Elna International Corps. SA 3210 / 3230 Service manual

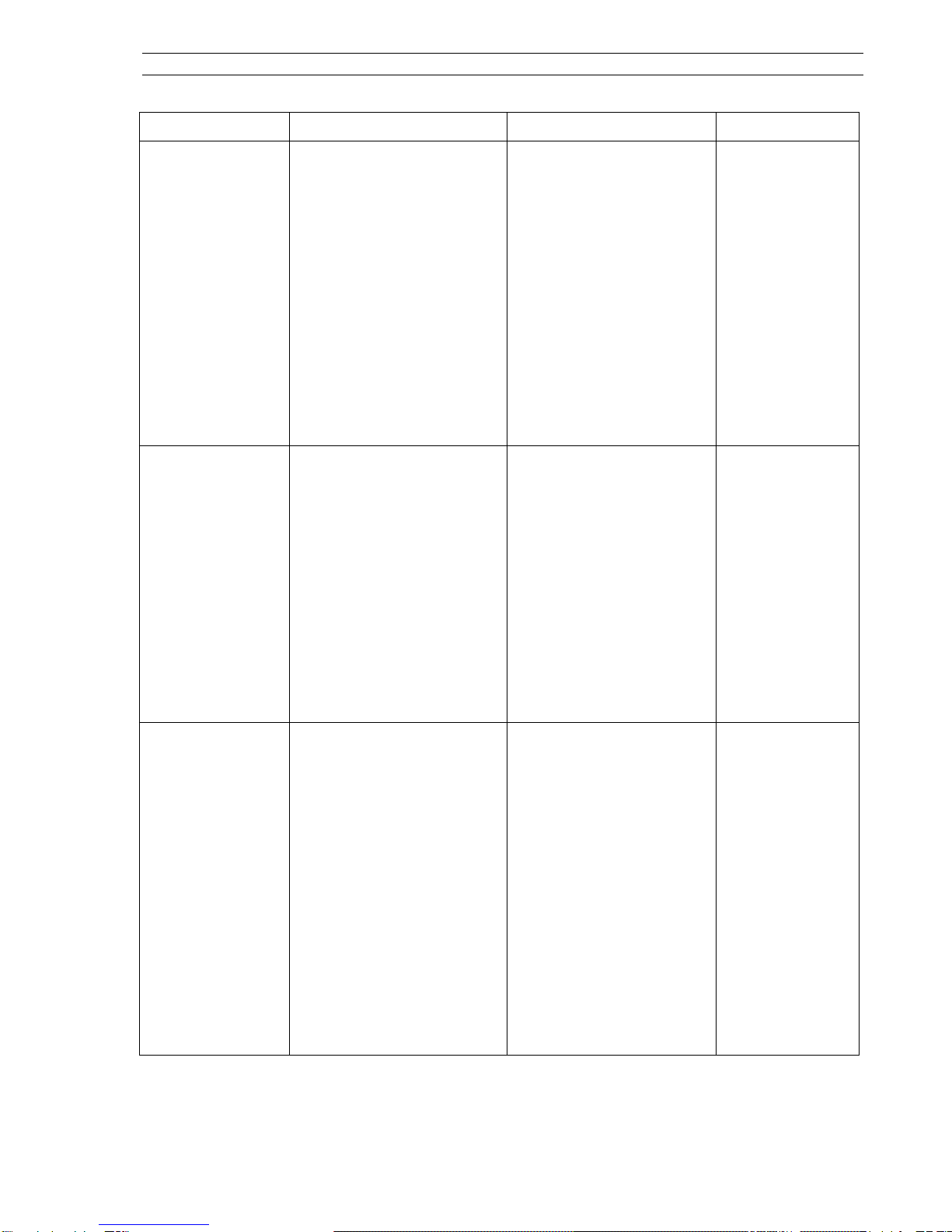

CONDITION CAUSE HOW TO FIX REFERENCE

3 Needle thread

breaks

1. Initial sewing speed is

too fast.

2. Thread path is incorrect.

3. Needle is bent or dull.

4. Upper thread tension is

too strong.

5. Needle size is

inappropriate for fabric.

6. Needle eye is worn.

7. Needle hole in needle

plate is worn or burred.

Start with medium speed

Use the proper thread path.

Replace with a new needle.

Adjust needle thread

tension correctly.

Use appropriate needle for

fabric and thread in use.

Change the needle.

Repair the hole or replace

the needle plate.

