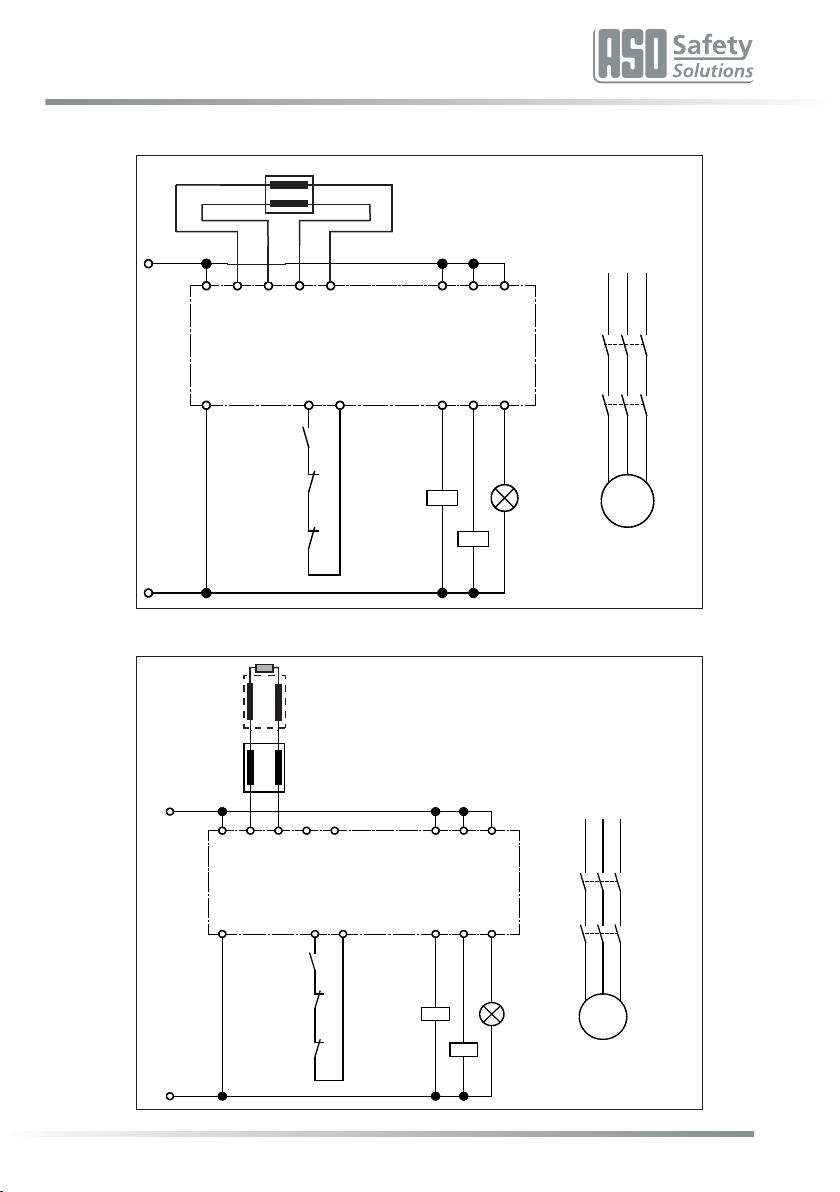

5.3 2-Wire Mulple Applicaon Example

+24V

M

13

14

K2

23

24

33

34

L1 L2 L3

31

8,2 ΚΩ

14

K1

24 34

13 23 33

2313X2X1B1 X4X3

S1

322414B2 Z2Z1

41

41

42

42

K2

K1 X1

Reset

0V

S1

S“n“

8k2 Ω

+24V

M

13

14

K2

23

24

33

34

L1 L2 L3

31

8,2 ΚΩ

14

K1

24 34

13 23 33

2313X2X1B1 X4X3

S1

322414B2 Z2Z1

41

41

42

42

K2

K1 X1

Reset

0V

8

Safety relais

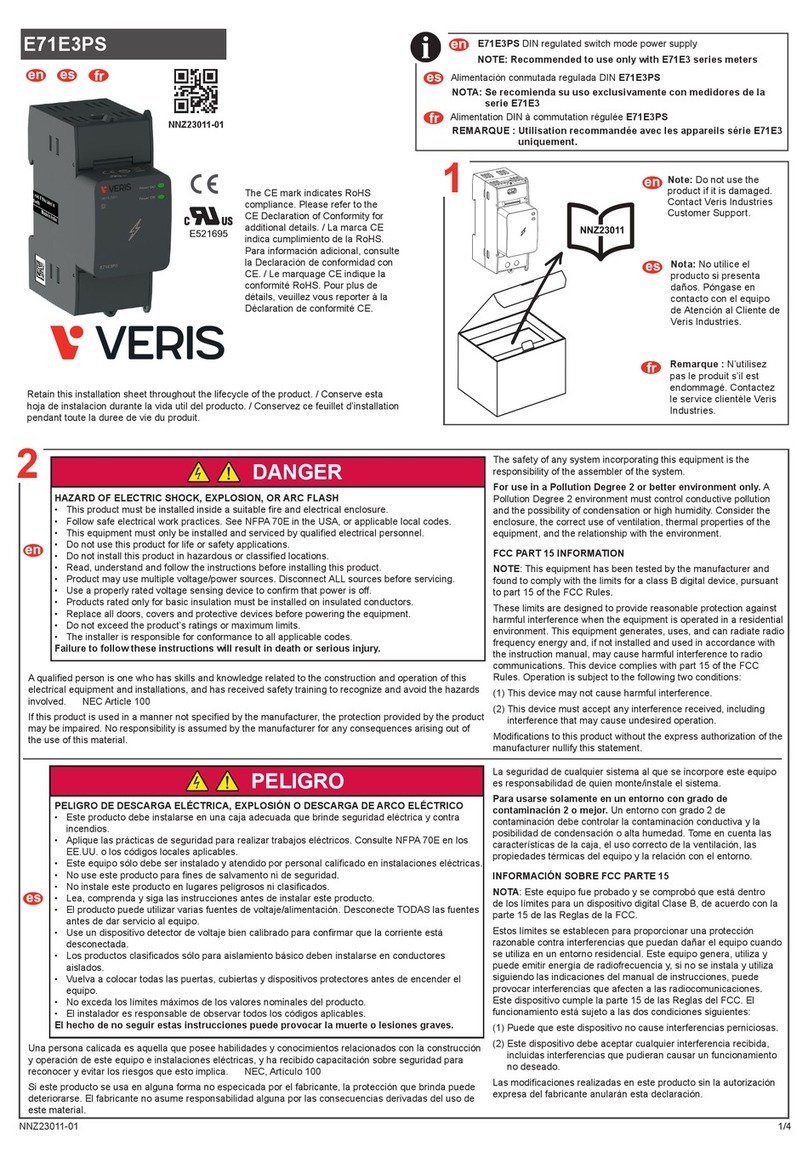

5.4 4-Wire Mulple Applicaon Example

+24V

M

13

14

K2

23

24

33

34

L1 L2 L3

31

8,2 ΚΩ

14

K1

24 34

13 23 33

2313X2X1B1 X4X3

S1

322414B2 Z2Z1

41

41

42

42

K2

K1 X1

Reset

0V

