Elster Instromet RVG User manual

Instruction Manual

Rotary Gas Meters

Type RVG · RVG-ST

Betriebsanleitung

Drehkolbengaszähler

Typ RVG · RVG-ST

Mode d’emploi

Compteur de gaz à pistons rotatifs

Type RVG · RVG-ST

Manual de instrucciones

Contador de gas de pistones rotativos

Modelos RVG · RVG-ST

Istruzioni d’uso

Contatore gas a pistoni rotanti

Tipo RVG · RVG-ST

Installatie voorschrift

Rotorgasmeters

Type RVG · RVG-ST

Elster GmbH

Steinern Straße 19 · 55252 Mainz-Kastel

Tel. +49 (0)6134/605-0 · Fax +49 (0)6134/605-390

www.elster-instromet.com

73019203f/04.2009/A P&M

1© Elster GmbH · All rights reserved · Subject to technical modification

English

Elster-Instromet

Deutsch

Nederlands Italiano Español Français

Instruction Manual

Rotary Gas Meters

Type RVG · RVG-ST

Betriebsanleitung

Drehkolbengaszähler

Typ RVG · RVG-ST

Mode d’emploi

Compteur de gaz à pistons rotatifs

Type RVG · RVG-ST

Manual de instrucciones

Contador de gas de pistones rotativos

Modelos RVG · RVG-ST

Istruzioni d’uso

Contatore gas a pistoni rotanti

Tipo RVG · RVG-ST

Installatie voorschrift

Rotorgasmeters

Type RVG · RVG-ST

2© Elster GmbH · All rights reserved · Subject to technical modification

Elster-Instromet

3© Elster GmbH · All rights reserved · Subject to technical modification

English

Elster-Instromet

RVG G16-G400

RVG-ST G10-G25, threaded version RVG-ST G10-G25, flanged version

Instruction Manual

Rotary Gas Meters

Type RVG · RVG-ST

4© Elster GmbH · All rights reserved · Subject to technical modification

Elster-Instromet

5© Elster GmbH · All rights reserved · Subject to technical modification

English

Elster-Instromet

Contents

1. Staff .......................................................................................................................... 06

2. Legal Declarations .................................................................................................... 06

3. Intended Use and Field of Application ..................................................................... 57

4. Technical Data .......................................................................................................... 08

5. Operating Location ................................................................................................... 09

6. Installation Position, Flow Direction and Wall Clearance ......................................... 09

7. Installation / Connection......................................................................................... 111

8. Lubrication and Maintenance ................................................................................... 13

9. Commissioning ......................................................................................................... 15

10. Function Check ........................................................................................................ 16

11. Pulse Generators ...................................................................................................... 16

12. Pressure Test Point .................................................................................................. 18

13. Temperature Test Points .......................................................................................... 18

14. Index Versions .......................................................................................................... 19

15. Absolute ENCODER S1D ......................................................................................... 20

16. Care and Cleaning .................................................................................................... 21

17. Recycling and Environmental Protection ................................................................. 21

18. Annex A (ATEX Approvals) ....................................................................................... 22

19. Annex B (Plastics Used) ........................................................................................... 23

20. Annex C (Declaration of Conformity) ........................................................................ 24

6© Elster GmbH · All rights reserved · Subject to technical modification

Elster-Instromet

1. Staff

2. Legal Declarations

These Instructions are aimed at staff who have adequate specialist and technical

knowledge (in Germany, for instance, in accordance with DVGW Codes of Practice 492 and

495 or comparable technical regulations) on the basis of their training and experience in the

sector of energy and gas distribution.

–Declaration of Conformity – see Annex C.

–Period of validity of calibration – this is based on the regulations of the country concerned,

in which the rotary gas meter will be used.

–The calibration of rotary gas meters is only valid for the period of validity of calibration.

Once this has elapsed, rotary gas meters may no longer be used for purposes which are

subject to obligatory calibration.

7© Elster GmbH · All rights reserved · Subject to technical modification

English

Elster-Instromet

3. Intended Use and Field of Application

This product is intended

for calibratable volumetric metering of

–flammable gases: natural gas/town gas/butane,

–non-flammable gases: air/nitrogen/inert gases,

–and is suitable for use in potentially explosive atmospheres of Category 2 (Zone 1) of

Class EX II 2 G c IIC.

Other fields of application / media on request.

This product is not intended for

–metering of aggressive gases, e.g. biologically produced methane or sewage gases,

oxygen, acetylene.

