elsner elektronik KNX PY User manual

KNX PY

Pyranometer

Technical specifications and installation instructions

Item number 70157

EN

Elsner Elektronik GmbH Control and Automation Engineering

Sohlengrund 16

Germany Fax +49 (0) 70 33 / 30 945-20 www.elsner-elektronik.de

1 Content

Elsner Elektronik GmbH • Sohlengrund 16 • D-75395 Ostelsheim • Germany

Pyranometer KNX PY • from software version 1.00, ETS programme version 1.11

Status: 22.07.2019 • Errors excepted. Subject to technical changes.

1. Description ........................................................................................... 3

1.1. Scope of delivery ...................................................................................................... 3

1.2. Technical specifications ........................................................................................... 3

2. Installation and commissioning ........................................................... 4

2.1. Installation notes ...................................................................................................... 4

2.2. Location ..................................................................................................................... 5

2.3. Mounting the sensor ................................................................................................ 6

2.3.1. Attaching the mount ..................................................................................... 6

2.3.2. View of rear side and drill hole plan ........................................................... 7

2.3.3. Preparing the sensor .................................................................................... 8

2.3.4. PCB layout ..................................................................................................... 9

2.3.5. Mounting the sensor .................................................................................... 9

2.4. Notes on mounting and commissioning .............................................................. 10

3. Addressing of the device at the bus .................................................. 10

4. Maintenance ....................................................................................... 10

5. Transmission Protocol ....................................................................... 11

5.1. List of all communication objects ......................................................................... 11

6. Setting of parameters ........................................................................ 13

6.1. General settings ..................................................................................................... 13

6.2. Threshold values .................................................................................................... 14

6.2.1. Threshold value 1 / 2 / 3 / 4 ........................................................................ 14

6.3. Logic ........................................................................................................................ 15

6.3.1. AND Logic 1 / 2 ............................................................................................ 16

6.3.2. Linkage inputs of AND Logic ..................................................................... 17

6.3.3. OR Logic 1 / 2 .............................................................................................. 17

6.3.4. Linkage inputs of OR Logic ........................................................................ 18

2 Clarification of signs

This manual is amended periodically and will be brought into line with new software

releases. The change status (software version and date) can be found in the contents footer.

If you have a device with a later software version, please check

www.elsner-elektronik.de in the menu area "Service" to find out whether a more up-to-

date version of the manual is available.

Clarification of signs used in this manual

Installation, inspection, commissioning and troubleshooting of the device

must only be carried out by a competent electrician.

Safety advice.

Safety advice for working on electrical connections, components,

etc.

DANGER! ... indicates an immediately hazardous situation which will lead to

death or severe injuries if it is not avoided.

WARNING! ... indicates a potentially hazardous situation which may lead to

death or severe injuries if it is not avoided.

CAUTION! ... indicates a potentially hazardous situation which may lead to

trivial or minor injuries if it is not avoided.

ATTENTION! ... indicates a situation which may lead to damage to property if it is

not avoided.

ETS In the ETS tables, the parameter default settings are marked by

underlining.

3 Description

Pyranometer KNX PY • Status: 22.07.2019 • Technical changes reserved. Errors reserved.

1. Description

The Pyranometer KNX PY measures global irradiance, which is perceived as heat.

The measured current irradiance (watts per squaremetre) allows for drawing conclu-

sions on the energy input to an area during a defined period of time (kilowatt hours per

squaremetre). Both values can be read out by the KNX PY. Four switching outputs

with adjustable threshold values as well as additional AND and OR logic gates are

available.The sensor system, the evaluation electronics and the electronics of the bus

connection are mounted in a compact housing.

Functions:

•Measurement of global irradiance: The current irradiance is measured

(W/m²). The energy input to an area during a defined period of time can be read

out (kWh/m²)

•4 threshold values can be adjusted per parameter or via communication

objects

•2 AND and 2 OR logic gates with each 4 inputs. Every switching incident as

well as 8 logic inputs (in the form of communication objects) may be used as

inputs for the logic gates. The output of each gate may optionally be configured

as 1 bit or 2 x 8 bits

Configuration is made using the KNX software ETS. The product file can be down-

loaded from the Elsner Elektronik website on www.elsner-elektronik.de in the “Ser-

vice” menu.

