Eltek Valere Flatpack2 User manual

2029242 R2

Installation Guide

Flatpack2 -

48V 150A DC Po er Systems

Flatpack2 Power System

2

Installation Guide Flatpack2 -48V 150A ~ 2029242 R2, May 2008

Information in this document is subject to change ithout notice and does not

represent a commitment on the part of Eltek Valere.

No part of this document may be reproduced or transmitted in any form or by any

means—electronic or mechanical, including photocopying and recording—for any

purpose ithout the explicit ritten permission of Eltek Valere.

Copyright © 2008

Eltek Valere

1303 E Arapaho Rd

Richardson, TX 75081

USA

Phone: +1 (469) 330-9100

Fax: +1 (469) 330-9101

Technical Support

+1 (866) 240-6614

.eltekvalere.com

2029242

R2

,

ay

2008

Published 30 May 2008

Installation Guide Flatpack2 -48V 150A ~ 2029242 R2, May 2008

3

Table of Contents

1.

Safety and Compliance................................................................... 5

FCC Compliance Statement.............................................................................................5

2.

Introduction .................................................................................... 7

About This Guide................................................................................................................7

About This Revision (2) .....................................................................................................7

3.

echanical Installation................................................................... 8

System Unpacking.............................................................................................................8

Rack Mounting....................................................................................................................8

Rack Installation................................................................................................................... 8

Anchor the Cabinet............................................................................................................9

Equipment Rack “Frame Ground”...................................................................................... 9

Converter Shelf Installation.............................................................................................9

4.

Electrical Installation.................................................................... 10

Individual Feed ................................................................................................................. 11

Dual Feed .......................................................................................................................... 11

5.

odule Installation ....................................................................... 12

6.

Distribution ................................................................................... 13

LVD Options...................................................................................................................... 14

Central Office Ground .................................................................................................... 14

Configurations ................................................................................................................. 15

T o Battery, T o Load (2B 2L).......................................................................................15

T o Battery, T o Load, 12 GMT (2B 2L GMT) .............................................................16

T o Battery, Four Load (2B 4L).......................................................................................16

Four Load, 12 GMT (4L GMT)............................................................................................17

Six Load (6L)........................................................................................................................17

Breakers and Fuses ........................................................................................................ 18

Plug-in Breakers .................................................................................................................18

Plug-in Fuse Holders..........................................................................................................18

GMT Fuses ...........................................................................................................................20

Battery Connections...................................................................................................... 20

Load Connections ........................................................................................................... 21

7.

Alarm and Control Terminations .................................................. 22

Alarm Contacts................................................................................................................ 22

Configurable Inputs ........................................................................................................ 23

Temperature Probe Terminations............................................................................... 23

Symmetry Terminations................................................................................................ 24

4

Installation Guide Flatpack2 -48V 150A ~ 2029242 R2, May 2008

8.

Controller Access.......................................................................... 25

Controller Configurations.............................................................................................. 25

Smartpack Extended ........................................................................................................25

Smartpack Web..................................................................................................................25

Local Keypad Access ..................................................................................................... 26

Local Computer Access................................................................................................. 28

9.

Startup Checklists........................................................................ 29

Installation Guide Flatpack2 -48V 150A ~ 2029242 R2, May 2008

5

1. Safety and Compliance

WARNING: For safety, the po er supply is required to be reliably connected to

PROTECTIVE GROUND. The equipment is to be connected to supply mains by

qualified personnel in accordance ith local and national codes (e.g., NEC, CEC, etc).

Do not disconnect and reconnect I/O po er connectors during lightning storms.

The output of the po er supply is not intended to be accessible due to energy

hazards. Rack mounting must be performed in accordance ith instructions

provided by the manufacturer to avoid potential hazards.

A readily accessible disconnect device shall be incorporated in the building

installation iring for all AC connections. Select all breakers according to section

AC input requirements (page 11).

FCC Compliance Statement

This device complies ith Part 15 of FCC Rules. Operation is subject to the

follo ing t o conditions:

1. This device may not cause harmful interference, and

2. This device must accept any interference received, including

interference that may cause undesired operation.

WARNING: Changes or modifications to this unit not expressly approved by the

party responsible for the compliance could void the user's authority to operate this

equipment.

Protecting personnel against electrical shocks: The po er system cabling must be

done by qualified personnel in conformance ith local and national electrical codes.

