Type N201

4

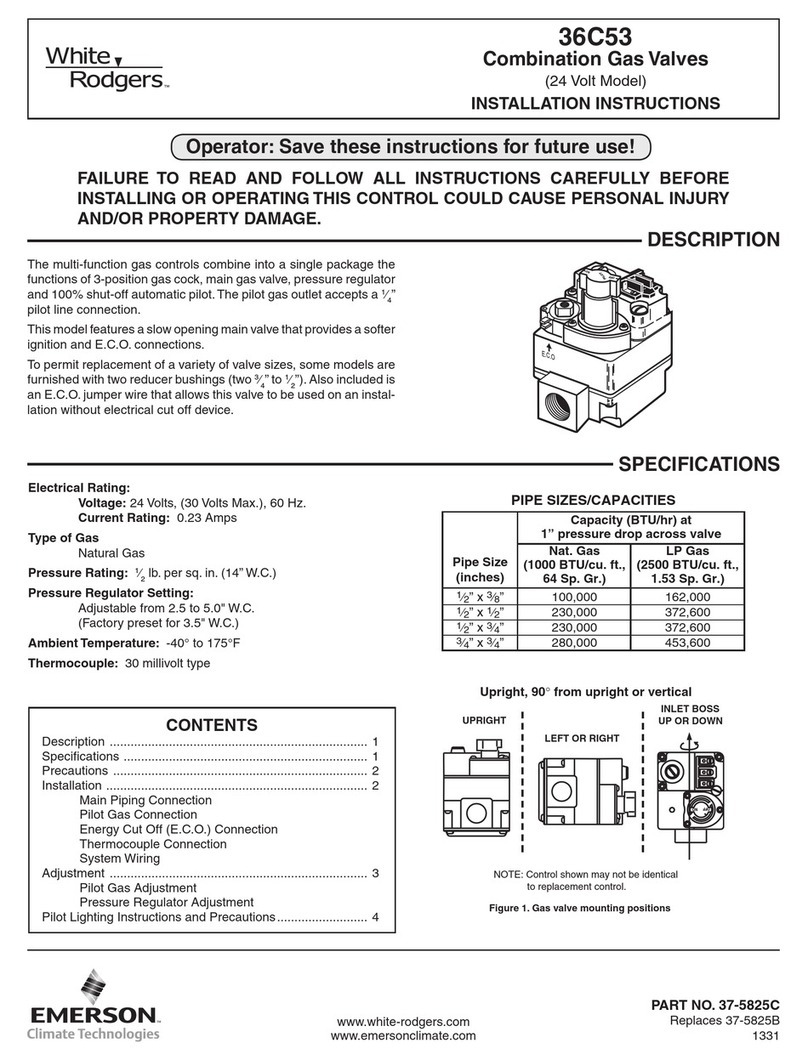

Table 1. Maximum Supply Pressure and Maximum

Recommended Pump Discharge

MINIMUM SUPPLY

PRESSURE, PSIG (bar)

MAXIMUM RECOMMENDED PUMP

DISCHARGE, PSIG (bar)

21 (1,4) 200 (13,8)

19 (1,3) 150 (10,3)

17 (1,2) 100 (6,9)

14 (0,97) 50 (3,4)

13 (0,90) 25 (1,7)

5. Attach the propane lling hose to one of the ller

valve outlets. Plug the other outlet. The lling hose

must be complete with a shutoff valve and suitable

cylinder valve connection. The lling hose and

shutoff valve can be counterbalanced for easy

handling if desired.

Operation

1. Place cylinder on scale platform and connect

ller hose.

2. Slide beam weight “H” to tare weight stamped

on cylinder.

3. Balance scales to compensate for the weight

added by the ller hose and shutoff valve. On

some scales this can be done by means of a small

weight near the beam pivot pin. On others a

suitable weight can be added to scale pan “F”.

4. Add a 100 pounds (45 kg) weight (or the net

weight desired) to scale pan “F”, and open the

cylinder and hose valve for trial automatic

lling operation.

5. Proceed with lling operation until scale beam

rises and contacts the trip valve stem. The ller

valve will close and the lling operation is

complete. This is indicated by the red button on

top of the ller valve. Close the hose shutoff valve

and the cylinder valve.

6. Check weight of full cylinder on another scale.

Balance weight or the weight in scale pan “F” may

have to be readjusted slightly until the correct

cylinder weight is obtained. Filling accuracy is

largely dependent upon the condition of the scale

used with Type N201.

7. After the scales have been checked and

adjusted, simply position the empty cylinder on

the scale, connect the lling hose, slide beam

weight “H” to the tare weight stamped on the

cylinder, open the hose shutoff valve and the

cylinder valve, and the Type N201 will ll the

cylinder to the weight added on the scale pan.

Note

When operating with high pump

pressure, the ller valve may close o,

then reopen for a short spurt and close

o again. This is due to the force of the

incoming liquid stream. If the proper

cylinder weight has been obtained

before the additional spurt, the operator

should immediately close the hose

shuto valve when the scale beam

contacts the trip valve stem. If the

scales are balanced after the additional

spurt, the operator should wait for this

before closing the hose shuto valve.

In Case of Trouble

1. If sticking of the main (upper) valve should

occur, place a few drops of oil below the disk

holder (key 5, Figure 4). This can be done

with an eye dropper or oil can through one of the

outlet ports. Refer to the disassembly instructions

if this does not correct the situation.

2. If the disk holder wears out quickly, check the

outlet pressure of regulator no. 2. Too high a

regulator setting will cause the disk to fail. Refer

to step 4 under “Installation”.

3. If the trip valve stem “B” should stick, remove the

lower trip valve body, and clean out all oil or

grease. Polish the seat in the trip valve body by

rotating the eraser end of a pencil against the seat

10 or 12 times.

Disassembly

To check disk holder assembly, O-ring, and

diaphragms proceed as follows (numbers in

parenthesis refer to key numbers in Figure 4):

1. Remove tubing connection from the angle adaptor

in Type 67/683 (key 30).

2. Mark the valve body (key 17), valve housing

(key 2), and valve head (key 1) so that they can be

aligned easily when reassembling.

3. Remove cap screws (key 22).

4. Separate the valve head (key 1), valve housing

(key 2), and valve body (key 17). Examine

the upper and lower diaphragms (keys 10 and 32).

Replace if necessary.