1.1. Scope of delivery

• Pyranometer with combined wall/pole mounting

• 2x stainless steel installation band for pole installation

1.2. Technical specifications

Housing Plastic material

Colour White / Transparent

Mounting On-wall

Protection category IP 44

Dimensions approx. 96 × 77 × 118 (W × H × D, mm)

Weight approx. 145 g

Ambient temperature Operation -25…+85°C, storage -30…+85°C

Operating voltage KNX bus voltage

Bus current max. 7 mA,

max. 10 mA when programming LED is active

Data output KNX +/- bus terminal plug

BCU type Own micro controller

PEI type 0

Group addresses max. 200

4 Installation and commissioning

Pyranometer KNX PY • Status: 22.07.2019 • Technical changes reserved. Errors reserved.

The product conforms with the provisions of EU directives.

2. Installation and commissioning

2.1. Installation notes

Installation, testing, operational start-up and troubleshooting should

only be performed by an electrician.

CAUTION!

Live voltage!

There are unprotected live components inside the device.

• National legal regulations are to be followed.

• Ensure that all lines to be assembled are free of voltage and take

precautions against accidental switching on.

• Do not use the device if it is damaged.

• Take the device or system out of service and secure it against

unintentional use, if it can be assumed, that risk-free operation is no

longer guaranteed.

The device is only to be used for its intended purpose. Any improper modification or

failure to follow the operating instructions voids any and all warranty and guarantee

claims.

After unpacking the device, check it immediately for possible mechanical damage. If it

has been damaged in transport, inform the supplier immediately.

The device may only be used as a fixed-site installation; that means only when assem-

bled and after conclusion of all installation and operational start-up tasks and only in

the surroundings designated for it.

Elsner Elektronik is not liable for any changes in norms and standards which may occur

after publication of these operating instructions.

Allocations max. 200

Communication objects 52

Measurement range 0…2500 W/m²

0…2196 kWh/m²

Measurement range 5 W/m²

0.1 kWh/m²

Accuracy ± 15% of the measured value

at above 150 W/m²

5 Installation and commissioning

Pyranometer KNX PY • Status: 22.07.2019 • Technical changes reserved. Errors reserved.

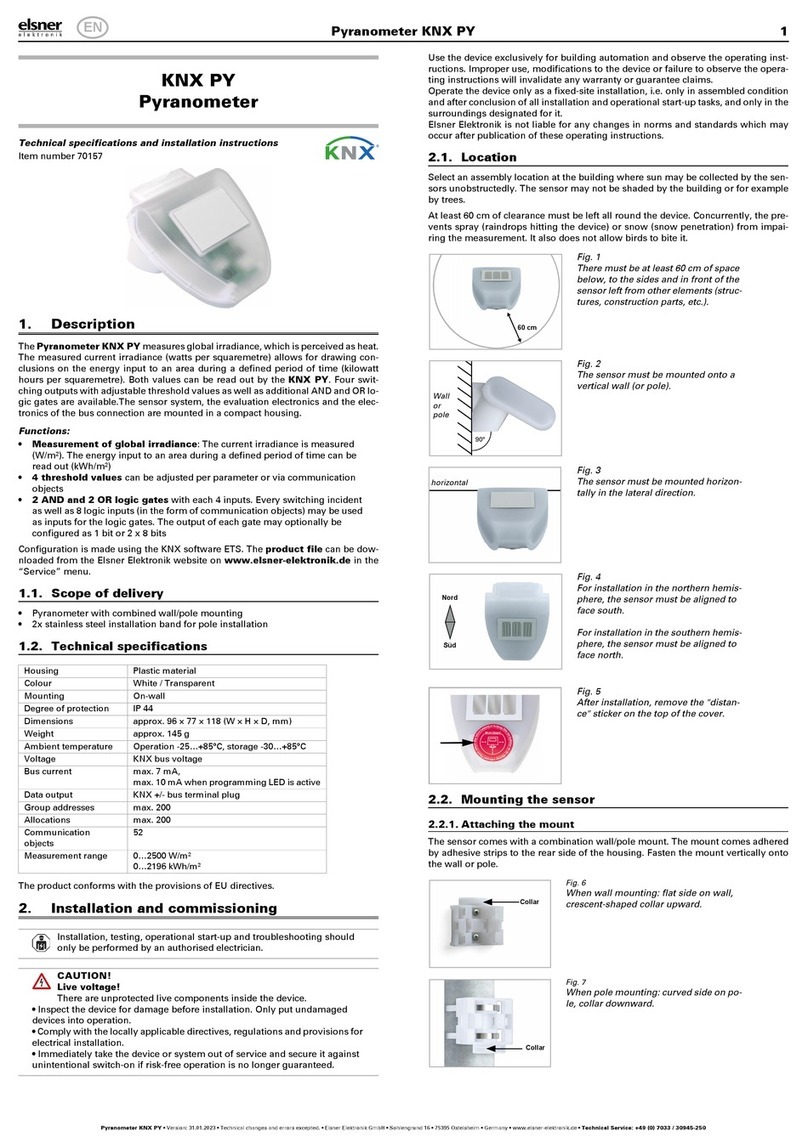

2.2. Location

Select an assembly location at the building where sun may be collected by the sensors

unobstructedly. The sensor may not be shaded by the building or for example by trees.

