Emerson Power Transmission Kop-Flex KOP-GRID H Series User manual

1

©EmersonPowerTransmissionManufacturing,L.P.1998.AllRightsReserved.

Installation and Alignment

Instructions

FORM 17200

DECEMBER, 1996

The trademarks KOP-FLEX,KOP-GRID and are registered trademarks of

Emerson Power Transmission Manufacturing. L. P. and/or Kop-Flex, Inc.

KOP-GRID®

Tapered Grid

Coupling -Type H

Horizontal Split Cover

INSTALLATION and ALIGNMENT

INSTRUCTIONS

Theseinstructions apply to KOP-GRID®type Htapered grid

couplings.

This sheet may be supplemented by Special Instructions

suppliedwith thecoupling formodifications andvariations of

these couplings. For dimensions, ratings, maximum bores,

interferencefits, and othertechnical information,pleaserefer

toBulletin 1700.

When working on rotating equipment be sure to lock out the

starting switch of prime mover so the equipment cannot be

started until work is complete, checked, and personnel are

safely away. Proper installation per this product instruction

sheet must be observed.Failure to do so may void warranty

and could result in injury to person or property.

MAINTENANCE and LUBRICATION

Lubricate the KOP-GRID®coupling with grease only. Use

KOP-FLEX®

KSG coupling grease or other grease meeting

theminimum specificationsshown.

Do not use oil in KOP-GRID®couplings.

Coupling lubrication is critical.The use of proper and suffi-

cientlubrication is partof a successfulinstallation.

Lubricants should be checked to ensure the proper level is

maintained and that the lubricant is free of contaminates. In

an average industrial application, the coupling should be

checkedfor lubricantcontaminationand replenishedwiththe

propervolumeevery twelvemonths. Conditions suchas very

slowspeed, reversing drives,high heatand severe environ-

mentsmay requiremore frequentlubrication.

RECOMMENDED LUBRICANT

KOP-FLEX®KSG Coupling Grease

Thisgreaseisspecificallycompoundedforstandardcouplings

toprovide improved lubricationand resistanceto centrifugal

separation.When KSG grease is used, lubrication intervals

may be extended, based upon operating experience. KSG

couplinggreaseis availablefrom Kop-Flex orauthorizeddis-

tributorsof Kop-Flex power transmission products.

OTHER GREASES

Alternate lubricating greases should equal or exceed the

specifications for KOP-FLEX®KSG coupling grease (speci-

ficationsheet3532 isavailable uponrequest).Greases other

thanKSG shouldmeet theseminimum specifications:

Grade:NLGI #1

Base oilViscosity:Min:

3000SSU at 100°F

160 SSU at 210°F

DroppingPoint,Min.:190°F

FourBallWear, ASTM D-2266:

.500mm Maximum

BaseOil Content:87%Minimum

K36 Factor, ASTM D-4425:

