Page 2 of 4 All Rights Reserved. IM-IND-553130-RevAA

No. 57, Kundrathur Main Rd., Gerugambakkam, Chennai - 6000128, India www.emerson.com

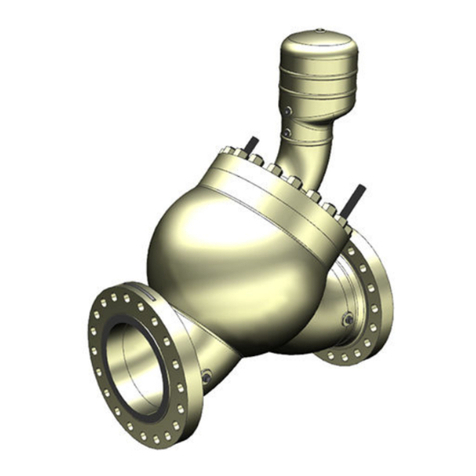

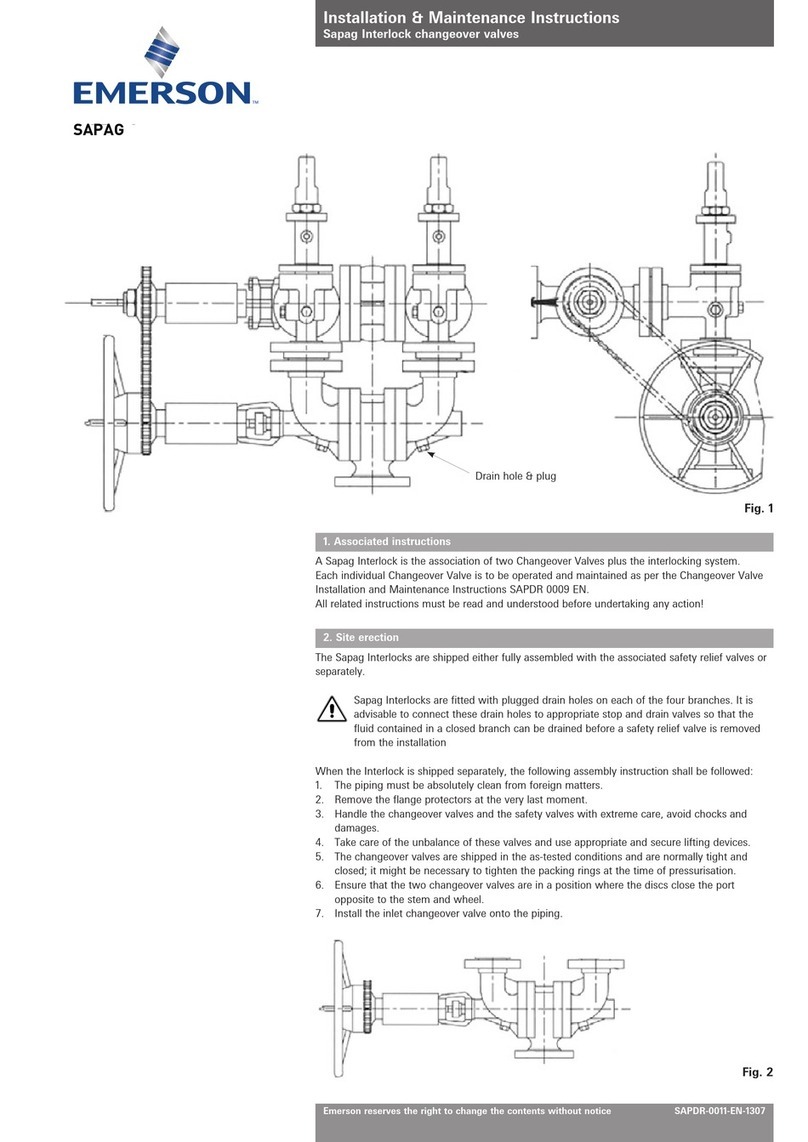

Figure 1. Valve Body Mounting Dimensions.

Piping

Debrisentering1/8"or1/4"NPTconnection

at top of solenoid may cause valve to malfunction. Use a

muer to vent to atmosphere or connect to main exhaust

system if the air or inert gas cannot be exhausted directly

to the atmosphere.

Connect piping or tubing to valve according to markings on

valve body. Refer to flow diagrams in OPERATION section.

To avoid damage or accidental

disengagement of cartridge assembly from valve body,

hold cartridge assembly securely by wrenching ats when

installing or removing muer or piping at top of solenoid.

Apply pipe compound sparingly to male pipe threads only. If

applied to valve threads, the compound may enter the valve

and cause operational difficulty. Avoid pipe strain by properly

supporting and aligning piping. When tightening the pipe, do

not use valve or solenoid as a lever. Locate wrenches applied to

valve body or piping as close as possible to connection point.

