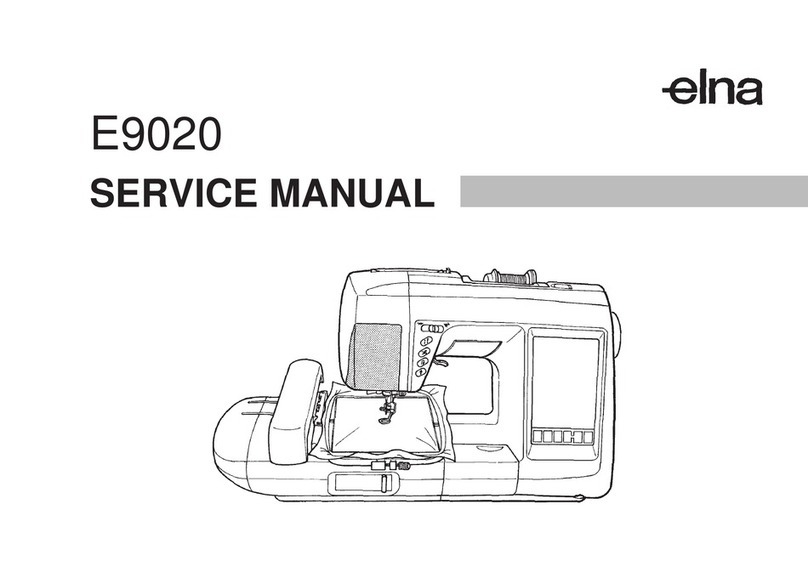

Changing External Parts (1) ...................................................................................... 1

Changing External Parts (2) ...................................................................................... 2

Changing External Parts (3) ...................................................................................... 3

Changing External Parts (4) ...................................................................................... 4

Changing External Parts (5) ...................................................................................... 5

Changing External Parts (6) ...................................................................................... 6

Changing Thread Tension Uni.................................................................................... 7

Replacing the Thread Cutter unit ............................................................................... 8

Replacing Needle Threader Motor (1) ....................................................................... 9

Replacing Needle Threader Motor (2) ...................................................................... 10

Connector Connection Diagaram.............................................................................. 11

Replacing Printed Circuit Board A ............................................................................ 12

Replacing Printed Circuit Board F1, F2/Slide Volume .............................................. 13

Replacing Printed Circuit Board B ........................................................................... 14

Replacing Switching Power Supply........................................................................... 15

Replacing DC Motor and Motor Belt Tension Adjustment......................................... 16

Adjusting Needle Drop Position ................................................................................ 17

Adjusting Hook Timing .............................................................................................. 18

Adjusting Needle Bar Height..................................................................................... 19

Adjusting Clearance between Needle and Hook ...................................................... 20

Adjusting Backlash between Hook Drive Gear and Lower Shaft Gear ..................... 21

Adjusting Presser Foot Position and Height.............................................................. 22

Adjusting Feed Dog Height ....................................................................................... 23

Adjusting Height of Embroidery Foot P..................................................................... 24

Adjusting Upper Shaft Shield Plate Position ............................................................. 25

Adjusting Tension Release Mechanism ................................................................... 26

Adjusting Needle Thread Tension ............................................................................. 27

Replacing Threader Plate and Adjustment ............................................................... 28

Adjusting Needle Threader Switch............................................................................ 29

TTP Adjusting Mode ................................................................................................. 30

Adjusting Stretch Stitch Balance............................................................................... 31

Adjusting Presser Foot Lifter Sensor ........................................................................ 32

Adjusting Buttonhole Lever ....................................................................................... 33

Adjusting Presser Foot Sensor ................................................................................. 34

Adjusting Remaining Bobbin Thread Sensor ............................................................ 35

Adjusting Thread Cutter Solenoid ............................................................................. 36

Adjusting Upper Shaft Clutch Solenoid..................................................................... 37

Adjusting Thread Cutter Switch ................................................................................ 38

Adjusting Bobbin Winder Stopper ............................................................................. 39

INDEX