KSG: K36 = 8/25 =.33

Required:Rustand Oxidation Inhibitors

E.P.Additives

KOP-FLEX, INC., P.O. BOX 1696, BALTIMORE MARYLAND 21203, 410-768-2000

KOP-FLEX CANADA, LTD., 19 METEOR DRIVE, REXDALE, ONTARIO, CANADA M9W-1A3, 416-675-7144

Emerson Power Transmission

Emerson Power Transmission

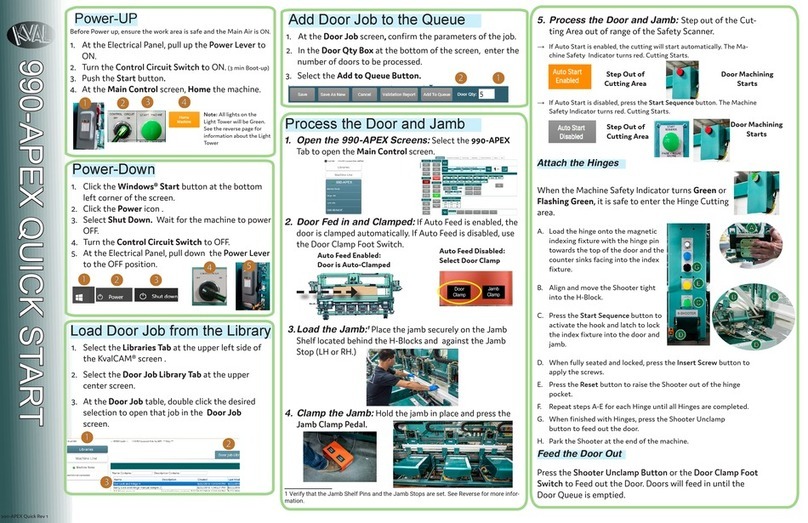

GRIDHUB

TYPE H COVER

TAPERED GRID

SEAL

COVER

FASTENERS

GASKET

SURFACE

↓

↓

CAUTION

If assembled

incorrectly,

equipment failure

and personal

injury may result.

Disconnect all power while adjusting units

2©EmersonPowerTransmissionManufacturing,L.P.1998.AllRightsReserved.

Themost reliabletestof asuitablelubricant isoften theresult

of user experience and satisfaction. If a lubricant has been

knowntosludge, separateinto heavycomponentsor dryout,

consider the use of KOP-FLEX®KSG grease.