Input voltages to rectifiers are at a dangerous level. Ensure that circuit breakers are

locked in the OFF position at the AC service panel before attempting to ork on the

po er system. Dangerous voltages may still be present at the terminals even if the

rectifiers are OFF. Use a voltmeter to verify the presence of such voltages. Do not

s itch circuit breakers to ON until the entire system has been assembled and you

have been instructed to do so according to the appropriate procedure. Improper

iring can cause bodily harm and equipment damage. Turn off all po er sources

before servicing units.

WARNUNG:

Schuetzen von Personal gegen elektrische Schocks. Die Spannungsversorgungs -

Leitungen darf nur durch qualifiziertes Personal in Anpassung mit Oertlichen und

nationalen elektrischen Codes ausgefuehrt erden. Unsachgemaesse Verdrahtung

kann koerperliche Verletzung und Schaeden verursachen. Eingangsspannungen von

der Netzspannungs - Versorgung Ihrer Hausanlage koennen unter Spannung stehen

beim Anschluss derLeitungen. Vesorgungsspannungen koennen bei

unsachgemaessen Gebrauch gefeahrliche Schaeden verursachen. Sorgen Sie dafür,

6

Installation Guide Flatpack2 -48V 150A ~ 2029242 R2, May 2008

dass die Cirquite Breaker in der aus position sind. Benutzen Sie ein

Spannungsmesser um sicher zu sein das keine Netzspannung mehr vorhanden ist.

Verg issern Sie sich das alle Schalter an Ihrem Gereat und in der Vesorgung beim

Anschluss abgeschaltet sind. Unsachgemaesse Verdrahtung kann koerperliche

Verletzung und an der Ausstattung Schaeden verursachen. Vor Wartungsarbeiten

am Gerät sind alle Netzkabel vom Stromnetz zu trennen, um die Gefahr eines

elektrischen Schlages oder andere mögliche Gefahren zu reduzieren.

Installation Guide Flatpack2 -48V 150A ~ 2029242 R2, May 2008

7

2. Introduction

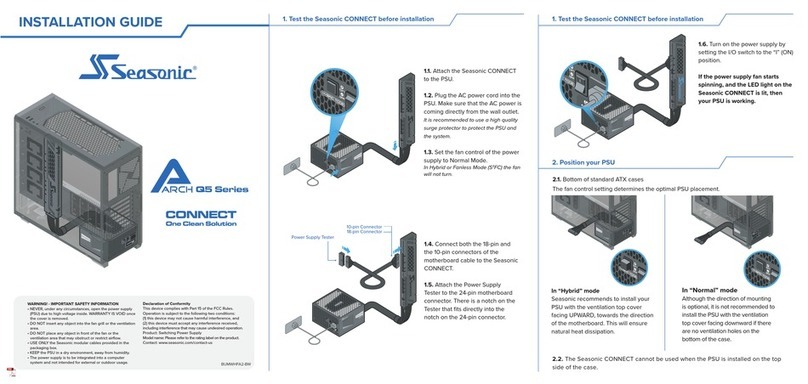

The Flatpack2 po er core consists of a 1U control and distribution panel and a 1U

rectifier shelf. Systems using the Flatpack2 -48V 150A design are ideal for sites

ith minimum available floor space. The compact size of this system allo s more

space for additional telecom equipment even ithin the same rack. This system is

mounted in a standard 19” or 23” telecommunications equipment rack. The

standard system configuration accommodates up to four (4) -48VDC Flatpack2 and

Flatpack2 HE rectifiers, providing a total po er output of 8kW.

Figure 1 -

Flatpack2 -48V 150A

System (2B 2L G T shown)

About This Guide

This manual provides a comprehensive overvie of and installation guidelines for

the Flatpack2 -48V 150A po er system. Additional information regarding

system components may be found in the follo ing documents:

o350002.013: User’s Guide—Flatpack2 Rectifiers

o350003.013: User’s Guide—Smartpack Monitoring & Control Unit

About This Revision (2)

A ne document format as adopted for this revision to reflect the transition to

the Eltek Valere brand. In addition, information from the Flatpack2 -48V 150A

Technical Bulletin (2033953) as incorporated into this manual.

Flatpack2 Rectifier Slots

(4)

Smartpack Controller

Distribution Section

8

Installation Guide Flatpack2 -48V 150A ~ 2029242 R2, May 2008

3. echanical Installation

U

SE OF FULLY INSULATED TOOLS IS REQUIRED WHEN WORKING WITH ANY POWERED

AC

OR

DC

CIRCUITS

.

