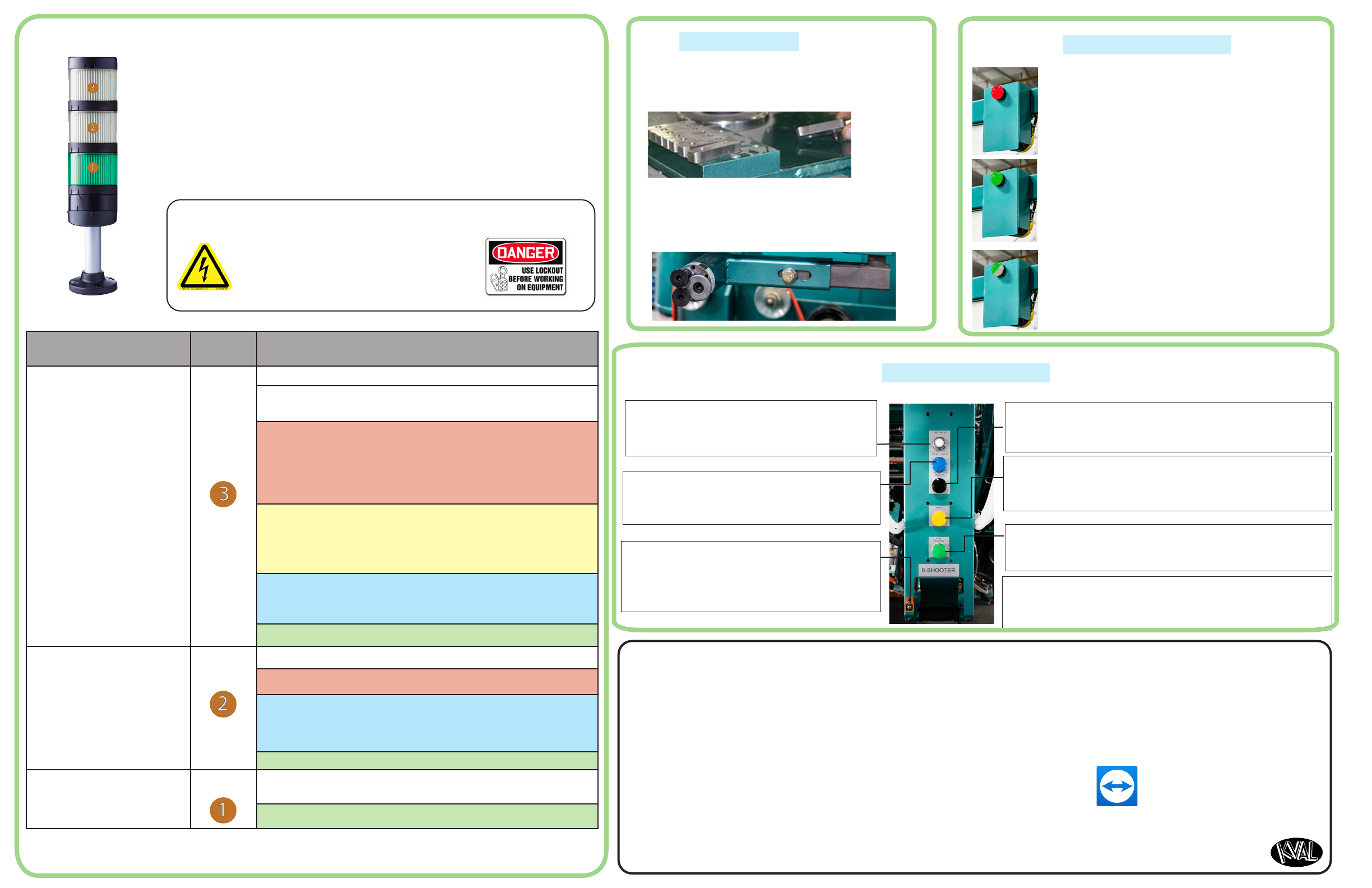

Categoy Desig. Descriptions

Machine Status

OFF (Clear): Machine not in operation.