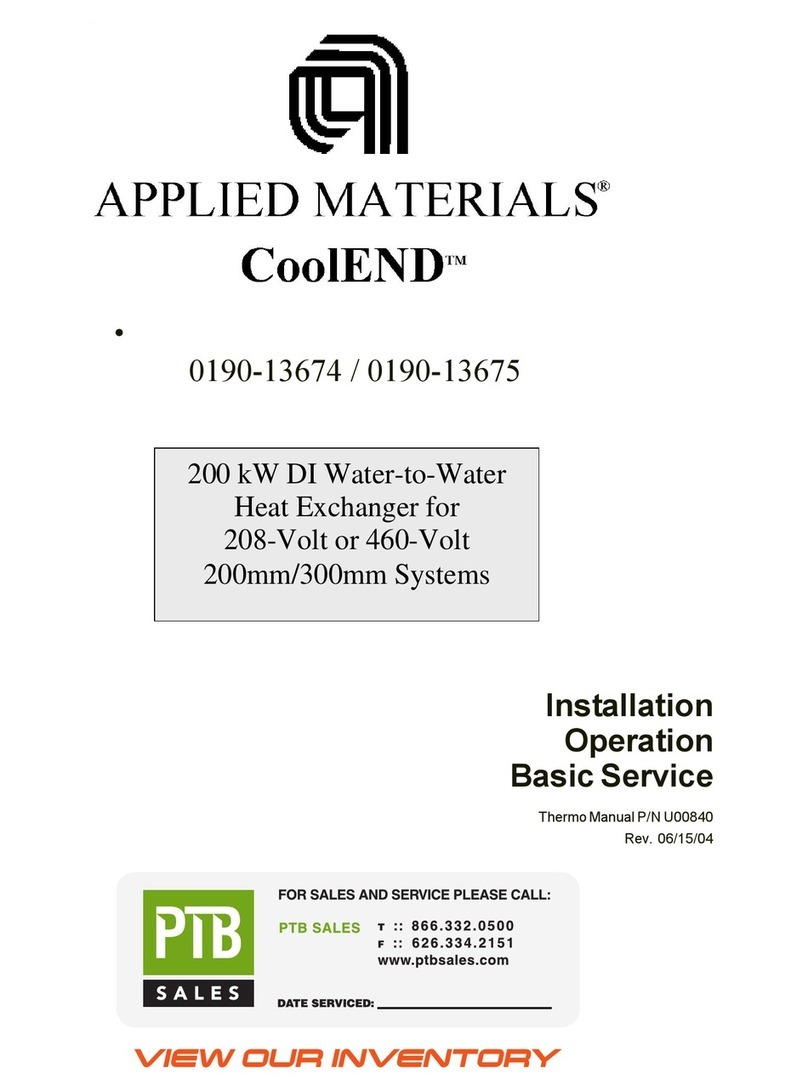

1. HUB INSTALLATION

Verify all parts are on hand and are as ordered, check that

the hub bores are correct.Prepare shafts by removing dirt

and burrs. Lightly apply grease on seals and place them on

shafts, before installing the hubs. Mount the hubs on their

shafts,withhub faceflushwiththe shaftend.Properlytighten

setscrews when furnished.For vertical shafts, seal the key-

Figure 2

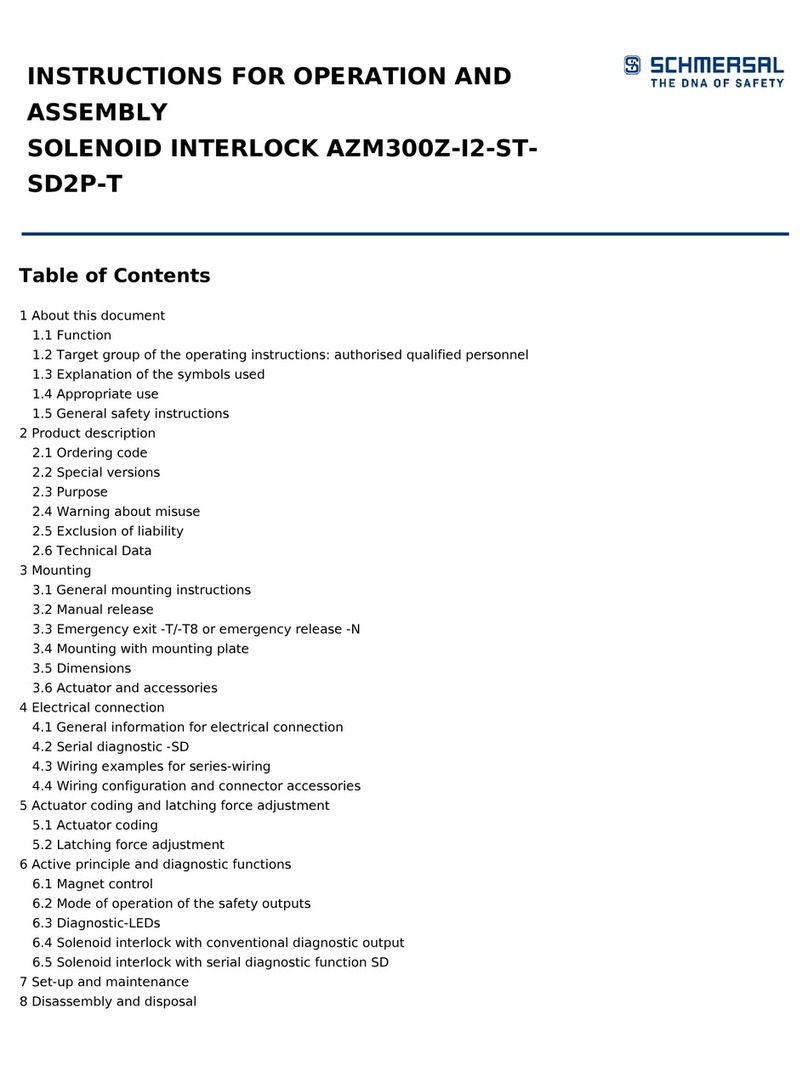

2. SHAFT SEPARATION & ANGULAR ALIGNMENT

Usea feeler gaugeto measurethegap betweenhubfaces at

4points90°apart.Thegapshouldnotexceedthe valuespeci-

fied in Table 1.Position equipment to obtain best alignment.

The measured difference between minimum and maximum

valueshould notexceedthe angularlimit specifiedinTable1.

Important Safety Instructions

Before start-up . . . forreasons ofsafety andto extendshaft

couplinglife, followthese requirements.