S1 S“n“

ELMON rail 41-822 / ELMON rail 41-322

Safety relais

9

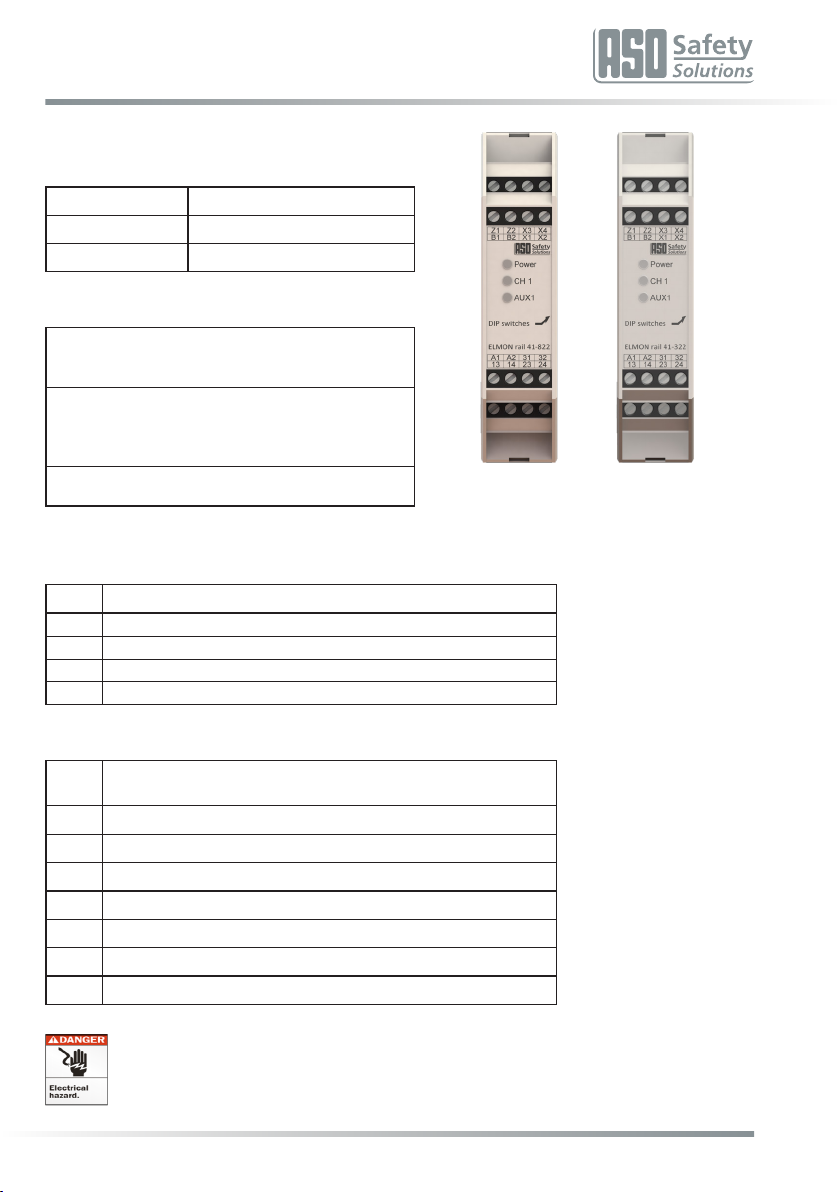

6. Device overview

6.1 Versions

Version Supply voltage

ELMON rail 41-822 120 V 50/60 Hz and 24V AC/DC

ELMON rail 41-322 230 V 50/60 Hz and 24V AC/DC

6.2 Signal indicators

LED Power (green)

Operang state (on)

Fault alarm (pulse)

LED CH 1 (red)

Sensor operated (on)

Sensor power circuit interrupted (fast ashing)

Fault self-retaining (slow ashing)

LED AUX 1 (yellow)

Signal output switched

If there is no fault alarm, then the operang state is shown via the Power LED (on). When a fault alarm is issued,

the number of pulses output indicates the fault:

Pulse Fault alarm

1Voltage supply outside the valid value range

2Fault when tesng signal input

3Output control relay faulty

4Data transmission between micro-controllers faulty

6.3 Connecon terminals

A1 A2 ELMON rail 41-822: Supply voltage 120 V 50/60 Hz

ELMON rail 41-322: Supply voltage 230 V 50/60 Hz

B1 B2 Supply voltage 24 V AC/DC

X1 X2 Connecon sensor

X3 X4 Internal terminang resistor

13 14 Switching contact safety relay 1

23 24 Switching contact safety relay 2

31 32 Switching contact signal relay

Z1 Z2 Connecon manual reset /re-start (key NO; oponal)

Installaon and electrical work must be performed by authorized electricians.