At least 60 cm of clearance must be left all round the device. Concurrently, the prevents

spray (raindrops hitting the device) or snow (snow penetration) from impairing the

measurement. It also does not allow birds to bite it.

Fig. 1

There must be at least 60 cm of space below,

to the sides and in front of the sensor left

from other elements (structures, construction

parts, etc.).

60 cm

Fig. 2

The sensor must be mounted onto a vertical

wall (or pole).

Wall

or

pole

Fig. 3

The sensor must be mounted horizontally in

the lateral direction.

horizontal

6 Installation and commissioning

Pyranometer KNX PY • Status: 22.07.2019 • Technical changes reserved. Errors reserved.

2.3. Mounting the sensor

2.3.1. Attaching the mount

The sensor comes with a combination wall/pole mount. The mount comes adhered by

adhesive strips to the rear side of the housing. Fasten the mount vertically onto the wall

or pole.

Fig. 4

For installation in the northern hemisphere,

the sensor must be aligned to face south.

For installation in the southern hemisphere,

the sensor must be aligned to face north.

Nord

Süd

Fig. 5

When wall mounting: flat side on wall, crescent-

shaped collar upward.

Collar

Fig. 6

When pole mounting: curved side on pole, collar

downward.

Collar

7 Installation and commissioning

Pyranometer KNX PY • Status: 22.07.2019 • Technical changes reserved. Errors reserved.

2.3.2. View of rear side and drill hole plan

Fig. 7

Different mounting arms are available from Els-

ner Elektronik as additional, optional accessories

for flexible installation of the weather station on

a wall, pole or beam (pictures of sensors exem-

plary).

Example of the use of a mounting arm: Due to

flexible ball joints, the sensor can be brought

into ideal position.

Fig. 8

Example use of the hinge arm mounting:

With the hinge arm mounting, the weather sta-

tion projects from beneath the roof overhang.

Sun, wind and precipitation can act upon the

sensors without hindrance.

Fig. 9

Example use of the hinge arm mounting:

Fitting to a pole with worm drive hose clips

Langloch 7,5 x 5 mm

Fig. 10 a+b

Drill hole plan

Dimensions of rear side of housing with bracket.

Subject to change for technical enhancement.

8 Installation and commissioning

Pyranometer KNX PY • Status: 22.07.2019 • Technical changes reserved. Errors reserved.

2.3.3. Preparing the sensor

The sensor cover snaps in on the left and right along the bottom edge (see Fig.).

Remove the cover.

Push the connection cable through the rubber seal on the bottom of the device and

connect voltage and data cable to the provided clamps.

Fig. 11

1 Cover snaps

2 Bottom part of housing

1

2

Unsnap cover

and remove upwards

9 Installation and commissioning

Pyranometer KNX PY • Status: 22.07.2019 • Technical changes reserved. Errors reserved.

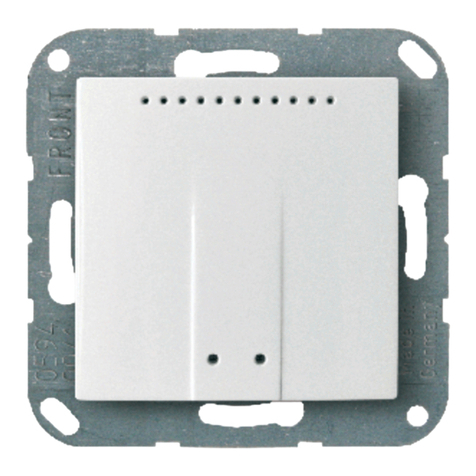

2.3.4. PCB layout

2.3.5. Mounting the sensor

Close the housing by putting the cover back over the bottom part. The cover must snap

in on the left and right with a definite “click”.