1. Coupling guards protect personnel. ALL COUPLINGS

MUST BE COVEREDWITH A GUARD AS PER OSHA

REQUIREMENTS.

2. Recheck alignmentafterall foundationboltsandmechani-

calconnections aretightened.

3. Make sure all fasteners are properly installed and tight-

ened.

4. Take the time to double check your work.

5. Only authorized Kop-Flex replacement parts are to be

used.

6. Call Kop-Flex for any clarification or questions.

WARNING

!

Failure to observe

safety precautions

could cause

personal injury

or equipment

damage.

INSTALL

SEAL

FIRST

HUB

FACE

Figure 1

↓

wayto prevent greaseleakage. For interferencefit, heatthe

hub in an oven to 300°F (150°C) before mounting the hub.

NEVER exceed 600°F (300°C).

Note: Allow heated hubs to cool to room temperature

before coupling alignment and assembly.

Figure 3

3. OFFSET ALIGNMENT

Useastraightedgeandfeeler gaugeto alignshaftsat4points

90° apart.The offset (parallel misalignment) should not ex-

ceed the offsetlimit specified inTable 1.

3

©EmersonPowerTransmissionManufacturing,L.P.1998.AllRightsReserved.

Adjust equipment as required. Recheck steps 2 and 3 after

tighteningthe foundationboltsand realignthe coupling,ifthe

offsetand angularmeasurementsexceedthe valuesinTable

1.Note: Bestcoupling alignmentis obtainedby using dial in-

dicators.If dial indicators are used,always rotatethe hub on

whichthe indicatoris mounted to obtain readings.