Wrong installaon can cause hazardous condions.

ELMON rail 41-822 ELMON rail 41-322

10

Safety relais

6.4 DIP switch for conguring the operang mode

S1

„ON“: Automac reset

„OFF“: Fault self-retaining – manual reset (factory seng)

S2

„ON“: AUX1 Mode signal output: RLU

„OFF“: AUX1 Mode signal output: RL (factory seng)

7. Operang modes

7.1 Safety output

Separate or series-connected output of the control circuits (redundant connuaon of the switching contacts).

In order to use the two safety relays separately, the bridge between 14 and 23 must be removed.

7.2 Automac reset

(S1 = „ON“)

Aer removing a fault in a sensor circuit or aer a voltage failure, the switching unit will automacally release

output again.

Aenon: Automac restart of mashine! If this seng is used, it has to be ensured that no one

is able to be in the dangerous zone to avoid hazardous situaons. The integrator or operator is

responsible for the correct sengs of the controller. In no case the manufacturer is liable for

incorrect sengs or missuse.

7.3 Fault self-retaining – manual reset

(S1 = „OFF“)

Following removal a fault of in a sensor circuit, or aer a voltage failure, the switching unit will only release

the output(s) again, if the Z1 and Z2 contacts, 500 ms aer the eliminaon of the disrupon, are closed by

means of a pushbuon. This completely prevents any automac re-start. A permanent bridging of the Z1 and

Z2 contacts does not cause an automac reset.

