2

Shell Tuck ...................................................................... 63

Twin Needle Sewing ................................................. 64-65

Satin Stitch Window Keys ............................................. 66

Satin Stitches – Single Repeat with Programmed

Lockstitch and Elongation ..................................... 67

Combining a Sequence with Mirror

Image and Auto-lock .............................................. 67

Reset Combined Sequence to Beginning ..................... 68

Adjusting Stitch Width or Length of an Individual Stitch

Within a Sequence ................................................ 68

Editing a Sequence ....................................................... 69

Alphabet Selection Window Keys ................................. 70

Sewing Alphabets .......................................................... 71

Check Memorized Sequence ........................................ 72

Files – Saving, Opening and Deleting ..................... 72-74

Quilting

Piecing Fabrics Together ............................................... 75

Quilt Guide ..................................................................... 75

Quilt Stitch ..................................................................... 76

Buttonhole Appliqué ...................................................... 76

Free Motion Quilting or Stippling .................................. 77

Stippling Stitch ............................................................... 77

Patchwork ...................................................................... 78

French Knots ................................................................. 78

Heirloom

Pintucks ......................................................................... 79

Bridging (Fagoting) ........................................................ 79

Hemstitches ................................................................... 80

Fringing .......................................................................... 81

Drawn Work ................................................................... 81

Smocking ....................................................................... 82

SECTION IV – Embroidery Sewing

Getting Ready to Embroider.......................................... 83

Adjusting the Needle Thread Tension ........................... 84

Embroidery Hoops ......................................................... 85

Stabilizers ...................................................................... 85

Templates ...................................................................... 86

Securing Fabric in Hoop ........................................... 86-87

Attaching Hoop to Carriage ........................................... 88

Thread Holder................................................................ 89

Embroidering Small Areas ............................................. 89

Embroidery Design Selection Window Keys ........... 89-90

How to Select a Built-in Design................................ 91-92

Sewing a Single Built-in Design .................................... 93

Ready to Sew Window After Embroidery Begins.......... 94

Alphabets .................................................................. 95-96

Sewing Alphabets ..................................................... 97-98

Alphabet Corrections ..................................................... 99

2 Letter or 3 Letter Monograms .................................. 100

Sewing with PC Design Cards (Optional) ................... 101

Edit Window .......................................................... 102-104

Combine a Built-in Design with Alphabet ............. 105-106

Files – Saving, Opening and Deleting ................. 107-109

Embroidering with Optional Free Arm Hoop C ........... 110

SECTION V – Taking Care of Your Machine

Cleaning .................................................................111-112

Changing the Light Bulb .............................................. 112

STITCH and EMBROIDERY CHARTS ...... 113-115

OPTIONAL ACCESSORIES ............................. 116

TROUBLESHOOTING ............................... 117-118

INDEX ......................................................... 119-121

NOTE: Information found in this instruction manual is

current at the time of printing. Elna reserves the right to

change and update specifications and information as

needed.