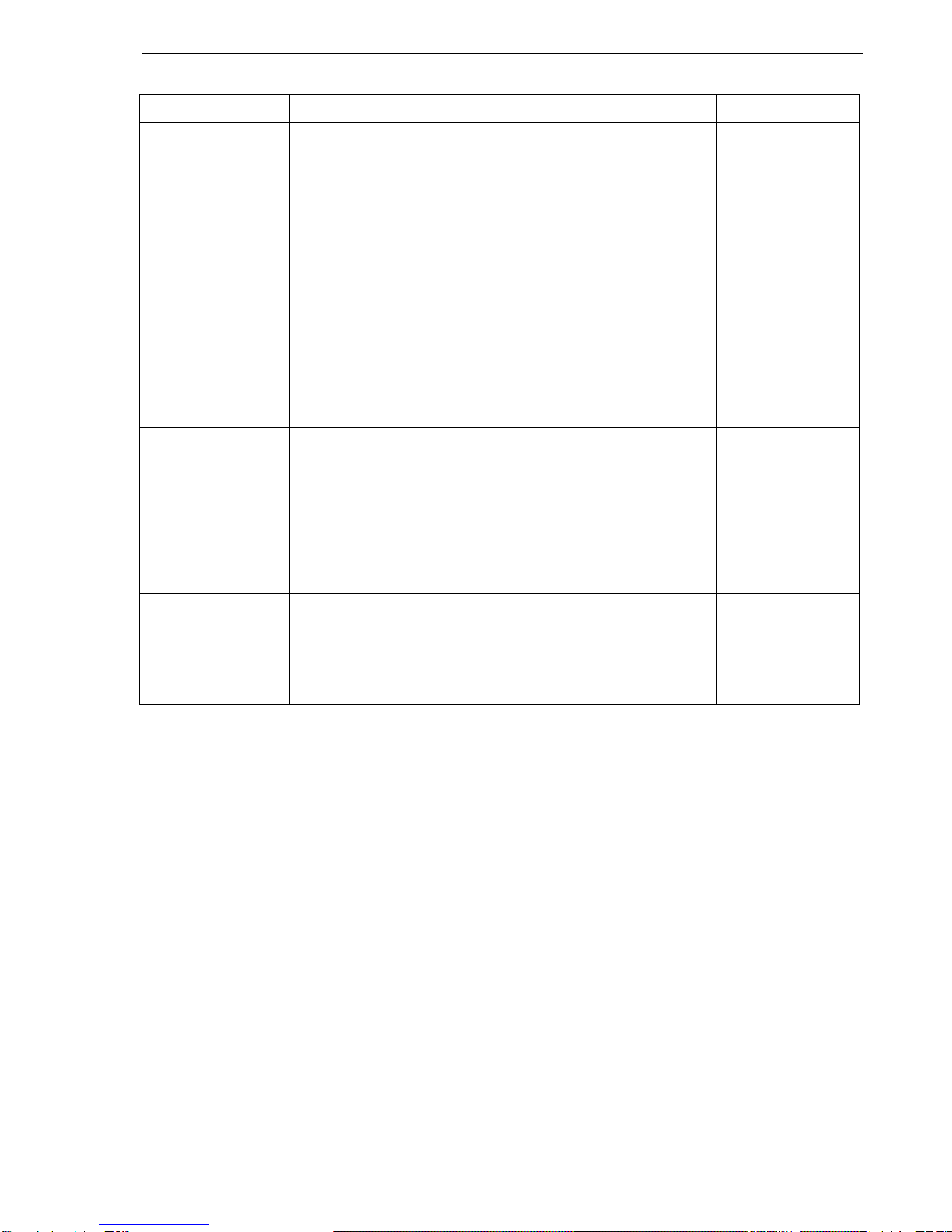

4 Bobbin thread

breaks.

1. Incorrectly threaded

bobbin.

2. Too much thread is on

the bobbin.

3. Lint is stuck inside the

bobbin holder.

4. Thread quality is too low.

5. Thread is jamming

around the bobbin.

Thread bobbin correctly

Adjust the position of

stopper.

Clean the shuttle.

Change to a higher quality

sewing thread.

Clear out the jamming

thread.

5. Needle breaks. 1. Needle is hitting the

needle plate

2. Needle is bent or worn.

3. Needle is hitting the

shuttle.

4. The fabric moves while

the needle is piercing it,

or the needle zigzags

while in fabric.

5. Fabric is being pulled too

strongly while sewing.

See mechanical adjustment

“Needle Drop Position”

Change the needle

See mechanical adjustment

“Clearance between

Needle and Hook”

See mechanical adjustment

“Needle Swing”.

Guide the fabric gently

while sewing.

Page 13

Page 18

Page 11

Page 02