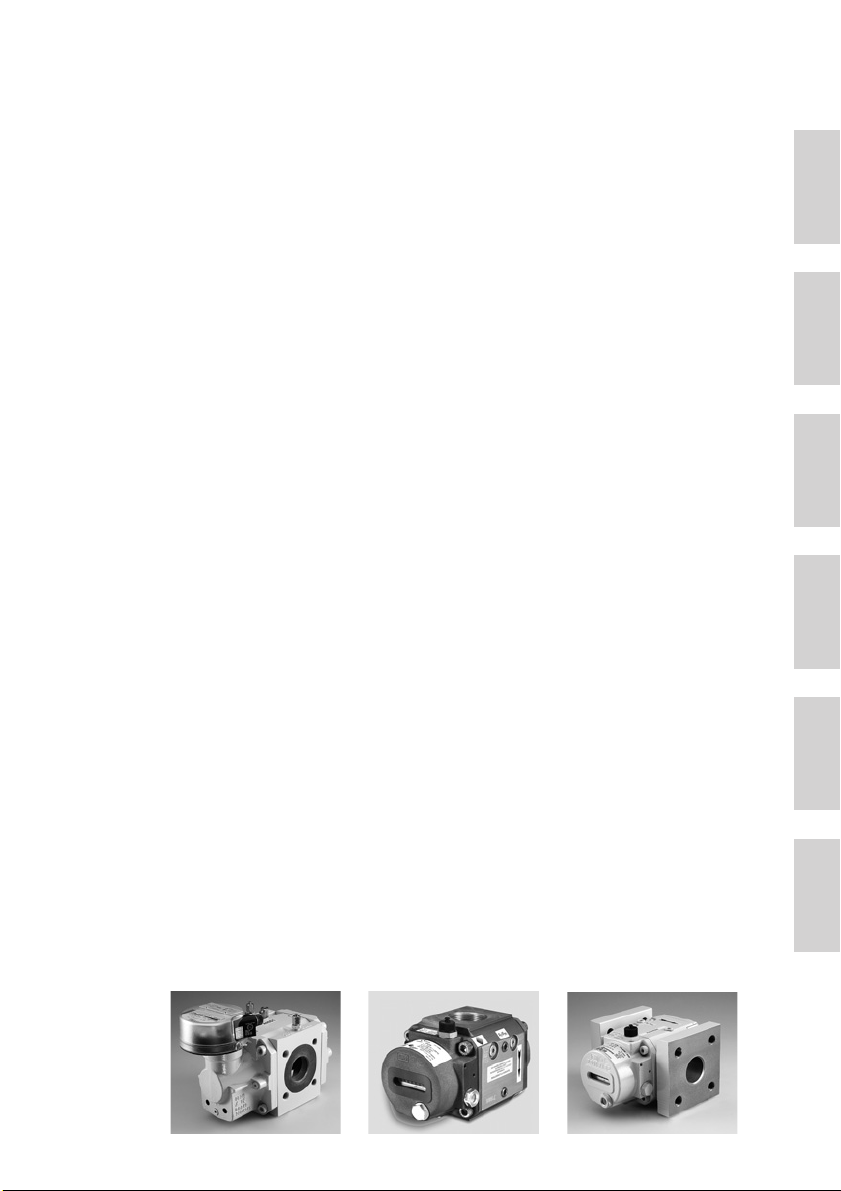

1Meter housing 17Index head

2Housing cover (front) 18HF pulse generator

3Housing cover (rear) 19LF pulse generator

4Pistons 10 Pressure test point

5Gear assembly 11 Temperature test point

6Synchronising gears 12 Volume corrector (optional)

Please contact your Elster-Instromet Customer Service (Tel. +49 (0)6134-605-0 / -346)

for assistance in commissioning, maintenance and installation of encoders, pulse generators

and volume correctors for instance.