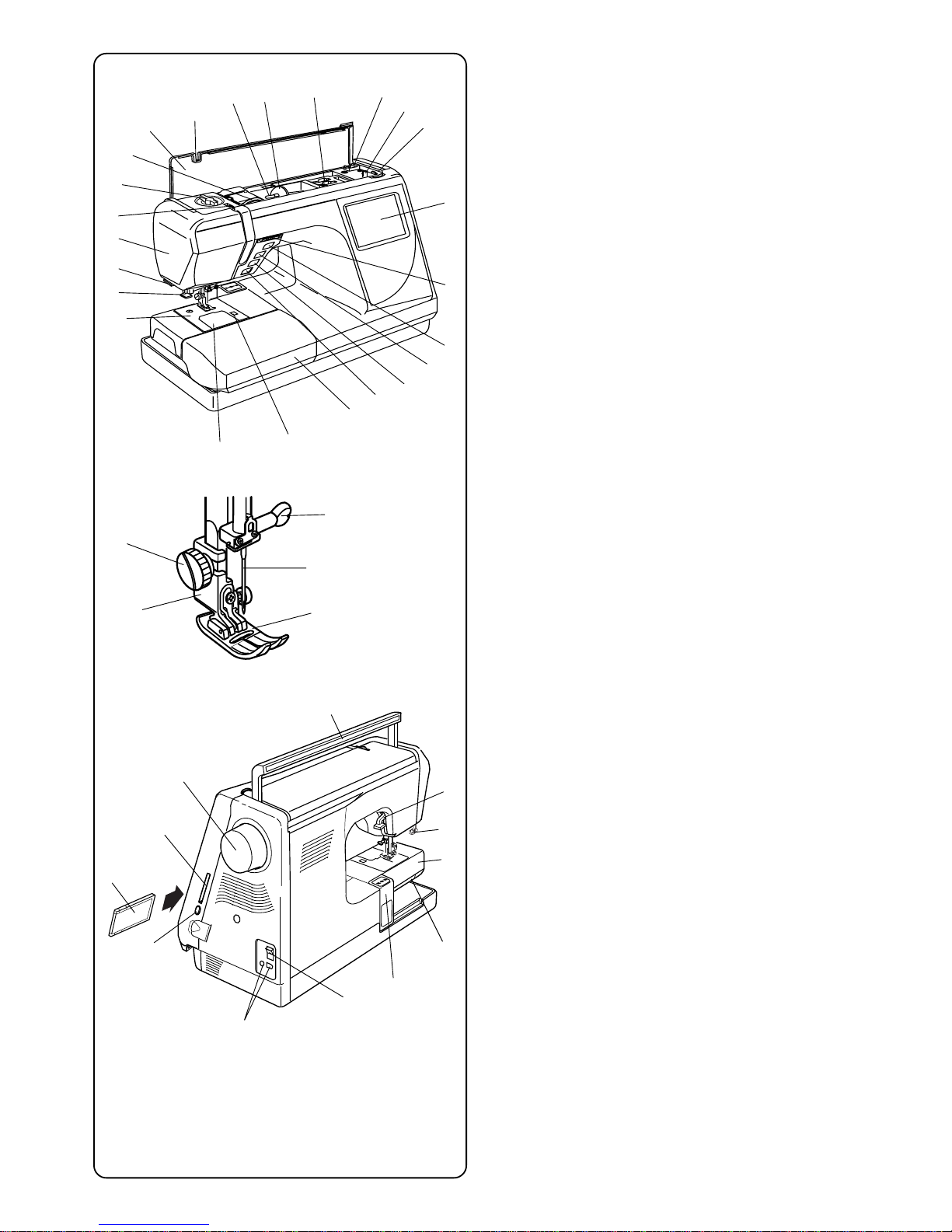

SECTION I – Machine Parts and Functions

Part Names ...................................................................... 3