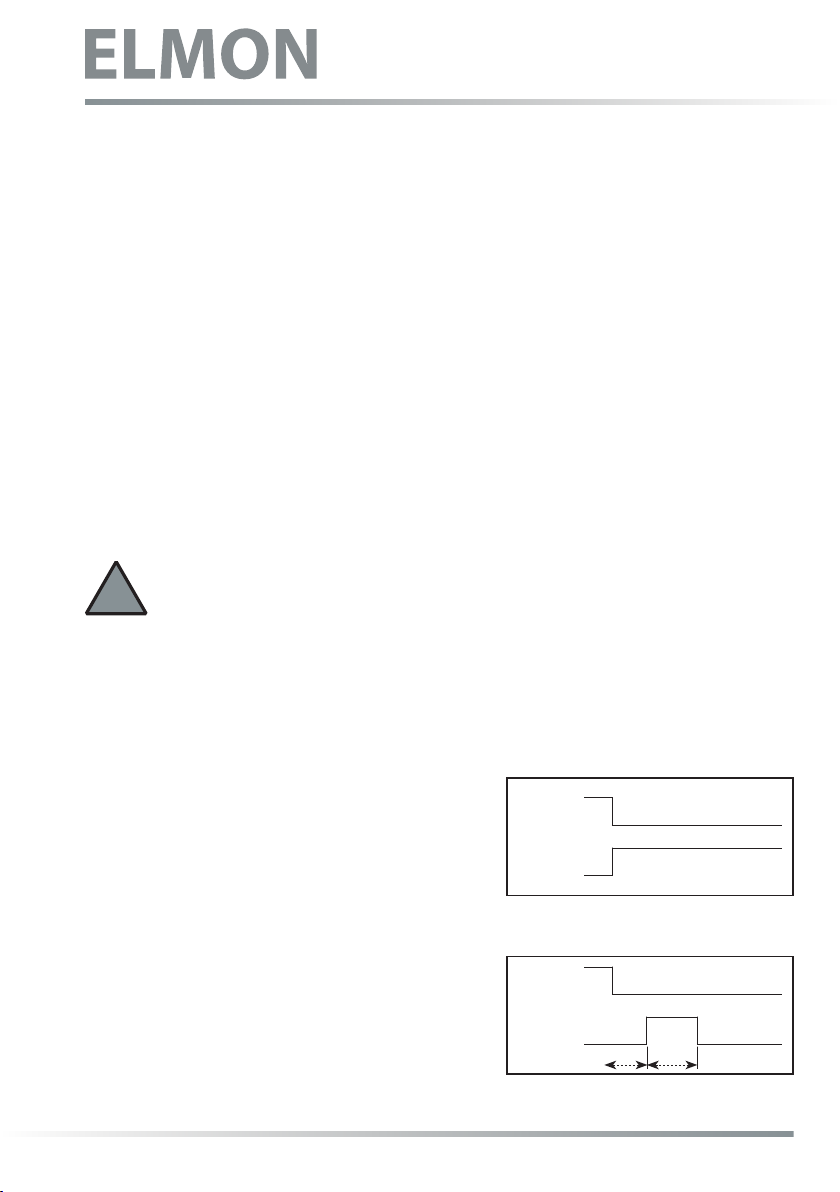

7.4 Signaling output without any delay (RLU)

(S2 = „ON“)

In this mode of operation the corresponding signaling

output is acvated without delay, if any fault is signaled on

the corresponding channel. The output is always inacve

in the de-energized state of the switching device.

7.5 Signaling output delayed (RL)

(S2 = „OFF“)

In this operang mode the corresponding signaling output

is acvated with a delay of 0.5 seconds and then remains

acve for a maximum of 3 seconds, if a fault is signaled.

!

Output

Aux. Relay

Output

Aux. Relay

3s

0,5s

Safety output (symbolic)

Signaling output (symbolic)

Safety output (symbolic)

Signaling output (symbolic)

ELMON rail 41-822 / ELMON rail 41-322

Safety relais

11

8. Mechanical mounng

The switching unit must be mounted correctly:

• In a dust-protected and moisture-protected switch cabinet or casing.

• For use in an environment with level 2 contaminaon.

• With a protecon type of at least IP54.

• On a 35 mm DIN support rail according to EN 50 022.

The switching unit can be installed in any posion.

The unit must not be operated in areas with major temperature changes.

9. Electrical connecon

Installaon and electrical work must be performed by authorized electricians.

The switching unit can be destroyed by connecon to the incorrect terminals.

Lines that are routed in the open air or outside the switch cabinet must be protected accordingly.

The limit values stated in the “Technical Data” for the supply voltage and the switching capability

of the relay must be observed.

9.1 Supply voltage

The supply voltage can oponally be eected by means of a mains voltage of 120 V AC 50/60 Hz

(ELMON rail 41-322: 230 V AC 50/60Hz) or a low voltage of 24 V AC/DC. For a supply with 24 V

AC/DC the voltage must correspond to the requirements for protecve low voltages (SELV). The

supply line to the switching device must be protected by means of a 5x20 glass tube fuse 200mA

medium me lag.

Never apply both voltages simultaneously!

The 120 V (230 V) supply voltage must be applied to the A1 and A2 terminals. For operaon with 24 V, the

supply voltage must be applied to the B1 and B2 terminals.

For a xed installaon a separang device must be available (for example, a main switch for the system). A

mains plug is sucient as a separang device, if it is freely accessible.

9.2 Connecon of sensor

The sensor with a terminang resistor of 8.2 kΩ must be connected to the X1 and X2 terminals.

The sensor without a terminang resistor is connected to the X1 and X2 terminals by means of one lead and

with the other lead to the X3 and X4 terminals.

9.3 Connecon of several sensors per sensor circuit

ASO-Sensors must not be connected in parallel.

One or several sensors can be connected to the signal transmier input. For this purpose, the individual

sensors are connected in series in accordance with Figure 1.

!

!

!

!

To avoid the risk of crushing, Safety gloves must be worn!

Installaon and electrical work must be performed by authorized

electricians.

12

Safety relais

Safety contact edge SENTIR edge:

A maximum of 5 SENTIR edge devices can be connected in series. The maximum total length of the SENTIR

edge must not exceed 100 m.

The length of a SENTIR edge can be up to 25 m.

The total line length of the series-connected SENTIR edge must not exceed 25 m.

Safety contact bumper SENTIR bumper:

A maximum of 5 SENTIR bumper devices can be connected in series. The maximum total length of the SENTIR

bumpers must not exceed 15 m.