8© Elster GmbH · All rights reserved · Subject to technical modification

Elster-Instromet

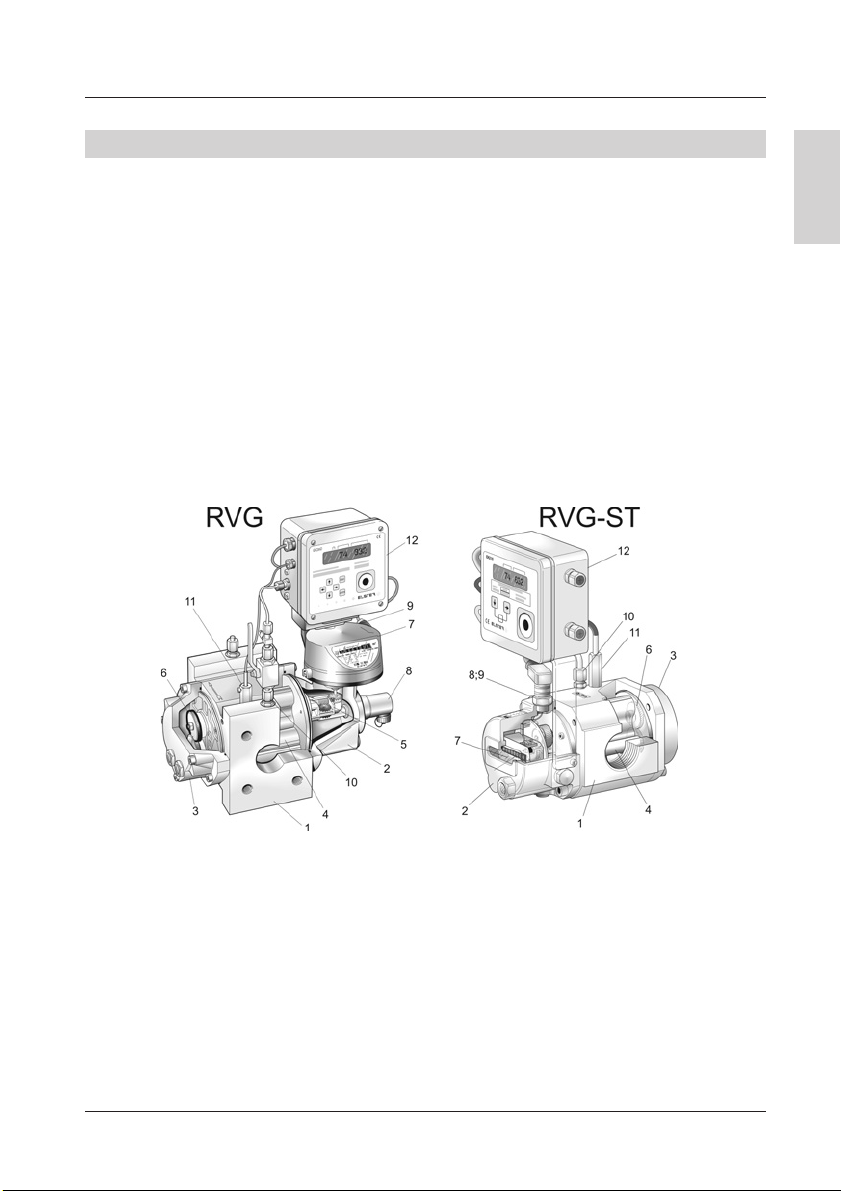

4. Technical Data

Rotary gas meters in accordance with DIN EN 12480

Type RVG-ST RVG

Size: G10 to G25 G16 to G400

Nominal diameter: DN 25 to DN 50 DN 40 to DN 150

Pressure ratings: PN 10/16 or CLASS 150

Temperature ranges:

– gas / ambient / storage -20 ˚C to +60 ˚C*

– gas / ambient / storage (MID) -10 °C to +55 °C-25 ˚C to +55 ˚C*

Housing material: Aluminium Spheroidal graphite

cast iron or aluminium

Mechanical ambient conditions: M1

*Measuring ranges ≥1:130, -10˚C

Pulse generators

LF pulse generator E1 Wiegand pulse generator HF pulse generator

(reed contact) (in accordance with

DIN EN 50227)

Umax = 24 V Umax = 30 V Urated = 8 V DC

Imax = 50 mA Imax = 100 mA I 욷2.1 mA (exposed)

I 울1.2 mA (covered)

Pmax = 0.25 VA Pmax = 600 mW U 쏝5.9 V (exposed)

U 쏜6.8 V (covered)

Ri= 100 Ω(series resistor) Ri= 1 kΩ

Absolute ENCODER S1D

Absolute ENCODER S1D

Index

Number of indexes 2

Number of digit rollers per index 8

Safety class IP 67

Interfaces NAMUR (II 2 G EEx ia IIC T4) or

ATEX approval SCR / SCR Plus (II 2 G EEx ib IIB T4) or

M-BUS

LF pulse generator Optional or retrofittable INS-10, -11, -12

Umax = 24 V, Imax = 50 mA, Pmax = 0.25 VA,

Ri= 100 Ω(series resistor)

9© Elster GmbH · All rights reserved · Subject to technical modification

English

Elster-Instromet

5. Operating Location

6. Installation Position, Flow Direction and Wall Clearance

If you …

–wish to mix in odorisation agents or

– use solenoid valves,

please always fit them only downstream of the meter. Otherwise, the device may be

damaged.

The flow through the meter must be free of vibrations / pulsations in order to avoid

measuring errors.

Compliance with the specified operating and ambient conditions as indicated on the type

label is absolutely essential for safe operation of the meter and additional equipment.

The gas may not contain suspended particles > 50 m. In addition, the gas must be dry.

Otherwise, the meter may be damaged.

To protect the meter, a coarse filter (cone strainer with mesh size 250 m) must be installed

on all new installations, and is also recommended for existing installations. The strainer

should be removed after approximately 4 to 6 weeks.