THE SYSTEM IS TO BE MOUNTED OVER A CONCRETE SURFACE ONLY AND INSTALLED IN

R

ESTRICTED

A

CCESS

L

OCATIONS

(RAL).

A

CCESS MUST BE LIMITED BY USE OF TOOL

,

I

.

E

.

LOCK

AND KEY

.

The follo ing tools are required for the installation:

oStandard rench and/or socket set (1/4” to 1”)

oTorque rench, 10-40 Ft-lb range.

oTorque scre driver, 5-10 in-lb range.

oSmall flat blade scre driver (3/32” ide)

oStandard blade scre driver and Phillips tip scre driver

oWire cutters / strippers

oFork-lift truck or similar heavy equipment handling transport

oHoist ith lifting straps

oElectric drill and appropriate bits (a hammer drill may be required for concrete

flooring)

System Unpacking

An individual Flatpack2 -48V 150A unit is shipped in a box ith protective

packing material. If pre-installed in a cabinet or rack, the assembly is rapped

ith a shroud of high-strength plastic and bolted to a ooden pallet ith four

anchors. Rectifier modules and expansion options are packed in separate

cartons.

Exercise care hen unpacking and setting the equipment in place.

Rack ounting

The Flatpack2 -48V 150A system can be installed in a rack or an enclosure. The

mounting brackets are pre-installed at the factory and designed to be mounted

ithin a standard EIA 19” or 23” rack. Systems are designed to be mid-mounted.

Other mounting configurations may require additional support brackets.

Rack Installation

1) Use proper lifting equipment to position the Flatpack2 -48V 150A system

so that the holes in the support bracket are aligned ith the correct

mounting holes in the rack.

2) Use rack scre s to connect the system brackets to the desired positions

of the rack.

Installation Guide Flatpack2 -48V 150A ~ 2029242 R2, May 2008

9

Anchor the Cabinet

If the system is delivered installed in a mounting rack, anchor the cabinet before

installing rectifiers and batteries. Refer to the accompanying system installation

guide for rack feet diagrams and floor loading concerns.

Equipment Rack “Frame Ground”

Connections are located at rear of the rectifier rack ith chassis studs

provided in the AC input chamber. Refer to the NEC and any local codes

practices to determine the appropriate ire size. Use of paint-penetrating

ashers, abrasive compounds, or other means to achieve a reliable frame

ground is recommended.

Converter Shelf Installation

If Flatpack DC-DC converters are to be installed, refer to the manual

accompanying the converters for instructions on mounting and making system

connections.

10

Installation Guide Flatpack2 -48V 150A ~ 2029242 R2, May 2008

4. Electrical Installation

CAUTION: V

ERIFY THAT ALL

AC

CIRCUIT BREAKERS FEEDING THE SYSTEM ARE IN THE

OFF

POSITION

.

K

EEP ALL

AC

BREAKERS OFF UNTIL ALL APPROPRIATE SYSTEM CONNECTIONS

HAVE BEEN MADE AND VERIFIED

.

R

EFER TO SECTION

9

FOR STARTUP CHECKLISTS

.

WARNING:

F

OR SAFETY REASONS

(

HIGH LEAKAGE CURRENT AND HIGH TOUCH CURRENT

)

ALWAYS CONNECT THE

AC

EARTH WIRE

(PE)

TO THE TERMINALS BEFORE CONNECTING

AC

INPUT CABLE

(

S

).

Flatpack2 rectifiers have an input voltage range of 85 to 300 VAC (Nominal 185 –

275 VAC), ith a frequency range bet een 45 and 66Hz. See the User’s Gu de—

Flatpack2 Rect f er Modules (350002.013) for further details.

The AC junction box of each rectifier shelf contains a

knockout hole for a standard trade-size conduit ith a

diameter of 0.75”.

To ire the AC input terminal block:

1) Remove the cover located at the

rear of each rectifier shelf using a

Phillips scre driver (t o scre s).

2) Unscre and remove the green AC

connector using a Phillips or flat

blade scre driver.

3) Use a small flat blade scre driver to

open each terminal and install AC

iring. See the sections “Individual

Feed” on page 11 and “Dual Feed” on

page 11 for iring details.

4) Pull a green safety ire in the AC

mains conduit and terminate it to

the ground terminal of the

connector. It should be longer in length than the black and hite AC ires.

