7

K4 - 6 .008 - .012 (.203 -.305)

K25 - 6 .010 - .012 (.254 -.305)

M5 - 6 .010 - .012 (.254 -.305)

M25 - 6 .010 - .012 (.254 -.305)

P25 - 6 .010 - .012 (.254 -.305)

CROSBY SERIES HE ISOFLEX®SELF-ACTUATED SAFETY VALVES

INSTALLATION, MAINTENANCE AND ADJUSTMENT INSTRUCTIONS

5 DESCRIPTION OF OPERATION

The operation of the Crosby Series HE safety

valve is as follows:

When the pressure in the valve inlet reaches

the set point, the valve will open with a sharp

pop with very little simmer or warn.

Full relieving capacity is reached within the

rated accumulation above set pressure.

Afterthe valve has popped, it will remain

open until the pressure under the valve has

decreased to the closing pressure, at which

point it will then close sharply.

CAUTION

The cotter pin head should be turned so that it fits between and into the retaining nut notch and makes

contact with the spindle. The split ends of the cotter pin should both be bent down.

CAUTION

The piston (2) should be seated within the housing

(1) before continuing. This seated position is

reached when the first notch on the piston (2) is

level with or below the top of the housing (1) as

indicated in Figure 7.

CAUTION

This device has a limited piston stroke that should

not be exceeded.

It is now necessary to remove the three spacer

blocks under the lower spring washer, thereby

transferring the spring load to the valve seats.

This is accomplished by unjacking the valve

using the hydraulic jacking device.

Referring to Figure 7, install the bonnet spacer

(5) on the bonnet (17). Position the jacking

device assembly by lifting it over the spindle

(12) and lowering it onto the bonnet spacer (5).

Lubricate the spindle threads with Never-Seez,

Molykote-G[3] or equivalent. Thread the spindle

adapter onto the spindle, turning until it comes

into contact with the jacking device assembly.

Attach the hand operated hydraulic pump (7)

and hose (8).

To raise the valve spindle, pressure is applied

to the jacking device assembly with the hand

operated hydraulic pump. This activates the

piston (2) which raises the lower spring washer,

compressing the spring.

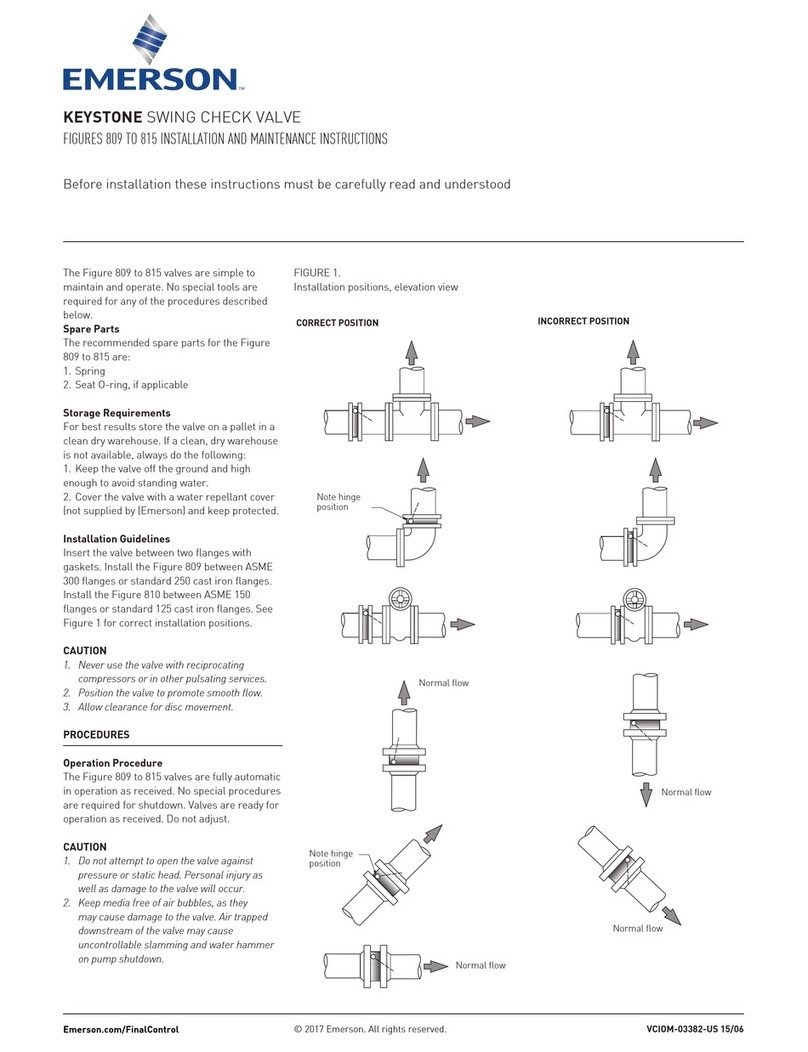

FIGURE 5

Clearance between disc holder and retaining nut

Clean

surface

Retaining

nut

clearance

If the piston stroke is exceeded, the second

notch on the piston (2) will be above the top

of the housing (1) and hydraulic fluid will flow

from the bleed hole, located in the housing.

Ifhydraulic fluid is flowing from the bleed hole,

but the piston stroke has not been exceeded,

the O-rings (3 and 3A) and the backup rings

(4 and 4A) should be inspected for wear or

damage and replaced if necessary.

The spacer blocks may now be removed and

the spring load transferred to the valve seats by

releasing the pressure in the hydraulic pump

slowly. Remove the spindle adapter, jacking

device assembly and bonnet spacer.

Stand assembly on clean surface making certain that

the end of the spindle rotates freely on the disc insert

bearing surface (not loading on the insert threads).

Thread disc holder retaining nut (7) down until it

makes contact with the disc holder (6). Locatethe

hole in the spindle (12) relative to a notch on the

retaining nut. Back off the retaining nut by turning

counterclockwise to establish proper clearance.

(Clearance for particular orifice sizes are listed in the

table below). Install cotter pin through retaining ring

notch and spindle hole.

RETAINER NUT CLEARANCE VALUES

Orifice size Retaining nut notches Clearance inches(mm)

* Lubrication points

Referring to Figure 1, set the nozzle ring (3)

and guide ring (10). The nozzle ring location

and guide ring location are determined at

the factory and their locations are stamped

on the valve bonnet where the cap is seated.

Place a screwdriver in the nozzle ring set

screw hole and turn the nozzle ring to the right

(counterclockwise - positive direction [+]) until

it makes contact with the disc holder. Then turn

the nozzle ring to the left (clockwise - minus

direction [-]) to the factory setting. Repeat the

same procedure described above to set the

guide ring.

Lock the set screws (4 and 11) in place making

sure that the proper set screws are installed

and engaged in a notch and lock wire in place.

Install the spindle nut (15), spindle nut cotter,

cap (28) and lifting gear assembly before

tightening the cap set screws. Be sure that the

forked lever (33) is free to move from

1

/

16 inch

(1.59 mm) to ⅛ inch (3.18 mm) before coming

into contact with the spindle nut. If travel is

excessive, thread the spindle nut down. If there

is not enough travel, back off on the spindle nut.