2

CAUTION

!

WARNING

!If you do not follow these instructions exactly, a fire or explosion may

result, causing property damage, personal injury or loss of life.

Pilot gas

outlet

PILOT

PRESS

TAP

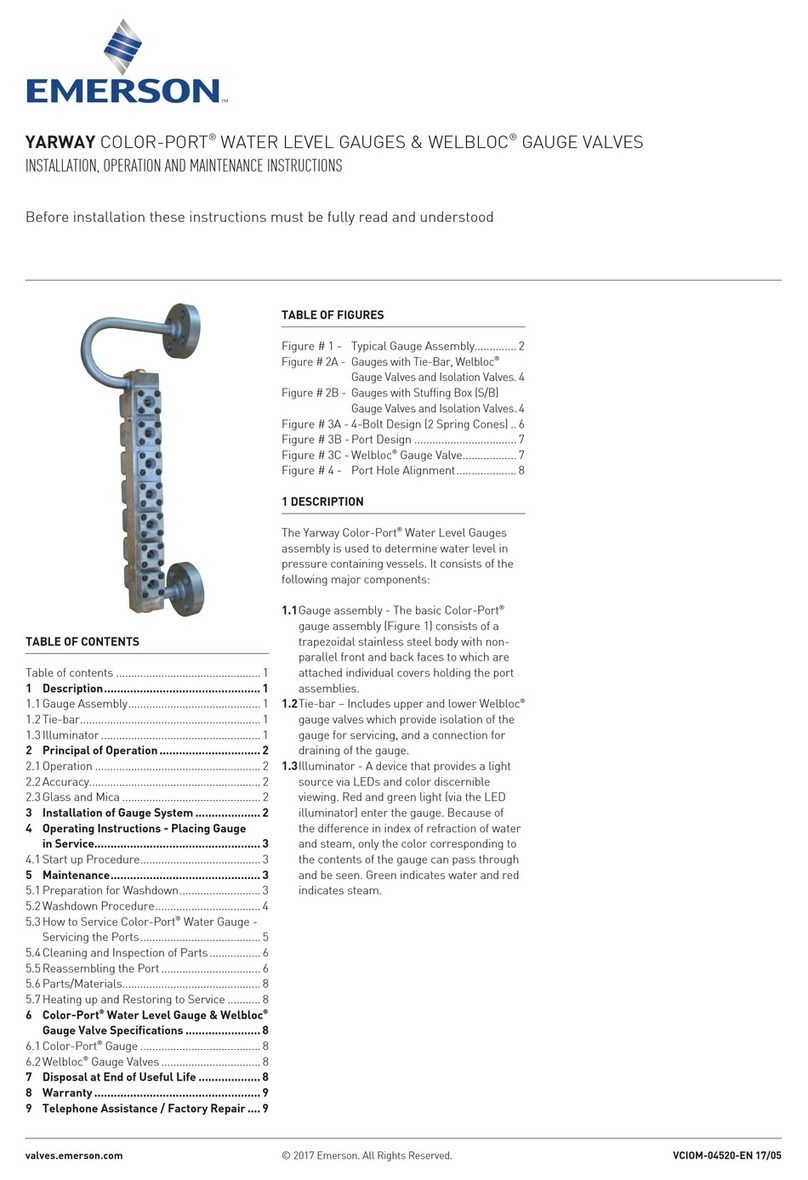

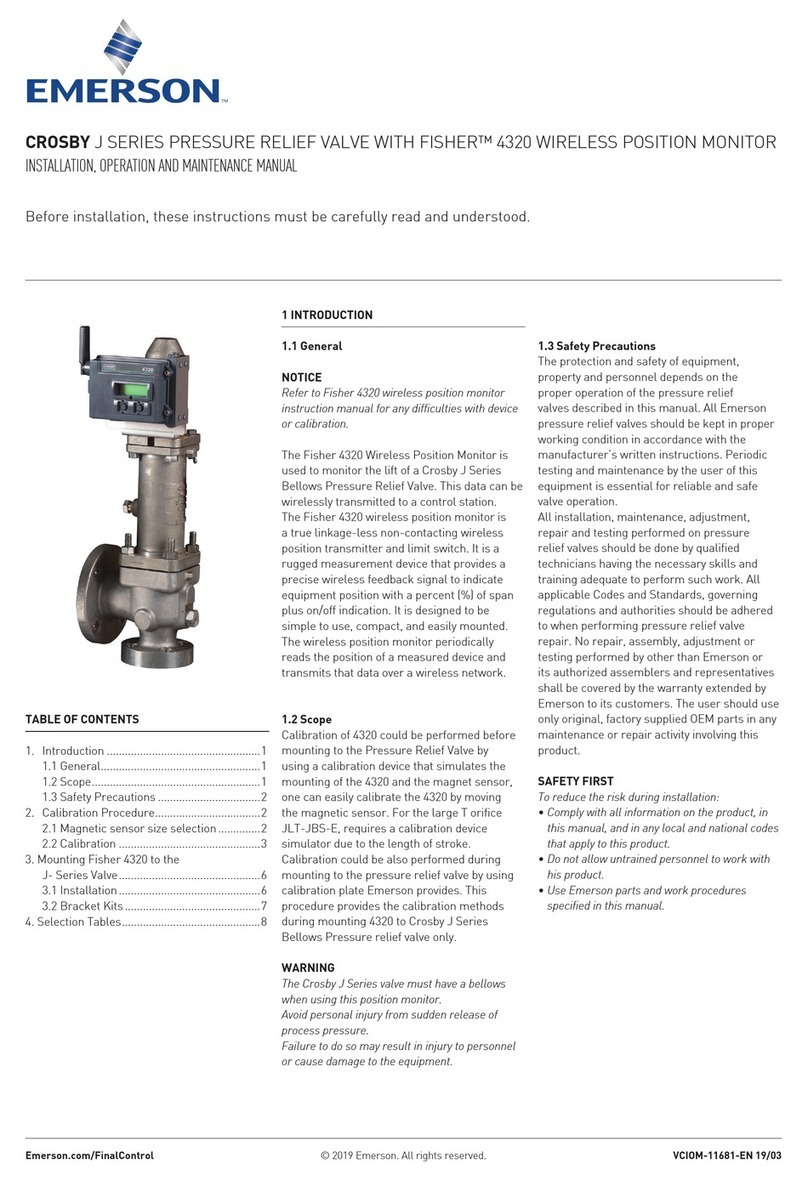

Figure 2. Gas valve side view

MAIN PIPING CONNECTIONS

All piping must comply with local codes, ordinances, and/or

national fuel gas codes.

1. Turn off electrical power to the system at the fuse box or circuit

breaker. Also turn off the main gas supply.

2. If replacing an existing valve, disconnect all plumbing and elec-

trical connections from the old control.

3. The control may be installed in any orientation except upside

down.The arrow on the valve indicates the direction of gas flow

through the control.

4. You should use new pipe that is properly chamfered, reamed,

and free of burrs and chips. If you are using old pipe, be sure it

is clean and free of rust, scale, burrs, chips, and old pipe joint

compound.

5. Apply pipe joint compound (pipe dope) or teflon tape that is

approved for all gases, only to the male threads of the pipe

joints. DO NOT apply compound or teflon tape to the first two

threads (see fig. 1 for typical piping connections).

6. If you are using a vise or open-end wrench to hold the valve

while installing piping, do not tighten excessively, as this may

damage the valve.

7. If additional clearance for the gas cock knob is required when

installing the new valve in an existing system, rotate the knob

to the position between ON and OFF. Depress the knob while

turning the valve.The knob will depress only while in this position.

8. See SYSTEM WIRING when making electrical connections.

After all gas and electrical connections are completed, turn gas

on and check for gas leaks with leak detection solution or soap

suds. Bubbles forming indicate a leak. SHUT OFF GAS AND

FIX ALL LEAKS IMMEDIATELY.