5) Double-check that each connection is secure and replace the connector.

6) If necessary, terminate additional safety ires to the

shelf ground termination stud located to the right of

the connector (see Figure 4 and Figure 5).

7) Replace the cover after AC terminations are

complete. Make sure to line up the bottom plate

bet een the guides on the bottom of the shelf.

Screws

Cov

er

Figure 3 - AC Terminal

Block (Removed)

Figure 2 - AC Input Cover

Installation Guide Flatpack2 -48V 150A ~ 2029242 R2, May 2008

11

Individual Feed

An individual feed shelf is fed by four (4) AC feeds; each feed supplies one

rectifier and should have 15A breakers. The figure belo illustrates the 9-pin AC

input connector. Termination points for Line 1,

Line 2, and Ground are listed in the table at right.

#12 AWG ire is recommended for each 15A

circuit, but up to #10 AWG may be used for each

feed termination position.

Figure 4 - Individual Feed Connector (Cover Removed)

Dual Feed

A dual feed shelf is fed by t o (2) AC feeds; each feed supplies t o rectifiers and

should have 30A breakers. The figure belo illustrates the 5-pin AC input

connector. Termination points for Line 1, Line 2, and Ground are listed in the

table at right. #10 AWG ire is recommended for

each 30A circuit.

Figure 5 - Dual Feed Connector (Cover Removed)

Pin

Description

1 Line 2, Rectifier 1 & 2

2 Line 2, Rectifier 3 & 4

3 Line 1, Rectifier 1 & 2

4 Line 1, Rectifier 3 & 4

5 Ground

Ground

T

ermination

Pin

Description

1 Line 1, Rectifier 1

2 Line 2, Rectifier 1

3 Line 1, Rectifier 2

4 Line 2, Rectifier 2

5 Line 1, Rectifier 3

6 Line 2, Rectifier 3

7 Line 1, Rectifier 4

8 Line 2, Rectifier 4

9 Ground

Ground

T

ermination

1

9

1

5

12

Installation Guide Flatpack2 -48V 150A ~ 2029242 R2, May 2008

5. odule Installation

CAUTION:

- Do not carry modules by the handles, even if they are arm

- Open the handles before inserting modules into shelves

Flatpack2 rectifiers incorporate an AC mains fuse in each line.

Double Pole / Neutral Fusing

Both the Smartpack controller and the Flatpack2 rectifier utilize the same locking

mechanism to keep the module fixed in place hen installed into a system shelf.

Typically, the Smartpack controller is delivered installed in the system. If it is not

pre-installed, make required connection to the back of the controller before

installing (see Section 7).

To install modules:

1) Release the handles by inserting a small flat-blade scre driver into the

release slots and pressing the tip up ard; extend each handle.

2) Slide the module firmly into the shelf.

3) Latch the handles to lock the rectifier in place.

To remove modules:

1) Release the handles by inserting a small flat-blade scre driver into the

release slots and pressing up.

2) Use the handles to pull the module out just far enough to here the body

can be held.

3) Slide the module out the rest of the ay. Do not carry it by the handles.

Flatpack2 rectifiers eigh just over 4 lbs (1.9 kg) each.

Device

hazard

Handle

Release

Installation Guide Flatpack2 -48V 150A ~ 2029242 R2, May 2008

13

6. Distribution

The Flatpack2 -48V 150A system consists of a 1U section for the controller and

distribution. When looking at the front, the Smartpack controller occupies the

leftmost position corresponding to the idth of one Flatpack2 rectifier slot in the

po er shelf belo . When vie ed from the rear of the system, the controller slot

occupies the rightmost position; the controller alarm board is accessible from this

side.

All termination points are located in the rear of the system and are stacked

vertically in pairs. For battery landings, the top cable landing is labeled “A” and is set

back to give clearance to the bottom landing, hich is labeled “B”; these landings

are labeled “1” and “2”, respectively, for load landings.

To make cable connections:

1) Remove the t o scre s securing the cover using a Phillips scre driver.

2) Make careful note of the labels for each landing before making connections.

Do not connect batteries until system turn-up.

3) Make connections ith a maximum #1 AWG cable ith t o-hole lugs having

1/4” diameter holes on 5/8” centers; 1/4-20 fastening hard are is provided.

4) Torque connections to 51-58 in-lbs.

Figure 6 – Rear Distribution Connections (4L G T shown)

Systems configured to accept GMT fuses have a 12-position GMT fuse block

installed in the leftmost distribution position (far right hen vie ed from the front).

