3

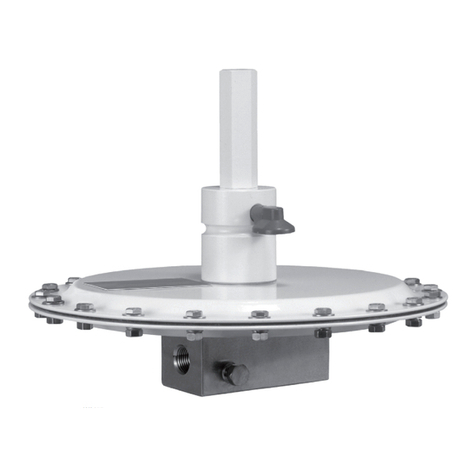

VAREC SERIES 2010B/2020B/3500B PRESSURE AND VACUUM RELIEF VALVE

INSTRUCTION, OPERATION AND MAINTENANCE MANUAL

Note: spun sheet metal pallets have a

compensating weight on top of the pallet.

Donot remove this weight. Refer to Table 1

forincremental weight information.

3. To load vacuum pallet weights, perform the

following:

a. With vacuum cover and gasket removed,

remove vacuum pallet assembly

frombody.

b. Remove grip ring from pallet stem.

c. Non-variable setting: locate weight

marked “VACUUM” and place on top

of compensating weight and/or pallet.

Secure with grip ring.

Note: if setting is less than 2” WC,

weightwill be pre-loaded on the pallet.

d. Variable setting: each lead weight

is calibrated from 1” WC increment.

(Increments of ¼” WC and ½” WC may

be supplied on special order). Those

weights necessary for the initial specified

setting will be tagged separately from

any extra weight provided. Remove the

packaging on the weights tagged from

the initial specified setting and place

the weights on top of the compensating

weight. Secure with grip ring. Store

remaining weights for future use (in case

the setting needs to be increased).

e. Weigh entire pallet assembly (including

installed weights). Using Table 1, confirm

that the assembly is the proper weight to

achieve the required setting. Allowable

weight tolerance is +5%,-5%.

f. Remove any remaining packing material

from valve body. Wipe vacuum seat ring,

guide posts and pallet assembly with a

soft cloth to remove any material which

could affect valve operation.

INSTALLATION

2010B/2020B/3500B Series pressure and

vacuum relief valves must be mated with the

appropriate flange(s). The nozzle must be

plumb and the inlet flange face level to ensure

proper operation of the relief valve.

1. Remove the valve from the shipping

container. Check to see if extra loading

weights were bagged and packed

separately.

2. Remove the weatherhood and/or cover(s)

and all packing material above the pallets

and within the valve.

CAUTION

Whenever the weatherhood and/or cover(s)

is removed and reinstalled, the end of the

pallet stem must engage the stem guide in the

weatherhood and/or the stem guide chamber

in the cover(s) for proper seating and valve

operation.

g. Place pallet assembly on valve body seat.

Ensure that pallet moves freely within

guide posts and rests flat on the seat

ring.

h. Replace the cover gasket and cover.

Tighten cover screws uniformly.

Note: spun sheet metal pallets have a

compensating weight on top of the pallet.

Donot remove this weight. Refer to Table 1

forincremental weight information.

4. To load pressure pallet weights, perform the

following:

a. With weatherhood from Model 2010B, or

pipe away adapter cover and gasket from

Model 2020B removed, remove pressure

pallet assembly from body.

b. Remove grip ring from pallet stem.

c. Non-variable setting: locate weight

marked “PRESSURE” and place on top

of compensating weight and/or pallet.

Secure with grip ring. If setting is less

than 2” WC, weight will be pre-loaded

onthe pallet.

d. Variable setting: each lead weight

is calibrated from 1” WC increment.

(Increments of ¼” WC and ½” WC may

be supplied on special order). Those

weights necessary for the initial specified

setting will be tagged separately from

any extra weight provided. Remove the

packaging on the weights tagged from

the initial specified setting and place

the weights on top of the compensating

weight. Secure with grip ring. Store

remaining weights for future use (in case

the setting needs to be increased).

e. Weigh entire pallet assembly (including

installed weights). Using Table 1, confirm

that the assembly is the proper weight to

achieve the required setting. Allowable

weight tolerance is +5%,-5%.

f. Remove any remaining packing material

from valve body. Wipe pressure seat ring,

guide posts and pallet assembly with a

soft cloth to remove any material which

could affect valve operation.

g. Place pallet assembly on seat. Ensure

that pallet moves freely within guide

posts and rests flat on the seat ring.

h. Replace the weatherhood on

Model2010B or the pressure cover and

gasket on Model 2020B. Tighten all nuts

and screws uniformly.

CAUTION

The end of the pallet stem must engage the stem

guide chamber in the cover for proper seating and

valve operation.