The length of a SENTIR bumper may be up to 3 m.

The total line length of the series-connected SENTIR bumpers must not exceed 25 m.

Safety contact mat SENTIR mat:

A maximum of 10 SENTIR mats can be connected in series. The maximum total surface area must not exceed

10 m2.

The size of a SENTIR mat can be up to 1350 x 2350 mm.

The total line length of the series-connected SENTIR mat must not exceed 25 m.

Before connecng the series-connected sensors, it is recommended to measure the resistance value of the

wiring. In the case of non-operated sensors the resistance must be 8.2 kΩ ± 500 Ω. If the sensor is operated,

the resistance must not exceed 500 Ω.

9.4 Connecon of control circuits

Connect the control circuit to be monitored to the 13 and 24 terminals. If the switching contacts are redundantly

connued, the factory-inserted bridge between the 14 and 23 terminals must be removed.

In the event of any redundant use of the switching contacts only voltages with the same potenal

may be connected. The use of dierent voltage potenals does not correspond to any intended

use within specicaons.

Depending on the nominal current, the control circuits are to be protected by a corresponding

fuse, or the nominal current on the control circuits must be limited to the maximum value by

means of other measures.

9.5 Connecon Reset

For the operang mode “manual reset” the necessary reset switch must be connected to the Z1 and Z2

terminals.

9.6 Connecon of signaling contact

The 31 and 32 signaling contact only serves as an auxiliary contact (signaling, display etc.) and must not be

integrated into the safety circuit.

The signaling contact may only switch extra low voltages (24V). The switching of low voltages

120 V (230V) is not permissible.

Installaon and electrical work must be performed by authorized electricians.

Wrong installaoncan cause hazardous condions.

The manufacturers liability will erase in any case of non-compliant or deliberate abuse.

Fig. 1: Interconnecng several sensors, here using the example of the safety contact edge

Sensor 1 Sensor 2 Sensor „n“

O

C

2

222

!

!

ELMON rail 41-822 / ELMON rail 41-322

Safety relais

13

10. Commissioning and funcon tesng

Following a corresponding connecon of all electrical connecons and switching on the supply voltage, the

system / machine must be checked for correct funconality.

Aer successful commissioning the 13 and 24 safety output is driven (relay contact “closed“). An operaon

of the sensor causes an opening of the 13 and 24 relay contact.

The signaling relay (31 32 connecon) switches in accordance with the present DIP switch posion. This is

indicated by means of the yellow AUX1 LED.

The safety system must be inspected by competent specialists at suitable intervals. The check must be

documented in a way that allows it to be traced at any me. The requirements of the system / machine

manufacturer are to be taken into account and observed.

Commissioning and funconal tesng, must be performed by authorized and professional trained sta.

11. Fault diagnosis

If the supply voltage is correctly wired and applied, only the green Power LED may be lit up. If the red LED

illuminates, there is a fault in the system which can be delimited by means of the LED.

LED Fault Fault removal

green Power LED

does not light up

Supply voltage is missing,

too low or

incorrectly connected.

Check connecons and supply voltage:

- 230 V AC (or 120 V) at terminals A1 A2 or

- 24 V AC/DC at terminals B1 B2

Tolerance range: ±10%

green Power LED

ashes cyclically

(pulse output)

Internal fault is indicated

by the number of pulses. See -> signal displays

red CH1 LED

lights up

The corresponding sensor

is recognized

as being operated.

- Check the connecons of the corresponding sensors

(squeezed or brile supply lines, etc.)

- Check signal sensor *

red CH1 LED

fast ashing

Sensor circuit interrupted,

sensor not connected,

defecvely connected or

defecve.

- Check the connecons of the corresponding sensors

(squeezed or brile supply lines, etc.)