Fig. 12

1KNXclamp+/-

2 Programming LED

3 Programming pushbutton for

the teach-in of the device

1

2

3

Fig. 13

Make sure the cover and bottom part are

properly snapped together! This picture is

looking at the closed sensor from under-

neath.

Fastening

10 Addressing of the device at the bus

Pyranometer KNX PY • Status: 22.07.2019 • Technical changes reserved. Errors reserved.

To remove it, the sensor can be simply pulled upwards out of the mount, against the

resistance of the fastening.

2.4. Notes on mounting and commissioning

Do not open the device if water (rain) might ingress: even some drops might damage

the electronic system.

After the bus voltage has been applied, the device will enter an initialisation phase last-

ing a few seconds. During this phase no information can be received or sent via the

bus.

3. Addressing of the device at the bus

The device is supplied with the bus address 15.15.250. You can program another ad-

dress into the ETS by overwriting the 15.15.250 address or by teaching via the pro-

gramming key on the circuit board inside the housing.

4. Maintenance

WARNING!

Risk of injury caused by components moved automatically!

The automatic control can start system components and place people in

danger.

• Always isolate the device from the mains for servicing and cleaning.

The device must regularly be checked for dirt twice a year and cleaned if necessary. In

case of severe dirt, the sensor may not work properly anymore.

ATTENTION

The device can be damaged if water penetrates the housing.

• Do not clean with high pressure cleaners or steam jets.

Fig. 14

Push the housing from above into the fas-

tened mount. The bumps on the mount must

snap into the rails in the housing.

11 Transmission Protocol

Pyranometer KNX PY • Status: 22.07.2019 • Technical changes reserved. Errors reserved.

5. Transmission Protocol

Units of measurement:

Irradiation intensity in Watt per square metre (W/m²)

Application of energy in kilowatt hours per square metre (kWh/m²)

5.1. List of all communication objects

Abbreviations Flags:

C Communication

R Read

WWrite

T Transmit

A Actualise

No. Name Function DPT Flags

0 Measured value W/m² Output 9.022 C R T

1 Measured value KWh/m² Output 9.022 C R T

2 Measured value KWh/m² set on 0 Input 1.006 C R W

3 Request maximum value Input 1.006 C R W

4 Maximum value Output 9.022 C R T

5 Reset maximum value Input 1.006 C R W

6 Sensor malfunction Output 1.001 C R T

7 Threshold value 1: 16 bit value Input / Output 9.008 C R W T A

8 Threshold value 1:

1 = increment | 0 = decrement

Input 1.006 C R W

9 Threshold value 1: Increment Input 1.006 C R W

10 Threshold value 1: Decrement Input 1.006 C R W

11 Threshold value 1:

Switching output

Output 1.006 C R T

12 Threshold value 1:

Switching output block

Input 1.006 C R W

13 Threshold value 2: 16 bit value Input / Output 9.008 C R W T A

14 Threshold value 2:

1 = Increment | 0 = Decrement

Input 1.006 C R W

15 Threshold value 2: Increment Input 1.006 C R W

16 Threshold value 2: Decrement Input 1.006 C R W

17 Threshold value 2:

Switching output

Output 1.006 C R T

18 Threshold value 2:

Switching output block

Input 1.006 C R W

19 Threshold value 3: 16 bit value Input / Output 9.008 C R W T A

12 Transmission Protocol

Pyranometer KNX PY • Status: 22.07.2019 • Technical changes reserved. Errors reserved.