White: Initializing

1 Flash: Waiting for all systems to initialize

Red: Machine Error

Solid: General Error

• 1 Flash: EtheCat Device not Ready to Run

• 2 Flashes: VFD, Sevo, or Motor Error

• 3 Flashes: 24 VDC Power Error

Yellow: External Error

Solid: General Error

• 1 Flash: 3 Phase Voltage Error

• 2 Flashes: Low Air Error

Blue: Operator Status

Solid: Waiting for Operator

• 1 Flash: Reposition Door

Green: Machine is Operational

Safey

OFF (Clear): Safey Project not Running

Red: Safey PLC Error

Blue: Waiting for Safey Re-Set

• Solid: General Error

• Flashing: Not Ready to Re-Stat (E-Stop Switch is Active)

Green: Machine is Operational

Control Power

O: No Control Power

ON (Green): 24 VDC Control Power ON

About the Light Tower

High Voltage may cause injury or death.

Troubleshooting checks must be performed

by a Qualied Electrical Technician.

The Light Tower indicates the working status of the system. The

Light Tower is mounted on top of the Electrical Boxes. Each light dis-

plays dierent colors and lashing codes to show the machine status.

The table below describes the dierent states of the Light Tower.

Be Smat! Follow all Safey Precautions.

Remote Troubleshooting

Kval’s Suppot Team is able to work remotely with your maintenance sta or contractor to diagnose and troubleshoot machiney

issues. Call (800)- 553-5825 or stat a suppot ticket Online htps://www.kvalinc.com/suppot.

Tools Needed for machine hardware troubleshooting:

• Access to a broadband internet connection

•An iPhone or Android smat-phone with Google Duo® for video.

• A Digital Multi-meter

• A standard tool set

For machine soware troubleshooting:

• Access to a broadband internet connection

• A computer running Windows

• Our remote suppot client

Allow Kval to Logon to the Machine

• Exit the KvalCAM® program. On the

Windows Screen, select the KVAL

Sevice Icon

Add Shelf Pins to the Jamb Shelf to adjust to your

backset. Spacers are stored at Operator’s Station. The

insetion points are behind each H-Block.

Rotate the Jamb Stop turrets to adjust to your Dado.

The turrets are located at A-side and B-Side of the

machine.

