2

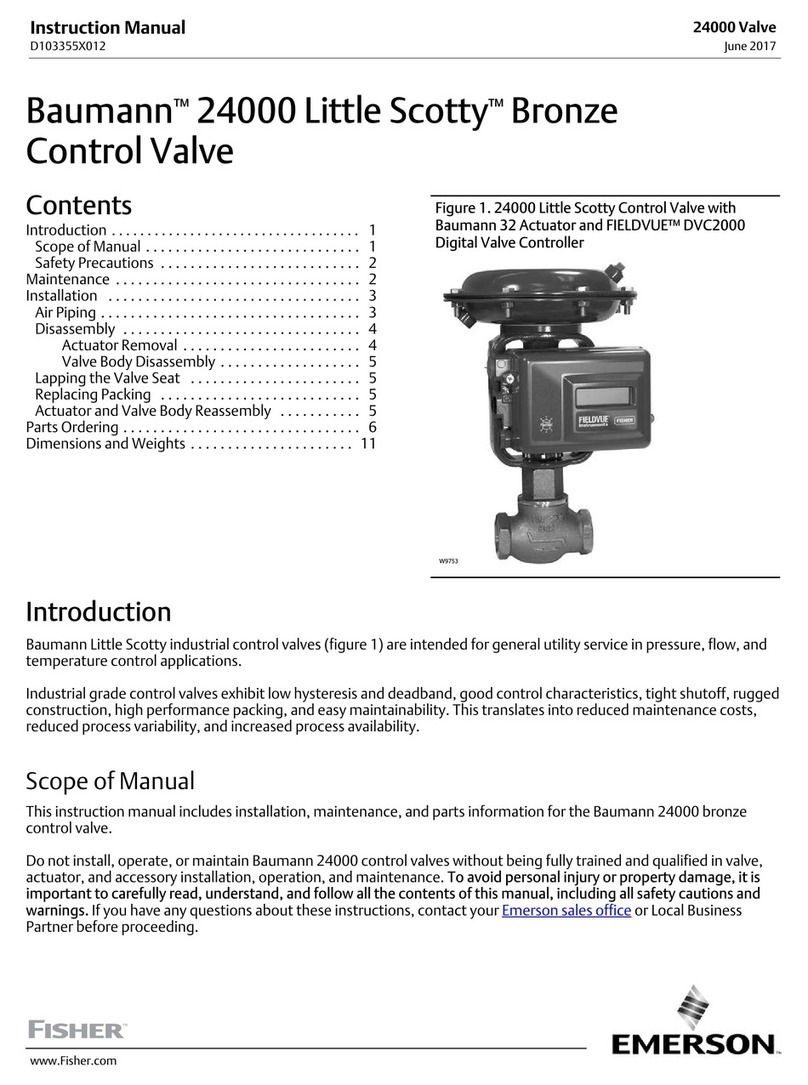

CASH VALVE TYPE FRM CRYOGENIC BACK PRESSURE OR ECONOMIZER VALVE

INSTALLATION, MAINTENANCE AND REPAIR PARTS INFORMATION

MAINTENANCE INSTRUCTIONS

The following procedures are provided for

servicing the Type FRM back pressure relief

valve. Repair parts can easily be installed

without removing the valve from the line.

CAUTION

Before attempting to replace any spare parts, be

sure to shut off all pressure connections to the

valve. With the valve closed, however, system

pressure could still be locked between the shut

off valve and the inlet and/or outlet sides of the

relief valve. Before proceeding with any valve

service, be certain to relieve the pressure from

BOTH sides of the valve.

Refer to the Type FRM exploded view for parts

identification.

Servicing the Pressure Spring (5),

Diaphragms (11), Seat Disc Gasket (13), Seat

Disc (14) and Seat Ring (15)

1. Loosen the lock nut (2) ¼ turn and turn the

adjusting screw (1) counter-clockwise until

the pressure spring (5) is no longer under

tension.

