TABLE OF CONTENTS

SECTION I – Machine Parts and Functions

Part Names .............................................................. 3

Accessory Storage ......... ..........................................4

Presser Foot Definitions.......... .................................5

ExtensionTableand FreeArm.......... ........................6

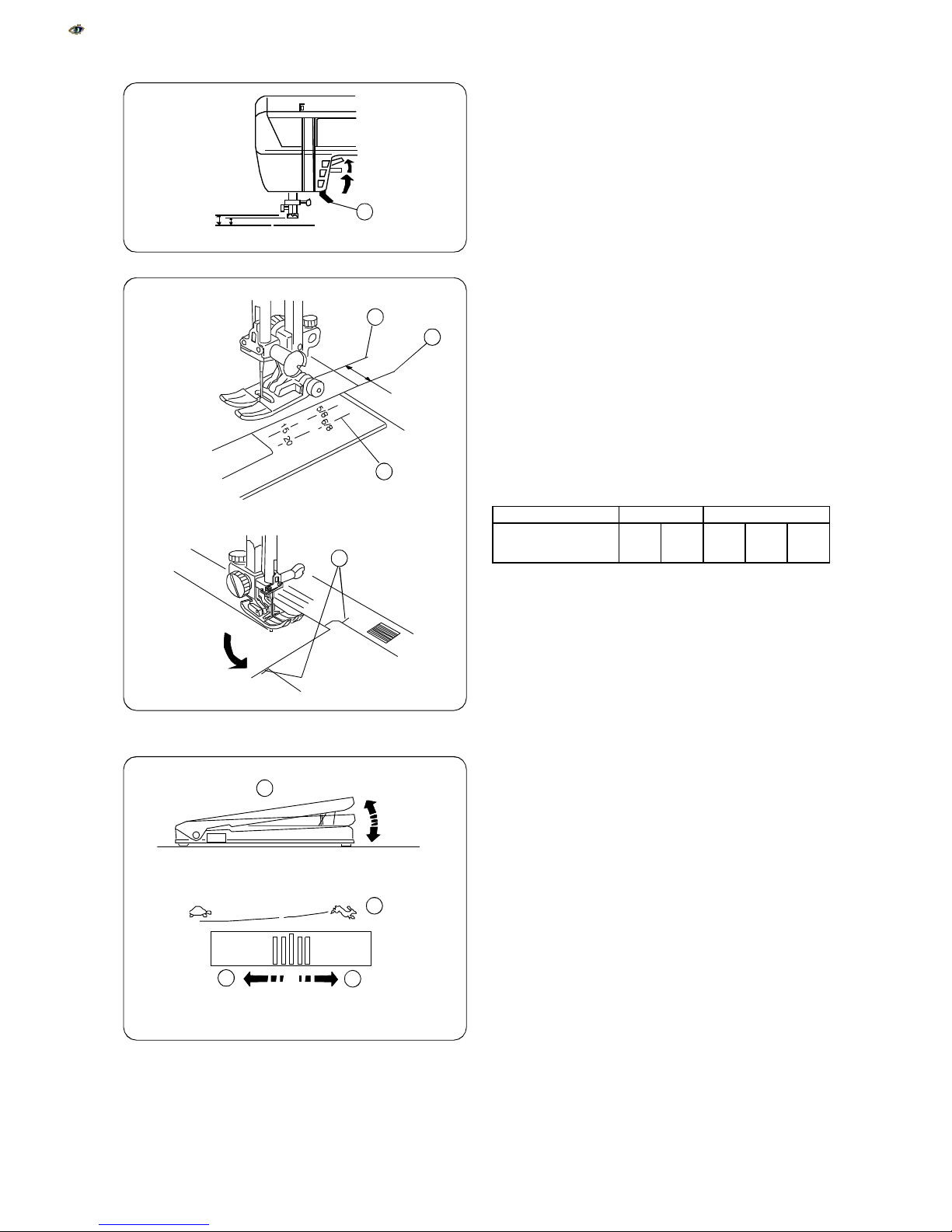

Using the Fine Adjustment Dial.......... .......................6

How to Drop the Feed Dog ....................................... 7

Foot Pressure Dial.................................................... 7

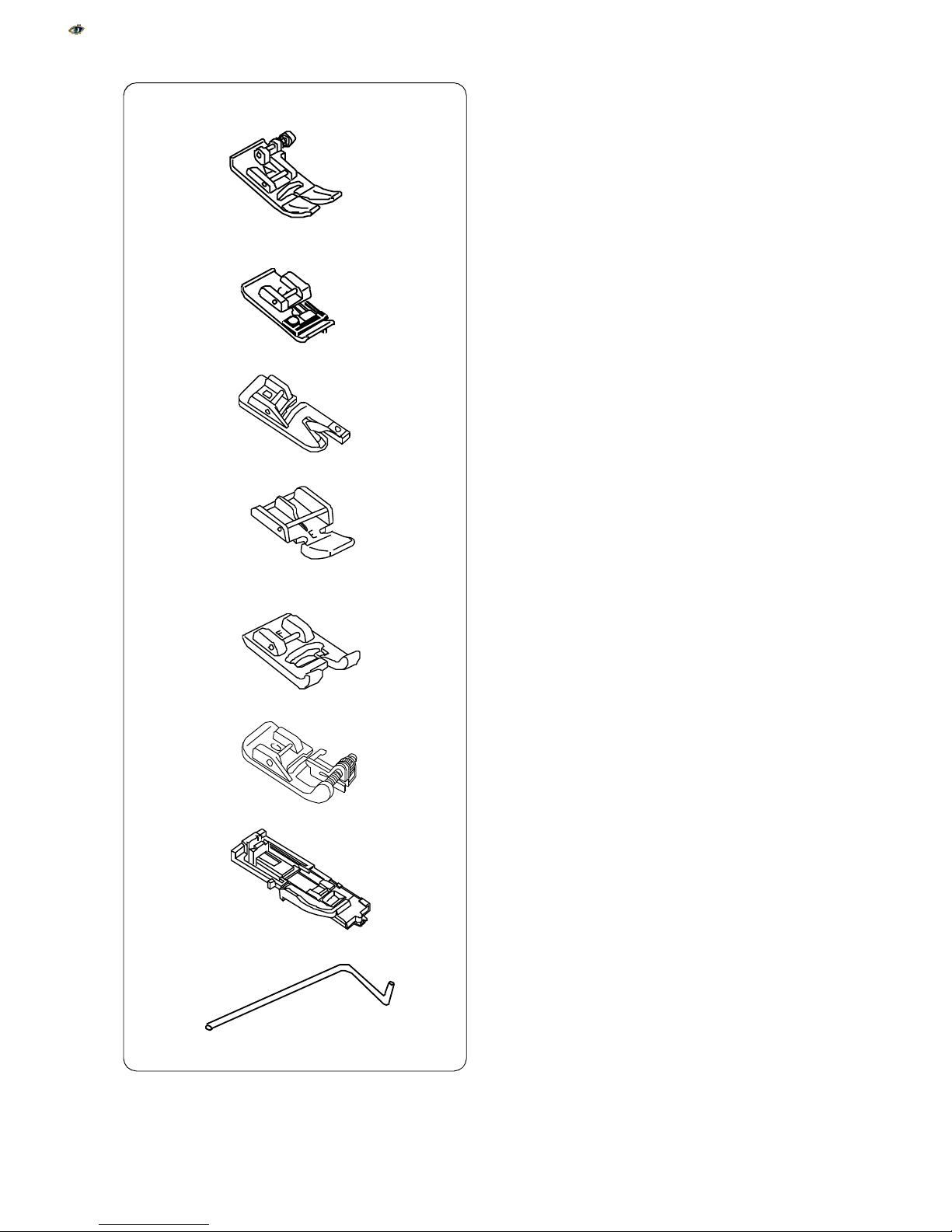

Attaching and Removing Presser Feet .................... 7

Attaching andRemoving Shank ............................... 7

Additional Presser Foot Clearance........................... 8

Seam Allowance Lines ............................................. 8

ControllingSewing Speed......................................... 8

AdjustingNeedleThreadTension ............................. 9

SECTION II – Getting Ready to Sew

Selecting the Correct Needle and Thread ............ 10

Changing Needles ................................................. 10

Needle Definitions...................................................11

Connecting Machine to Power Supply.................. 12

Main Function of Keys ...................................... 13-15

Winding a Bobbin .............................................. 16-17

Additional Spool Pin............................................... 17

Inserting the Bobbin ............................................... 18

Threading the Machine .......................................... 19

Built-in Needle Threader........................................ 20

Drawing Up the Bobbin Thread ............................. 21

SECTION III – Sewing

Example of How to Read the Machine Set-up

Information ............................................................ 22

Straight Stitch ......................................................... 22

Starting to Sew....................................................... 22

Finishing Off a Seam ............................................. 23

Changing Sewing Direction ................................... 23

Sewing on Heavy Fabrics...................................... 23

Gathering................................................................ 24

Zipper Insertion ................................................. 25-26

Pintucks .................................................................. 27

Quilt Guide ............................................................. 27

Rolled Hem (optional foot) ..................................... 28

Twin Needle Hem................................................... 29

Zigzag Stitch .......................................................... 30

Overcasting ............................................................ 30