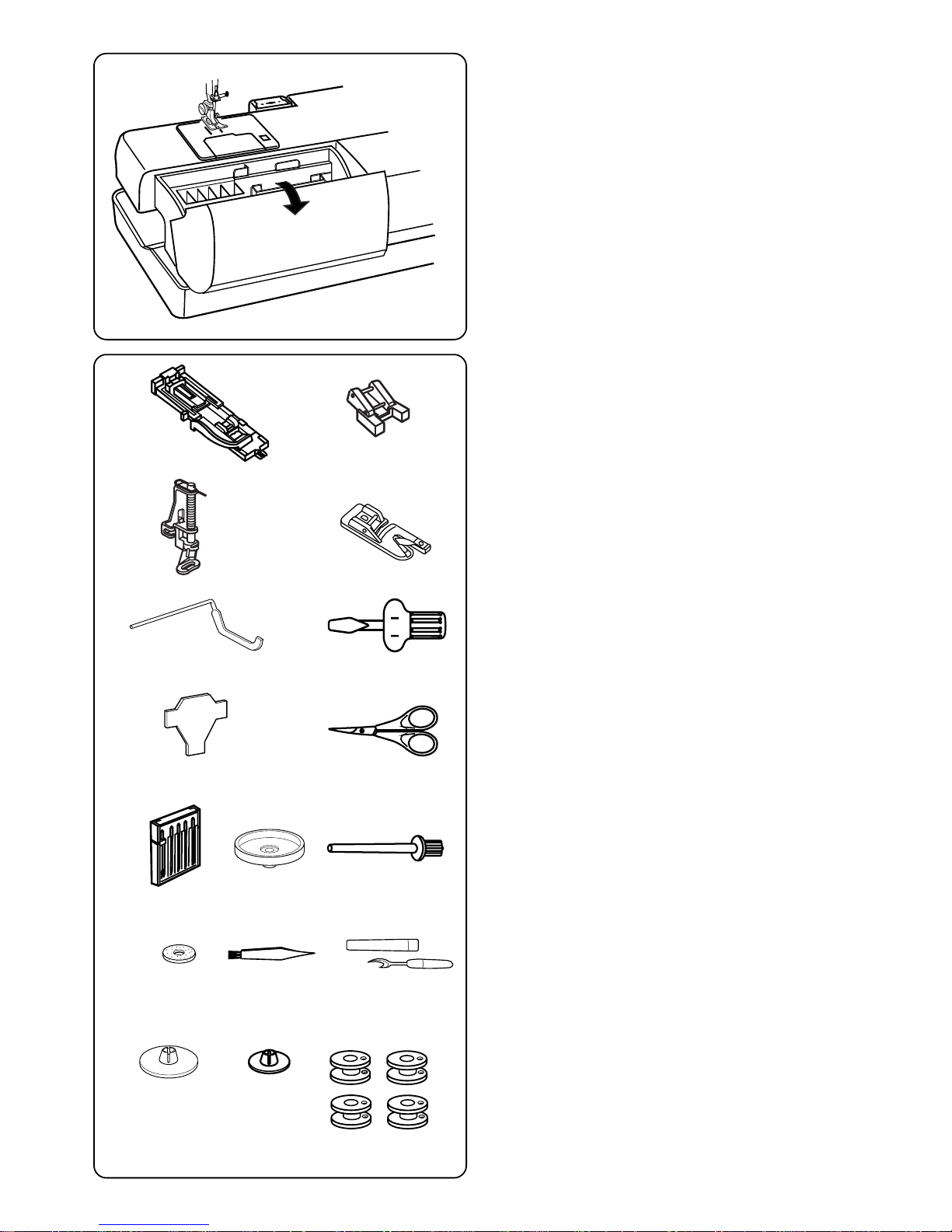

Standard Accessories................................................... 4-5

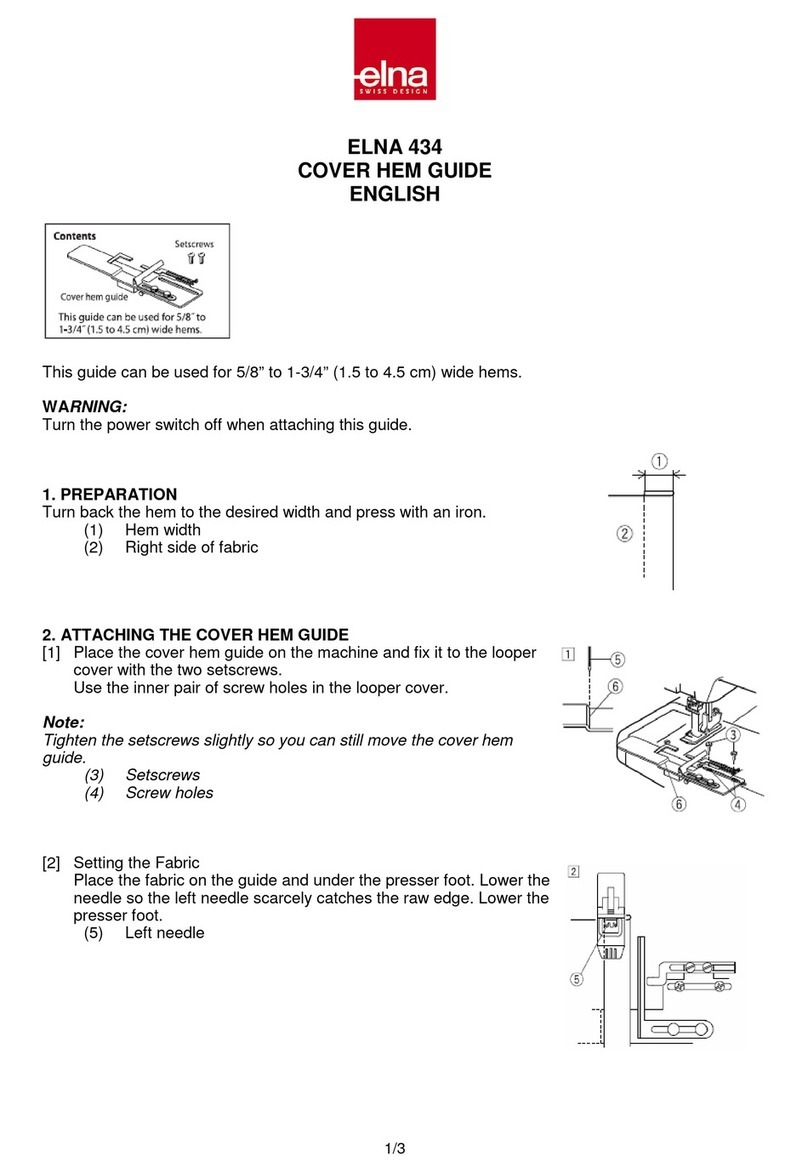

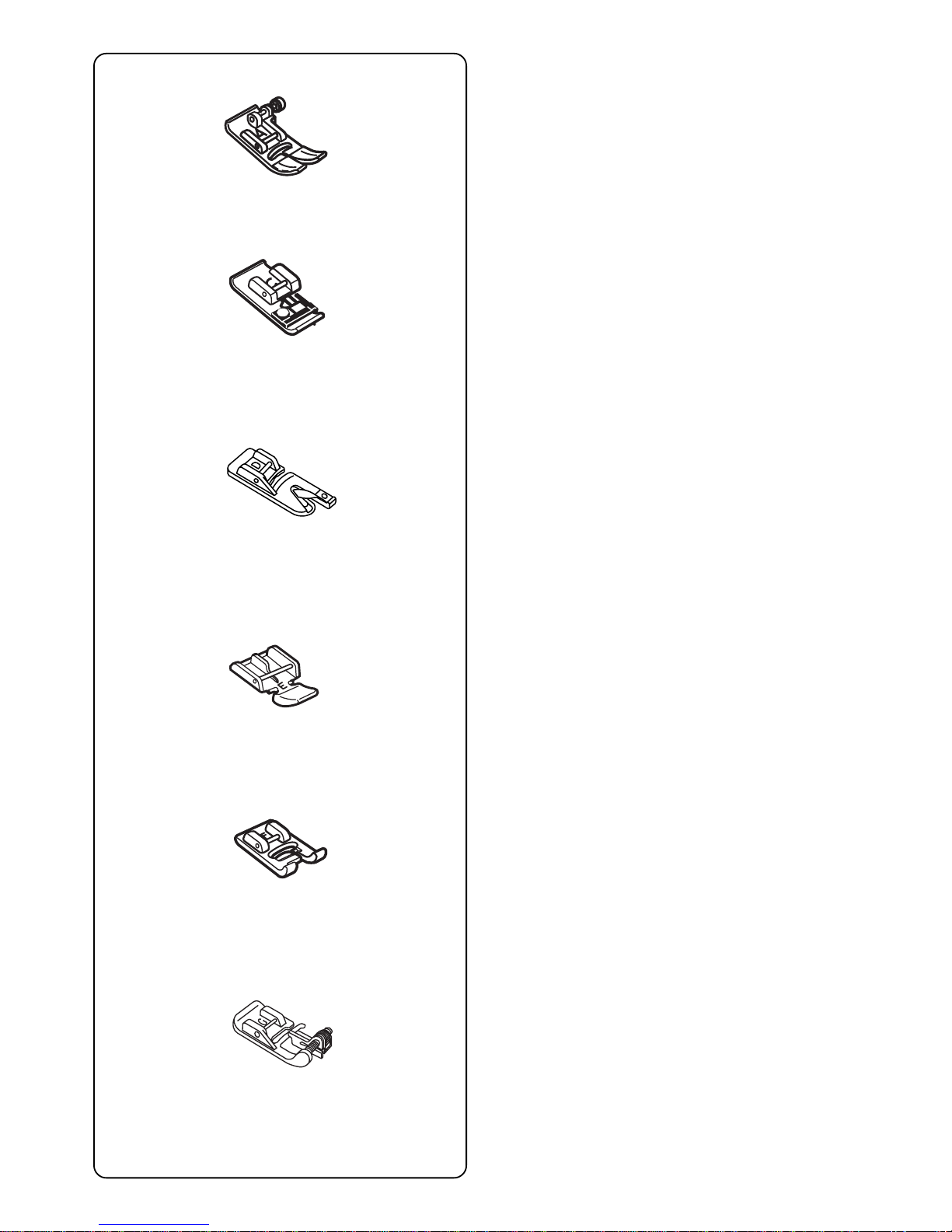

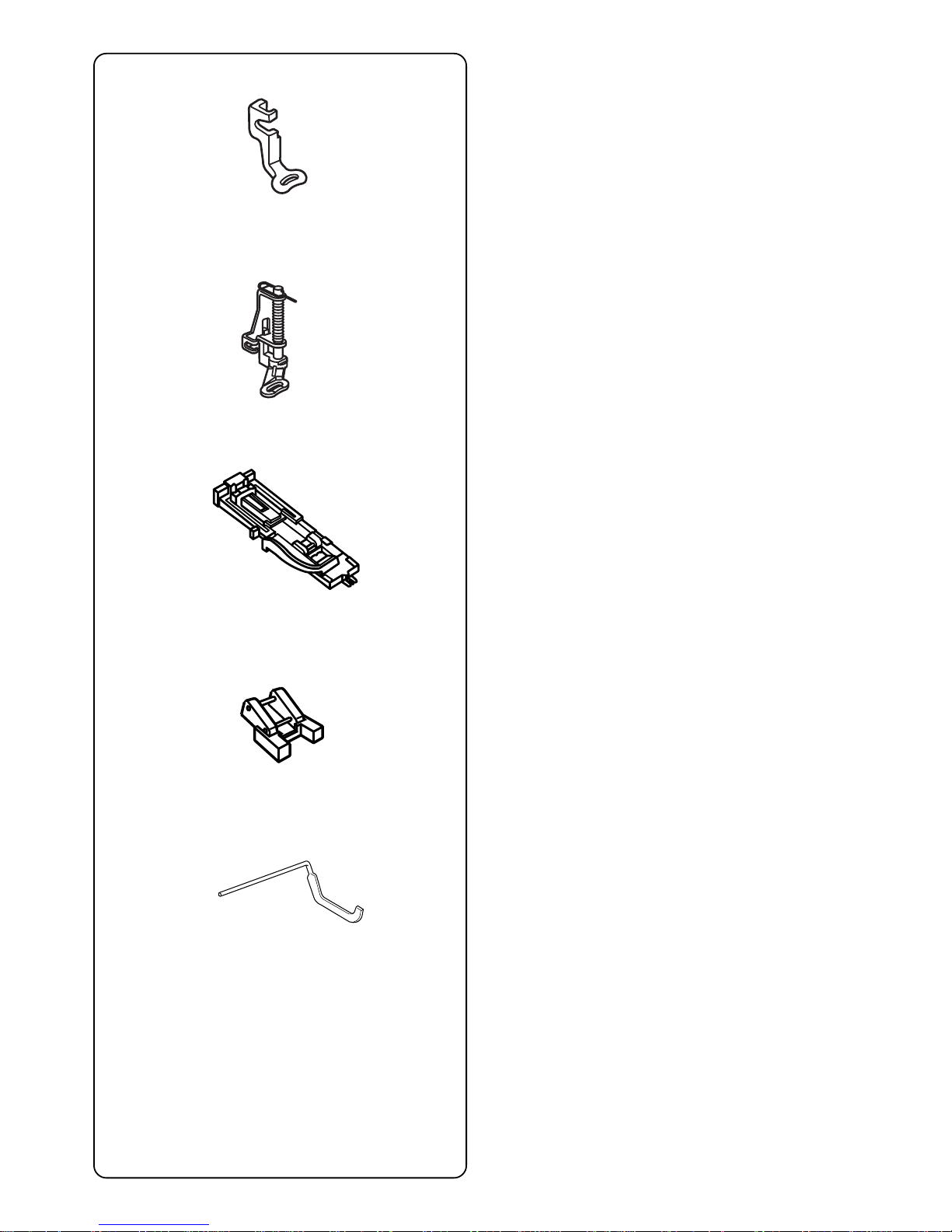

Presser Foot and Accessory Definitions ...................... 6-7

Extension Table and Free Arm ........................................ 8

Controlling Sewing Speed ............................................... 9

Foot Pressure Dial ........................................................... 9

How to Drop the Feed Dog ........................................... 10

Presser Foot Lever and Additional Presser

Foot Clearance ........................................................ 10

Attaching and Removing Presser Feet ......................... 11

Attaching and Removing Shank .................................... 11

Seam Allowance Lines .................................................. 11

Needle Thread Tension ................................................. 12

Using the Fine Adjustment Screw ................................. 13

SECTION II – Getting Ready to Sew

Connecting Machine to Power Supply .......................... 14

LCD Touch Screen ........................................................ 15