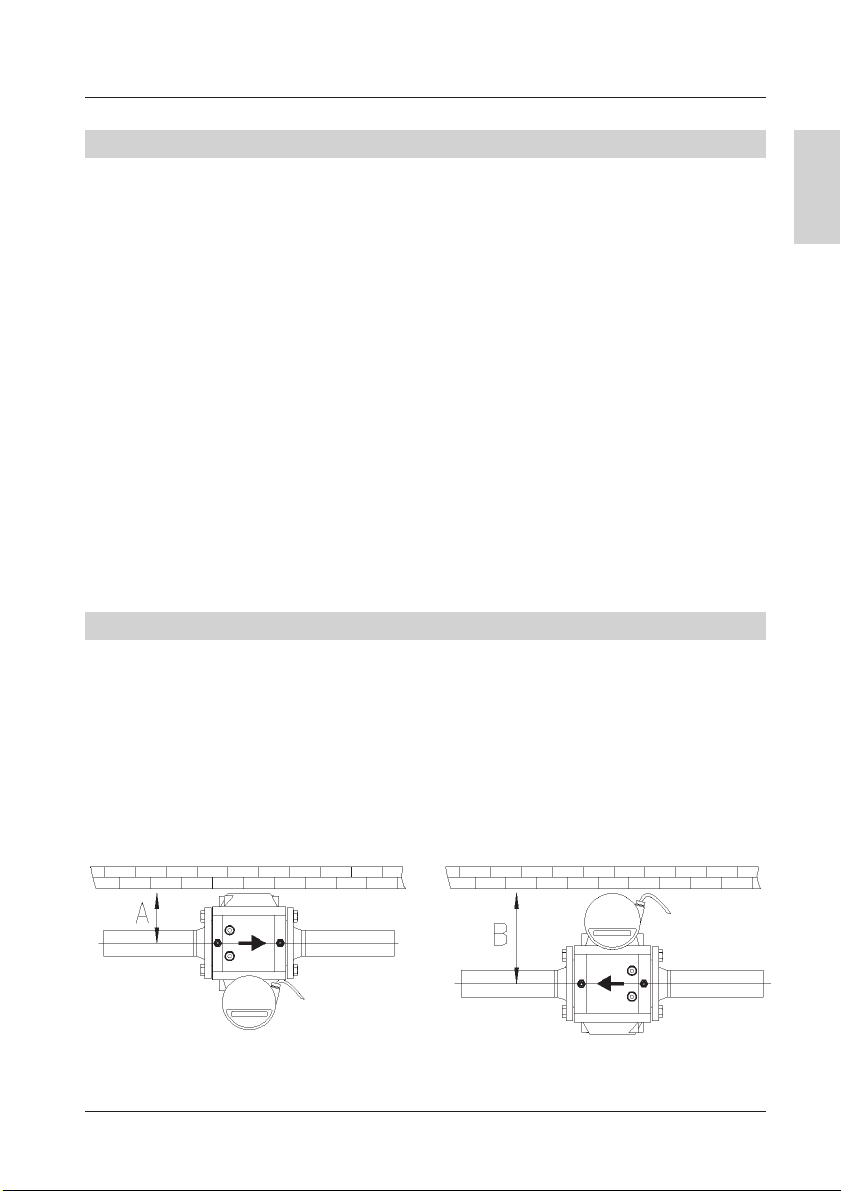

Type RVG:

Gas can be passed through the Type RVG rotary gas meter both horizontally and vertically.

The index head can be turned through up to 355°for optimum ease of reading in different

installation/operating positions. If the meter is equipped with oil-level gauge glasses on just

one side, then the meter must be mounted with a gap (욷B + 30 mm) from the centre of the

pipe to the wall, in order to facilitate access for maintenance (Figure 1 and Table 1):

Figure 1: Horizontal flow from left to right and from right to left

Wall Wall

10 © Elster GmbH · All rights reserved · Subject to technical modification

Elster-Instromet

ABB

with HF transmitter

G16 – G65 120 190 250

G100 170 240 300

G160 200 245 305

G250 230 275 335

G400 290 335 395

Table 1: Minimum wall clearance A or B in mm

Type RVG-ST:

The Type RVG-ST rotary gas meter can be installed both horizontally and vertically, but the

direction of flow must be set at the factory. The meter only has an oil-level gauge glass on

the front and must be mounted with a gap of at least 85 mm between the pipe centre and the

wall (Figure 2).

Figure 2: Horizontal flow from left to right

Wall

11© Elster GmbH · All rights reserved · Subject to technical modification

English

Elster-Instromet

7. Installation / Connection

Warning! Never clean the plastic hood of the index with a

dry cloth owing to the risk of explosion resulting from

electrostaticdischarge!Please only ever use an adequately

moistened cloth!

Before installation please ensure:

– that the protective caps and/or plastic sheeting is or are removed,

–that the meter and accessories have been inspected for transport damage,

– that the pistons rotate easily in the measuring chamber (e.g. by blowing on them),

–that the accessories have been checked for completeness (e.g. plug connectors, oil for

initial filling).

