KNX eTR M push button 1

KNX eTR M push button • Version: 05.02.2021 • from version 0.1.4 • Technical changes and errors excepted. • Elsner Elektronik GmbH • Sohlengrund 16 • 75395 Ostelsheim • Germany • www.elsner-elektronik.de • Technical Service: +49 (0) 7033 / 30945-250

EN

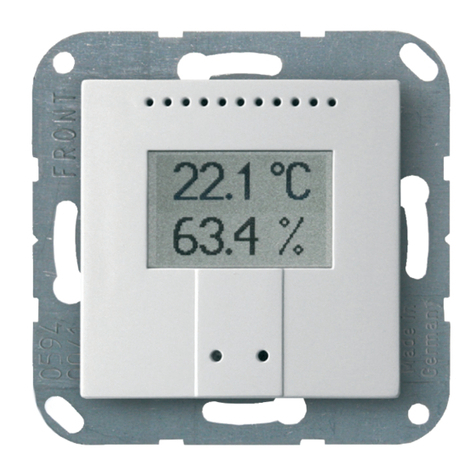

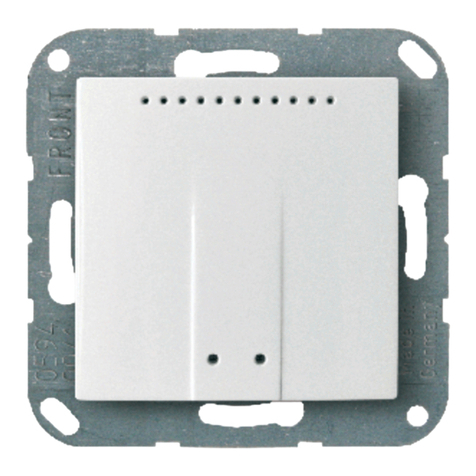

KNX eTR M1, KNX eTR M2,

KNX eTR M4

Push Button with Temperature Sensor

Technical specifications and installation instructions

1. Description

The KNX eTR M push button has touch-sensitive buttons, with which functions

in the KNX building bus system can be called, such as switch lights and devices,

dim, activate drives, send values, scenarios. A white LED is integrated into each

touch button, the behaviour of which can be adjusted.

A temperature sensor is integrated into KNX eTR M. An external temperature rea-

ding can be received via the bus and processed with its own data to create a total

temperature (mixed value).

Communication objects can be connected by AND and OR logic gates.

KNX eTR M1 functions:

•1Touch bus button, can be configured as switch, selector switch, dimmer,

blind (position and slats up/stop OR down/stop), shutters (up/down/stop),

awning (in/out/stop), window (closed/open/stop), as 8 or 16-bit encoder or for

scenario recall/storage

KNX eTR M2 functions:

•2 Touch bus button, can be configured as switch, selector switch, dimmer,

for operating drives, as 8 or 16-bit encoder or for scenario recall/storage

•Area function when touching both push buttons. Can be configured as

switch, selector switch, as 8 or 16 bit encoder or for scenario recall

KNX eTR M4 functions:

•4 Touch bus button, can be configured as switch, selector switch, dimmer,

for operating drives, as 8 or 16-bit encoder or for scenario recall/storage

•Area function when touching two or more push buttons. Can be configured

as switch, selector switch, as 8 or 16 bit encoder or for scenario recall

Function of all models:

•OneLED per touch area. On for object value = 1 / Off for object value = 0, On

after pressing button for settable time or always off. Settable, as to whether

LED flashes at block object value = 1

•Temperature measurements. Mixed value from own measured value and

external values (proportion can be set by percentage)

•2 AND and 2 OR logic gates each with 4 inputs. 8 logic inputs (in the form

of communications objects) can be used as inputs for the logic gates. The

output from each gate can be configured optionally as 1-bit or 2 x 8-bit

Configuration is made using the KNX software ETS 5. The product file can be dow-

nloaded from the ETS online catalogue and the Elsner Elektronik website on

www.elsner-elektronik.de in the “Service” menu.