Jamb Setup

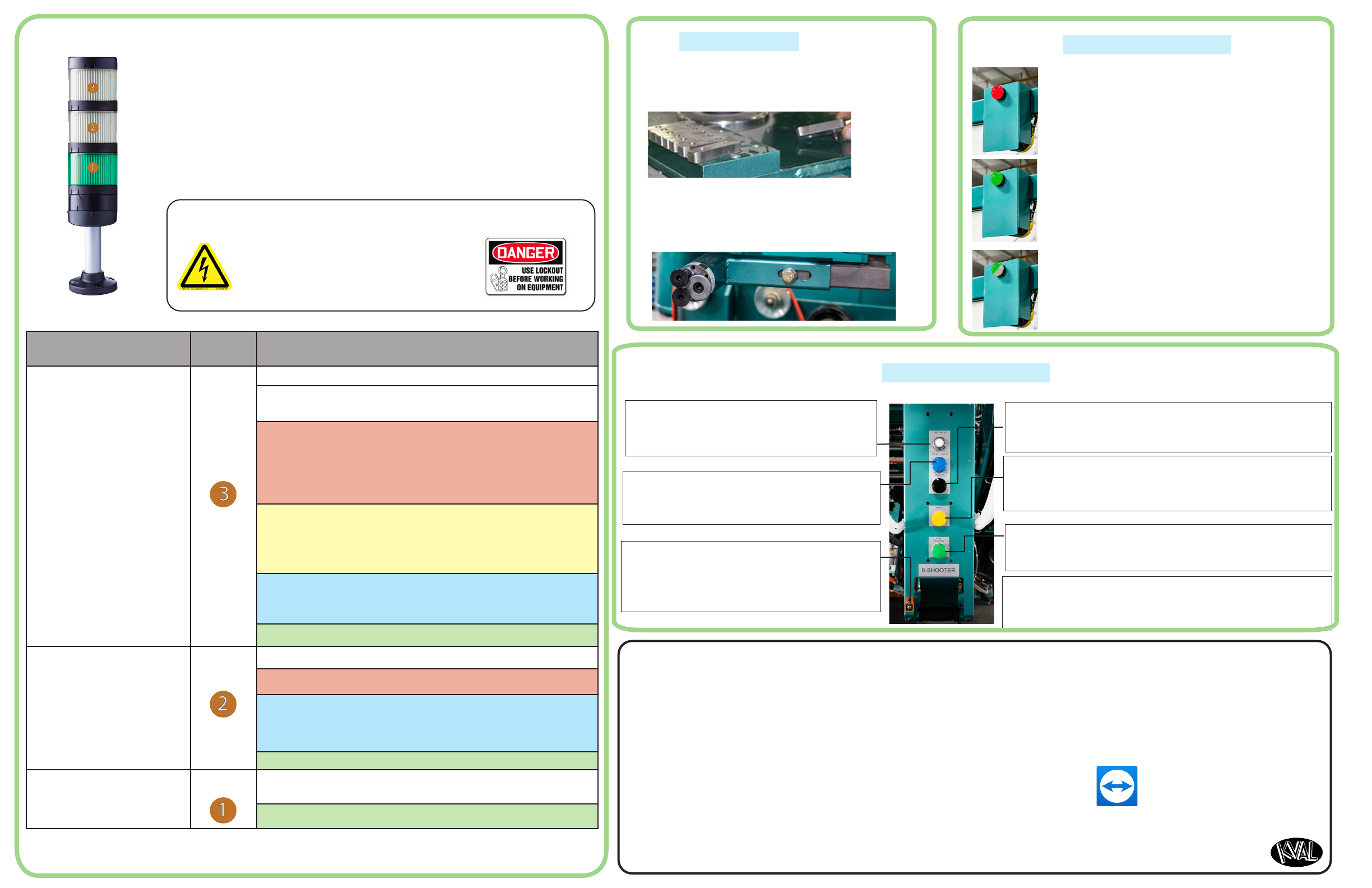

Stat Sequence Buton–After the Shooter is aligned with the

H-Block, press the Start Sequence button to drop the indexing

assembly into the pocket, drop the screws down.

* Screw Drop Switch–is located on the side of the Shooter. In the OFF posi-

tion, screw delivery system is shut off. If the switch is in the ON position,

normal screw delivery is active. One of the uses for this function is to

troubleshoot with out the screw delivery active.

Inset Screw Buton–After the Hinge and the Screw

Shooter has been locked in into the pocket, push

the Insert Screw button to attach the screws to the

jamb and door hinge

SOLID GREEN Light–No Processing is occurring, OK

to enter the Hinge Cutting Area.

Clear Screws Buton–Pull the Screw Shooter away

from the machine and press the button to cause

a last of air to clear the line of a stuck screw.

Unclamp Buton–After all the hinges have been applied, press this

button to unclamp the jamb and the door. If the machine is set to

Auto-Feed the door will feed-out to the next machine.

Reset Buton–Press the Reset button to raise the 6/8 Shooter

back into the Start position.

Be aware, if the tilt cylinder is set to retract too fast, it can cause

the 6/8 Shooter to jump out of the pocket and bounce

RED Light–Do not enter the Hinge cutting area the

cutting process will stop.

BLINKING GREEN Light–Lock section is busy pro-

cessing, It is OK to enter the Hinge Cutting Area.

Load/Unload Buton–Press to add new screws.

The Hopper will dump the existing screws into a

container. After the Hopper is empty, pour in the

new type/color screws.