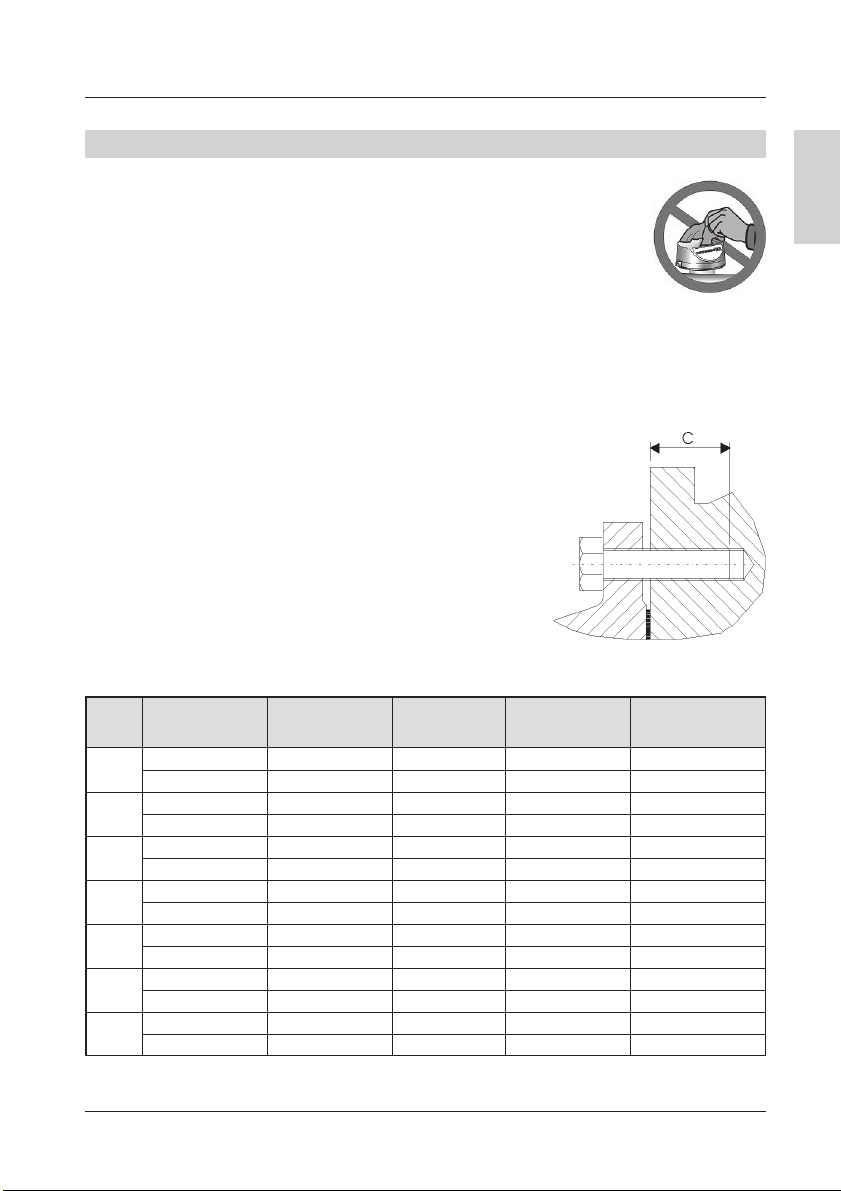

You will require the following items for installation:

Type RVG and Type RVG-ST with flange:

–Suitable seals/gaskets for the relevant gases.

–For installing the meter in the pipe, use screws in accord-

ance with DIN 931. The screw length must be selected so

that a thread reach of C mm (Table 2) into the meter is

guaranteed (Figure 3). The recommended maximum

tightening torque is defined in the table 2.

Figure 3

DN Screw size Screws Thread reach Max. tight-

per meter C mm ening torque Nm

25 PN 10/16 M12 8 14 – 20 23

CLASS 150 M12 8 14 – 20 25

32 PN 10/16 M16 8 16 – 22 46

CLASS 150 M12 8 14 – 20 31

40 PN 10/16 M16 8 16 – 22 58

CLASS 150 M12 8 14 – 20 36

50 PN 10/16 M16 8 16 – 22 60

CLASS 150 M16 8 16 – 22 47

80 PN 10/16 M16 16 16 – 22 52

CLASS 150 M16 8 16 – 22 83

100 PN 10/16 M16 16 16 – 22 58

CLASS 150 M16 16 16 – 22 59

150 PN 10/16 M20 16 20 – 28 83

CLASS 150 M20 16 20 – 28 96

Table 2: Flange screws

12 © Elster GmbH · All rights reserved · Subject to technical modification

Elster-Instromet

Type RVG-ST threaded version:

–Suitable seals/gaskets for the relevant gases.

–You will require the following connection elements (which can be ordered from Elster-

Instromet) for installing the meter into the pipe:

Figure 4: Connection elements for Type RVG-ST

Then install the meter (Type RVG and Type RVG-ST):

– gas-tight,

–with the supplied accessories,

–only in flow direction (as marked by an arrow on the meter housing or index head S1D),

– only unstressed,

–he piston axes must be horizontal, check using a spirit level (Figure 5),

–when fitting the seals and gaskets, ensure that they are aligned concentrically and do

not project into the flow channel,

–weatherproof.