Whip and Roll Hem ................................................ 31

Satin Stitch Applique .............................................. 31

How to Sew on a Button ........................................ 32

3-Step Zigzag ......................................................... 33

Mending a Tear....................................................... 33

Blind Hem Stitches ................................................ 34

Shell Tuck ............................................................... 35

Box Stitch ............................................................... 35

Triple Seam ............................................................ 36

Saddle Stitch .......................................................... 36

Stretch Seam ......................................................... 36

Decorative Stretch Stitches ................................... 37

Super Stretch Stitch ............................................... 37

Super Overlock Stitch ............................................ 38

Double Overlock Stitch .......................................... 38

Buttonhole Variations ........................................ 39-42

Corded Buttonhole ................................................. 43

Buttonhole Applique ............................................... 44

Fringing................................................................... 45

Hemstitches............................................................ 45

Drawn Work............................................................ 46

Picot Stitch ............................................................. 46

Patchwork............................................................... 47

Twin Needle Decorative Stitches .......................... 47

Single Pattern – Auto-Lock Key ............................ 47

Scallop Edges ........................................................ 48

Complete Pattern – Auto-Lock Key ....................... 48

Combining Patterns ............................................... 48

Smocking................................................................ 49

SECTION IV – Exclusive Optional Elna

Accessories

Elastic Gatherer Plate............................................ 50

Fagoting (Bridging) Plate....................................... 50

SECTION V – Taking Care of Your Machine

Cleaning the Bobbin Area...................................... 51

Cleaning the Hook Area and Feed Dog ........... 51-52

Replacing the Bobbin Case ................................... 52

Changing the Light Bulb ........................................ 52

TROUBLESHOOTING ..........................53

INDEX ...................................................54

NOTE: Information found in this instruction

manual is current at the time of printing. Elna

reserves theright to change and update specifi-

cations and information as needed.

2