Figure 4

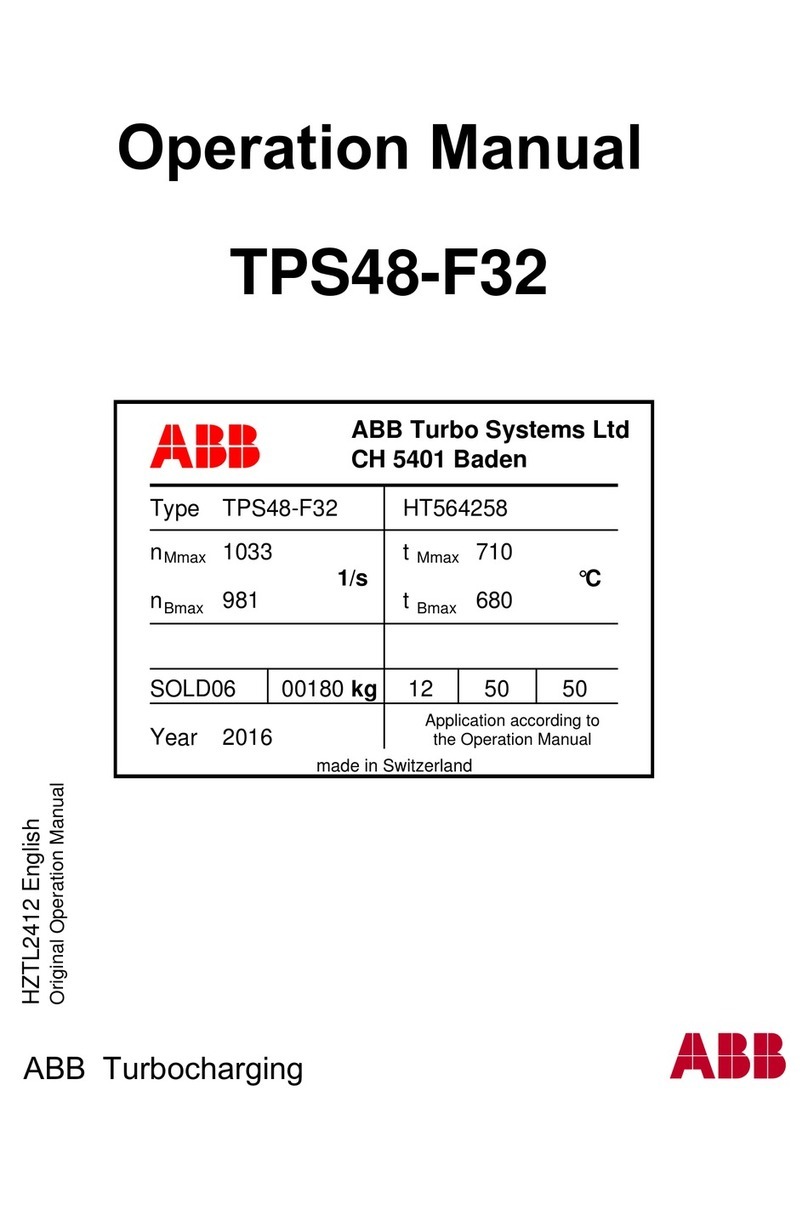

4. TAPERED GRID INSTALLATION

Fillthe hubgapand gridteeth grooves withKOP-FLEX®KSG

grease or a comparable alternate. Lightly open the grid to

engagewith thegrooveson thehub.Use asoft mallettoseat

thegrids inthe tapered teethgrooves. Fortapered gridsthat

aresupplied with morethan one segment,make sureall the

segment’s openends are onthe same side.

Figure 5

Figure 6

5.COVER INSTALLATION & LUBRICATION

Pack the grid with additional KSG grease or the equivalent

and wipe off the excess flush with the top of the grid. Slide

seals over the hub and adjust to line up with the cover seal

grooves. Place gaskets on both flanges of the lower cover

and install top cover. Align cover match marks on the same

side. For vertical applications or inclined shafts, make sure

the match marks are UP, or on the higher side.Tighten the

cover fasteners to the cover bolt torque value specified in

Table 1.For lubrication, remove the two lube plugs from the

covers and fill with KOP-FLEX®KSG grease or specified al-

ternate, until thegreasestartsseepingoutfrom theotherlube

hole. Re-install the two lube plugs in the covers and tighten

securely.

Note: Do not operate coupling without the lube plugs.

GASKET

COVER MATCH

MARKS

→

↓

→

Emerson Power Transmission

Disconnect all power while adjusting units

4©EmersonPowerTransmissionManufacturing,L.P.1998.AllRightsReserved.