If you have specified the installation or operating position when ordering, all attachments will

have been fitted in accordance with the installation position ex-works.

1Pipe

2Insert

3Union nut

4O-ring

5Threaded part

6O-ring

7Strainer

8Retaining ring

Figure 5: Checking the meter using a spirit level

Horizontal installation Vertical installation Incorrect installation

13© Elster GmbH · All rights reserved · Subject to technical modification

English

Elster-Instromet

–Only use original spare parts supplied by Elster-Instromet.

–Fill with oil before commissioning.

–To fill with oil, depressurise the meter.

–The quantity of oil required for operation, as well as a syringe for filling, are included in

the delivery.

–Use Shell Morlina S2 BL 10 oil or equivalent (e.g. Shell Risella 917) (Inspection kit Ident.

No. 73016605 or 73014893).

–The front and rear oil chambers are linked with one another, so that the meter can be

serviced with oil from just one side.

Type RVG:

–There are three openings available for filling or draining oil, and two oil-level gauge

glasses on the front and (optionally) on the rear of the meter (Figure 7).

–Unscrew and remove the oil filler plug (E, Figure 7) from the front housing cover.

–Remove one oil filler plug (E) from the rear housing cover, so that the oil can flow more

easily into the rear oil chamber.

Type RVG-ST:

–In the case of horizontal flow, there are two openings available for filling with oil (E or V).

The drain opening A is located at the lowest point. The oil-level gauge glass O is located

on the front side of the meter, below the index (Figure 8, left).

–In the case of vertical flow, there is only one opening available (E) for filling with oil. The

drain opening A is located at the lowest point. The oil-level gauge glass is now located

on the right on the front housing cover (Figure 8, right).

–Remove the oil filler plug (E, and if applicable V) from the front housing cover.

Type RVG and Type RVG-ST:

–Fill with oil slowly, using the syringe. It will take 5 to 10

minutes until the oil reaches the same level in both oil

chambers. The oil volume is correct when the oil level is

located in the lower third of the gauge glass (Figure 6). The

required quantity of oil depends on the installation position;

for guidance, see Tables 3 and 4.

8. Lubrication and Maintenance

Figure 6:

Oil level in gauge glass

If you wish to install the unit vertically at a later point, you must turn any other attachments,

e.g. volume corrector, through 90°.

We recommend that you contact our Elster-Instromet Customer Service (Tel. +49

(0)6134-605-0 / -346) for such conversion work.

14 © Elster GmbH · All rights reserved · Subject to technical modification

Elster-Instromet

–Excess lubricant can contaminate the measuring chamber.

– Re-close all oil filler necks (seal using O-rings).

–The time interval for checking the oil level depends on the individual operating conditions

and gas qualities. Once it has been commissioned, the measuring instrument does not

require any special servicing. In the case of operation with natural gas, the oil should

generally be changed every 5 years, or earlier in the case of contamination.

Instructions for checking oil:

–During operation the oil is distributed in the meter, which means that under certain

circumstances no oil is visible in the gauge glass. The oil level must therefore be checked

once the meter has been idle for approx. 5 minutes. To refill it, the meter must be

depressurised.

–Never transport a rotary gas meter containing oil. Make sure that the oil is drained out

before transporting the meter (e.g. when sending the meter for repairs), otherwise the oil

will penetrate the measuring chamber and damage the meter.

Flow Flow Flow Flow

(vertical) (horizontal) (vertical) (horizontal)

from bottom to top from left to right from top to bottom from right to left

E= Oil filler neck O= Oil-level gauge glass A= Oil drain sleeve

Figure 7: Permitted operating positions, oil filling and oil-level display for Type RVG

Oil quantity

Flow direction RVG with GGG 40 housing RVG with aluminium housing

G16 – G100 G160 – G250 G16 – G100 G160 – G400

Horizontal Approx. 100 ml Approx. 240 ml Approx. 65 ml Approx. 190 ml

Vertical Approx. 225 ml Approx. 525 ml Approx. 170 ml Approx. 535 ml

Table 3: Guide values for oil quantity on commissioning and for oil changes for Type RVG

15© Elster GmbH · All rights reserved · Subject to technical modification

English

Elster-Instromet

9. Commissioning

Flow (horizontal) Flow (vertical)

from left to right from top to bottom

E = Oil filler neck O = Oil-level gauge glass

A = Oil drain sleeve V = Screw plug

Figure 8: Horizontal and vertical installation positions, oil filling and oil-level display for Type

RVG-ST

Flow direction Oil-level gauge glass Oil quantity

Horizontal On the front side Approx. 25 ml

of the meter

Vertical On the side Approx. 80 ml

of the housing cover

Table 4: Guide values for oil quantity on commissioning and for oil changes for Type

RVG-ST

In order not to damage the meter,

–slowly fill the system until operating pressure is reached.