20 Threshold value 3:

1 = Increment | 0 = Decrement

Input 1.006 C R W

21 Threshold value 3: Increment Input 1.006 C R W

22 Threshold value 3: Decrement Input 1.006 C R W

23 Threshold value 3:

Switching output

Output 1.006 C R T

24 Threshold value 3:

Switching output block

Input 1.006 C R W

25 Threshold value 4: 16 bit value Input / Output 9.008 C R W T A

26 Threshold value 4:

1 = Increment | 0 = Decrement

Input 1.006 C R W

27 Threshold value 4: Increment Input 1.006 C R W

28 Threshold value 4: Decrement Input 1.006 C R W

29 Threshold value 4:

Switching output

Output 1.006 C R T

30 Threshold value 4:

Switching output block

Input 1.006 C R W

31 Logic input 1 Input 1.001 C R W

32 Logic input 2 Input 1001 C R W

33 Logic input 3 Input 1001 C R W

34 Logic input 4 Input 1001 C R W

35 Logic input 5 Input 1001 C R W

36 Logic input 6 Input 1001 C R W

37 Logic input 7 Input 1001 C R W

38 Logic input 8 Input 1001 C R W

39 AND Logic 1 Switching output 1.001 C R T

40 AND Logic 1 8 bit output A 5.010 C R T

41 AND Logic 1 8 bit output B 5.010 C R T

42 AND Logic 2 Switching output 1.001 C R T

43 AND Logic 2 8 bit output A 5.010 C R T

44 AND Logic2 8 bit output B 5.010 C R T

45 OR Logic 1 Switching output 1.001 C R T

46 OR Logic 1 8 bit output A 5.010 C R T

47 OR Logic 1 8 bit output B 5.010 C R T

48 OR Logic 2 Switching output 1.001 C R T

49 OR Logic 2 8 bit output A 5.010 C R T

50 OR Logic 2 8 bit output B 5.010 C R T

51 Software version readable 217.001 C R

No. Name Function DPT Flags

13 Setting of parameters

Pyranometer KNX PY • Status: 22.07.2019 • Technical changes reserved. Errors reserved.

6. Setting of parameters

6.1. General settings

Measurement value in W/m² • do not transmit

• transmit periodically

• transmit on change

• transmit on change and periodically

From measurement value change of

(only if sending “on change“ )

1 … 50%; 5 %

Periodically transmit measured value all

(only if sending “periodically“)

5 secs … 2 h

Use measurement value in kWh/m² No • Yes

Transmission behaviour as with measured value in W/m²

Reset measurement value KWh/m² to 0 • at sunrise

• on reception of a communication object

Use maximum value No • Yes

(Value is not retained after reset)

Use malfunction object No • Yes

Maximum message rate 1 • 2 • 3 • 5 • 10 • 20 messages per second

14 Setting of parameters

Pyranometer KNX PY • Status: 22.07.2019 • Technical changes reserved. Errors reserved.

6.2. Threshold values

The instantaneous global radiation in Central Europe at mid-day in summer is when

the sky is clear 900 … 1000 W/m² and when the sky is overcast approx. 100 W/m².

6.2.1. Threshold value 1 / 2 / 3 / 4

Threshold value

If threshold value is set via Parameter:

If threshold value is set via Communication object

Switching output

Transmission delays after power up and programming

Measurement values and threshold values 5 secs … 2 h

Switching outputs and logic outputs 5 secs … 2 h

Use threshold value 1 / 2 / 3 / 4 No • Yes

Threshold value setting via Parameter • Communication object

Threshold value setting via Parameter

Threshold value in W/m² 0 … 2500; 500

Hysteresis of the threshold value in % 0 … 50; 20

Threshold value setting via Communication object

The last communicated value shall be retai-

ned

• not

• after voltage restoration

(the changed threshold value can be safed

at least 100,000 times )

• after voltage restoration and

programming (Attention: Do not use

during initial start-up)

Start threshold value in W/m²

valid until 1. communication

0 … 2500; 500

Type of threshold value change • Absolute value with a 16-bit comm. object

• Increase / Decrease with a comm. object

• Increase / Decrease with two

comm. objects

Step length in W/m²

(only if type of threshold value change is

„Increase/Decrease“)

1 • 2 • 5 • 10 • 20 • 50 • 100 • 200

Hysteresis of the threshold value in % 0 … 50; 20

Output is

(TV = Threshold Value)

• TV above = 1 | TV - Hyst. below = 0

• TV above = 0 | TV - Hyst. below = 1

• TV below = 1 | TV + Hyst. above = 0

• TV below = 0 | TV + Hyst. above = 1

Switching delay from 0 to 1 none • 1 secs … 2 h

15 Setting of parameters

Pyranometer KNX PY • Status: 22.07.2019 • Technical changes reserved. Errors reserved.

Block

Only if switching output block is used:

Blocking

„Blocking“ only appears if using „Switching output sends on change“

If block of the switching output is used:

6.3. Logic

Switching delay from 1 to 0 none • 1 secs … 2 h

Switching output transmits • on change

• on change to 1

• on change to 0

• on change and periodically

• on change to 1 and periodically

• on change to 0 and periodically

Transmit switching output in the cycle of

(only if sending “periodically“)

5 secs … 2 h

Use switching output block No • Yes

Use switching output block Yes

Evaluation of blocking object • on value 1: block | on value 0: release

• on value 0: block | on value 1: release

Value of blocking object

before 1. communication

0 • 1

Behaviour of switching output on block • do not transmit message

• transmit 0

• transmit 1

Behaviour of switching output on release if switching output = 0 transmit 0

Use block of the switching output Yes • No

Use block of the switching output Yes

Evaluation of the blocking object • if value 1: block | if value 0: release

• if value 0: block | if value 1: release

Value of the blocking object before

1. communication

0• 1

Behaviour of the switching output

with blocking

• do not send telegram

•send0

•send1

Behaviour of the switching output

with release (selection possible according

to previous settings)

• do not send telegram

• send status of the switching output

• if switching output = 1 => send 1

• if switching output = 0 => send 0

Communication objects logic inputs do not release • release

16 Setting of parameters

Pyranometer KNX PY • Status: 22.07.2019 • Technical changes reserved. Errors reserved.