OPERATING INSTRUCTIONS

Adjusting the Back Pressure

The regulator's back pressure setting is

adjusted by turning the adjusting screw (1) at

the top of the spring chamber after loosening

the adjusting screw lock nut (2). To obtain a

higher pressure setting, turn the adjusting

screw clockwise (into the spring chamber). To

lower the pressure setting, turn the adjusting

screw counter-clockwise (out of the spring

chamber). Tighten the adjusting screw lock nut

after the adjustment has been made and install

the closing cap.

NOTE

When installing the adjusting screw during

reassembly, turn the screw clockwise untl the lock nut

just touches the spring chamber. When the valve is

placed in service, the pressure setting should be very

close to the original setting.

2. Unscrew the spring chamber (3) from the

valve body (16). During reassembly, tighten

the spring chamber securely.

3. Remove the spring seat (4), pressure spring

(5), diaphragm stop (6), and the upper

diaphragm gasket (7) from the valve body.

4. The Diaphragm assembly, consisting of

the pressure plate nut (8), lock washer (9),

diaphragm pressure plate (10), diaphragms

(11), seat disc gasket (13) and seat disc

(14), can now be lifted off the body (16).

Disassemble the parts by unscrewing

the pressure plate nut (8) from the seat

disc (14). Inspect all parts and replace if

necessary. The diaphragm gasket (12) below

the diaphragm should be replaced when

new diaphragms (11) are installed.

IMPORTANT

Excercise care to ensure that the surface of

the seat disc (14) is not scratched, marred or

damaged during disassembly and reassembly.

5. Once the diaphragm assembly has been

removed, the seat ring (15), which is sitting

loosely in a recess of the valve body, can be

removed.

IMPORTANT

Handle the seat ring carefully to avoid damage

to the seat ring surface which contacts the seat

disc (14).

NOTE

Be sure to install the seat disc, with the machined

groove around the outer edge of the flat face, so that

this face is up (away from the body).

6. Inspect all parts and replace if necessary.

Reassemble in reverse order. After placing

the valve back in service, adjust the

delivery pressure setting as detailed under

Operating Instructions.

REPAIR PARTS INFORMATION

Refer to the Type FRM exploded view for parts

identification.

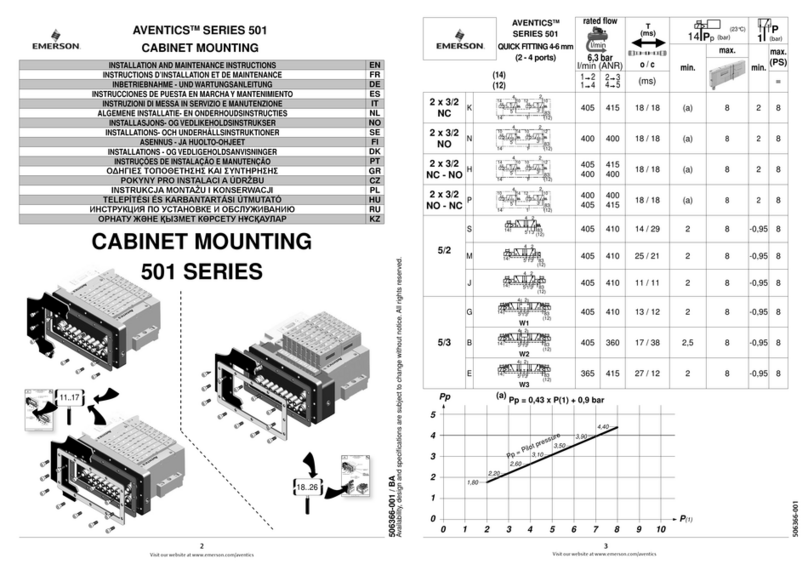

SPECIFICATIONS

Each Type FRM back pressure valve is supplied

with a pressure spring selected to provide

the desired pressure setting. The range of

adjustment or satisfactory "working range"

of individual springs is shown in the table

below for each valve. Each valve has the "set"

pressure and range or adjustment stamped on

a tag fastened to the valve.

SPRING RANGES

SPRING RANGE (psi)

2-25 15-65 40-100 50-100 75-175 100-250 200-400 200-600 300-600