Horizontal

Drop

Piped Gas

Supply

Gas Valve

3 in.

minimum

Gas Valve

Riser

Piped Gas

Supply

3 in.

minimum

Horizontal

Riser Gas Valve

Tubing Gas

Supply

3 in.

minimum

NOTE:

Always Include

A Drip Leg In Piping

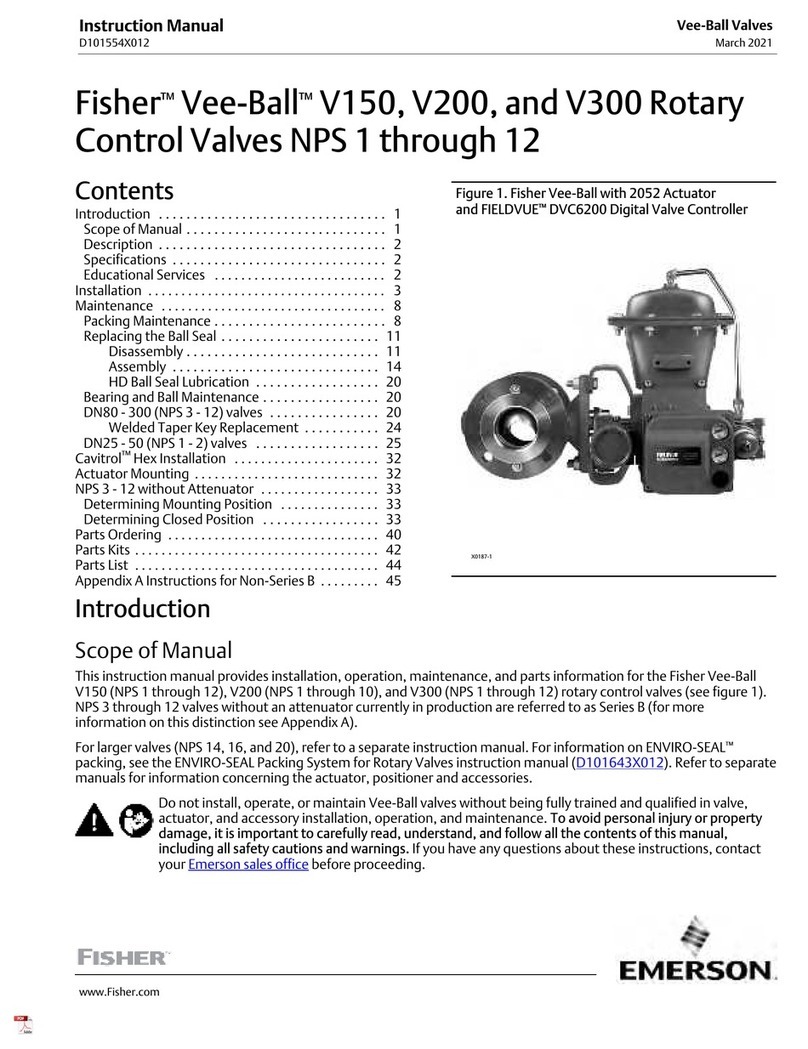

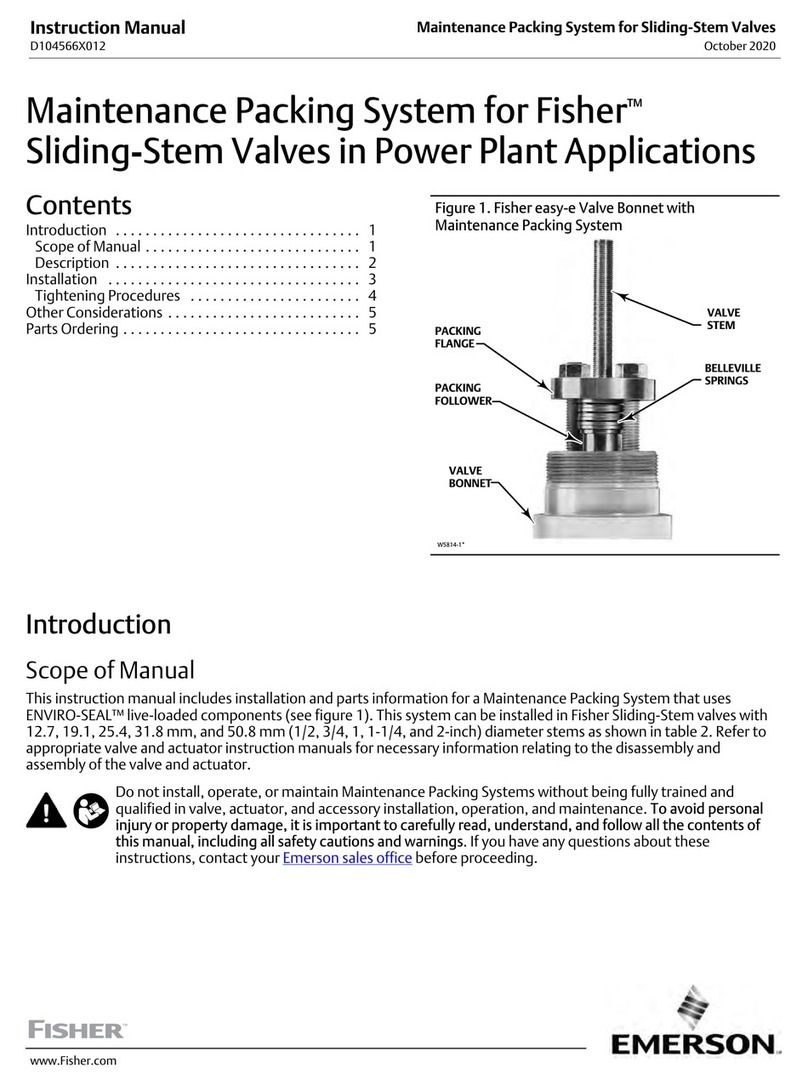

Figure 1. Typical gas valve piping

DO NOT BEGIN INSTALLATION UNTIL YOU READ THE

FOLLOWING PRECAUTIONS.

1. Failure to turn off electric or main gas supply to heating

system could cause personal injury and/or property damage

by shock, gas suffocation, fire, and/or explosion.

2. Do not use this control on circuits exceeding specified volt-

age. Higher voltage will damage the control and may cause

shock or fire hazard.

3. NEVER USE FLAME OR ANY KIND OF SPARKTO CHECK FOR

GAS LEAKS–COULD CAUSE FIRE AND/OR EXPLOSION.

4. DO NOT USEWIRE JUMPER on pilot systems, such as stand-

ing pilot, proven pilot, or spark-to-pilot ignition–a fire and/or

explosion may result.

5. Do not use a control set for natural gas with LP gas, or a

control set for LP gas with natural gas. Personal injury and/

or property damage, gas suffocation, fire, and/or explosion

may result.

1. Do not short out terminals on gas valve or primary control to

test. Short or incorrect wiring can cause equipment damage,

property damage, and/or personal injury.

2. This control is not intended for use in locations where it may

come in direct contact with water. Suitable protection must

be provided to shield the control from exposure to water

(dripping, spraying, rain, etc.).

PRECAUTIONS

INSTALLATION

Horizontal

Drop

Piped Gas

Supply

Gas Valve

3 in.

minimum

Gas Valve

Riser

Piped Gas

Supply

3 in.

minimum

Drop

Horizontal

Riser Gas Valve

Tubing Gas

Supply

3 in.

minimum

NOTE:

Always Include

A Drip Leg In Piping

Figure 1. Typical gas valve piping

Pilot gas

outlet

Gas outlet

PILOT

PRESS

TAP

Figure 2. Gas valve side view