The block is rated at a total of 65A, ith each position accepting up to a 15A fuse.

The positions are numbered 1 to 12 from r ght to left (see Figure 7). The top ro is

the “hot” or “output” terminal; the bottom ro is for returns. These terminals accept

ire sized from #22 AWG to #14 AWG.

Batteries

Loads

Returns

Loads

Loads

(G T Fuse Block)

14

Installation Guide Flatpack2 -48V 150A ~ 2029242 R2, May 2008

Figure 7 - G T Block Distribution Terminals

To ire the GMT fuse block:

1) Remove the t o scre s securing the cover using a Phillips scre driver.

2) Use a small flat blade scre driver to open the desired terminals (the clamp

scre is belo each terminal).

3) Strip load ire 3/8” and insert it into the top terminal.

4) Tighten the scre to secure the ire.

5) Strip the return ire 3/8” and insert it into the bottom terminal.

6) Tighten the scre to secure the ire.

7) Repeat for each remaining GMT position

LVD Options

A single lo -voltage disconnect (LVD) contactor can be

installed for either battery or load equipment. The

“Configuration” label (in front of the return bus to the right

of the “RETURN” label) describes hich of the three LVD

configuration options the distribution section contains:

LVBD (battery disconnect), LVLD (load disconnect), or NO

LVD.

Central Office Ground

A dedicated central office (CO) grounding conductor connection is recommended.

This conductor should be of the same or larger gauge than the largest system

conductor. It should be able to discharge total system current in a fault

condition. A THHN style cable is recommended. This cable should be installed

bet een the DC system point (as sho n) and the primary site ground bar. See

Figure 8 for the recommended organization of return connections.

1

12

Hot/Output Row

Return Row

Installation Guide Flatpack2 -48V 150A ~ 2029242 R2, May 2008

15

Configurations

Configurations for the Flatpack2 -48V 150A system are defined by the number of

breaker positions provided for batteries and load equipment. The follo ing are

common configurations:

Two Battery, Two Load (2B 2L)

The t o leftmost breaker position sets are populated, and the rightmost bus

set is not installed in the “2B 2L” configuration.

Figure 8 - Recommended Return Bus Organization

Battery Returns

Load Re

turns

CO Ground

Battery A

Battery B

Load 1

Lo

ad 2

Returns

Battery

Load

16

Installation Guide Flatpack2 -48V 150A ~ 2029242 R2, May 2008

Two Battery, Two Load, 12 G T (2B 2L G T)

This configuration comes ith t o battery breaker positions, t o load

positions, and a 12-position GMT fuse block in the rightmost section.

Two Battery, Four Load (2B 4L)

The “2B 4L” configuration populates all six plug-in positions. As usual, the

leftmost positions are dedicated to batteries; the rest are for load output.

NOTE: Battery breakers turn ON to the left; load breakers turn ON to the

r ght.

Figure 9 - Connections to G T Block (Rear View)

Battery A

Battery B

Load 1

Load 2

Load 3

Load 4

Batteries

Loads

1 & 2

Loads

3 & 4

Installation Guide Flatpack2 -48V 150A ~ 2029242 R2, May 2008

17

CAUTION: T

HE FOLLOWING CONFIGURATIONS FEATURE UNPROTECTED BATTERY

TERMINALS

.

I

T IS STRONGLY RECOMMENDED THAT EXTERNAL BREAKERS OR FUSES BE

INSTALLED BETWEEN THE SYSTEM AND BATTERIES

.

NOTE: When facing the front of the system, the leftmost load breakers in the

follo ing distributions turn ON to the left; the rest turn ON to the r ght.

Four Load, 12 G T (4L G T)

The “4L GMT” configuration changes the t o 100A battery breaker positions

into 60A load positions by tying them to the internal load bus. T o bulk,

unprotected battery landings are available in the rear of the system (see

Figure 10). The rightmost position is populated by a GMT fuse block.

Figure 10 - Bulk Battery and Protected Load Landings

Six Load (6L)

This configuration differs from the “4L GMT” system only in that, rather than a

GMT fuse block, the rightmost position is populated by a set of parallel load

buses.