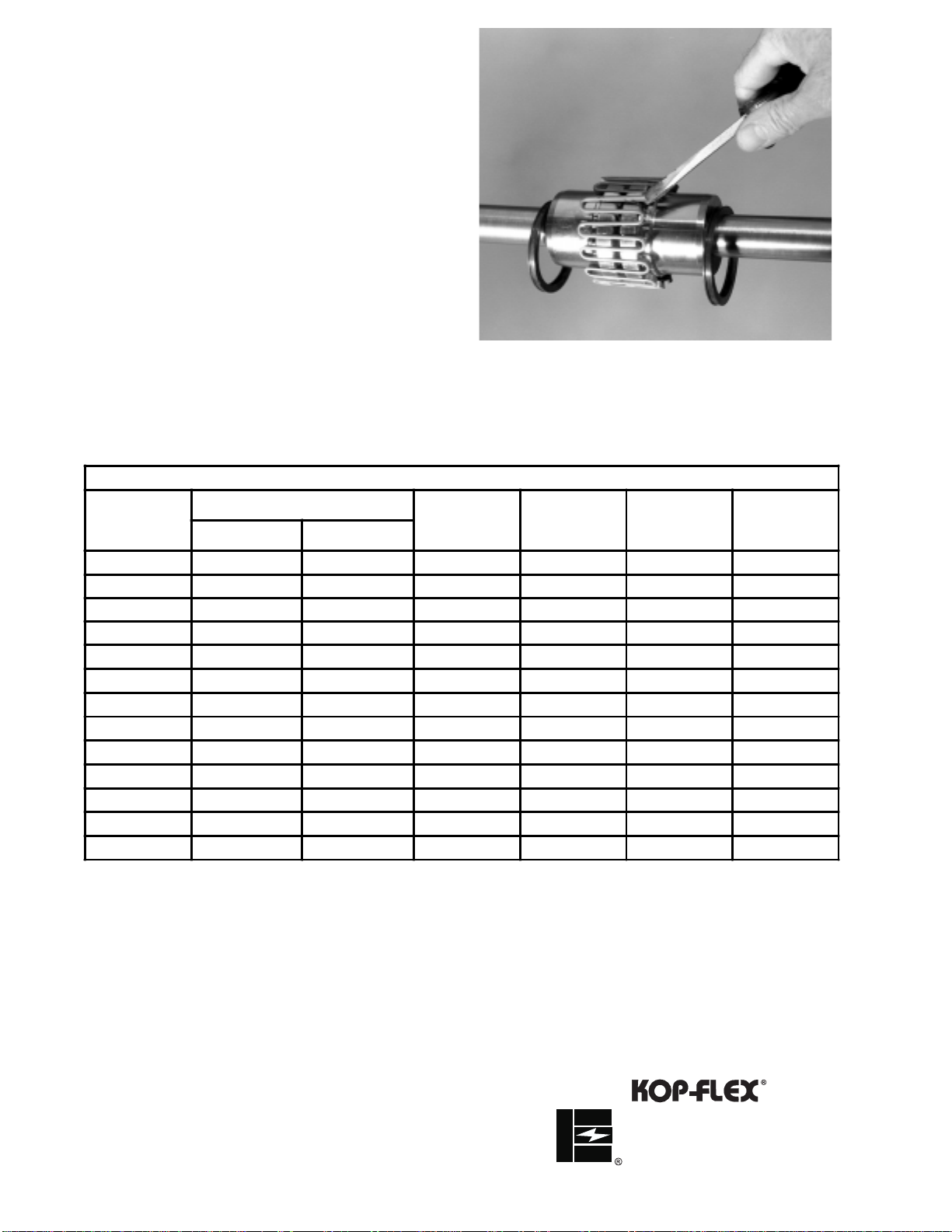

GRID REMOVAL:

Remove the coupling cover assembly.Insert a rod or screw

driverintotheopen endloopofthe taperedgrid.Usethe teeth

onthe coupling hubas asupport to graduallyand gentlypry

offthe grid,proceeding alternately fromside toside.

Figure 7

Table 1

Form17200 12/4/96

Printed in U.S.A.

INSTALLATION AND ALIGNMENT VALUES

SIZE

MAXIMUM RECOMMENDED

MISALIGNMENT LIMITS GAP

(IN.)

COVER

BOLT

TORQUE

(LB-IN.)

ALLOWABLE

MAXIMUM

SPEED

(RPM)

LUBE/

GREASE

WEIGHT

(LB.)

OFFSET

(IN.) ANGULAR

(IN.)

1020 0.006 0.003 0.125 100 4,500 0.07

1030 0.006 0.003 0.125 100 4,500 0.07

1040 0.006 0.003 0.125 100 4,500 0.11

1050 0.008 0.004 0.125 200 4,500 0.11

1060 0.008 0.005 0.125 200 4,350 0.20

1070 0.008 0.005 0.125 200 4,125 0.24

1080 0.008 0.006 0.125 200 3,600 0.37

1090 0.008 0.007 0.125 200 3,600 0.55

1100 0.010 0.008 0.188 260 2,440 0.95

1110 0.010 0.009 0.188 260 2,250 1.12

1120 0.011 0.010 0.250 650 2,025 1.61

1130 0.011 0.012 0.250 650 1,800 2.00

1140 0.011 0.013 0.250 650 1,650 2.50

KOP-FLEX, INC.

EMERSON POWER TRANSMISSION

P. O.Box 1696

Baltimore,MD 21203-1696