- Check signal sensor *

red CH1 LED

slow ashing Fault self-retaining Carry out manual reset

* If the fault is not found in the wiring, the funcon of the electronic system can be checked by applying

a resistance of 8.2 kΩ to the sensor-input on the switching device. Subsequently, if the electronics work

perfectly, the sensor must be checked by means of an ohmmeter. For this purpose, the connecon of

the sensor to the switching device must be separated and connected by means of an ohmmeter. In the

case of a non-operated sensor the resistance must be 8.2 kΩ ± 500 Ω. If the sensor is operated, the

resistance must not exceed 500 Ω.

12. Decommissioning and disposal

The products manufactured by ASO are exclusively intended for commercial use (B2B). At the end of use, the

products must be disposed of according to all local, regional and naonal regulaons. ASO is also happy to

take back the products and disposes of them properly.

14

Safety relais

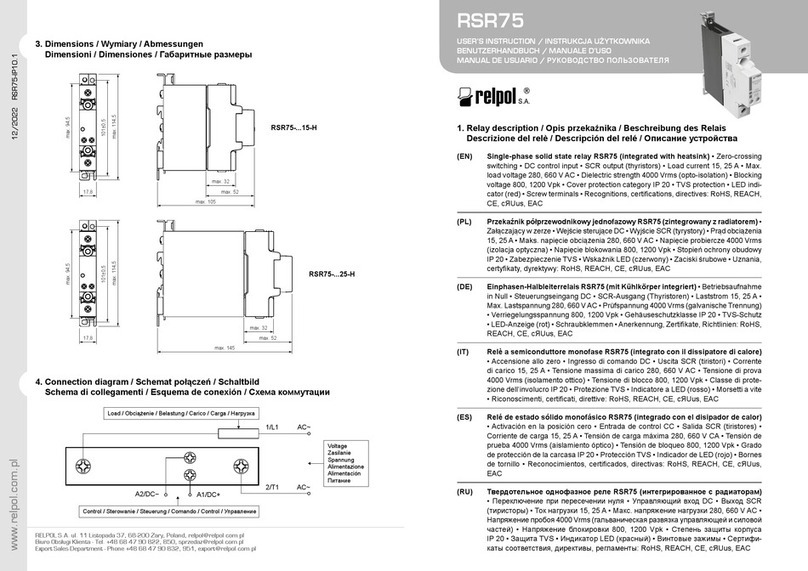

13. Technical data

Mains voltage UNetz ELMON rail 41-822: 120 V AC ± 10% 50/60 Hz

ELMON rail 41-322: 230 V AC ± 10% 50/60 Hz

Low voltage UE24 V AC/DC ±10%

Power

consumpon

PNetz_

max

3,5 VA 230 V AC

3,8 VA 120V AC 50Hz / 3,5VA 120V AC 60Hz

PE_max 1,5 W 24 V DC

PE_max 1,2 VA 24 V AC

Fuse Mains voltage

(external) 200 mA middle me-lag fuse (glass tube 5x20)

Fuse Low voltage

(external) 200 mA middle me-lag fuse (glass tube 5x20)

Nominal value RNom = 8,2 kΩ

upper switching value RAO > 12,0 kΩ

lower switching value RAU < 5,0 kΩ

Supply voltage Terminang resistor – sensor

Nominal current DC 1 A (24 V DC)

Nominal current AC 1 A (230 V AC)

Mechanical service life >106 operaons

Switch-o delay

(reacon me) < 11 ms

Switch-on delay ≤ 550 ms (Power on < 850 ms)

Ulizaon category AC-15 (230V AC; 1A; 800000 Op.)

DC-13 (24V DC; 1A; 950000 Op.)

Protecon 1A middle me-lag fuse (glass

tube 5x20)

Safety relay

Max. switching current 2 A (24 V AC/DC)

Mechanical service life > 106 operaons

Operang mode RL:

Switch-on delay 0,5 Sek.

Operang mode RL:

Switch-on duraon 3 sec.