AND Logic

OR Logic

6.3.1. AND Logic 1 / 2

Logic output sends “one 1 bit Object“:

Logic output sends “two 8 bit objects“:

Logic 1 / 2 not active • active

Logic 1 / 2 not active • active

1. / 2. / 3. / 4. Input • do not use

• all switching events which the sensor

provides (see “Linkage inputs of the AND

logic”)

Logic output sends • not

• one 1 bit object

• two 8 bit objects

Logic output sends one 1 bit object

if logic = 1 object value 1 • 0

if logic = 0 object value 1 • 0

Communication object

AND Logic 1 sends

• in case of the change of logic

• in case of the change of logic to 1

• in case of the change of logic to 0

• in case of the change of logic and

cyclically

• in case of the change of logic to 1 and

cyclically

• in case of the change of logic to 0 and

cyclically

send cyclically every

(only if sending “cyclically”)

5 sec … 2 h

Logic output sends two 8 bit objects

if logic = 1 object A value 0 … 255; 127

if logic = 0 object A value 0 … 255

if logic = 1 object B value 0 … 255; 127

if logic = 0 object B value 0 … 255

17 Setting of parameters

Pyranometer KNX PY • Status: 22.07.2019 • Technical changes reserved. Errors reserved.

6.3.2. Linkage inputs of AND Logic

do not use

Communication object logic input 1

Communication object logic input 1 inverted

Communication object logic input 2

Communication object logic input 2 inverted

Communication object logic input 3

Communication object logic input 3 inverted

Communication object logic input 4

Communication object logic input 4 inverted

Communication object logic input 5

Communication object logic input 5 inverted

Communication object logic input 6

Communication object logic input 6 inverted

Communication object logic input 7

Communication object logic input 7 inverted

Communication object logic input 8

Communication object logic input 8 inverted

Threshold value 1

Threshold value1 inverted

Threshold value 2

Threshold value 2 inverted

Threshold value 3

Threshold value 3 inverted

Threshold value 4

Threshold value 4 inverted

Malfunction

Malfunction inverted

6.3.3. OR Logic 1 / 2

Communication objects

AND Logic 1 A and B sends

• in case of the change of logic

• in case of the change of logic to 1

• in case of the change of logic to 0

• in case of the change of logic and

cyclically

• in case of the change of logic to 1 and

cyclically

• in case of the change of logic to 0 and

cyclically

send cyclically every

(only if sending “cyclically”)

5 sec … 2 h

1. / 2. / 3. / 4. Input • do not use

• all switching events which the sensor pro-

vides (see “Linkage inputs of the OR logic”)

18 Setting of parameters

Pyranometer KNX PY • Status: 22.07.2019 • Technical changes reserved. Errors reserved.

All settings of the OR logic correspond to those of the AND logic.

6.3.4. Linkage inputs of OR Logic

The linkage inputs of the OR logic correspond with the parameters of the AND logic.

The OR logic is additionally provided with the following inputs:

AND Logic output 1

AND Logic output 1 inverted

AND Logic output 2

AND Logic output 2 inverted

Logic output sends • one 1 bit object

• two 8 bit objects

Other manuals for KNX PY

1

Table of contents

Other elsner elektronik Measuring Instrument manuals

elsner elektronik

elsner elektronik TH PF Series User manual

elsner elektronik

elsner elektronik KNX SO250 Guide

elsner elektronik

elsner elektronik KNX LW sl 70164 Guide

elsner elektronik

elsner elektronik KNX RW Series User manual

elsner elektronik

elsner elektronik KNX TH-UP basic Guide

elsner elektronik

elsner elektronik KNX PY User manual

elsner elektronik

elsner elektronik KNX TH-UP basic Guide

elsner elektronik

elsner elektronik KNX I4-ERD Guide

elsner elektronik

elsner elektronik KNX eTR M1 User manual