Main Function of Keys ................................................... 16

Operation Keys .............................................................. 17

SET Preference Keys ............................................... 18-20

How to Access On Screen Information ......................... 21

Selecting the Correct Needle and Thread .................... 22

Changing Needles ......................................................... 22

Needle Definitions ......................................................... 23

Winding a Bobbin ..................................................... 24-25

Additional Spool Pin ...................................................... 24

Inserting the Bobbin ...................................................... 26

Threading the Machine.................................................. 27

Built-in Needle Threader ............................................... 28

Drawing Up the Bobbin Thread ..................................... 29

SECTION III – Traditional Sewing

Traditional Sewing Window Keys .................................. 30

How to Select a Stitch and What

the Symbols Represent ......................................... 31

Straight Stitch ................................................................ 31

Starting to Sew .............................................................. 31

Changing Sewing Direction ........................................... 32

Finishing Off a Seam ..................................................... 32

Cutting the Threads ....................................................... 32

Adjusting Needle Position or Stitch Length .................. 33

Sewing on Heavy Fabrics ............................................. 34

Gathering ....................................................................... 34

Zipper Insertion ........................................................ 35-37

Rolled Hem .................................................................... 38

Zigzag Stitch .................................................................. 39

Overcasting ................................................................... 39

Satin Stitch Appliqué ..................................................... 40

3-Step Zigzag ................................................................ 40

Mending a Tear .............................................................. 41

Applying Elastic ............................................................. 41

Blind Hem Stitches ........................................................ 42

Lingerie Stitch ................................................................ 43

Basting Stitch................................................................. 43

Triple Seam ................................................................... 44

Stretch Seam ................................................................. 44

Double Overlock Stitch .................................................. 45

Super Overlock Stitch.................................................... 45

Super Stretch Stitch ...................................................... 46

Buttonholes ............................................................... 47-55

How to Sew on a Button ................................................ 56

Darning ..................................................................... 57-58

Bartacks ......................................................................... 59

Arrowtack ....................................................................... 60

Eyelets ........................................................................... 60

Decorative Stitch Window Keys ............................... 61-62

Saddle Stitch ................................................................. 63

TABLE OF CONTENTS