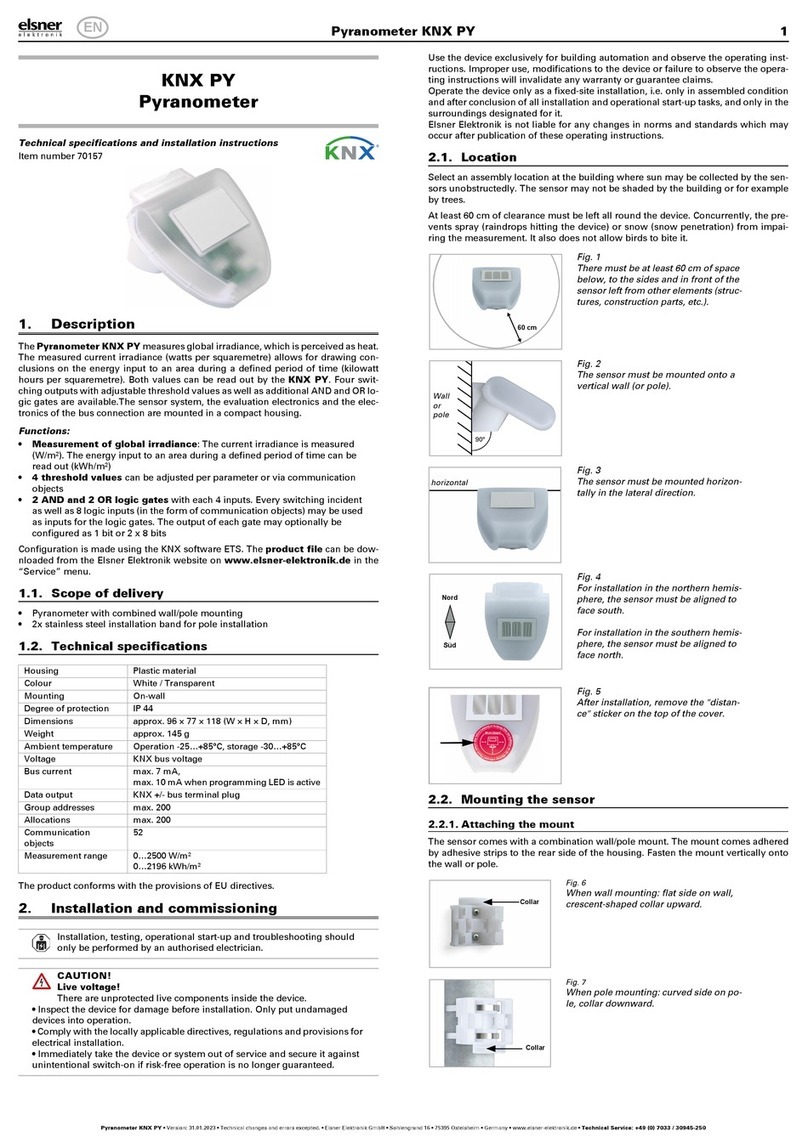

1.0.1. Area function

If the area function in ETS has been activated, another function is available alongsi-

de the regular key functions. This is triggered by touching multiple keys, e.g. if you

touch the sensor with the palm of your hand.

Using the area function

If a key is pressed and another (different) key is touched within 0.2 seconds, the ac-

tion set in the ETS is performed for the area operation (See Fig. 1 a) and b)). The keys

are then blocked for 0.5 seconds.

Using the normal key function

If a key is pressed and no other key is touched within 0.2 seconds, the normal key

function is enabled/provided for 5 seconds (See Fig. 1 c) and d)). This is extended

for 5 seconds with each push of the button.

If the area function in the ETS is disabled, the keys can be used normally at any time.

1.0.2. Scope of delivery

• Push button with mounting

• 4 screw anchors 4 × 20 mm, 4 flat head screws 3 × 25 mm

1.1. Technical data

The product is compliant with the provisions of EU Directives.

1.1.1. Accuracy of the measurement

Measurement variations from permanent sources of interference (see chapter Ins-

tallation position) can be corrected in the ETS in order to ensure the specified accu-

racy of the sensor (offset).

When measuring temperature, the self-heating of the device is considered by the

electronics. The heating is compensated by the software.

2. Installation and commissioning

2.1. Installation notes

Installation, testing, operational start-up and troubleshooting should

only be performed by an electrician.

CAUTION!

Live voltage!

There are unprotected live components inside the device.

• National legal regulations are to be followed.

• Ensure that all lines to be assembled are free of voltage and take

precautions against accidental switching on.

• Do not use the device if it is damaged.

• Take the device or system out of service and secure it against

unintentional use, if it can be assumed, that risk-free operation is

no longer guaranteed.

The device is only to be used for the intended purpose described in this manual. Any

improper modification or failure to follow the operating instructions voids any and

all warranty and guarantee claims.

After unpacking the device, check it immediately for possible mechanical damage.

If it has been damaged in transport, inform the supplier immediately.

KNX eTR M1:

Item numbers

71110 (white),

71112 (black)

KNX eTR M2

Item numbers

71120 (white),

71122 (black)

KNX eTR M4

Item numbers

71130 (white),

71132 (black)

Casing Genuine glass, plastic

Colours • similar to RAL 9003 signal white

• similar to RAL 9005 deep black

Installation on-wall (directly or with a socket Ø60 mm,

resp. cavity wall socket for hole Ø68 mm)

Degree of protection IP 10

Dimensions housing approx. 81,5 x 81,5 (W x H, mm),

mounting depth approx. 12 mm

Total weight approx. 70 g

Ambient temperature Operating 0…+55°C, storage -30…+85°C

Ambient humidity 5...95% RH, avoid condensation

Operating voltage KNX bus voltage

Bus current max. 10 mA

Data output KNX +/- Bus plug-in terminal

Group addresses max. 183

Allocations max. 183

Communication

objects

KNX eTR M1: 44

KNX eTR M2: 55

KNX eTR M4: 73

Temperature measu-

rement range

0…+55°C

Temperature resolu-

tion

0.1°C

Key function readiness

Key function readiness

Fig. 1

0s 0.2s 5.2s

Key Y

Key X

Key X

Design

FunctionY

Key function readiness

Area function

Examples of normal key functions

0.5 s block

Key X

Design

Area function

KeyY

Design

Function X

a)

b)

c)

d)

Key X

KeyY 0.5 s block

Design

Area function

Area function examples

readiness