ELNA Cl.11 User manual

Other ELNA Sewing Machine manuals

ELNA

ELNA eXpressive920 User manual

ELNA

ELNA 654 - User manual

ELNA

ELNA 450 User manual

ELNA

ELNA Air Artist Installation guide

ELNA

ELNA TSP AIR ELECTRONIC User manual

ELNA

ELNA 2600 User manual

ELNA

ELNA EnVision 8006 User manual

ELNA

ELNA eXplore 220 User manual

ELNA

ELNA eXcellence 760 User manual

ELNA

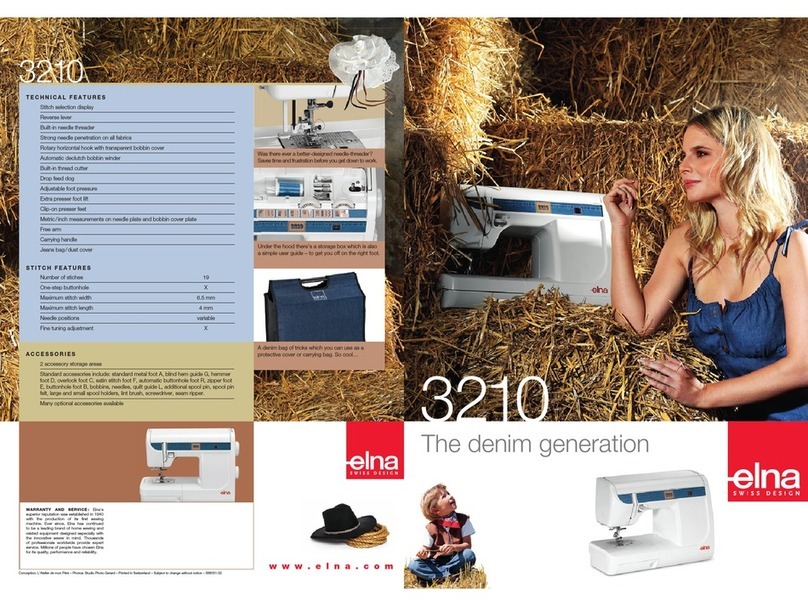

ELNA 3210 User manual