Batteries

Loads

1 & 2

18

Installation Guide Flatpack2 -48V 150A ~ 2029242 R2, May 2008

Breakers and Fuses

CAUTION:

SIGNIFICANT EXTRACTION FORCE IS REQUIRED TO REMOVE DISTRIBUTION

DEVICES DUE TO THE CONTACT PRESSURE REQUIRED FOR HIGHLY RELIABLE

,

LOW

-

TEMPERATURE RISE CONNECTIONS

.

Up to six distribution busses, arranged into three sets of t o, can be configured

to receive plug-in breakers or plug-in fuse holders from the front of the Flatpack2

-48V 150A system. Plug-in positions are like ise grouped into a maximum of

three sets of t o positions, ith each set stacked vertically and oriented

horizontally.

Do not use any type of clamps, pliers, or other hard tools to remove distribution

devices as the housing may be cracked by excessive force. Damaged distribution

device represent an operational hazard and should never be used.

Figure 11 - Plug-in Disconnect Device Positions (2B 4L shown)

Plug-in Breakers

Auxiliary contact circuit breakers are standard over-protection devices used

this distribution. All breakers are connected to system alarming so that an

open breaker ( hether tripped or manually placed in the OFF position) triggers

a “Load Distribution Alarm” in the Smartpack controller. Breakers should be

removed from any unused positions to prevent nuisance alarms. Single-pole

circuit breakers rated up to 100A can be installed. Each set of positions also

accepts a t o-pole breaker rated up to 175A.

Plug-in Fuse Holders

As an alternative to plug-in circuit breakers, plug-in fuse modules may be

installed. The same considerations regarding insertion and removal of

breakers should be observed.

A plug-in fuse assembly consists of three main parts: A fuse, an alarm fuse

indicator, and a plug-in module. If the main fuse element opens, the alarming

fuse also opens, giving a visible indication of a fault condition; a signal is then

sent via the Smartpack alarm board that activates the remote system

monitor. The alarming fuse must be replaced henever a ne main fuse is

required. A fuse holder may be removed and inserted into the plug-in module

at any time; it is not necessary to remove the plug-in module to replace the

fuse.

Two (2) Plug-

in Positions

per Set

Three (3) Sets of Plug-in

Positions (maximum)

Installation Guide Flatpack2 -48V 150A ~ 2029242 R2, May 2008

19

NOTE: If breakers or fuse-holders are not installed in the correct orientation,

the alarm may not signal properly hen a device opens.

To install plug-in breakers or fuse-holders for LOAD:

1) Remove the t o scre s holding the front cover in place using a Phillips

scre driver.

2) Orient the “LINE” and “LOAD” bullets to the correct bus. The leftmost

breaker set (next to the Smartpack controller) has LINE to the right

and LOAD to the left; the actuator turns ON to the left. The other

positions have LINE to the left and LOAD to the right; the actuator

turns ON to the r ght.

To install plug-in breakers or fuse-holders for BATTERY (if used):

1) Connect the battery alarm ire to the device’s normally closed (NC)

alarm pin.

2) Orient the “LINE” and “LOAD” bullets to the correct bus. The battery

breaker set (next to the Smartpack controller) has LINE bus to the right

and its LOAD bus to the left; the actuator turns ON to the left.

Securely insert device into the receptacles.

3) Remove fuses and turn breaker actuators OFF until system turn-up.

Figure 12 - Proper Battery Breaker Orientation and Alarm Connection

Battery Breaker

Alarm Wires

Indicator

fuse (G T)

TPS Fuse

Holder

Plug-in

odule

20

Installation Guide Flatpack2 -48V 150A ~ 2029242 R2, May 2008

G T Fuses

T elve (12) GMT fuse positions are provided in a standard

block, hich is rated for a maximum of 65A (total). GMT fuses

rated from 1/8A to 15A can be used in each position. Open

fuses are easily identified by the graduated movement of the

metal fuse tab. The tab moves in a manner that exposes the

colored tip to indicate a failed circuit. If installed, the GMT fuse block

populates the rightmost disconnect device position.

From the front, the fuse positions are numbered 1 to 12 from left to r ght.

Naturally, the numbering is reversed hen vie ed from the back.

Battery Connections

CAUTION: D

O NOT CONNECT BATTERIES UNTIL SYSTEM TURN

-

UP

.

F

OLLOW THE

CHECKLIST PROVIDED FOR THE PROPER PROCEDURE

.

Every distribution configuration of the Flatpack2 -48V 150A system features t o

battery termination points. When vie ed from the rear, the battery bus landings

take up the one of the rightmost positions of the distribution section, just to the

left of the Smartpack alarm board. A label reading “BATT (-)” appears directly in

front of the landings.