– The pressure rise may not exceed 350 mbar/s. You should use a bypass line for filling

(recommendation: 12 mm pipe diameter).

–Do no exceed the measuring range even briefly!

–Conduct a tightness test!

Attention: you must please note the instructions in Section 5, „Operating Location“.

Oil level

Oil level

16 © Elster GmbH · All rights reserved · Subject to technical modification

Elster-Instromet

10. Function Check by Means of Pressure Loss Measurement

11. Pulse Generators

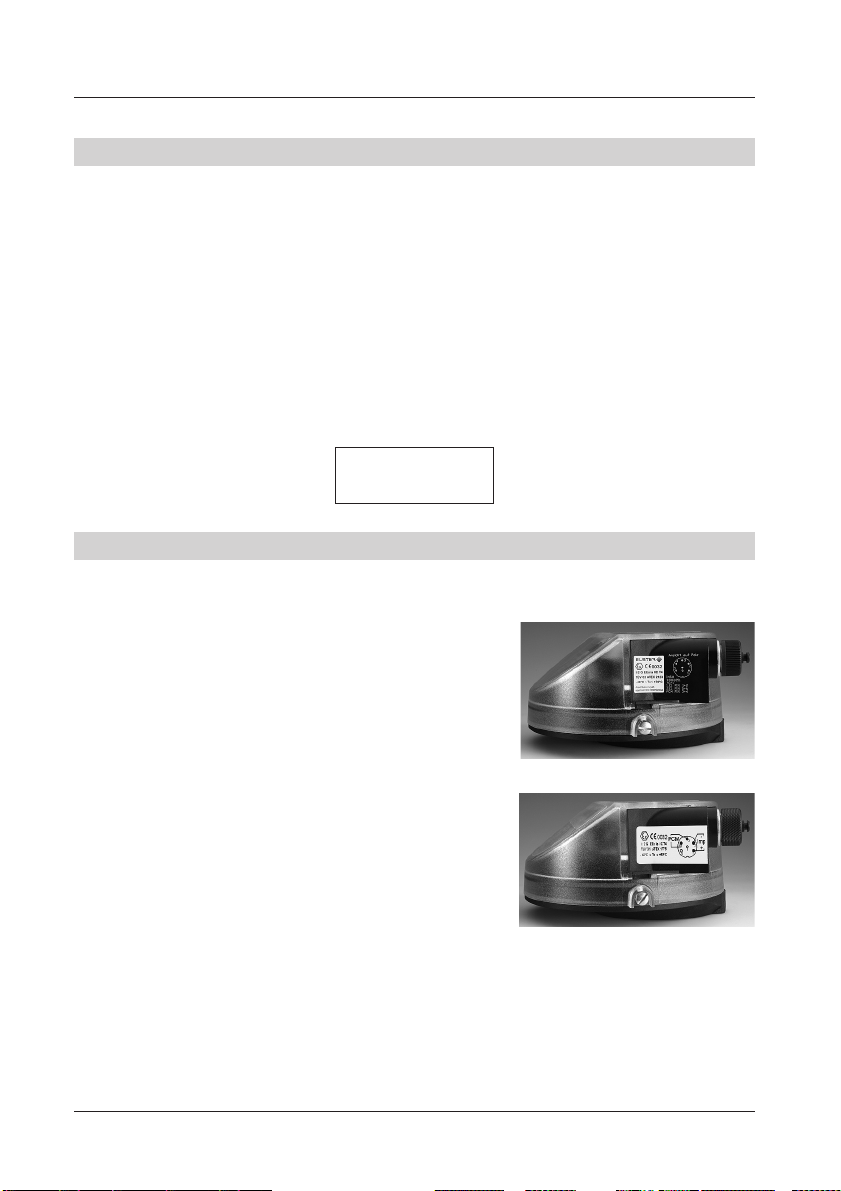

IN-S11

IN-W11

The correct function of the rotary gas meter can be inferred by measuring the pressure loss.

If the pressure loss has increased by more than 50% compared to the value at the initial start-

up, then there may be dirt, for example, in the measuring chamber that can lead to an

incorrect result being obtained. In comparing the pressure loss, the load and the operating

pressure must be considered.

We recommend recording the pressure loss at several points in the flow when commissioning

and logging these with the current operating pressure. If the current flow rate and operating

pressure in later checks deviate from the original values, then the nominal pressure loss can

be calculated from the original values. The pressure loss is proportional to the absolute

pressure (pabs) and the square of the flow rate (Q).

욼p ~ pabs · Q2

Type RVG:

LF pulse generators (Type IN-S) or Wiegand pulse

generators (Type IN-W) may be plugged onto the side

of the index cover for volume pulse output to external

devices (e.g. a volume corrector).