These solenoid valves are intended for

use on clean dry air or inert gas, ltered to 50 micrometres

or better. The dew point of the media should be at least 10

°C (18 °F) below the minimum temperature to which any

portion of the clean air/inert gas system could be exposed

to prevent freezing. If lubricated air is used, the lubricants

must be compatible with Buna N elastomers. Diester

oils may cause operational problems. Instrument air in

compliance with ANSI/I SA Standard S7.3-1975 (R1981)

exceeds the above requirements and is, therefore, an

acceptable media for these valves.

MAINTENANCE

To prevent the possibility of death,

serious injury or property damage, turn· o electrical

power, depressurize valve, and vent uid to a safe area

before servicing the valve .

NOTE: It is not necessary to remove the valve from the pipeline

for repairs. However, piping or tubing must be removed from

pilot exhaust on top of the solenoid if present. See Piping section.

Cleaning

All solenoid valves should be cleaned periodically. The time

between cleanings will vary depending on the medium and

service conditions. In general, if the voltage to the coil is

correct, sluggish valve operation, excessive noise or leakage

will indicate that cleaning is required. In the extreme case, faulty

valve operation will occur and the valve may fail to shift. Clean

filter when cleaning the valve.

Preventive Maintenance

• Keep the medium flowing through the valve as free from

dirt and foreign material as possible.

• Periodic exercise of the valve should be considered

if ambient or fluid conditions are such that corrosion,

elastomer degradation, fluid contamination build up or

other conditions that could impede solenoid valve shifting

CAUTION

CAUTION

CAUTION

WARNING

are possible. In many cases, solenoid valves are periodically

exercised during normal system use or as part of routine

maintenance or surveillance activities and no additional

exercise is necessary. The actual frequency of exercise

necessary will depend on specific operating conditions.

A successful operating history is the best indication of a

proper interval between exercise cycles.

• Depending on the medium and service conditions, periodic

inspection of internal valve parts for damage or excessive

wear is recommended. Thoroughly clean all parts. If parts

are worn or damaged, install a complete ASCO Rebuild Kit.

Causes of Improper Operation

• Incorrect Pressure: Check valve pressure. Pressure to

valve must be within range specified on nameplate.

• Excessive Leakage: Disassemble valve and clean all

parts. If parts are worn or damaged, install a complete

ASCO Rebuild Kit.

Valve Disassembly

1. Disassemble valve in an orderly fashion using exploded

view for identification and placement of parts.

2. Disconnect tubing from valve body and top of solenoid

"A". Then remove tube fitting on adapter with tube fitting

from solenoid "A".

3. Where applicable; remove piping from cartridge assembly

at the top of solenoid ''B". Hold cartridge assembly securely

by wrenching flats, when removing piping.

Notice: Internal parts on solenoid "A" and "B" sides are identical.

4. Remove solenoid, see separate instructions.

5. For low power or intrinsically safe constructions, unscrew

cartridge assembly from valve body. Then remove cartridge

gasket from valve body and orifice gasket from recess in

base of cartridge assembly.

6. For standard construction, unscrew solenoid base sub-

assembly and remove plugnut gasket, solenoid base gasket

and core assembly with core spring and core guide.

7. All parts are now accessible for cleaning or replacement.

If parts are worn or damaged, install a complete

ASCO Rebuild Kit.

Valve Reassembly

1. Lubricate all gaskets with DOW CORNING®200 Fluid

lubricant or an equivalent high-grade silicone fluid lubricant.

2. Proceed as follows:

• For standard construction

A. Install plugnut gasket on solenoid base sub-assembly

and solenoid base gasket in valve body.

B. Install core assembly with core spring and core

guide into solenoid base sub-assembly.

C. Hand thread solenoid base sub-assembly into valve

body. Torque solenoid base sub-assembly to 175 ±

25 in-lbs [19,8 ± 2,8 Nm].

• For Low Power/ or Intrinsically Safe Construction

A. Position cartridge gasket in valve body.

B. Install orifice gasket in recess in base of

cartridge assembly.

C. Hand thread cartridge assembly with orifice gasket

into valve body. Then torque cartridge assembly to

175 ± 25 in-lbs [19,8 ± 2,8 Nm].

3. Install solenoids A and B, see separate instructions.

4. As required, make up tubing and piping to valve body and

top of solenoids A and B.

5. Make electrical connection to solenoid A and B.

To prevent the possibility of death,

serious injury or property damage, check valve for proper

operation before returning to service. Also perform internal

seat and external leakage tests with a non-hazardous, non-

combustible uid.

6. Restore line pressure and electrical power supply to valve.

7. After maintenance is completed, operate the valve a few

times to be sure of proper operation.

WARNING