There are t o possible configurations for battery connections: With breaker

positions or ithout breaker positions.

If breaker positions are utilized, the battery busses take up the rightmost

position hen the system is vie ed from the rear. The corresponding breaker

positions are located to the right of the Smartpack controller at front (leftmost

position hen facing the front of the system).

NOTE: Battery breakers turn ON to the left and OFF to the r ght.

If there are no breakers installed, the battery busses take up the position just to

the left of the bus ith breaker positions and to the immediate right of the

return bus. In this case, the rightmost busses may be used for load output. In

every case, make sure to check the labels before connecting batteries to the

system.

1

12

Other manuals for Flatpack2

2

Table of contents

Other Eltek Valere Power Supply manuals

Popular Power Supply manuals by other brands

Agilent Technologies

Agilent Technologies 654xA Series operating manual

Lathem

Lathem PS8-2412 Specifications

Rockwell Automation

Rockwell Automation Allen-Bradley SensaGuard 440N-Z21 Series installation instructions

Goobay

Goobay DF 1730 LCD manual

Power One

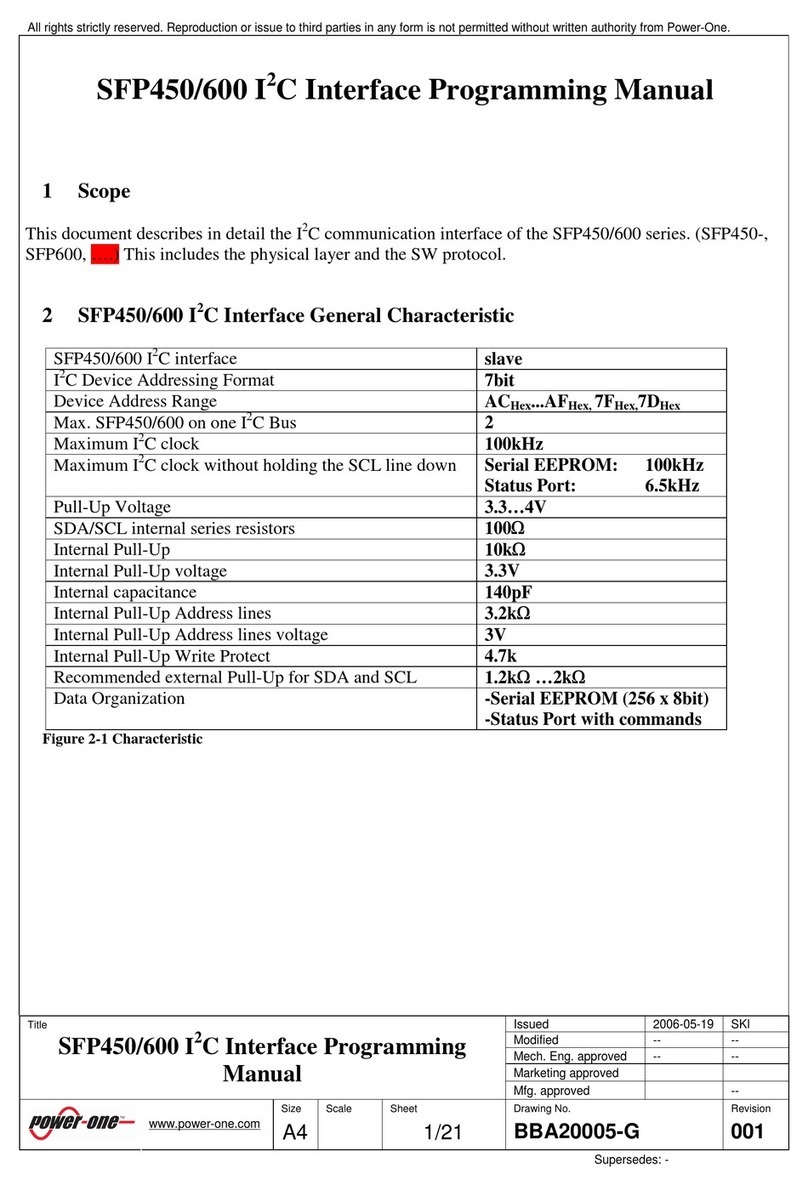

Power One SFP450 Series Programming manual

Cooler Master

Cooler Master Silent Pro Platinum RS-550-SPPA user guide