Signal relay

Housing Polyamide PA 6.6

Self-exnguishing according to UL 94-V2

Dimensions (HxWxD) 99 x 22,5 x 114 mm

Protecon type IP20

Protecon class II (protecve insulaon)

Polluon Degree 2

Overvoltage category III

Rated insulaon voltage 250 V

Rated impulse voltage resistance 4,00 kV

Weight 210 g

Temperature range single mounng -20 °C to +55 °C

Temperature range mounng in row max. +35 °C

Connecon cable cross-secon single- or ne-stranded cable 0,75-1,5 mm2

Temperature class copper conductors 60/75°C

ELMON rail 41-822 (41-322)

EN ISO 13849-1:2015 Category 3 PL e

(MTTFD 195 years, DC 99 %)

EN 62061:2013 SILCL 3

(PFHd 6,51E-09 1/h)

Electronics MTTFD 625 years, DC 99 %

Electromechanics B10D 500000

MTTFD 285 years, DC 99% (Nop 17520)

Cercaons

With the RLU version, the signal relay switches synchronously

to the operaon of the signal transmier.

114

22,5

99

ELMON rail 41-822 / ELMON rail 41-322

Safety relais

15

14. Warnings and Disclaimers

Read this document and the documents listed in the addional resources secon about installaon, congu-

raon, and operaon of this equipment before you install, congure, operate, or maintain this product. Users

are required to familiarize themselves with installaon and wiring instrucons in addion to requirements of

all applicable codes, laws, and standards.

Acvies including installaon, adjustments, pung into service, use, assembly, disassembly, and main-

tenance are required to be carried out by suitably trained personnel in accordance with applicable code of

pracce.

If this equipment is used in a manner not specied by the manufacturer, the protecon provided by the

equipment may be impaired.

In no event will the manufacturer be responsible or liable for indirect or consequenal damages resulng

from the use or applicaon of this equipment.

The examples and diagrams in this manual are included solely for illustrave purposes. Because of the many

variables and requirements associated with any parcular installaon, the manufacturer cannot assume

responsibility or liability for actual use based on the examples and diagrams.

No patent liability is assumed by the manufacturer with respect to use of informaon, circuits, equipment, or

soware described in this manual.

Beyond that, the current version of ASO’s General Terms and Condions shall apply.

16

Safety relais

15. EC declaraon of conformity

We hereby declare that the following products of the series:

ELMON rail 41-322

(arcle number 1114-0030,

format serial number yymmnnnnn

)

ELMON

rail 41-822

(

arcle number

1114-0040, format serial number yymmnnnnn)

Safety switching device for the combinaon of switching edges, switching mats and

switching bumpers for avoiding hazards at crush and shear locaons corresponds to

the relevant basic safety and health requirements of the following EC Direcves as a

result of its concepon and construcon as well as the design we put on the market:

Machine Direcve 2006/42/EC

EN ISO 13849-1:2015

EN ISO 13849-2:2013-2

EN 62061:2013-09

EN 60947-5-1:2010-04

EN 61000-6-2:2005

EN 61000-6-3:2007

EC - type approval

Noed Body 0044

TÜV NORD CERT GmbH

Langemarckstraße 20

D-45141 Essen

EC type-examinaon no.: 44 205 13031827

This declaraon of conformity does not absolve the machine designer/manufacturer of

his obligaon to guarantee the conformity of the overall machine to which this product is

aached in accordance with the EC Direcve

.

Manufacturer and authorized representave for documents:

ASO, Antriebs- und Steuerungstechnik GmbH,

Hansastraße 52, D 59557 Lippstadt

17

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Notes

ELMON rail 41-822 / ELMON rail 41-322

Safety relais

18

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Notes

Safety relais

19

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Notes

ELMON rail 41-822 / ELMON rail 41-322

Safety relais

20

11.DB.17.004 Operang Manual Rev 03

Subject to technical modicaons.

No liability can be assumed for errors or misprints.

This operang manual is valid for the following versions:

from V 1.0 to V 5.1

English

Safety relais

ASO Safety Soluons Inc.

300 Roundhill Drive, Unit 6 • Rockaway. NJ 07866

Phone: +1 973 586 9600 • Fax: +1 973 784 4994

www.asosafety.com • e-mail: sales-us@asosafety.com

This manual suits for next models

1

Table of contents

Other ELMON Relay manuals