Fit the pulse generator (if required) as follows:

–Slide both guides of the pulse generator into the

guide slot on the index cover until the guides can be

heard to engage (clicking sound).

–Assign the terminals on the plug in accordance with

the pin assignment on the meter/pulse generator.

– Use screened cables to the external device (in

accordance with DIN 60079-14).

17© Elster GmbH · All rights reserved · Subject to technical modification

English

Elster-Instromet

A1K

Coupler socket

Flange connector

YoucanuseHFpulsegeneratorsforhigherfrequencies

(Type A1K) (optional). HF pulse generators are screwed

pressure-tight into the housing cover. However, the

connection plug can be turned.

–Assign the terminals on the plug in accordance with

the pin assignment on the unit.

–Use a screened cable to the external device (in

accordance with DIN 60079-14).

Pulse generators for subsequent installation are also available.

HF pulse generators (Type A1K) can, however, be fitted only by the Elster-Instromet

Customer Service (Tel. +49 (0)6134-605-0 / -346). By contrast, you can connect the plug

yourself, as described above.

Type RVG-ST:

Elster-Instromet rotary gas meters of Type RVG-ST can be equipped with one or two low

frequency (LF) pulse generators. In addition, the unit can also be equipped with a monitoring

contact (PCM) for checking open circuits or manipulation.

In addition, a high frequency (HF) pulse generator (optional) is also available. The pulse values

of the fitted pulse generators are stated on the meter.

The pin assignments of the pulse generators are stated on an adhesive label on the unit.

These assignments show the plan view of the pin contacts of the fitted flange connector or

the view of the soldered connection terminals of the coupler socket.

Figure 9: Coupler socket and flange connector for Type RVG-ST

Warning!All pulse generators are intrinsically safe and may be connected onlyto intrinsically

safe circuits if used in potentially explosive atmospheres. The safety barriers must comply

with the requirements of ignition protection EEx ib IIC (see also Marking in Annex A).

18 © Elster GmbH · All rights reserved · Subject to technical modification

Elster-Instromet

12. Pressure Test Point

13. Temperature Test Points

A straight male coupling in accordance with DIN 2353 is pre-fitted on the meter housing for

connection of a pressure sensor for instance.

The pressure test point is marked pmand is designed for connection of d = 6 mm steel tube

in accordance with DIN EN 10305-1 (e.g. steel grade E 235).

Important: Do not connect the straight male coupling to pipes made of stainless steel or

pipes made of nonferrous materials.

Note: We recommend that you use original Parker-Ermeto pipe unions only. Functional

safety and reliability are ensured only if the material combination of the union component and

the pipe are intermatched. We recommend that you contact our Elster-Instromet Customer

Service (Tel. +49 (0)6134-605-0 / -346) for conversion work and when installing additional

devices.

Youcanuseamaximum of twotemperaturesensors

for measuring the gas temperature in the meter

housing

(Series RVG EBL67, Ident. No. 73013525),

(Series RVG-ST EBL45, Ident. No. 73013410).

Note that temperature measurement on measuring

systems in the open air may be influenced by the

ambient temperature. For this reason, the metering

elements outside the pipe should be adequately

insulatedagainst ambient temperature influences. In

order to achieve optimum thermal conduction, also

fill the thermowell(s) with a heat-conductive fluid or

paste.

If no temperature test points in the meter housing are planned, measure the temperature

in the pipe upstream of the rotary gas meter at a distance of up to 3 x DN.

19© Elster GmbH · All rights reserved · Subject to technical modification

English

Elster-Instromet

14. Index Versions (Type RVG)

S1V

Version II

S1

S1D

The meter can be equipped with various index versions:

Index head S1

–This is the standard version with an 8-digit mechanical

roller index.

–Provides universal read-off.

– Can be rotated up to 355°about its axis.

–Suitable for outdoor installation.

–Designed for LF pulse generators which can be plugged

on from the outside and which can be exchanged on

site.

Index head S1V

–This has the same features as index head S1.

–Themechanical roller index canbe read off fromthe top.

Index head S1D

–This has the same features as index head S1V.

–It has two 8-digit mechanical roller indexes (depending

on the flow direction, one index will be covered).

–MeterswithS1Dscanbeusedinallinstallationpositions.

Index head MI-2

–provides universal read-off,

–can be rotated up to 355˚ about its axis,

–Aluminium cover,

–can be optionally fitted with a mechanical index drive

pointing upwards or backwards in accordance with EN

12480,

–designed for LF pulse generators which can be plugged

on from the outside and which can be exchanged on

site,

–equipped with dry cartridge,

lifetime of cartridge depends on installation conditions

(minimum life 12 months),

replace dry cartridge when colour has changed from blue to pink.

MI-2

This manual suits for next models

1

Table of contents

Languages:

Other Elster Instromet Measuring Instrument manuals